Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

DAY 1 (OCTOBER 25, 2016) Time Activity

Caricato da

Jomel CuaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

DAY 1 (OCTOBER 25, 2016) Time Activity

Caricato da

Jomel CuaCopyright:

Formati disponibili

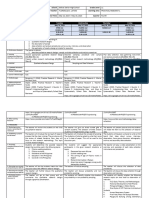

DAY 1 (OCTOBER 25, 2016)

TIME

1:00 2:30

2:30 3:00

3:00 3:30

3:30

5:30

6:30

7:00

7:30

5:30

6:30

7:00

7:30

7:45

ACTIVITY

ASSEMBLY TIME

DISCUSSION OF THE PROJECTS OBJECTIVES

DISCUSSION OF THE APPLICATION OF THE PROJECT MATERIAL

RECOVERY PROGRAM

RESEARCH ON THE POSSIBLE DESIGN AND ITS MECHANISM

SKETCHING OF THE DESIGNED PARTS

LAYOUT THE PROCESS FLOWCHART

PLANNING OF THE GANTT CHART

SUMMARY AND DOCUMENTATION OF THE MEETING

On the first day. The members first discuss the projects objective, a conveyor

that separates metal and plastic. Its commonly used in the material recovery

program. After that, the group research for the possible sensors that can be used

the possible design of the conveyor and its proponents. Then the design has

been sketched, its a conveyor that uses a material alignment mechanism to hold

and align the metal or plastic that will be inserted and sorted in the conveyor. A

tentative flowchart has been generated and a gantt chart to follow for the next

weeks to come.

DAY 2 (OCTOBER 27, 2016)

TIME

1:00 2:30

2:30 3:00

3:00 3:30

3:30

5:30

6:30

6:45

5:30

6:30

6:45

6:55

ACTIVITY

ASSEMBLY TIME

CHANGING THE PROJECTS OBJECTIVES

DISCUSSION OF THE APPLICATION OF THE PROJECT LOGISTICS

INDUSTRY

RESEARCH ON THE MATERIALS

SKETCHING OF THE DESIGNED PARTS

LAYOUT THE PROCESS FLOWCHART

PLANNING OF THE GANTT CHART

6:55 7:00

SUMMARY AND DOCUMENTATION OF THE MEETING

On the second day, the group alter the objective of the project. From a material

recovery program to logistic industry, so that the previous project using an

ultrasonic sensor will still be applicable. The researchers just add a color sensor

to separate the different color of the boxes. Each color will represent the

destination of the packages. Designing two separate conveyors to accommodate

the two size of the parcel. The group decide to use the old conveyor as its main

conveyor, so that the expense will be lessen. The conveyor has been inspected

to see how will be the parts be layout. Afterwards, the members strategically

planned the activities within the given period of time.

DAY 3 (NOVEMBER 3, 2016)

TIME

1:00 2:30

2:30 4:00

4:00 5:30

5:30 6:30

6:30 6:45

6:45 6:55

6:55 7:00

ACTIVITY

ASSEMBLY TIME

ALTERING THE DESIGN

RESEARCH ON THE MATERIALS

SKETCHING OF THE DESIGNED PARTS AND POSSIBLE LAYOUT

LAYOUT THE PROCESS FLOWCHART

UPDATING THE GANTT CHART

SUMMARY AND DOCUMENTATION OF THE MEETING

The group decided to meet for the third time to continue

improving the project. The design of the conveyor was

altered once more for a more concrete design. The group plans to study more

about the color sensor since it's new to them before buying it. The materials

were gathered and tested and also the group's gantt chart has been updated.

The following are more accomplishments done by the group as of present: More

concrete idea of the process flow of the project. Tentative design of the conveyor.

Lengthen the conveyor to accommodate more processes to be done on it. Gather

the materials needed. (i.e., sensors, connecting wires and wood) Tested the

sensors and checked if it is still fit for usage. Planned the size and material to use

for the sample boxes that will go on the conveyor. Updated gantt chart of the

groups's plan.

Potrebbero piacerti anche

- GH13 Heavy Duty Body Installation Manual PDFDocumento132 pagineGH13 Heavy Duty Body Installation Manual PDFPrashant Sharma100% (14)

- Accounting Principles Ifrs Version Global 1st Edition Weygandt Solutions ManualDocumento26 pagineAccounting Principles Ifrs Version Global 1st Edition Weygandt Solutions ManualKimberlyMendezyptr98% (40)

- Design of Jigs Fixtures and Press Tools PDFDocumento4 pagineDesign of Jigs Fixtures and Press Tools PDFniharika kadiriNessuna valutazione finora

- Transportation Planning and Public Participation: Theory, Process, and PracticeDa EverandTransportation Planning and Public Participation: Theory, Process, and PracticeNessuna valutazione finora

- Microcontroller-Based Design Progress Report: (Material Sorter (Logistics) )Documento10 pagineMicrocontroller-Based Design Progress Report: (Material Sorter (Logistics) )Jomel CuaNessuna valutazione finora

- Plca Document Draft WebDocumento28 paginePlca Document Draft Webkatherine tabordaNessuna valutazione finora

- Report Class ActivityDocumento2 pagineReport Class ActivitybendigeriabhishekNessuna valutazione finora

- Report Class ActivityDocumento2 pagineReport Class ActivitybendigeriabhishekNessuna valutazione finora

- Resumen de ArtículosDocumento28 pagineResumen de ArtículosMilvia Santiago CristobalNessuna valutazione finora

- 17 PendulumDocumento2 pagine17 Pendulumapi-293577945Nessuna valutazione finora

- Paps U3 A1 AmmDocumento13 paginePaps U3 A1 AmmAry Medina MartínezNessuna valutazione finora

- Architectural Design Studio 1 Project 2 Brief March2016Documento5 pagineArchitectural Design Studio 1 Project 2 Brief March2016api-289017690Nessuna valutazione finora

- Kanga Apl Journal Quarter 4Documento3 pagineKanga Apl Journal Quarter 4api-612240482Nessuna valutazione finora

- Quiel Dizon Performance Assessment 2-3a ScienceDocumento9 pagineQuiel Dizon Performance Assessment 2-3a Scienceapi-689180234Nessuna valutazione finora

- 5e Lesson PlanDocumento6 pagine5e Lesson Planapi-302319953Nessuna valutazione finora

- DesignDocumento9 pagineDesignJackNessuna valutazione finora

- HRSSP AC Meeting 5 AgendaDocumento1 paginaHRSSP AC Meeting 5 AgendaHRNERRNessuna valutazione finora

- Stem Integration Assignment-3Documento5 pagineStem Integration Assignment-3api-281010247Nessuna valutazione finora

- Faculty of Architecture and Planning: A. K. T. U. L U C K N O WDocumento1 paginaFaculty of Architecture and Planning: A. K. T. U. L U C K N O WSunilNessuna valutazione finora

- 6.3 Tips in Writing Action ResearchDocumento10 pagine6.3 Tips in Writing Action ResearchArchessNessuna valutazione finora

- Aerospace 1 and 2Documento5 pagineAerospace 1 and 2api-287954898Nessuna valutazione finora

- 3-Architectural Design Studio 1 Project 2 Brief Aug2016Documento5 pagine3-Architectural Design Studio 1 Project 2 Brief Aug2016api-302681845Nessuna valutazione finora

- TimesheetsDocumento1 paginaTimesheetsapi-320212932Nessuna valutazione finora

- Edar 517 Unit 3 ScopeDocumento3 pagineEdar 517 Unit 3 Scopeapi-311053248Nessuna valutazione finora

- UAL BRIEF 5 Unit 8Documento4 pagineUAL BRIEF 5 Unit 8miskinmusic123Nessuna valutazione finora

- Outline OutcomeDocumento2 pagineOutline Outcomeاحمد الدلالNessuna valutazione finora

- Grupo 5 Empirical Design Methods - Update (2014)Documento10 pagineGrupo 5 Empirical Design Methods - Update (2014)Fidel Angel CercedoNessuna valutazione finora

- New Progress ReportDocumento64 pagineNew Progress ReportAyush KishoreNessuna valutazione finora

- DLL May 15 19Documento4 pagineDLL May 15 19Maristela RamosNessuna valutazione finora

- 41053154Documento31 pagine41053154Luis Fernando Bejar LuksicNessuna valutazione finora

- Team Analysis Week 2 5 FinalisedDocumento9 pagineTeam Analysis Week 2 5 Finalisedgabrielhii1995Nessuna valutazione finora

- Una Caminata Sonora en La Ciudad de Rosario, ArgentinaDocumento13 pagineUna Caminata Sonora en La Ciudad de Rosario, ArgentinaStellaOliveiraNessuna valutazione finora

- SRPA Lecture October 12Documento1 paginaSRPA Lecture October 12roxannevicedo52Nessuna valutazione finora

- Teaching Practice 1 Toco Lesson PlanDocumento4 pagineTeaching Practice 1 Toco Lesson Planapi-298948027Nessuna valutazione finora

- Project Study Proposal Presentation Format 1 1Documento15 pagineProject Study Proposal Presentation Format 1 1Franz DefanteNessuna valutazione finora

- Building A Pyramid PTDocumento6 pagineBuilding A Pyramid PTapi-224567327Nessuna valutazione finora

- Pothole Workshop at IISC Bangalore On 11 September 2018 - Program PDFDocumento1 paginaPothole Workshop at IISC Bangalore On 11 September 2018 - Program PDFabhay kumarNessuna valutazione finora

- Conveyor RRLDocumento2 pagineConveyor RRLVeronica MangundayaoNessuna valutazione finora

- Kanga Apl Journal Quarter 1Documento5 pagineKanga Apl Journal Quarter 1api-612240482Nessuna valutazione finora

- Admin, 28 Anasrul Septian PrayogiDocumento10 pagineAdmin, 28 Anasrul Septian PrayogiNaufal WahyuNessuna valutazione finora

- Primary Science Design BriefDocumento1 paginaPrimary Science Design Briefapi-451123503Nessuna valutazione finora

- Short-Term Planning For Open Pit Mines: A ReviewDocumento24 pagineShort-Term Planning For Open Pit Mines: A ReviewJERINNessuna valutazione finora

- December 18-22, 2023 LogbookDocumento1 paginaDecember 18-22, 2023 LogbookIan DibNessuna valutazione finora

- Chapter IiiDocumento4 pagineChapter IiiMariel Erica RootNessuna valutazione finora

- Komba3 2013Documento191 pagineKomba3 2013MILON KUMAR HORENessuna valutazione finora

- (Springer Series in Materials Science 245) Christopher R. Weinberger, Garritt J. Tucker (Eds.) - Multiscale Materials Modeling For Nanomechanics-Springer International Publishing (2016)Documento554 pagine(Springer Series in Materials Science 245) Christopher R. Weinberger, Garritt J. Tucker (Eds.) - Multiscale Materials Modeling For Nanomechanics-Springer International Publishing (2016)Anonymous RuEybHNessuna valutazione finora

- Architecture Design Studio 1 Project 3 Brief March2016Documento6 pagineArchitecture Design Studio 1 Project 3 Brief March2016api-289042707Nessuna valutazione finora

- Project CLARCDocumento3 pagineProject CLARCJustin RoxasNessuna valutazione finora

- BrainSpaces Agenda March 26-28Documento2 pagineBrainSpaces Agenda March 26-28phase1bloggerNessuna valutazione finora

- Science Lesson PlanDocumento12 pagineScience Lesson PlanVicenta MontoyaNessuna valutazione finora

- Design Brief - GoodDocumento2 pagineDesign Brief - Goodapi-443327549Nessuna valutazione finora

- Intasc Standard 5 Application of ContentDocumento7 pagineIntasc Standard 5 Application of Contentapi-253456954Nessuna valutazione finora

- Etc MPDocumento12 pagineEtc MPMr UnknownNessuna valutazione finora

- (Lecture Notes in Civil Engineering 14) T Thyagaraj - Ground Improvement Techniques and Geosynthetics - IGC 2016 Volume 2-Springer Singapore (2019)Documento403 pagine(Lecture Notes in Civil Engineering 14) T Thyagaraj - Ground Improvement Techniques and Geosynthetics - IGC 2016 Volume 2-Springer Singapore (2019)Gustavo Henrique RossiNessuna valutazione finora

- Stemf - Unit of Work RollercoasterDocumento15 pagineStemf - Unit of Work Rollercoasterapi-409728205Nessuna valutazione finora

- s2909727 Userinterfacedesignbrief Group4 s2909727 s2935994 s2845106 s2893004 - Alpha V 2Documento31 pagines2909727 Userinterfacedesignbrief Group4 s2909727 s2935994 s2845106 s2893004 - Alpha V 2api-282835562Nessuna valutazione finora

- Finite Element Analysis and Design of Experiments in Engineering DesignDocumento113 pagineFinite Element Analysis and Design of Experiments in Engineering DesignRitanshu AnandNessuna valutazione finora

- Integrated Design of Multiscale, Multifunctional Materials and ProductsDa EverandIntegrated Design of Multiscale, Multifunctional Materials and ProductsNessuna valutazione finora

- Seismic Data Interpretation and Evaluation for Hydrocarbon Exploration and Production: A Practitioner’s GuideDa EverandSeismic Data Interpretation and Evaluation for Hydrocarbon Exploration and Production: A Practitioner’s GuideNessuna valutazione finora

- Inside Anthropotechnology: User and Culture Centered ExperienceDa EverandInside Anthropotechnology: User and Culture Centered ExperienceNessuna valutazione finora

- Composite Materials: Concurrent Engineering ApproachDa EverandComposite Materials: Concurrent Engineering ApproachNessuna valutazione finora

- The Problem: Rationale and BackgroundDocumento6 pagineThe Problem: Rationale and BackgroundJomel CuaNessuna valutazione finora

- Information Systems and Supply Chain ManagementDocumento4 pagineInformation Systems and Supply Chain ManagementJomel CuaNessuna valutazione finora

- Group Discussion For The Prototype Design, Materials Required and Illustration of Project ScheduleDocumento1 paginaGroup Discussion For The Prototype Design, Materials Required and Illustration of Project ScheduleJomel CuaNessuna valutazione finora

- Product Chart and Systems Product SystemsDocumento2 pagineProduct Chart and Systems Product SystemsJomel CuaNessuna valutazione finora

- Interr ModifDocumento180 pagineInterr ModifJoaquin CampitiNessuna valutazione finora

- Ece T 2012 ToppersDocumento13 pagineEce T 2012 ToppersRajesh LingamalluNessuna valutazione finora

- cHIPSET AND CONTROLLERDocumento9 paginecHIPSET AND CONTROLLERMelody MwhengwereNessuna valutazione finora

- Solution of Tutorial Sheet-3 (Three Phase Networks) : Ans. Given, - Vab - 45kV, ZL (0.5 + j3), Z (4.5 + j9)Documento10 pagineSolution of Tutorial Sheet-3 (Three Phase Networks) : Ans. Given, - Vab - 45kV, ZL (0.5 + j3), Z (4.5 + j9)Shroyon100% (2)

- STR Mpa-MpmDocumento8 pagineSTR Mpa-MpmBANGGANessuna valutazione finora

- Trodat Standard Self Inking Stamp and Accessory Mini CatalogDocumento12 pagineTrodat Standard Self Inking Stamp and Accessory Mini CatalogpromotesourceNessuna valutazione finora

- Catalogo de Oleohidraulica AGVDocumento73 pagineCatalogo de Oleohidraulica AGVadjime3Nessuna valutazione finora

- Tramlink Low-Floor Light Rail Vehicle: Rostocker Strassenbahn Ag, Rostock, GermanyDocumento2 pagineTramlink Low-Floor Light Rail Vehicle: Rostocker Strassenbahn Ag, Rostock, GermanyLuca Marius CristianNessuna valutazione finora

- What Are The Good Research QuestionDocumento26 pagineWhat Are The Good Research Questionkavindukarunarathna100% (2)

- Introduction To R: Shanti.S.Chauhan, PH.D Business Studies ShuatsDocumento53 pagineIntroduction To R: Shanti.S.Chauhan, PH.D Business Studies ShuatsShanti Swaroop ChauhanNessuna valutazione finora

- BUT11F/11AF: NPN Silicon TransistorDocumento4 pagineBUT11F/11AF: NPN Silicon TransistorfabioboogNessuna valutazione finora

- Definitions - NFPADocumento365 pagineDefinitions - NFPAAnand KrishnaNessuna valutazione finora

- Lab Manual No 13Documento3 pagineLab Manual No 13Hammad JawadNessuna valutazione finora

- 888 Gallant Security Services Corp NewDocumento12 pagine888 Gallant Security Services Corp Newnareyes11Nessuna valutazione finora

- 4 - 5.1 - Fluid Action On Surfaces (Plane Surface)Documento16 pagine4 - 5.1 - Fluid Action On Surfaces (Plane Surface)Jacky CagampanNessuna valutazione finora

- Workover Kill Fluid Density CalculationDocumento3 pagineWorkover Kill Fluid Density CalculationSanny Astari100% (1)

- EmpanelHospList HelpFAQDocumento13 pagineEmpanelHospList HelpFAQaditi001Nessuna valutazione finora

- Ref: Bboneblk - SRM Beaglebone Black System Reference Manual Rev BDocumento125 pagineRef: Bboneblk - SRM Beaglebone Black System Reference Manual Rev BhernangycNessuna valutazione finora

- 1743 LKWActrosXXXXXX 954frDocumento4 pagine1743 LKWActrosXXXXXX 954frgeothermal3102100% (1)

- Case StudyDocumento2 pagineCase StudyAyeng 1502100% (1)

- Shear Stress Though Tapered Pipe Thread - Eng-TipsDocumento4 pagineShear Stress Though Tapered Pipe Thread - Eng-TipsrodrigoperezsimoneNessuna valutazione finora

- NDT NablDocumento3 pagineNDT NablPrabir KumarNessuna valutazione finora

- 08L76 HR3 A21Documento6 pagine08L76 HR3 A21liebofreakNessuna valutazione finora

- PR-1078 - Hydrogen Sulphide Management ProcedureDocumento22 paginePR-1078 - Hydrogen Sulphide Management Procedureromedic360% (1)

- SMDocumento36 pagineSMharan2000Nessuna valutazione finora

- Electrical Load For Indoor UnitsDocumento2 pagineElectrical Load For Indoor UnitsMD BILAL ASLAMNessuna valutazione finora

- ABB - AppNotes - 2.2 - 1HC0138868 EN AADocumento8 pagineABB - AppNotes - 2.2 - 1HC0138868 EN AADeoudrafNessuna valutazione finora

- 6.hydraulic Pressure SpesificationDocumento3 pagine6.hydraulic Pressure SpesificationTLK ChannelNessuna valutazione finora