Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Establish Yield Ranges Trials

Caricato da

Purushothaman SubramanianTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Establish Yield Ranges Trials

Caricato da

Purushothaman SubramanianCopyright:

Formati disponibili

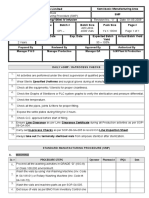

STANDARD OPERATING PROCEDURE

ESTABLISHING % YIELD RANGE FOR TRIAL AND VALIDATION

Title

BATCHES

SOP No.

ARDXXX-00

Effective Date

1.0

Function

Research and

Development

Page No.

1 of 4

`OBJECTIVE

To lay down a procedure for establishing % yield for intermediate and Active

Pharmaceutical Ingredients (API) stages.

2.0

SCOPE

This procedure is applicable to all APIs and intermediates developed in IPD

(Integrated Product Development) of Dr.Reddys laboratories limited.

3.0

RESPONSIBILITY

3.1

R&D and PE are responsible for establishing the yield range for trial batches from

development batches & CPP batches data.

3.2

NPM and R&D and PE are responsible for establishing the yield ranges for Process

Validation (PV) and commercial batches.

4.0

DEFINITION(s)

Not applicable.

5.0

TO BE REVISED BEFORE

6.0

PROCEDURE

6.1

Formula for the calculation of % yield for intermediate or API.

6.2

Output Weight

Molecular weight of input

------------------- X ------------------------------------ X 100

Input Weight

Molecular weight of output

R&D and PE shall finalise the % yield from lab and pilot plant batches after

completion of Optimization, what-if and spiking study experiments.

PREPARED BY

User Function

Name:

REVIEWED BY

Head - Function

Name:

APPROVED BY

Development Quality Assurance

Name:

Sign:

Sign:

Sign:

Date:

CDQ-F-001-00

Date:

Date:

STANDARD OPERATING PROCEDURE

ESTABLISHING % YIELD RANGE FOR TRIAL AND VALIDATION

Title

BATCHES

SOP No.

ARDXXX-00

Effective Date

6.3

Function

Research and

Development

Page No.

2 of 4

Minimum three batches as per final process, purging experimental data with specified

impurities and scale dependent what-ifs shall be considered for fixing the yield

range. Why purging & what-if are required?

6.3

An example for the yield finalization is given in below table

S.No.

1.

2.

3.

4.

Experiment /

Batch No.

#001

#002

#003

#004

Input

(g/ Kg)

100.0 g

100.0 g

100.0 g

100.0 g

(%) Yield

Remarks

75.0

74.0

76.0

68.0

Final Process yield from lab

experiments

Purging experiment with input having

2-3% impurities (for intermediates)

5.

#005

100.0 g

67.0

Least yielding scale dependent (SD)

parameter what-if experiment shall be

considered (Ex: longer hours addition)

6.

#006

5.0 Kg

64.0

% yield from CPP batch executed with

final process.

(Fixing of lower range).

Lower range of % yield shall be considered from spiking data / SD what-if data/ CPP batch

executed with final process.

%Yield shall be proposed as : 64 76% (Average %Yield: 70)

6.4

%Yield range for trial batch shall be fixed based on the T&V batch size also

considering the handling losses (high contribution of handling loss in lower batch

sizes) as per below table.

S.No.

T&V Batch size

Allowed variation from lab %

% Yield Range

PREPARED BY

User Function

Name:

REVIEWED BY

Head - Function

Name:

APPROVED BY

Development Quality Assurance

Name:

Sign:

Sign:

Sign:

Date:

CDQ-F-001-00

Date:

Date:

STANDARD OPERATING PROCEDURE

ESTABLISHING % YIELD RANGE FOR TRIAL AND VALIDATION

Title

BATCHES

SOP No.

ARDXXX-00

Effective Date

1.

1-2 Kg

2.

2-5 Kg

3.

5-10 Kg

4.

>10 Kg

Note: Higher % Yield should be maximum 100.

Function

Research and

Development

Page No.

3 of 4

yield

25 %

70 25 %

20 %

70 20 %

15 %

70 15 %

10 %

70 10 %

What is the rationale for allowed variation & yield

range?

6.5

Actual yield obtained in trial batches shall be considered for establishing the yield

range for process validation batches.

6.6

Acceptable limit for % Yield for unit operations (Sieving, milling, micronisation,

blending etc.,) shall be established by NPM team based on previous products

historical data.

6.7

Based on actual yield obtained in process validation batches and 10-15 commercial

batches control limits, action and alert limits for % yield shall be established.

6.8

% Yield variations in validation and commercial batches which are beyond the

acceptance criteria shall be investigated in the below areas (but not limited to)

6.8.1

Charging less quantity of raw materials / intermediates etc.,

6.8.2

Losses during charging operations

6.8.3

Spillage during the work-up / layer separation operations

6.8.4

Hold up losses

6.8.5

Product loss in to the Filtered MLs during the filtration due to the solubility of

material in solvent/ Leakage of filtration bed.

PREPARED BY

User Function

Name:

REVIEWED BY

Head - Function

Name:

APPROVED BY

Development Quality Assurance

Name:

Sign:

Sign:

Sign:

Date:

CDQ-F-001-00

Date:

Date:

STANDARD OPERATING PROCEDURE

ESTABLISHING % YIELD RANGE FOR TRIAL AND VALIDATION

Title

BATCHES

SOP No.

ARDXXX-00

Effective Date

6.8.6

Function

Research and

Development

Page No.

4 of 4

Sublimation during the drying due to lower boiling point of product.

.

What is the rationale for allowed variation & yield range?

Validation

Allowed % yield

Batch size

variation from lab

1-2 Kg

25%

2-5 Kg

20%

5-10 Kg

15%

>10 Kg

10%

7.0

REFERENCE(s) :

SOP No(*)

% Yield

Range

70 25 %

70 20 %

70 15 %

70 10 %

Acceptance criteria for yield variations

in validation batches (%RSD)

NMT 20%

NMT 15%

NMT 10%

Title

ARD007

Process development flow

*Current Version

8.0

9.0

ABBREVIATION(s)

Abbreviation

AR&D

DQA

R&D

API

PE

ANNEXURE(s)

Full Description

Analytical Research and Development

Development Quality Assurance

Research and Development

Active pharmaceutical ingredient

Process Engineering

Not applicable.

10.0

FORMAT(s)

Details/Title of Format

Format No.*

PREPARED BY

User Function

Name:

REVIEWED BY

Head - Function

Name:

APPROVED BY

Development Quality Assurance

Name:

Sign:

Sign:

Sign:

Date:

CDQ-F-001-00

Date:

Date:

STANDARD OPERATING PROCEDURE

ESTABLISHING % YIELD RANGE FOR TRIAL AND VALIDATION

Title

BATCHES

SOP No.

ARDXXX-00

Effective Date

Function

Research and

Development

Page No.

5 of 4

NA

*Current Version

PREPARED BY

User Function

Name:

REVIEWED BY

Head - Function

Name:

APPROVED BY

Development Quality Assurance

Name:

Sign:

Sign:

Sign:

Date:

CDQ-F-001-00

Date:

Date:

Potrebbero piacerti anche

- Establishing A CGMP Laboratory Audit System: A Practical GuideDa EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNessuna valutazione finora

- Practical Approaches to Method Validation and Essential Instrument QualificationDa EverandPractical Approaches to Method Validation and Essential Instrument QualificationNessuna valutazione finora

- Bimatoprost PDRDocumento81 pagineBimatoprost PDRmohit100% (1)

- Labaid Pharmaceuticals Limited: Deviation Control Status Open Closed TotalDocumento33 pagineLabaid Pharmaceuticals Limited: Deviation Control Status Open Closed TotalgolamnobiNessuna valutazione finora

- Preparation of Culture Suspension SOPDocumento9 paginePreparation of Culture Suspension SOPMichaelNessuna valutazione finora

- Analytical Method Transfer Protocol for EzetimibeDocumento8 pagineAnalytical Method Transfer Protocol for EzetimibeDany RockNessuna valutazione finora

- Alarm Verification FOR Incubators (Microbiology, Q-Block)Documento13 pagineAlarm Verification FOR Incubators (Microbiology, Q-Block)cpkakopeNessuna valutazione finora

- SOP-BDTO-QA021-10-Guideline For Personnel Training & Maintenance of Training Records - UnlockedDocumento26 pagineSOP-BDTO-QA021-10-Guideline For Personnel Training & Maintenance of Training Records - UnlockedRasel Uddin ShahNessuna valutazione finora

- Validate Furosemide Tablet ProcessDocumento26 pagineValidate Furosemide Tablet ProcessPatricia Joyce Malabanan SunglaoNessuna valutazione finora

- Elsanhouty Pharma Hold Time Study NotesDocumento6 pagineElsanhouty Pharma Hold Time Study NotesHuỳnh Ngọc SángNessuna valutazione finora

- VP-08-107 - Protocol For Hold Time of Softgel EquipmentsDocumento7 pagineVP-08-107 - Protocol For Hold Time of Softgel EquipmentsprakashNessuna valutazione finora

- Pe009 Pics Guide GMP Medicinal Products PDFDocumento68 paginePe009 Pics Guide GMP Medicinal Products PDFhuykhiemNessuna valutazione finora

- Xrex 50mg CapDocumento20 pagineXrex 50mg Capziauddin bukhariNessuna valutazione finora

- Pantoprazole 40mg InjectionDocumento36 paginePantoprazole 40mg Injectiondaizhussain004Nessuna valutazione finora

- Laboratory Investigation RequirementsDocumento16 pagineLaboratory Investigation RequirementsSebastian LopezNessuna valutazione finora

- CPV - Option 2Documento23 pagineCPV - Option 2DiemTrinhNguyenThienNessuna valutazione finora

- Amlodipine and Celecoxib Tablets PDFDocumento38 pagineAmlodipine and Celecoxib Tablets PDFNarongchai PongpanNessuna valutazione finora

- Protocol Design Qualification (DQ) : Romaco Kilian S 710 PrimeDocumento6 pagineProtocol Design Qualification (DQ) : Romaco Kilian S 710 PrimeTim100% (1)

- Example RA For Transport To Regulated MarketsDocumento7 pagineExample RA For Transport To Regulated MarketsDoan Chi ThienNessuna valutazione finora

- PDE Sample Document PDFDocumento29 paginePDE Sample Document PDFdhananjay100% (1)

- SMP 200mgDocumento7 pagineSMP 200mgTahir IbrahimNessuna valutazione finora

- Microbiological Best Lab Practices & Environmental MonitoringDocumento26 pagineMicrobiological Best Lab Practices & Environmental MonitoringNurul Hardiyanthi SadikinNessuna valutazione finora

- Juvia Protocol 50-1000Documento16 pagineJuvia Protocol 50-1000ziauddin bukhariNessuna valutazione finora

- Sterile Drug Insp CPGM 7356-002a - Ora - Lao-Nm 9-10-15 - Emc Lao FinalDocumento54 pagineSterile Drug Insp CPGM 7356-002a - Ora - Lao-Nm 9-10-15 - Emc Lao Finaltito1628100% (1)

- OOS调差Documento17 pagineOOS调差Smartishag BediakoNessuna valutazione finora

- Validation Req. in CTD & ProcessDocumento38 pagineValidation Req. in CTD & ProcessOula HatahetNessuna valutazione finora

- Procedure for release of Drug Substance and ProductsDocumento4 pagineProcedure for release of Drug Substance and Productsom shankar JhaNessuna valutazione finora

- Site Master File SummaryDocumento31 pagineSite Master File SummaryAnonymous cZ0Sn4hxF100% (1)

- Xoxiban 20mg Tab VPDocumento13 pagineXoxiban 20mg Tab VPziauddin bukhariNessuna valutazione finora

- Excipient Master File GuideDocumento30 pagineExcipient Master File GuideVanna Alyssa YuNessuna valutazione finora

- Eskag Pharma Pvt. LTD., Haridwar, Unit-I Department: Quality Assurance Product MatrixDocumento20 pagineEskag Pharma Pvt. LTD., Haridwar, Unit-I Department: Quality Assurance Product MatrixMohit ChauhanNessuna valutazione finora

- Pharmaceutical excipients auditing SOPDocumento55 paginePharmaceutical excipients auditing SOPFarheen FurqanNessuna valutazione finora

- Manuf Overseas Medicines GMP Clearance 17Documento39 pagineManuf Overseas Medicines GMP Clearance 17Vikram ChauhanNessuna valutazione finora

- Amendment 1: Replacement of 3Kl Uf Storage Tank & Installation of New 500 Ltr. Brine TankDocumento8 pagineAmendment 1: Replacement of 3Kl Uf Storage Tank & Installation of New 500 Ltr. Brine TankprakashNessuna valutazione finora

- STP Montelukast Sa.Documento6 pagineSTP Montelukast Sa.ShagorShagor100% (1)

- Stability Studies India 0307Documento75 pagineStability Studies India 0307Shailendra TripathiNessuna valutazione finora

- Hold Time Stability Studies in Pharmaceutical Industry Review 2167 7689.1000104Documento8 pagineHold Time Stability Studies in Pharmaceutical Industry Review 2167 7689.1000104iloveit52252Nessuna valutazione finora

- Manufacturing Formula: Product: Univit SyrupDocumento6 pagineManufacturing Formula: Product: Univit SyrupMohammed ZubairNessuna valutazione finora

- Eneric: G G D DDocumento75 pagineEneric: G G D Dlalooprasad15Nessuna valutazione finora

- ACTD Format Part IDocumento14 pagineACTD Format Part Iultimate_2226252Nessuna valutazione finora

- UTM - Packaging Process ValidationDocumento14 pagineUTM - Packaging Process Validation김소정Nessuna valutazione finora

- IVT - Validation Final ReportDocumento5 pagineIVT - Validation Final ReportDoan Chi ThienNessuna valutazione finora

- WHO CSDT SampleDocumento120 pagineWHO CSDT SampleYen-Yee Lim JacqNessuna valutazione finora

- DQ - CRAB For Lyo LoadingDocumento30 pagineDQ - CRAB For Lyo Loadingdhanu_lagwankarNessuna valutazione finora

- QCD-036-01 Good Chromatography PracticesDocumento12 pagineQCD-036-01 Good Chromatography Practicesarnab rayNessuna valutazione finora

- Scale - Up and Post Approval Changes (Supac)Documento31 pagineScale - Up and Post Approval Changes (Supac)Nim DCNessuna valutazione finora

- EN - Rita Cabaco - A Validation Master Plan For Small Volume Parenterals - 08-2014Documento93 pagineEN - Rita Cabaco - A Validation Master Plan For Small Volume Parenterals - 08-2014Anzari Muhammad100% (1)

- PV 01Documento20 paginePV 01Logan KandanNessuna valutazione finora

- Applicant's PartDocumento114 pagineApplicant's PartCesar RodriguezNessuna valutazione finora

- Standard Operating Procedure Department: ProductionDocumento2 pagineStandard Operating Procedure Department: Productionasit_mNessuna valutazione finora

- What Are The Key Benefits of Validation?Documento6 pagineWhat Are The Key Benefits of Validation?siva sankarNessuna valutazione finora

- Preparation of MFR in Pharmaceutical Industry.Documento4 paginePreparation of MFR in Pharmaceutical Industry.jaimurugesh100% (1)

- Annex4-TRS992 Hold Time Study GuidelineDocumento8 pagineAnnex4-TRS992 Hold Time Study Guidelinensk79in@gmail.com100% (1)

- Template Data PQR SANTA E 100Documento124 pagineTemplate Data PQR SANTA E 100Dina FadillaNessuna valutazione finora

- SOP For Handling of Spillage of Solid - Liquid Media Containing Growth - Pharmaceutical GuidelinesDocumento1 paginaSOP For Handling of Spillage of Solid - Liquid Media Containing Growth - Pharmaceutical GuidelinesJose Ramon Dalo BautistaNessuna valutazione finora

- Yield Investigation ReportDocumento1 paginaYield Investigation ReportNishant ShresthaNessuna valutazione finora

- Malaysia PRP Pharmaceutical Industry LogbookDocumento77 pagineMalaysia PRP Pharmaceutical Industry LogbookAiWeiNessuna valutazione finora

- Procedure For Leak Testing of Strips - BlistersDocumento7 pagineProcedure For Leak Testing of Strips - BlistersashishdrNessuna valutazione finora

- Artemis Non-Compliance ReportDocumento3 pagineArtemis Non-Compliance ReportPurushothaman SubramanianNessuna valutazione finora

- GDP ModuleDocumento18 pagineGDP ModulePurushothaman SubramanianNessuna valutazione finora

- IDMA Workshop on Lab Data IntegrityDocumento3 pagineIDMA Workshop on Lab Data IntegrityPurushothaman SubramanianNessuna valutazione finora

- Short Answer QuestionsDocumento4 pagineShort Answer QuestionsPurushothaman SubramanianNessuna valutazione finora

- Book Review HHWDocumento3 pagineBook Review HHWPurushothaman SubramanianNessuna valutazione finora

- AnimalDocumento14 pagineAnimalPurushothaman SubramanianNessuna valutazione finora

- Documents Required For (BT) Salaried CustomersDocumento1 paginaDocuments Required For (BT) Salaried CustomersPurushothaman SubramanianNessuna valutazione finora

- kELLER Book ReviewDocumento2 paginekELLER Book ReviewPurushothaman SubramanianNessuna valutazione finora

- School Bolta HaiDocumento1 paginaSchool Bolta HaiPurushothaman SubramanianNessuna valutazione finora

- Book Review HHWDocumento3 pagineBook Review HHWPurushothaman SubramanianNessuna valutazione finora

- CLEANING LIMITS FOR PHARMA INTERMEDIATESDocumento8 pagineCLEANING LIMITS FOR PHARMA INTERMEDIATESPurushothaman SubramanianNessuna valutazione finora

- UnitDocumento3 pagineUnitPurushothaman SubramanianNessuna valutazione finora

- Audit AgendaDocumento1 paginaAudit AgendaPurushothaman SubramanianNessuna valutazione finora

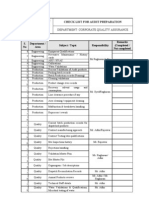

- Laboratories Limited Corporate QA Department: Corporate Quality AssuranceDocumento3 pagineLaboratories Limited Corporate QA Department: Corporate Quality AssurancePurushothaman SubramanianNessuna valutazione finora

- Process Validation PresentationDocumento8 pagineProcess Validation PresentationPurushothaman SubramanianNessuna valutazione finora

- Change Control PresentationDocumento20 pagineChange Control PresentationPurushothaman SubramanianNessuna valutazione finora

- Process Validation PresentationDocumento8 pagineProcess Validation PresentationPurushothaman SubramanianNessuna valutazione finora

- Process Validation PresentationDocumento8 pagineProcess Validation PresentationPurushothaman SubramanianNessuna valutazione finora

- Oot 1Documento5 pagineOot 1Purushothaman SubramanianNessuna valutazione finora

- Blackening Antiquing BrochureDocumento8 pagineBlackening Antiquing BrochureMala PrasadNessuna valutazione finora

- BS 4346 - 3Documento13 pagineBS 4346 - 3Ronnie1478Nessuna valutazione finora

- Green Processes Manufacturer of Paints and CoatingsDocumento5 pagineGreen Processes Manufacturer of Paints and CoatingsRai JeanNessuna valutazione finora

- Early international trade routes using camels and donkeysDocumento6 pagineEarly international trade routes using camels and donkeysGian Paul JavierNessuna valutazione finora

- Inventory Decisions in Dell's Supply ChainDocumento16 pagineInventory Decisions in Dell's Supply ChainFelipestr8Nessuna valutazione finora

- PB Uddeholm Sverker 21 EnglishDocumento12 paginePB Uddeholm Sverker 21 EnglishulfwisenNessuna valutazione finora

- Itp ErectionDocumento6 pagineItp ErectionvigneshNessuna valutazione finora

- Vestamid NRG 2101Documento2 pagineVestamid NRG 2101Leonardo MonroyNessuna valutazione finora

- Mk5 Modbus address mapping for ZR160A2 gen. 1 compressorDocumento10 pagineMk5 Modbus address mapping for ZR160A2 gen. 1 compressorhectorpazos100% (2)

- PPC ProblemDocumento7 paginePPC ProblemNiponIslamBeckham100% (1)

- Evidence 4 PRODUCT DISTRIBUTIONDocumento2 pagineEvidence 4 PRODUCT DISTRIBUTIONYAMILE HIGUITANessuna valutazione finora

- Clay Brick Making Machine Mew CB 3000Documento5 pagineClay Brick Making Machine Mew CB 3000Aakansh NigamNessuna valutazione finora

- CastingDocumento10 pagineCastingAkshay GargNessuna valutazione finora

- Company Profile - LatestDocumento5 pagineCompany Profile - LatestThalapathy VenkatNessuna valutazione finora

- 2015 Foster HVAC Selection GuideDocumento2 pagine2015 Foster HVAC Selection Guidesiva_nagesh_2Nessuna valutazione finora

- Polytrack Clinker Cooler.: PolysiusDocumento3 paginePolytrack Clinker Cooler.: PolysiushathamphanNessuna valutazione finora

- 3 Bumax Inox Classe 88 Et 109Documento4 pagine3 Bumax Inox Classe 88 Et 109grouhNessuna valutazione finora

- 01 SAP OverviewDocumento41 pagine01 SAP OverviewKushal Varshney50% (2)

- CONCRETE TECHNOLOGY DEVELOPMENTSDocumento20 pagineCONCRETE TECHNOLOGY DEVELOPMENTSvpmohammed100% (1)

- Operations Management: Facility LayoutDocumento54 pagineOperations Management: Facility LayoutSunnyNessuna valutazione finora

- Rust Mill Scale and Other Surface Contaminants - ETN-M-5-14 CRSIDocumento8 pagineRust Mill Scale and Other Surface Contaminants - ETN-M-5-14 CRSISayed Diab AlsayedNessuna valutazione finora

- Hoist Yale 360Documento10 pagineHoist Yale 360Vitor OlivettiNessuna valutazione finora

- A Presentation On Inventory ManagementDocumento24 pagineA Presentation On Inventory ManagementHari RittiNessuna valutazione finora

- Allied Office ProductsDocumento5 pagineAllied Office ProductsAdeel Jalil100% (1)

- Adaptive Orbital Pipe Welding - Hamidreza LatifiDocumento140 pagineAdaptive Orbital Pipe Welding - Hamidreza LatifiTejveer Yadav100% (1)

- LIST of GTDocumento5 pagineLIST of GTSonali BanerjeeNessuna valutazione finora

- 5s, Sixsigma, TPM, PQM, Pert Etc.Documento17 pagine5s, Sixsigma, TPM, PQM, Pert Etc.manpreetsodhi08Nessuna valutazione finora

- Auto Parts Inventory SystemDocumento4 pagineAuto Parts Inventory SystemVince Ryan L. ArboledaNessuna valutazione finora

- Welding Process Work InstructionDocumento6 pagineWelding Process Work InstructionmkcsekarNessuna valutazione finora

- Crockmeter (Manual & Motorised)Documento3 pagineCrockmeter (Manual & Motorised)senthilkumar7374Nessuna valutazione finora