Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

TDS - Protectosil SC Concentrate

Caricato da

Venkata RaoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

TDS - Protectosil SC Concentrate

Caricato da

Venkata RaoCopyright:

Formati disponibili

PROTECTOSIL SC

CONCENTRATE

Easy-to-clean protection for porous

mineral building materials

Description

Protectosil SC Concentrate is an aqueous silane-based

system intended to render porous mineral substrates

hydro- and oleophobic, making them easy to clean. It is

practically free from volatile organic components (VOC).

Facades treated with Protectosil SC remain clean

longer, show no unsightly dark water streaks and are less

susceptible to the growth of microorganisms such as

mold and algae. Stains caused by common liquids

Coffee, cola and oils, dark liquids that are easily

absorbed by untreated surfaces leaving permanent

stains, are easily removed from surfaces treated with

Protectosil SC. Even chewing gum and posters dont

stick quite so well, facilitating their removal.

We recommend diluting Protectosil SC Concentrate with

water to achieve an easy-to-clean treatment for mineralbased substrates.

Recommended applications

Protectosil SC Concentrate can be used to create and

easy-clean surface on many porous, mineral-based

building materials. Some examples include:

Sand limestone masonry

Sandstone masonry

Brick masonry

Concrete

Mineral-based stucco

Polished surfaces such as marble and granite

The concentration of Protectosil SC Concentrate and the

application method both depend on the porosity and

absorbency of the building material to be treated.

Product characteristics

Protectosil SC Concentrate

Is a colorless, water-vapor permeable, hydro and

oleophobic treatment

Does not form a sticky silicone film

Beads water and oils on absorbent mineral

building materials

Keeps facades clean longer and makes cleaning

easier

Slows down the growth of micro-organisms

Prevents unsightly water streaks caused by rain

One section of the sand limestone wall shown below was

treated with Protectosil SC. The other section was left

untreated. After five years of outdoor weathering, the

difference is clear (neither section was cleaned before

the photographs were made).

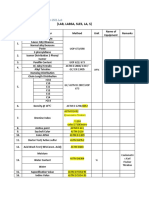

Technical data

Property

Density (20C)

Appearance

Viscosity (20C)

pH(20C,1:linH2O)

Flash point

Value

approx. 1,06

yellowish, slightly

cloudy liquid

approx. 1,6

4

>61

Unit

q/cm

Method

DIN 51757

mPas

DIN 53015

EN 22719

Method

Application information

The facade to be treated must be clean surface-dry. Dirt,

grime, efflorescence, algae and moss must be removed.

Water absorbed during cleaning must be allowed to dry

so that the surface is dry before application begins.

Imperfections such as cracks, cracked joints or defective

seams must be repaired using appropriate methods.

Mortar used for repairs must be fully cured and surface

dry.

Do not apply the product in rain or strong winds.

Due to the water content, the treatment solution is

susceptible to freezing and must not be used at

temperatures under 0C.

The recommended application method is with HVLP

(High Volume Low Pressure) equipment. Product

application using airless sprayers (low pressure, socalled flooding method) is also possible if the substrate

is sufficiently absorbent. The ready-to-use solution (a

dilution of 1 part Protectosil SC Concentrate to 2 to 14

parts water) is best applied starting from the bottom and

going up the wall. This avoids pretreating the substrate

with runoff from above. Avoid using dirty application

equipment, which can contaminate the product.

The easy-to-clean effect may be in many cases

(especially on very coarse and very porous substrates)

be enhanced by additional treatments. The amount of

product required for the second and all subsequent

treatments is considerably less. Additional treatments

should be done using HVLP technology; the resulting

droplets must be rubbed in quickly using a brush or swab

to distribute the liquid evenly across the surface.

Storage

Unopened containers of Protectosil SC Concentrate

have a shelf life of at least 12 months. The product

should be stored at temperatures between 0C and 40C.

04/2005 Degussa-UAE

Since previous building material treatments may not be

known, a Protectosil SC test patch is recommended to

avoid any undesired side effects.

Amount of product required

We recommend using a mixture of one part Protectosil

SC Concentrate to 2 to 14 parts water. The exact dilution

and the amount of dilute solution required depend on the

absorbency of the substrate to be treated, and also if the

surface has already been treated with a penetrating water

repellent (e.g. DYNASYLAN BHN oder Protectosil WS

405). Porous, absorbent substrates can require more

than 300 ml ready-to-use solution per square meter. The

optimum dilution and exact amount of dilute solution

required should be determined by testing.

Information on consumption

rate

If a solution of Protectosil SC Concentrate is applied by

the flooding method, the amount of solution required is

dependent on the porosity and the absorbency of the

substrate combined. Exact values should be determined

using test patches.

The amount of product used can be greatly reduced by

using HVLP equipment. As a rule 80-120 ml/m are

required in the first step. The easy to clean effect can be

improved by additional treatments. Especially in the case

of very coarse and very porous materials we recommend

more than one treatment using HVLP equipment (see

Application Information above).

A single application is usually sufficient for polished stone

and glazed tiles. In this case simply apply undiluted

Protectosil SC Concentrate with a cloth, microfiber

glove, or other suitable aid until a liquid film is no longer

visible. Significantly less product is required for polished

surfaces compared to rough ones.

Safety and handling

Before considering the use of any chemical read its

Safety Data Sheet thoroughly for safety and toxicological

data as well as for information on proper transportation,

storage and use. The Safety Data Sheet is available

upon request from your local Degussa representative.

Degussa Construction Chemicals UAE LLC

P.O. Box 37127, Dubai, UAE

Tel: +971 4 8851000

www.degussa-cc.ae

Fax: +971 4 8851002

e-mail: marketingcc.mideast@degussa.com

Whilst any information contained herein is true, accurate and

represents our best knowledge and experience, no warranty is given or

implied with any recommendations made by us, our representatives or

distributors, as the conditions of use and the competence of any labour

involved in the application are beyond our control.

Certificate No.

963680

As all Degussa technical datasheets are updated on a regular basis it is the user's responsibility to obtain the most recent issue.

Certificate No.

945787

Certificate No.

772556

Potrebbero piacerti anche

- Clays and Clay Minerals: Proceedings of the Fourteenth National Conference, Berkeley, CaliforniaDa EverandClays and Clay Minerals: Proceedings of the Fourteenth National Conference, Berkeley, CaliforniaS. W. BaileyNessuna valutazione finora

- PrecipitatedSlica PDFDocumento19 paginePrecipitatedSlica PDFAndryan Setya RamadhanNessuna valutazione finora

- DYCOTE E.pdf - DownloadassetDocumento32 pagineDYCOTE E.pdf - DownloadassetJAnottama werdhabudiNessuna valutazione finora

- DeDocumento3 pagineDesindromfall100% (1)

- Amorphous Sugar ProductionDocumento9 pagineAmorphous Sugar ProductionnghiNessuna valutazione finora

- Sodium SilicateDocumento12 pagineSodium Silicatemoses_cNessuna valutazione finora

- Conversion of Waste Glasses Into Sodium Silicate Solutions PDFDocumento9 pagineConversion of Waste Glasses Into Sodium Silicate Solutions PDFJesha LibreaNessuna valutazione finora

- Limestone and MarbleDocumento5 pagineLimestone and MarbleWem TijNessuna valutazione finora

- Geopolymer Concrete: Sardar Vallabhbhai Patel Institute of Technology, Vasad Gujarat Technological University AhmedabadDocumento43 pagineGeopolymer Concrete: Sardar Vallabhbhai Patel Institute of Technology, Vasad Gujarat Technological University AhmedabadRakesh7770Nessuna valutazione finora

- Sorbitan Esters PlantDocumento9 pagineSorbitan Esters PlantHolman SanabriaNessuna valutazione finora

- AdmixtureDocumento7 pagineAdmixturevinay rodeNessuna valutazione finora

- Silica Gel Production Report PDFDocumento8 pagineSilica Gel Production Report PDFChoice Organo0% (1)

- Technological Result of Decomposition Sodium Aluminate SolutionDocumento10 pagineTechnological Result of Decomposition Sodium Aluminate SolutionDragana Dragojlović SmiljanicNessuna valutazione finora

- Precipitated SilicaDocumento4 paginePrecipitated Silicaraman_mlrNessuna valutazione finora

- Extraction of Molybdenum From Molybdenite ConcentratesDocumento5 pagineExtraction of Molybdenum From Molybdenite ConcentratesFranciscoIgnacioNessuna valutazione finora

- Tosoh Silica Precipitated Silica BrochureDocumento16 pagineTosoh Silica Precipitated Silica BrochureDewiNessuna valutazione finora

- Sodium Silicate PDFDocumento19 pagineSodium Silicate PDFnasirtaxila9094Nessuna valutazione finora

- TDS - KemFoamX 2550 - ENDocumento2 pagineTDS - KemFoamX 2550 - ENSteven CoultonNessuna valutazione finora

- Role of Sugar, Gur, Liquid SweetnersDocumento10 pagineRole of Sugar, Gur, Liquid SweetnersBharath Jaganathan100% (1)

- Sucralose: Omar A.A. Aldeeb, Hoda Mahgoub, Nagwa H. FodaDocumento40 pagineSucralose: Omar A.A. Aldeeb, Hoda Mahgoub, Nagwa H. FodaDanaeNessuna valutazione finora

- GRANITEDocumento27 pagineGRANITEIrene Ann Tomi100% (1)

- Zacsil Potassium Silicate DataDocumento5 pagineZacsil Potassium Silicate DatadancercelNessuna valutazione finora

- Outline For Calcium Carbonate ProcessDocumento9 pagineOutline For Calcium Carbonate ProcessRobert DsouzaNessuna valutazione finora

- BASF Tech Data Sheet Librel BMXDocumento6 pagineBASF Tech Data Sheet Librel BMXAhmad SaputraNessuna valutazione finora

- Renoclean Bio Rig WashDocumento2 pagineRenoclean Bio Rig WashMuh yusup100% (1)

- Performance Chemical Catalog 2006Documento24 paginePerformance Chemical Catalog 2006Maximiliano MackeviciusNessuna valutazione finora

- Sodium Silicate From RHA-BD-ARJ-V.4n.2.37-42Documento5 pagineSodium Silicate From RHA-BD-ARJ-V.4n.2.37-42Samia SharifNessuna valutazione finora

- Caustic Soda ChE 308Documento24 pagineCaustic Soda ChE 308gcavagliNessuna valutazione finora

- WHO TN 01 Cleaning and Disinfecting WellsDocumento4 pagineWHO TN 01 Cleaning and Disinfecting WellsgeminexNessuna valutazione finora

- Sodium Carboxymethyl Cellulose CMC PDFDocumento7 pagineSodium Carboxymethyl Cellulose CMC PDFErick FaundezNessuna valutazione finora

- ZirconiumDocumento6 pagineZirconiumHarshavardhanNessuna valutazione finora

- Cappuccitti Nesset (2010)Documento16 pagineCappuccitti Nesset (2010)Jose Patricio Velarde100% (1)

- Advancement in Concrete TechnologyDocumento20 pagineAdvancement in Concrete TechnologyKuldeep Chakerwarti100% (1)

- Extraction of Soluble Sodium Silicate Using Corn Cob Ash As A Silica SourceDocumento3 pagineExtraction of Soluble Sodium Silicate Using Corn Cob Ash As A Silica SourceAJER JOURNALNessuna valutazione finora

- (Lab, Labsa, Sles, La, S) : No. Test Parameter Method Unit Name of Equipment RemarksDocumento2 pagine(Lab, Labsa, Sles, La, S) : No. Test Parameter Method Unit Name of Equipment RemarksMd Nazim UddinNessuna valutazione finora

- As 2542.2.2-2005 Sensory Analysis Specific MethodsDocumento8 pagineAs 2542.2.2-2005 Sensory Analysis Specific MethodsSAI Global - APACNessuna valutazione finora

- Brisil - Green Precipitated Silica PDFDocumento10 pagineBrisil - Green Precipitated Silica PDFTanmay PandyaNessuna valutazione finora

- Precipitated SilicaDocumento6 paginePrecipitated Silicamastmona100% (1)

- Zeofree SlicaDocumento2 pagineZeofree Slicas.sabapathyNessuna valutazione finora

- Sodium SilicateDocumento3 pagineSodium SilicateOcta RioNessuna valutazione finora

- Changes in Key Aroma Compounds of Criollo Cocoa Beans During Roasting 1Documento8 pagineChanges in Key Aroma Compounds of Criollo Cocoa Beans During Roasting 1Moyo AntNessuna valutazione finora

- Durst Suppressor FluidsDocumento2 pagineDurst Suppressor FluidsderekfisherNessuna valutazione finora

- What Is A Sugar Refinery?: 4th Slide The Refining ProcessDocumento2 pagineWhat Is A Sugar Refinery?: 4th Slide The Refining Processbabe0% (1)

- Deosen - F200-Xanthan GumDocumento2 pagineDeosen - F200-Xanthan Gumkapil chopra100% (1)

- Each Detailed Project Reports Cover All The Aspects of Business, From Analysing The Market, ConfirmingDocumento5 pagineEach Detailed Project Reports Cover All The Aspects of Business, From Analysing The Market, ConfirmingSnatak MundadaNessuna valutazione finora

- 5.1 Alginate Production MethodsDocumento15 pagine5.1 Alginate Production MethodsLana NairfanaNessuna valutazione finora

- Nouryon. mTA Salt. Electrolysis Salt PDFDocumento3 pagineNouryon. mTA Salt. Electrolysis Salt PDFAbigail HernandezNessuna valutazione finora

- Glass Manufacture and DecorationDocumento27 pagineGlass Manufacture and DecorationPothuraju PrudhiviNessuna valutazione finora

- Effect of Sugars On The BiscuitDocumento8 pagineEffect of Sugars On The BiscuitlpuntyNessuna valutazione finora

- The Staling of Coffee IDocumento20 pagineThe Staling of Coffee IdartstudNessuna valutazione finora

- 39 24 225Documento12 pagine39 24 225A MahmoodNessuna valutazione finora

- Gypsum: Gypsum As A Construction MaterialDocumento29 pagineGypsum: Gypsum As A Construction Materialsarah KhalidNessuna valutazione finora

- Ch-4, Cleaning AgentsDocumento14 pagineCh-4, Cleaning Agentsshrisha sureshNessuna valutazione finora

- Hydrous and Calcined Kaolin Technical DetailsDocumento2 pagineHydrous and Calcined Kaolin Technical DetailsForeverNessuna valutazione finora

- 08 Chemicals For Water Boilers PDFDocumento6 pagine08 Chemicals For Water Boilers PDFpsaayoNessuna valutazione finora

- CIR Dicalcium Phospate PDFDocumento75 pagineCIR Dicalcium Phospate PDFNurulNessuna valutazione finora

- FMC Soda Ash Brochure FINAL 2012Documento12 pagineFMC Soda Ash Brochure FINAL 2012Rehan RaufNessuna valutazione finora

- Calcium CarbonateDocumento24 pagineCalcium CarbonateFrederic WustNessuna valutazione finora

- Liquid Sodium SilicatesDocumento5 pagineLiquid Sodium SilicatesJavad MousavyNessuna valutazione finora

- CIOB - Construction Claims in The UAEDocumento24 pagineCIOB - Construction Claims in The UAEVenkata Rao100% (1)

- Standard DrawingsDocumento134 pagineStandard DrawingsVenkata RaoNessuna valutazione finora

- Volume 1 - Instruction To Tenderers & CoCDocumento105 pagineVolume 1 - Instruction To Tenderers & CoCVenkata RaoNessuna valutazione finora

- Pe IeiDocumento3 paginePe IeiVenkata RaoNessuna valutazione finora

- Recommended Application Procedures: CoatingsDocumento1 paginaRecommended Application Procedures: CoatingsVenkata RaoNessuna valutazione finora

- TDS - Emaco CP 30Documento3 pagineTDS - Emaco CP 30Venkata RaoNessuna valutazione finora

- TDS - Concresive ERLDocumento2 pagineTDS - Concresive ERLVenkata RaoNessuna valutazione finora

- TDS - Masterseal SP120Documento2 pagineTDS - Masterseal SP120Venkata RaoNessuna valutazione finora

- TDS - Emaco CP 60Documento3 pagineTDS - Emaco CP 60Venkata RaoNessuna valutazione finora

- Tds - Emaco Cp10h - Emaco Cp10vDocumento3 pagineTds - Emaco Cp10h - Emaco Cp10vVenkata RaoNessuna valutazione finora

- TDS - Emaco CP15 GroutDocumento2 pagineTDS - Emaco CP15 GroutVenkata RaoNessuna valutazione finora

- Tds - Emaco Cp20Documento3 pagineTds - Emaco Cp20Venkata RaoNessuna valutazione finora

- Tds - Emaco s66 CPDocumento2 pagineTds - Emaco s66 CPVenkata RaoNessuna valutazione finora

- TDs - Masterseal MCI 2120Documento2 pagineTDs - Masterseal MCI 2120Venkata RaoNessuna valutazione finora

- TDS - Masterseal110PDocumento2 pagineTDS - Masterseal110PVenkata RaoNessuna valutazione finora

- TDS - Protectosil CITDocumento3 pagineTDS - Protectosil CITVenkata RaoNessuna valutazione finora

- Mbt-Mbrace Resicem: Vapour Permeable Saturant For Mbt-Mbrace FRP Sheet SystemsDocumento2 pagineMbt-Mbrace Resicem: Vapour Permeable Saturant For Mbt-Mbrace FRP Sheet SystemsVenkata RaoNessuna valutazione finora

- TDS - Masterflow 400Documento2 pagineTDS - Masterflow 400Venkata RaoNessuna valutazione finora

- TDS - Masterflex 610Documento2 pagineTDS - Masterflex 610Venkata RaoNessuna valutazione finora

- TDS - Flowcable 50Documento2 pagineTDS - Flowcable 50Venkata RaoNessuna valutazione finora

- PBRDocumento3 paginePBRTio PrasetyoNessuna valutazione finora

- Amino Acids Reference Chart Sigma AldrichDocumento3 pagineAmino Acids Reference Chart Sigma AldrichcfmonarquiaNessuna valutazione finora

- Amount of Acetic Acid Present in Vinegar - ChemistryDocumento16 pagineAmount of Acetic Acid Present in Vinegar - ChemistryKgmaster100% (1)

- Knowledge Sharing Session: Topic: AnodizingDocumento23 pagineKnowledge Sharing Session: Topic: AnodizingRaj Kumar GiriNessuna valutazione finora

- Chemistry Investigatory Azo Dye Classification and PreparationDocumento28 pagineChemistry Investigatory Azo Dye Classification and Preparationdivyank tiwariNessuna valutazione finora

- Electroless Plating28266Documento17 pagineElectroless Plating28266fsarfrazNessuna valutazione finora

- HO1 Importance of Wood ChemistryDocumento2 pagineHO1 Importance of Wood ChemistryElla Rey67% (3)

- Ions Worksheet 1Documento4 pagineIons Worksheet 1Vasto L OrdeNessuna valutazione finora

- Green PlasticsDocumento10 pagineGreen PlasticsPedro MaravilhaNessuna valutazione finora

- Sodium Sulphate Manufacturing Feasibility Study Project Proposal Business Plan in Ethiopia Pdf. - Haqiqa Investment Consultant in EthiopiaDocumento1 paginaSodium Sulphate Manufacturing Feasibility Study Project Proposal Business Plan in Ethiopia Pdf. - Haqiqa Investment Consultant in EthiopiaSulemanNessuna valutazione finora

- 7 Stoichiometric RelationshipsDocumento73 pagine7 Stoichiometric RelationshipsShuaib MohamedNessuna valutazione finora

- Ejeb 2013 3 5 502 507Documento6 pagineEjeb 2013 3 5 502 507Jamilah Ghozy (Mila)Nessuna valutazione finora

- Script: CarlDocumento4 pagineScript: CarlJohn Rahzl NaradaNessuna valutazione finora

- Report Experiment 1 Chemistry LaboratoryDocumento15 pagineReport Experiment 1 Chemistry LaboratoryAnh HoàngNessuna valutazione finora

- Indole and Pyrrole Synthesis: "Sitcom: RichterDocumento19 pagineIndole and Pyrrole Synthesis: "Sitcom: Richterthor888888Nessuna valutazione finora

- 10 Diapers Report PDFDocumento7 pagine10 Diapers Report PDFABHIJITH J KUMARNessuna valutazione finora

- United States Patent: (10) Patent No.: US 6,420,470 B1Documento6 pagineUnited States Patent: (10) Patent No.: US 6,420,470 B1SiddharthBhasneyNessuna valutazione finora

- Reaction Pathways and Mechanisms in Thermocatalytic Biomass Conversion IDocumento268 pagineReaction Pathways and Mechanisms in Thermocatalytic Biomass Conversion IPedro Milton Chibulacho100% (1)

- Edexcel AS Chemistry Note 3 - Different Types of ReactionDocumento7 pagineEdexcel AS Chemistry Note 3 - Different Types of ReactionSajaniNessuna valutazione finora

- Back UpDocumento6 pagineBack UpNamiNessuna valutazione finora

- Peroxide ValueDocumento15 paginePeroxide ValueLigia Teodoro100% (1)

- 1 - (Science) ReviewerDocumento5 pagine1 - (Science) Reviewerranulfo mayolNessuna valutazione finora

- Nomenclature of A2Documento5 pagineNomenclature of A2SophieStevensNessuna valutazione finora

- chm510 Experiment 3Documento7 paginechm510 Experiment 3Naz Helmi100% (1)

- AP Paper With AnswersDocumento228 pagineAP Paper With AnswersAtulNessuna valutazione finora

- Chem LabDocumento4 pagineChem LabSean M. InocencioNessuna valutazione finora

- Inorganic ChemistryDocumento36 pagineInorganic ChemistryNada MerzougNessuna valutazione finora

- Chapter 12: Structures & Properties of CeramicsDocumento10 pagineChapter 12: Structures & Properties of Ceramics윤종현Nessuna valutazione finora

- Class - Xi - Biology: Photosynthesis in Higher Plants Module - 1Documento20 pagineClass - Xi - Biology: Photosynthesis in Higher Plants Module - 1priyam dasNessuna valutazione finora

- Warp Dyeing With Indigo DyesDocumento12 pagineWarp Dyeing With Indigo DyesMohammed Atiqul Hoque ChowdhuryNessuna valutazione finora