Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

BB.G VSP Pve Ed 20 Me Das 004 - 0

Caricato da

Luong AnhTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

BB.G VSP Pve Ed 20 Me Das 004 - 0

Caricato da

Luong AnhCopyright:

Formati disponibili

BLOCK B - O MON PIPELINE

OPERATING COMPANY

PROJECT

BLOCK B - O MON GAS PIPELINE

PHASE

EPC

DATA SHEET FOR FUEL/INSTRUMENT

GAS HEATER - MUI TRAM LFS

18/03/13

Issued for Approval

Rev

Date

Description

PVE

EPC CONTRACTOR

(VSP-PVC-PTSC)

VSP

Approval

BPOC

Approval

CA

Approval

Document Number:

BB.G-VSP-PVE-ED-20-ME-DAS-004

Number of Pages: 5 (Including this page)

PROJECT

BLOCK B - O MON GAS PIPELINE

PHASE

EPC

DATA SHEET FOR FUEL/INSTRUMENT

GAS HEATER - MUI TRAM LFS

18/03/13

Issued for Approval

NTQ

Rev.

Date

Description

CAJ

Prepared Checked

by

by

JMS

NNT

EM

PM

Discipline

Sub-Contractor

Team

Leader

SPMB

EPC Contractor

EPC CONTRACTOR

(VSP-PVC-PTSC CONSORTIUM)

Document Number:

PV ENGINEERING J.S.C

BB.G-VSP-PVE-ED-20-ME-DAS-004

BLOCK B - O MON GAS PIPELINE

EPC

FOR FUEL/INSTRUMENT

TER - MUI TRAM LFS

SPMB

EPC Contractor

EPC CONTRACTOR

(VSP-PVC-PTSC CONSORTIUM)

BB.G-VSP-PVE-ED-20-ME-DAS-004

Block B - O Mon Gas Pipeline Project

EPC Phase - Detailed Design

Datasheet No.: BB.G-VSP-PVE-ED-20-ME-DAS-004

BLOCK B - O MON PIPELINE OPERATING COMPANY

Rev

0 Sheet: 3 of 5

DATA SHEET FOR FUEL/INSTRUMENT GAS HEATER - MUI TRAM LFS

Tag No.:

Service:

P & ID No.:

Calculation Ref.:

Service Description:

1

20-H-1000A/B

Plant Location:

Viet Nam, Landfall Station at Mui Tram

Natural Gas

Supplier:

BB.G-VSP-PVE-ED-20-PR-PID-005

Purchase Order No.:

BB.G-VSP-PVE-ED-20-PR-CAL-002

No. of Units:

2 x 100% (Note 8)

Heating for Instrument/Fuel Gas

OPERATING DATA

Contents

Cases

Natural Gas

Max. Duty (Note 6)

Design Temperature

Design Pressure

Operating Temperature

Operating Pressure

Pressure Drop

(Max./Min.)

Inlet

98

0.76

55.39

21.01

47.35

barg

85.69

85.39

66.05

65.75

0.3 / VTA

Sm3/h

11 Molecular Weight

108.3

10.2

12 Mass Density

13 Viscosity

Outlet

C

bar

10 Gas Flowrate

Inlet

80 / -29

barg

(Allow./Calc.)

Min. Duty (Note 7)

Outlet

23.39

kg/m3

130.5

87.47

79.52

68.06

cP

0.0156

0.0159

0.0143

0.0149

14 Cp/Cv

2.147

1.569

1.659

1.52

15 Compressibility

0.6826

0.8458

0.8065

0.861

16 Overall Heat Transfer Coefficient

w/m2K

VTA

17 Absorbed Heat Duty (Note 5)

kw

18 Design Heat Duty

kw

VTA

19 Total Surface Area

m2

VTA

W/cm2

VTA

21 Element Load

kw

VTA

22 Sheath Temperature

20 Heat Flux

DESIGN DATA

23

ASME Sec VIII DIV. 1, TEMA

25 Service Class

ASME Class 900

27 Joint Efficiencies

28 Corrosion Allowance

29 Wind Speed

65 Power Supply for

66

Heating Element

N/m2

950

67

Heater Control Panel

31 Relative Humidity (Min./Max.)

67 / 89

32 Insulation

Required

33 Fireproofing

VTA

34 Painting

Note 23

CONSTRUCTION

36 Vessel Orientation

T3

ELECTRICAL SUPPLY AND CONTROL PANEL

mm

17.9 / 37

Class 1, Zone 2, Gas Group IIA

63 Temperature Class

64

35

AREA CLASSIFICATION FOR EQUIPMENT (NOTE 9)

62 Hazardous Area (API RP 505)

30 Ambient Temperature (Min./Max.)

0.0785

VTA

61

24 Design Code

26 ASME Code Stamping

415 VAC 5% / 3 Phase / 50 Hz 1%

Uninterrupted Power: 240 VAC 2% UPS

68 Thyristor Control Panel

69 Outer Casing Material

SS316

70 Environmental Protection

IP65 (Min.)

71 Location

In Safety Area Away from

Hazardous Area Boundary

72

73

MATERIALS

Horizontal

74 Shell/Head/Pads

ASME SA516 Gr.70(N)

75 Tubesheet

ASME SA105

76 Nozzle Necks

ASME SA106 Gr.B

37 Shell Outside Diameter

mm

168 (VTC)

38 Length (Tanget Line to FoF)

mm

3,081 (VTC)

39 Wall Thickness - Shell

mm

VTA

77 Flanges & Girth Flanges

ASME SA105

40 Wall Thickness - Head

mm

VTA

78 Elements

INCOLOY 800

79 Baffles/Tie Rods

316L SS

80 Support, Base Plate

ASME SA36

81 Stud Bolts/Nuts External

ASME SA193 Gr.B7/

41 Type of Heads

2:1 Ellipsoidal (Seamless)

42 Type of Support

Saddle

43 Platform / Ladder / Pipe Support

N/A

44 Earthing Boss M10

Required

82

SA194 Gr.2H (Note 16)

45 Lifting Lugs / Eyes

Required

83 Bolts/Nuts Internal (Note 17)

ASME SA193 Gr.B8/SA194 Gr.8

46 Nameplate

Required

84 Gaskets

Note 15

47 No. of Active Elements

VTA

85 Nameplate, Earth Lugs

316 SS

48 No. of Spare Elements

VTA

86 Lifting Lugs

ASME SA516 Gr.70

87 Terminal Box & J-Box

316L SS

316L SS

49 Element Immersed Length

(Note 18)

50

Active

mm

VTA

88 Element Couplings

51

Inactive

mm

VTA

89

52 Element Diameter

mm

VTA

90

53 Baffle Pitch

mm

VTA

91 One Bundle C/w Terminal Box, J-Box

VTA

kg

54 Baffle Cuts

VTA

92 Total Empty C/w Shell, Tube, J-Box Etc.

VTA

kg

55 Baffle Thk

mm

VTA

93 During Operating

VTA

kg

56 Tie Rods Dia.

mm

VTA

94 During Hydrotest

464 (VTC)

kg

VTA

95 Control Panel

VTA

kg

57 No. of Tie Rods

WEIGHTS

58 Feeder Cable Size

VTA

96

59

97

60

98

Block B - O Mon Gas Pipeline Project

EPC Phase - Detailed Design

Datasheet No.: BB.G-VSP-PVE-ED-20-ME-DAS-004

BLOCK B - O MON PIPELINE OPERATING COMPANY

Rev

Sheet:

4 of 5

DATA SHEET FOR FUEL/INSTRUMENT GAS HEATER - MUI TRAM LFS

Tag No.:

Service:

P & ID No.:

Calculation Ref.:

Service Description:

20-H-1000A/B

Plant Location:

Viet Nam, Landfall Station at Mui Tram

Natural Gas

Supplier:

BB.G-VSP-PVE-ED-20-PR-PID-005

Purchase Order No.:

BB.G-VSP-PVE-ED-20-PR-CAL-002

No. of Units:

2 x 100% (Note 8)

Heating for Instrument/Fuel Gas

FABRICATION AND INSPECTION

1

2

Inspection Authority

Required

Heat Treatment

Per code

Non-Destructive Testing

Radiography

Ultrasonic

Magnetic Particle

Dye Penetrant

Per Code

Mill Test Reports (MTRs)

EN 10204 3.2

100% all Pressure Containing Full Penetration Butt Welds

100% Non-radiographable Pressure Contianing Welds

Per Code

10 Impact Testing

Per Code

11 Hydrostatic Test

Per Code

12 Leak Test for Tube-Sheet to Tube

Per Code

NOZZLES

13

14

Nozzle

NPS

15 Number

mm

16

N1

50

17

N2

18

Flange

Number

GAS COMPOSITION

28

Service

Remark

29

Composition

Mole%

30

Methane

71.55

Rating

Type

900# WN

RTJ

Inlet Gas

31

Ethane

2.81

50

900# WN

RTJ

High Point Vent

32

Propane

1.47

N3

50 (VTC)

900# WN

RTJ

Pressure Safety Valve

33

I-Butane

0.42

19

N4

50

900# WN

RTJ

Outlet Gas

34

N-Butane

0.33

20

N5

50

900# WN

RTJ

Low Point Drain

35

I-Pentane

0.16

21

VTA

VTA

Heater Element

36

N-Pentane

0.09

N-Hexane

0.09

N-Heptane

0.06

0.02

24

Supply shall be

37

with it's Terminal

Box, J-Box (Min. IP 38

56)

39

25

40

N-Octane

N2

26

41

CO2

20.00 (Note 4)

27

42

H2O

0.0147

22

23

2.99

VTA

VTA

VTA

Outlet

Inlet

H

N2

N1

N3

N4

Insulation

VTA

N5

Sliding Saddle

Fixing Saddle

NOTES

1.

2.

3.

4.

5.

6.

7.

VTA = Vendor To Advise.

This data sheet shall be read in conjunction with "Specification for Fuel Instrument Gas Heater" document no.

BB.G-VSP-PVE-ED-00-ME-SPC-018, refer to "Basis of Design" document no. BB.G-VSP-PVE-ED-00-PM-BOD-001 and

"Specification for Instrumentation for Packaged Equipment" document no. BB.G-VSP-PVE-ED-00-IC-SPC-007.

Vendor to note that the maximum Mercury content in the pipeline gas is 50 g/m3, hence no Aluminium or Aluminium alloy

material shall be used for any wetted part of the equipment or package.

Maximum H2S concentration in the incoming gas is 79 mg/m3 (55 ppmv), total sulfur is 82 ppmv.

Maximum CO2 concentration of 21mole% to be considered for equipment design.

The duty listed is the energy gain by gas and excludes heat loss e.g to environment. Vendor shall determine and provide the

required Heater duty.

Maximum required duty was calculated based on 20% margin maximum operating flowrate of instrument gas and purge gas.

Minimum required duty based on fuel gas consumption of purge gas (HP and LP vent header) and two control valves. Minimum

8.

required duty of each heater is 50% of total required duty (0.157 kW).

Both Heater units shall be running normally in parallel and handle 50% of total required heat load. If one Heater trips, the

other shall automatically ramp up to handle 100% total required heat load.

Block B - O Mon Gas Pipeline Project

EPC Phase - Detailed Design

BLOCK B - O MON PIPELINE OPERATING COMPANY

Datasheet No.: BB.G-VSP-PVE-ED-20-ME-DAS-004

Rev 0 Sheet:

of

DATA SHEET FOR FUEL/INSTRUMENT GAS HEATER - MUI TRAM LFS

Tag No.:

Service:

P & ID No.:

Calculation Ref.:

Service Description:

20-H-1000A/B

Natural Gas

BB.G-VSP-PVE-ED-20-PR-PID-005

BB.G-VSP-PVE-ED-20-PR-CAL-002

Heating for Instrument/Fuel Gas

Plant Location:

Viet Nam, Landfall Station at Mui Tram

Supplier:

Purchase Order No.:

No. of Units:

2 x 100% (Note 8)

NOTES

9.

The Heater (elements, terminations etc) and all instrument / electrical equipment shall be certified for use in the applicable

hazardous area unless otherwise noted.

10.

11.

12.

13.

14.

15.

16.

17.

18.

The Heater shall be interface to SDS for shutdown and PCS for alarm via hardwire connection.

The Heater should be electrically checked and certified for insulation, flash, resistance check etc., during final acceptance.

Vendor to furnish general arrangement drawing in tender showing all leading dimensions and nozzle connections.

Vendor to verify that specified materials are suitable for the proposed service and design conditions.

Flange gasket contact face shall have ASME B16.5 standard finish of Ra 3.2 to 6.3 microns.

RTJ gaskets shall be solution heat-treated 316 stainless steel octagonal ring to ASME B16.20 Type R with max. 160 Brinell.

All stud bolts, nuts and washers shall be coated with Type II Class 8 chromated/cadmium plating.

All internal bolting shall be double-nutted or provided with "lock-tab" washers.

The provision of lifting lugs shall be for the whole unit (provided on Shell) and separately for the lifting and removal of the

elements c/w it's terminal box and junction box. The TCP also shall have it's lifting cleats etc. fitted. The lift lugs design shall be

tested and approved by the third party.

Vendor to advise details of impingement baffle (as required) at the inlet entrance of the shell side flow.

Deleted.

Vessel shall be provided with two support saddles, one shall be fixed and the other shall be sliding to allow for the expansion

of the shell.

Vendor to design and indicate the anchor bolt details (number, diameter, material specification, location, loading etc). Based on

Vendor's design and approvals, the anchor bolts will be provided by others.

The painting shall be as per "Specification for Onshore Painting" document no. BB.G-VSP-PVE-ED-60-CR-SPC-009.

19.

20.

21.

22.

23.

Potrebbero piacerti anche

- APNEA-J-DSH-0002 Rev. 1Documento3 pagineAPNEA-J-DSH-0002 Rev. 1Michelle MartinezNessuna valutazione finora

- Ras Markaz Crude Oil Park Project (Phase1) Material Take-Offs For Piping Bulks-InitialDocumento24 pagineRas Markaz Crude Oil Park Project (Phase1) Material Take-Offs For Piping Bulks-Initialanil pkNessuna valutazione finora

- JB & Field Wiring, Schematics CombineDocumento81 pagineJB & Field Wiring, Schematics CombineCezarinaNessuna valutazione finora

- As BuiltDocumento8 pagineAs BuiltArfanAliNessuna valutazione finora

- 421FN 6se38028+l08Documento64 pagine421FN 6se38028+l082003vinay0% (1)

- General Arrangement DrawingDocumento1 paginaGeneral Arrangement DrawingWulan Glh100% (1)

- Current (Dec2012) TA Work Order List 05-12-11Documento116 pagineCurrent (Dec2012) TA Work Order List 05-12-11subhaNessuna valutazione finora

- Appendix B Engineering DrawingsDocumento32 pagineAppendix B Engineering DrawingsProtheuss01Nessuna valutazione finora

- 20" Mol Replacement Project: Data Sheet PipelineDocumento7 pagine20" Mol Replacement Project: Data Sheet PipelineAdvisNessuna valutazione finora

- Bangladesh Grid NetworkDocumento1 paginaBangladesh Grid NetworkShuhan Mohammad Ariful HoqueNessuna valutazione finora

- PressureDrop CalculatorDocumento7 paginePressureDrop CalculatorHomer SilvaNessuna valutazione finora

- PipeClass NG 11.08.09 PDFDocumento138 paginePipeClass NG 11.08.09 PDFbadelitamariusNessuna valutazione finora

- S - Curve Execution Work Pemasangan 1 Unit Regulator Class 900 CSR PempingDocumento1 paginaS - Curve Execution Work Pemasangan 1 Unit Regulator Class 900 CSR PempingWulan Glh100% (1)

- Engineering All in OneDocumento245 pagineEngineering All in OneozchrisNessuna valutazione finora

- Technical Data: 150x100 FS2KA 5 90Documento5 pagineTechnical Data: 150x100 FS2KA 5 90infonetsmgNessuna valutazione finora

- Annexure of LPGDocumento6 pagineAnnexure of LPGKathir HaiNessuna valutazione finora

- NaturalConvectionHeatTransferCoefficients SI Units Final ProtectedDocumento44 pagineNaturalConvectionHeatTransferCoefficients SI Units Final ProtectedFabio MiguelNessuna valutazione finora

- Pdi EspDocumento1 paginaPdi EspSonratNessuna valutazione finora

- Approved: Pöyry EnergyDocumento2 pagineApproved: Pöyry Energytvpham123Nessuna valutazione finora

- Natural Gas System Equipment List: I.P.D.CDocumento5 pagineNatural Gas System Equipment List: I.P.D.CepbamdadNessuna valutazione finora

- Fuel Oil, Auxiliary Steam & Condensate Return System Piping Flushing ProcedureDocumento13 pagineFuel Oil, Auxiliary Steam & Condensate Return System Piping Flushing ProcedureepbamdadNessuna valutazione finora

- Hardware Wiring ConceptDocumento1 paginaHardware Wiring ConceptFalcon EgyNessuna valutazione finora

- A11Documento1 paginaA11liviu_dovaNessuna valutazione finora

- U CalDocumento16 pagineU CalSrinivasa Rao VenkumahanthiNessuna valutazione finora

- Condition input: Product code φv (lm) Vf (V) Pd (W) lm/WDocumento2 pagineCondition input: Product code φv (lm) Vf (V) Pd (W) lm/Wpvenky_kkdNessuna valutazione finora

- Cable Schdule For ReferenceDocumento22 pagineCable Schdule For ReferenceNishi mallickNessuna valutazione finora

- Oil Feeding System Design For 132Kv U/G Oil Filled Cable Circuit 8092-8123Documento6 pagineOil Feeding System Design For 132Kv U/G Oil Filled Cable Circuit 8092-8123Muhammad MahmudNessuna valutazione finora

- Tie in Point (TP) 08 ADocumento19 pagineTie in Point (TP) 08 At_i_f_anoNessuna valutazione finora

- PMS Rev 0Documento36 paginePMS Rev 0rami ghorbelNessuna valutazione finora

- Fuel Oil System Tanks Data Sheet: I.P.D.C Shirvan Gas Turbine Power Plant (Bop2 Portion)Documento7 pagineFuel Oil System Tanks Data Sheet: I.P.D.C Shirvan Gas Turbine Power Plant (Bop2 Portion)epbamdadNessuna valutazione finora

- SCH-00-J-7000 Inst. Cable Schedule Rev - 3Documento28 pagineSCH-00-J-7000 Inst. Cable Schedule Rev - 3Kishore KrishnaNessuna valutazione finora

- Combined Status of BoqmDocumento22 pagineCombined Status of Boqmhemant1284Nessuna valutazione finora

- PID ScrollbarDocumento10 paginePID ScrollbarZohaib AlamNessuna valutazione finora

- Storage Tank Data SheetDocumento16 pagineStorage Tank Data SheetSalman EngineeringNessuna valutazione finora

- M M M M M M M M: Product Condenser 101-A-0001-A / C / E / G / B / D / F / HDocumento1 paginaM M M M M M M M: Product Condenser 101-A-0001-A / C / E / G / B / D / F / Hahm3d16nNessuna valutazione finora

- KSS NumberingDocumento2 pagineKSS NumberingLucious LightNessuna valutazione finora

- Pipe Size Flange Rating Operating Condition: E F SFDocumento4 paginePipe Size Flange Rating Operating Condition: E F SFvivekpec100% (1)

- BOQ ValveDocumento2 pagineBOQ Valvemkchy12Nessuna valutazione finora

- 9 Three Line DiagramDocumento1 pagina9 Three Line Diagramapi-302117883Nessuna valutazione finora

- Perancangan Plate Adn Frame HEDocumento36 paginePerancangan Plate Adn Frame HEDavid LambertNessuna valutazione finora

- Un 2004-02 - Ud-Au-000-Eb-0008 PDFDocumento4 pagineUn 2004-02 - Ud-Au-000-Eb-0008 PDFManjeet SainiNessuna valutazione finora

- Pressure Transmitter Specification Sheet: GeneralDocumento1 paginaPressure Transmitter Specification Sheet: GeneralFranklin J Talero BNessuna valutazione finora

- CMP Gand Selection Flow ChartDocumento1 paginaCMP Gand Selection Flow Chartlimkokchiang809Nessuna valutazione finora

- Attachment#4 Instrument AirDocumento13 pagineAttachment#4 Instrument AirYusufNessuna valutazione finora

- Appendix 5 - Control and Alarm SetpointsDocumento20 pagineAppendix 5 - Control and Alarm SetpointsCù Xuân HuyNessuna valutazione finora

- Silo Blower Compressor ModelDocumento1 paginaSilo Blower Compressor ModelSonratNessuna valutazione finora

- Alarm List FOR Water Treatment Plant: I.P.D.C. Project: Shirvan Gas Turbine Power PlantDocumento3 pagineAlarm List FOR Water Treatment Plant: I.P.D.C. Project: Shirvan Gas Turbine Power PlantepbamdadNessuna valutazione finora

- Dokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsDocumento28 pagineDokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsCorne SalcedoNessuna valutazione finora

- 00000-JDS-014 (Pressure Safety Valve) Rev 0Documento4 pagine00000-JDS-014 (Pressure Safety Valve) Rev 0sithulibra100% (1)

- Tire Temp CalculatorDocumento2 pagineTire Temp CalculatorMiguel CustódioNessuna valutazione finora

- Positioner SpecsDocumento1 paginaPositioner Specsbiswasdipankar05Nessuna valutazione finora

- Procedure For Fire Water Max. Demand Calculation: Quality Management System DocumentDocumento4 pagineProcedure For Fire Water Max. Demand Calculation: Quality Management System DocumentmNessuna valutazione finora

- BMS Cable MeasurmentDocumento2 pagineBMS Cable MeasurmentsamhardworkerNessuna valutazione finora

- Common Alloys SpecificationsDocumento1 paginaCommon Alloys SpecificationsSARATH KRISHNAKUMARNessuna valutazione finora

- Colored Smith Chart PDFDocumento1 paginaColored Smith Chart PDFvoltagecrapNessuna valutazione finora

- Bb.g-Vsp-Pve-Ed-20-Me-Das-001 - 0Documento24 pagineBb.g-Vsp-Pve-Ed-20-Me-Das-001 - 0Luong AnhNessuna valutazione finora

- Volume3A MechDocumento321 pagineVolume3A MechAdeel JamilNessuna valutazione finora

- TBDP A M DS 0007 2Documento7 pagineTBDP A M DS 0007 2Bùi Văn HợpNessuna valutazione finora

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- SGS Panel EpsDocumento2 pagineSGS Panel EpsLuong AnhNessuna valutazione finora

- JICA Project - Preparatory Survey On Transit Oriented Development in Binh Duong Province PDFDocumento142 pagineJICA Project - Preparatory Survey On Transit Oriented Development in Binh Duong Province PDFLuong AnhNessuna valutazione finora

- FIG.01 FIG.02: 1/ Bearing Must Be Sealed (High Risk of Extraneous Matter Contamination Coming From The GreaseDocumento3 pagineFIG.01 FIG.02: 1/ Bearing Must Be Sealed (High Risk of Extraneous Matter Contamination Coming From The GreaseLuong AnhNessuna valutazione finora

- Crimper and Knife Set-Up Tips For Horizontal Flow WrappersDocumento3 pagineCrimper and Knife Set-Up Tips For Horizontal Flow WrappersLuong AnhNessuna valutazione finora

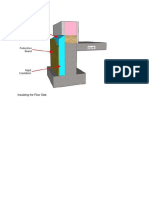

- Structural Steel and Concrete ElementsDocumento3 pagineStructural Steel and Concrete ElementsLuong AnhNessuna valutazione finora

- Insulating The Floor SlabDocumento3 pagineInsulating The Floor SlabLuong AnhNessuna valutazione finora

- Insulating The Floor SlabDocumento3 pagineInsulating The Floor SlabLuong AnhNessuna valutazione finora

- JICA Project - Preparatory Survey On Transit Oriented Development in Binh Duong Province PDFDocumento142 pagineJICA Project - Preparatory Survey On Transit Oriented Development in Binh Duong Province PDFLuong AnhNessuna valutazione finora

- S-000-1360-0001V - 1 General Specification For PipingDocumento28 pagineS-000-1360-0001V - 1 General Specification For PipingLuong AnhNessuna valutazione finora

- Air Receivers Volume CalculationDocumento86 pagineAir Receivers Volume CalculationLuong AnhNessuna valutazione finora

- Best Practice Compressed Air V5Documento20 pagineBest Practice Compressed Air V5Rizwan AliNessuna valutazione finora

- Design of Steam & Gas Turbines: A Table of Geometrical Details .Documento25 pagineDesign of Steam & Gas Turbines: A Table of Geometrical Details .Luong AnhNessuna valutazione finora

- Cooling TowerDocumento14 pagineCooling TowerLuong AnhNessuna valutazione finora

- H335 H375Documento1 paginaH335 H375Luong AnhNessuna valutazione finora

- 204-4C-1-Main Cooling Water System 19-12-2016 Rev01Documento21 pagine204-4C-1-Main Cooling Water System 19-12-2016 Rev01Luong AnhNessuna valutazione finora

- 01 - Isometric DWGDocumento1 pagina01 - Isometric DWGLuong AnhNessuna valutazione finora

- 204-4C-1-Main Cooling Water System 19-12-2016 Rev01Documento21 pagine204-4C-1-Main Cooling Water System 19-12-2016 Rev01Luong AnhNessuna valutazione finora

- 3 Layout and FlowDocumento39 pagine3 Layout and FlowSam ChaduaryNessuna valutazione finora

- 206-3H-1 SMC Hook Up Compressed Air - 16!12!2016 Rev.01Documento14 pagine206-3H-1 SMC Hook Up Compressed Air - 16!12!2016 Rev.01Luong AnhNessuna valutazione finora

- Profile - Viet Phat Industry Technology JSCDocumento15 pagineProfile - Viet Phat Industry Technology JSCLuong AnhNessuna valutazione finora

- Subject 7. Equipment Sizing and Costing OCW PDFDocumento30 pagineSubject 7. Equipment Sizing and Costing OCW PDFhamzashafiq1100% (1)

- Residential ConstructionDocumento5 pagineResidential ConstructionLuong AnhNessuna valutazione finora

- Bb.g-Vsp-Pve-Ed-20-Me-Das-001 - 0Documento24 pagineBb.g-Vsp-Pve-Ed-20-Me-Das-001 - 0Luong AnhNessuna valutazione finora

- Cost of Equipment 93851 - 20Documento7 pagineCost of Equipment 93851 - 20genergiaNessuna valutazione finora

- WT - P U ' G: ERF SER S UideDocumento4 pagineWT - P U ' G: ERF SER S UideLuong AnhNessuna valutazione finora

- LG Piping HandbookDocumento373 pagineLG Piping Handbookgutmont83% (6)

- Dry Granulation: - Powder Is Squeezed Between Two Rollers To Produce Sheet of MaterialDocumento5 pagineDry Granulation: - Powder Is Squeezed Between Two Rollers To Produce Sheet of MaterialLuong AnhNessuna valutazione finora

- Schultz Clemson 0050M 11185Documento151 pagineSchultz Clemson 0050M 11185Luong AnhNessuna valutazione finora

- (Thesis) On MpCCI As A Coupling Library For FSI With CFXDocumento87 pagine(Thesis) On MpCCI As A Coupling Library For FSI With CFXLuong AnhNessuna valutazione finora

- Postharvest Manual of Cabbage and ChiliDocumento160 paginePostharvest Manual of Cabbage and ChiliRepublic of Korea (Korea.net)100% (6)

- RPLLDocumento61 pagineRPLLLloyd GonzalesNessuna valutazione finora

- Jonathan Orenge CV-2017-1Documento8 pagineJonathan Orenge CV-2017-1Anonymous QetGjPoklNessuna valutazione finora

- Bow Thruster ManualDocumento178 pagineBow Thruster Manualaaaguilarm100% (1)

- 08 - Gearbox PDFDocumento22 pagine08 - Gearbox PDFdicksonNessuna valutazione finora

- RYA SRC ExamDocumento12 pagineRYA SRC ExamJag Gonzalez100% (12)

- Supply Chain StrategyDocumento11 pagineSupply Chain StrategyNantha Kumar100% (1)

- Documents For Lowari Tunnel 1Documento117 pagineDocuments For Lowari Tunnel 1Naveed ShaheenNessuna valutazione finora

- Catalogo BiMe Eng RusDocumento12 pagineCatalogo BiMe Eng RusabnicolescuNessuna valutazione finora

- DAF CF Driver's Manual: A Paccar Company Driven by QualityDocumento375 pagineDAF CF Driver's Manual: A Paccar Company Driven by Qualitysidiki OuedraogoNessuna valutazione finora

- BlackboxDocumento18 pagineBlackboxArpit BhardwajNessuna valutazione finora

- Subramanian SankaranarayananDocumento161 pagineSubramanian SankaranarayananSharon FreemanNessuna valutazione finora

- The Future of The GermanDocumento32 pagineThe Future of The GermanJon LeonNessuna valutazione finora

- Hamburg RulesDocumento16 pagineHamburg RulesArman PinedaNessuna valutazione finora

- Process of GlobalizationDocumento15 pagineProcess of GlobalizationAndriejus RadčenkoNessuna valutazione finora

- Introduction To Maritime LawDocumento13 pagineIntroduction To Maritime Lawplatonalexandru67% (3)

- Trade Route Economics Tool User Guide Version 1 - 2Documento13 pagineTrade Route Economics Tool User Guide Version 1 - 2Jedi21Nessuna valutazione finora

- NR 18 Safety Harnesses in MEWPsDocumento2 pagineNR 18 Safety Harnesses in MEWPsCPSSTNessuna valutazione finora

- Job Hazard Analysis For Filtration Job)Documento3 pagineJob Hazard Analysis For Filtration Job)Chibuzor Samuel100% (1)

- Turning Gear MotorDocumento7 pagineTurning Gear Motorahmet ozturkNessuna valutazione finora

- Experiment 102:: 1. ConclusionDocumento1 paginaExperiment 102:: 1. ConclusionChristopherHiladoNessuna valutazione finora

- Essay On Ratan Tata ...Documento3 pagineEssay On Ratan Tata ...GAURAV JAINNessuna valutazione finora

- CRN Bill PDFDocumento3 pagineCRN Bill PDFDheeraj SharmaNessuna valutazione finora

- 16.10 Site Equipment (72dpi)Documento24 pagine16.10 Site Equipment (72dpi)Jack JeffNessuna valutazione finora

- Design and Simulation of A Railway Vehicle For TheDocumento15 pagineDesign and Simulation of A Railway Vehicle For TheMustafa SahinNessuna valutazione finora

- Geometric Design and Standards: For Refrence by ParibeshDocumento40 pagineGeometric Design and Standards: For Refrence by ParibeshSubas ShresthaNessuna valutazione finora

- Anthropogenic Hazard - Wikipedia, The Free EncyclopediaDocumento8 pagineAnthropogenic Hazard - Wikipedia, The Free EncyclopediaDeepjyoti Kalita0% (1)

- Model Course 1.10 Dangerous - Hazardous and Harmful Cargoes - 2014 EdDocumento221 pagineModel Course 1.10 Dangerous - Hazardous and Harmful Cargoes - 2014 EdkhavihongNessuna valutazione finora

- FGD FinalDocumento33 pagineFGD Finalajeng putriNessuna valutazione finora

- TowersDocumento72 pagineTowersboltgingerkoppyNessuna valutazione finora