Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

10.flac Reference

Caricato da

PhuocTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

10.flac Reference

Caricato da

PhuocCopyright:

Formati disponibili

FLAC-GIIC Reference

Figure 1.8

1 - 11

Library

tool

Select a grid object, press OK , and a dialog will then prompt for the objects x- and y-dimension

range. After the range is entered, a grid-plot tool will open, and the grid can be manipulated.

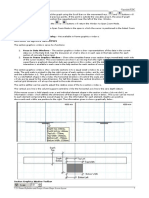

Figure 1.9 shows the grid-plot tool for the thin seam with fault grid object. The library object can

be manipulated in the same manner as the other grid tools. For example, you can easily increase

the mesh density in the region of interest by using the Mesh Density mode. By right-clicking on one

of the handle boxes, a dialog will open, as shown in Figure 1.9, to specify a different zone density

for a given grid block.

Figure 1.9

Grid tool for thin seam with fault object

FLAC Version 5.0

1 - 12

The grid object files are written in JAVA, and the class files and source code files for all of the grid

objects in the Library are stored in the ITASCA\FLAC500\GUI\Gridlib directory. If you wish,

you can create your own grid object; use the source-code files provided in the directory as a guide

to create your grid-object template. You can add your grid to the Library by copying your JAVA

*.CLASS file to the ITASCA\FLAC500\GUI\Gridlib directory, and then pressing the Refresh

button in the Library tool (see Figure 1.8). The library list will be updated to include the new grid

object.

1.2.2

Alter

Tools

After you have completed the Build operation and created the grid to fit the problem domain, click

on the Alter tab to access tools that you can use to define sub-regions or add additional shapes (e.g.,

excavation boundaries, layered materials or discontinuous features) to the grid. Four Alter tools are

provided to alter or shape the grid:

1.2.2.1

Mark

Tool

Mark gridpoints to delimit regions in your model by pressing the Mark button; you will then enter the

Mark-tool pane. This tool is useful, for example, to define layered materials in a model. With the

Set

radio button checked, you can mark a gridpoint simply by moving the mouse to that gridpoint

and pressing the left mouse button. Click and drag to mark multiple gridpoints. Note that when you

mark a gridpoint, a MARK command will be created in the Changes sub-pane. See Figure 1.10*.

Commands in the Changes pane have not yet been sent to FLAC. You can clear these commands

with the arrow buttons located at the top of the Changes pane. Once you are satisfied with your

selections, press the Execute button and the commands will then be sent to FLAC. This approach

allows you to change your selections and view the results in the GIIC before sending the commands

to FLAC. This method is used in several of the model-tool panes.

You can return to this tool at any time and mark new gridpoints or un-mark a marked gridpoint. To

un-mark, check the Clear radio button and then click on the gridpoint you wish to un-mark. The

UNMARK command is created for the specified gridpoint.

* The View / Show axis values menu item is selected to display x- and y-coordinate axes on the left

and bottom borders of the model view. See Section 1.6.4 for further information on manipulating

the model view.

FLAC Version 5.0

FLAC-GIIC Reference

Figure 1.10

1.2.2.2

Shape

1 - 13

Mark

tool

Tool

The Shape tool is mainly used to conform the grid to specified shapes, such as tunnels, geological

boundaries and construction boundaries. Note that if a construction sequence is to be modeled

(e.g., emplacement of layers in an earth dam), the grid should be adjusted to conform to all future

geometrical stages at the start. The grid should not be adjusted with the Shape tool after the solution

process has begun.

When using the Shape tool, it is recommended that the Bad Zone Geometry setting be active. (This is the

default setting for the Shape tool.) Bad Zone Geometry is set on the pop-up menu accessed through the

pop-up button on the View toolbar, or by right-clicking on the background of the grid plot view.

(See Section 1.4.1.1 for more information on the pop-up menu.) When distorting the grid in the

Shape

tool, you will be able to see immediately if you have created a bad-geometry condition (as

defined by the criteria illustrated in Figure 2.40 in the Users Guide). You can then correct the bad

geometry condition before the calculation starts.

FLAC Version 5.0

1 - 14

Figure 1.11

tool with Bad Zone

bad-zone condition)

Shape

Geometry

active (gridpoint moved to illustrate

You can conform the grid to fit given shapes, such as circles, arcs and lines, with the Shape tool.

The various shape modes are listed to the right. Select the shape mode you wish to apply, click and

drag in the grid to apply the shape; the shape will appear on the grid. Release the mouse button

and click the Generate button to conform the grid to the shape. Note that this is a virtual grid; the

commands have not yet been sent to FLAC. Press Clear to remove the shape from the virtual grid.

Press Execute to send the corresponding commands to FLAC.

For example, select the Circle mode, position the circles center on the grid, then click and drag

to position the circles periphery. A circle outline will appear with two handle boxes, one at the

centroid and one along the circle periphery (see Figure 1.12). Click and drag on these handle boxes

to move the circle and/or adjust its radius. Right-click on the handle boxes to access pop-up dialogs

to specify values for the center and radius. When you click Generate , the virtual grid is adjusted to

fit the circular shape, as shown in Figure 1.13. Click Execute to send the corresponding GENERATE

circle command to FLAC.

FLAC Version 5.0

FLAC-GIIC Reference

Figure 1.12 GIIC virtual grid with

1 - 15

Circle

button active

Figure 1.13 GIIC virtual grid altered to fit

Circle

shape

FLAC Version 5.0

1 - 16

The Line and Arc modes are implemented in the same way as the Circle mode. When you select

these modes, a corresponding tool adjusts the grid to fit each shape. Once executed, Line and Arc

modes send GENERATE line and GENERATE arc commands, respectively, to FLAC. The Point mode

allows you to move individual gridpoints. This mode creates INITIAL x and INITIAL y commands to

reposition gridpoints in the FLAC mesh.

For the Table mode, a table must first be created from the Utility / Table tool.* (See Section 1.2.6

for the procedure to create a geometric table.) Tables are assigned identification numbers. After

you click on the Table radio button in the Shape tool, select the ID number of the table you wish to

generate and then point and click the mouse on the table in the grid plot. The table line will be

highlighted, as shown in Figure 1.14. Press Generate to conform the grid to fit the table line (see

Figure 1.15).

Figure 1.14 Table highlighted when

Table

button active

* A table can also be read into FLAC by pressing the ? button located to the right of the ID number

pulldown. The table file must be an ASCII file in the format of a TABLE command, as described in

Section 1 in the Command Reference.

FLAC Version 5.0

FLAC-GIIC Reference

Figure 1.15 GIIC virtual grid altered to fit

1 - 17

Table

line

You will note in Figure 1.15 that the gridpoints at the ends of the line were not adjusted to fit the line.

This can happen if the table line does not extend far enough, or if the grid is too coarse. Press the

Point

radio button to move the end gridpoints, as shown in Figure 1.16. By right-clicking on each

end gridpoint, a dialog opens to specify new x- and y-coordinates for these gridpoints. This creates

the INITIAL commands to reposition the gridpoints, as shown in the Changes pane in Figure 1.16.

Now it is necessary to mark these end gridpoints. This is done with the Mark tool, as shown

in Figure 1.17. In order to define two separate regions in the FLAC model, a contiguous line of

marked gridpoints must be delineated. The regions can be viewed in the model-view pane by turning

on the regions-view mode. This is done from the model-view pop-up menu. Position the mouse

anywhere within the model-view pane and press the right button. The pop-up menu will appear, as

shown in Figure 1.18. See Section 1.4.1.1 for more information on the model-view pop-up menu.

FLAC Version 5.0

1 - 18

Figure 1.16 Adjust end gridpoints with the

Point

Figure 1.17 Mark the end gridpoints from the

FLAC Version 5.0

mode in the

Mark

tool

Shape

tool

FLAC-GIIC Reference

1 - 19

Figure 1.18 Model view with regions active

FLAC Version 5.0

1 - 20

You can reposition the entire grid or portions of the grid by using the Range mode in the Shape tool.

Drag the mouse over the portion of the grid that you wish to reposition. This portion is highlighted.

Handle boxes appear at the corner gridpoints of the highlighted region. See Figure 1.19. Click and

drag on a handle box to distort the highlighted region. All gridpoints within the region are adjusted

to maintain the original zone spacing. Right-click on any handle box to call a pop-up dialog to

specify new x- and y-coordinates. A handle box also appears in the center of the highlighted region;

this box can be used to change the grid ratio for the highlighted zones.

For example, if you wish to distort a 20 20 zone grid to form a rectangular opening, first highlight

the right half of the grid, as shown in Figure 1.19. Then right-click on each of the four corners

of the highlighted region. Enter the following coordinates, beginning with Corner 4. (The corner

number is identified on the title bar of the pop-up dialog.)

Corner

Corner

Corner

Corner

4

3

2

1

:

:

:

:

x=5.0,

x=20.0,

x=20.0,

x=5.0,

y=0.0;

y=0.0;

y=20.0;

y=5.0.

Then, press Generate . Now highlight the left half of the grid and enter the new coordinates, beginning

with Corner 4:

Corner

Corner

Corner

Corner

4

3

2

1

:

:

:

:

x=5.0,

x=20.0,

x=0.0,

x=0.0,

y=5.0;

y=20.0;

y=20.0;

y=5.0.

Press Generate again, and the distorted mesh will be formed, as shown in Figure 1.20. Two GENERATE

commands are created; these are the same as those issued for the command-line example given in

Example 2.2 in the Users Guide.

FLAC Version 5.0

FLAC-GIIC Reference

1 - 21

Figure 1.19 Highlighting a portion of grid to reposition using the

Figure 1.20 Distorted grid formed with

Range

Range

mode

mode

FLAC Version 5.0

1 - 22

The Region mode in the Shape tool is used to move the entire grid, or sub-grids, by a specified

displacement. This mode creates INITIAL x add and INITIAL y add commands for FLAC. Select the

Region

mode, then select a gridpoint within the sub-grid you wish to move, and drag-and-drop the

sub-grid to a new location. Alternatively, right-click over the grid; a dialog will open to enter xand y-displacement values to move the sub-grid.

Sub-grids are separated by null zones. In order to apply the Region mode to a sub-grid, null zones

must first be created using the Material / Assign tool. (See Section 1.2.3 for the procedure to create

null zones.) For example, Figure 1.21 shows a model with two sub-grids separated by a vertical

column of null zones. In order to close the gap between the two sub-grids, first select the Region

mode. Now, left-click on the bottom left corner of the right sub-grid. While holding down the

<Ctrl> key on your keyboard, drag the bottom-left corner node toward the bottom-right corner

of the left sub-grid. The node will snap to this location, because the <Ctrl> key is depressed.

When the left mouse button is released, the right sub-grid will be shifted to the left and an INITIAL

x add command will be created, as shown in Figure 1.22. Note that, even though the boundaries

of the two sub-grids are now at the same location, the sub-grids will not interact. It is necessary to

either attach the sub-grids, or add an interface along the boundaries, for interaction to occur. This

is accomplished with either the Attach and Interface tools, described below, in Sections 1.2.2.3 and

1.2.2.4, respectively,

FLAC Version 5.0

FLAC-GIIC Reference

1 - 23

Figure 1.21 Two sub-grids separated by vertical column of null zones

Figure 1.22 Shift right sub-grid to the left with

Region

mode

FLAC Version 5.0

1 - 24

1.2.2.3

Attach

Tool

The ATTACH command is implemented via the Attach tool. When in this tool, select the A-side radio

button and click and drag along one boundary of a sub-grid you wish to attach. A highlight bar will

be drawn along this boundary when you release the button. Then, repeat this process with the B-side

radio button selected and drag, in the same direction, along the boundary of the other sub-grid to

be attached. A highlight bar will appear along this boundary. Click Assign to create the ATTACH

command, and Execute to send this command to FLAC.

For example, to attach the two sub-grids shown in Figure 1.22, enter the Attach tool, click on the

A-side

radio button and drag the mouse along the right boundary of the left sub-grid. A highlight

bar will appear along this boundary. Select B-side and drag along the left boundary of the right

sub-grid, in the same direction as that for the A-side. A highlight bar will appear. The two bars are

shown in Figure 1.23.

Figure 1.23 Sub-grid boundaries to be attached using the

Attach

tool

When the Assign button is pressed, marks are placed at all attached gridpoints, and an ATTACH

command is shown in the Changes pane. See Figure 1.24.

FLAC Version 5.0

FLAC-GIIC Reference

Figure 1.24 Attached gridpoints are identified by marks after

in the Attach tool

1 - 25

Assign

is pressed

The Attach tool will attach sub-grids with matching gridpoints and sub-grids with non-matching

gridpoints. However, sub-grids with non-matching gridpoints must have an integral ratio between

gridpoint segments along the two boundaries to be attached. For example, if one boundary has

3 segments (4 gridpoints), then the matching boundary must have an integral multiple number of

segments e.g., 6 segments (7 gridpoints). The Assign button will only activate if this condition is

satisfied. The segment ratio is monitored and printed at the top right of the Attach tool.

As an example, a sub-grid with 20 segments along a boundary is attached to a sub-grid with 10

segments along a boundary. The two sub-grids are first created from a 20 16 zone grid by nulling

zones to separate the sub-grids (using the procedure described in Section 1.2.3). The sub-grids are

shown in Figure 1.25. The A-side for the attached boundaries is assigned to the top boundary of

the lower sub-grid (10 segments), and the B-side is assigned to the bottom boundary of the upper

sub-grid (20 segments), as shown in Figure 1.25. The attached gridpoints between the two sub-grids

are identified by connecting lines, as shown in Figure 1.26, when Assign is pressed. After the Attach

tool is executed, the Shape tool is used to move the two sub-grids together. All zones in the upper

sub-grid are selected; then the upper sub-grid is positioned on top of the lower sub-grid by using the

Range

mode. Figure 1.27 shows the upper sub-grid highlighted with its bottom-left corner relocated

to the position of the top-left corner of the lower sub-grid. (The <Ctrl> key is held to snap the

upper sub-grid corner to the location of the lower sub-grid corner.) Next, the other three corners

of the upper sub-grid are moved to their new positions. Figure 1.28 shows the final position of the

upper sub-grid after all four corners are relocated.

FLAC Version 5.0

1 - 26

Figure 1.25 Two sub-grids with unequal boundary segments

Figure 1.26 Attached gridpoints identified by marks and connecting lines using the Attach tool

FLAC Version 5.0

FLAC-GIIC Reference

1 - 27

Figure 1.27 Moving corner gridpoints of the upper sub-grid using the

mode in the Shape tool

Range

Figure 1.28 Final position of two attached sub-grids with unequal boundary

segments

FLAC Version 5.0

1 - 28

Note that it does not matter whether the sub-grids are moved together first and then attached

(Figures 1.22 and 1.23), or attached first and then moved together (Figures 1.25 through 1.28).

However, the directions in which the A-side and B-side of the attached grid are defined does matter.

If the B-side of the upper sub-grid is specified by dragging the mouse in the direction opposite to

that for the A-side of the lower sub-grid, the attached gridpoints will not be coincident when the

sub-grids are moved together. This can easily be seen when the sub-grids are apart initially because

the connecting lines will cross. If this happens, press Reset in the Attach tool and reassign the A-side

and B-side in the same direction.

The ability to match unequal grids provides more flexibility in creating graded meshes. It is

convenient to use the Build / Radial tool to create a radially graded grid to provide the boundary

conditions for a single tunnel. However, it is difficult to extend this approach to multiple tunnels

that interact with each other. As an alternative approach, it is possible to insert and completely

attach several fine-zone sub-grids within voids in a coarse-zone sub-grid. In this way, a grid can be

constructed in which each tunnel has its own fine grid for good local accuracy, while the interactions

and boundary conditions make use of a coarse grid.

Figure 1.29 shows an initial 78 50 grid divided into four sub-grids: one large sub-grid containing

three regions of null zones; and three smaller, 16 16 zone, sub-grids. (See Section 1.2.3 for the

procedure to create the null-zone regions.) The Shape tool in Range mode is used to move each of the

three sub-grids into the null-zone regions of the large sub-grid. Figure 1.30 shows this operation in

progress. Note that the <Ctrl> key is pressed when each sub-grid corner is dragged, so that the

corner will be snapped onto the corresponding corner of the null-zone region. Also, note that the

integral ratio of the boundaries between the smaller sub-grid and the larger sub-grid is 2:1.

After the three sub-grids are repositioned inside the larger sub-grid, they are attached to the larger

sub-grid using the Attach tool. The attachment is done in two steps for each of the three small

sub-grids. First, the A-side is assigned along the bottom and right side of the boundary of the large

sub-grid, and the B-side is assigned along the bottom and right side of the adjacent small sub-grid,

as shown by the highlight bars in Figure 1.31.* When the B-side is assigned, the highlight bar may

flip from the bottom-right to the top-left of the sub-grid while being drawn. In order to change the

path direction, check the B-long box, as shown in Figure 1.31. After clicking Assign , the procedure

is repeated to attach the left-side and top boundaries see Figure 1.32. The two-step procedure is

repeated to attach all three sub-grids inside the large sub-grid. The result is shown in Figure 1.33.

Tunnels can now be defined within the three fine-grid regions, using the Shape tool. See Example 3.18

in Theory and Background for a comparison of this model to that for a model created with a uniform

grid, using the same mesh size throughout as that for the fine-zone region.

* The View / Zoom box menu item is selected to magnify the view of one of the small sub-grids shown

in Figures 1.31 and 1.32, to facilitate the use of the Attach tool.

FLAC Version 5.0

FLAC-GIIC Reference

1 - 29

Figure 1.29 Initial grid divided into large sub-grid with null-zone regions plus

three separate sub-grids

Figure 1.30 Moving sub-grids using the

Shape

tool in

Range

mode

FLAC Version 5.0

1 - 30

Figure 1.31 Attaching the bottom and right-side boundaries of a sub-grid

inside a sub-grid using the Attach tool

Figure 1.32 Attaching the left-side and top boundaries of a sub-grid inside a

sub-grid using the Attach tool

FLAC Version 5.0

FLAC-GIIC Reference

1 - 31

Figure 1.33 Three fine-zone sub-grids attached to a coarse sub-grid

FLAC Version 5.0

1 - 32

1.2.2.4

Interface

Tool

An interface between two sub-grids is created in the same manner as an attached grid. An A-side and

B-side of the interface are defined by left-clicking and dragging the mouse along the boundaries

of the sub-grids that will be assigned an interface. This operation is performed in the Interface

tool. Figure 1.34 illustrates the creation of an interface beginning with the two sub-grids shown

previously in Figure 1.22. When the Assign button is pressed, an Interface properties dialog opens

so that the interface type and properties can be prescribed. See Sections 4.2 and 4.4 in Theory and

Background for information on the interface material model and selection of properties. When OK

is pressed in the dialog, a line is drawn along the boundary to denote the location of the interface,

with marks indicating the locations of interface nodes. An identification (ID) number circle at one

end of the interface identifies the interface. See Figure 1.35. An INTERFACE command is created,

as shown in the Changes pane in this figure. Note that interface creation does not have the same

restriction as an attached grid on non-matching gridpoints between sub-grids. An integral ratio

between gridpoint segments along the boundaries is not required.

Interface properties can be changed at any stage of a model analysis by first clicking on the Property

radio button in the Interface tool and then pointing and clicking the mouse on the ID number circle

in the Interface tool grid plot. This will cause the Interface properties dialog to reopen so that

properties can be changed.

An interface can be removed in a manner similar to that employed when editing interface properties

i.e., first click on the Remove radio button in the Interface tool and then point and click the mouse

on the ID number circle.

An interface can also allow interaction between beam elements and a grid. The procedure to create

an interface between a beam and grid is described in Section 1.2.5.4.

FLAC Version 5.0

FLAC-GIIC Reference

Figure 1.34 Creating an interface with the

1 - 33

Interface

tool

Figure 1.35 Interface identified by a line with marks and ID number

FLAC Version 5.0

1 - 34

1.2.3

Material

Tools

Material models and properties are assigned to the FLAC model using the Material tools. By default,

only two tools are provided: Assign and Cut&Fill . These tools are sufficient for simple static analyses

and use only the null, isotropic elastic and Mohr-Coulomb models.

Default material tools

If the GWFlow box is checked in the Model Options dialog, a GWProp tool is added to the Material tool

bar. This allows the assignment of groundwater flow properties associated with CONFIG gw.

Default material tools plus groundwater properties tool

If the Include Advanced Constitutive Models? box is checked in the Model Options dialog, then two additional

tools, Model and Property , are made available to implement the advanced constitutive models and

property variations. Note that if FLAC is configured to include the optional creep-analysis feature,

the Include Advanced Constitutive Models? box must be checked in order for the Creep option to be invoked

in the Model Options dialog. Creep material models will then be available through the Model tool.

Material tools with advanced constitutive models

FLAC Version 5.0

FLAC-GIIC Reference

1 - 35

If the Thermal box is checked in the Model Options dialog, a Thermal tool is added to the Material tool

bar. This allows the assignment of thermal properties associated with CONFIG thermal.

Default material tools plus thermal properties tool

In order to include the C++ user-defined model option, the Include Advanced Constitutive Models? box must

be checked to access the C++ UDMs check box in the Model Options dialog. When these options are

invoked, a LoadModel tool is added to the Material tool bar.

Material tools with advanced constitutive models plus option for

C++ user-defined models

FLAC Version 5.0

1 - 36

1.2.3.1

Assign

Tool

The Assign tool is used to create and assign null, isotropic elastic and Mohr-Coulomb materials to

zones within the grid. The tool is shown in Figure 1.36.

Figure 1.36

Assign

tool

Elastic and Mohr-Coulomb materials are created via a Define Material dialog that is opened by

pressing the Create button in the Edit group in the Assign tool. After the material is created, the

material name is added to a material List pane in the tool. Materials are then assigned to zones

by selecting a material name in the material List modes and then selecting the mode in which that

material is assigned to zones. Four modes are available:

(1) If all zones in the model are to have the same material, click the

material List in the Assign tool.

SetAll

button below the

(2) To assign the material to one zone at a time, select Rectangle in the Zone Range mode

groups; click (single zone) or click and drag (multiple zones) to assign the material.

(3) To assign a material to a lateral layer of zones, select

and drag (multiple layers) to assign the material.

Layer

; click (single layer) or click

(4) By selecting Region , a highlight line will be drawn around all defined regions in the model.

Click on any zone within a region to assign the material to all zones within that region.

FLAC Version 5.0

FLAC-GIIC Reference

1 - 37

When the FLAC grid is first created with one of the Build tools, an isotropic-elastic model (MODEL

elastic) is automatically assigned to all of the non-null zones in the grid.* When you first enter

the Assign tool, the null material is the only material available to be assigned, and is listed in the

material List pane, as shown in Figure 1.36. Null zones can then be added to the grid using mode

(2), (3) or (4) described above. For example, a column of null zones is created to separate two

sub-grids, as shown in Figure 1.36, by checking the Rectangle radio button and then holding the left

button and dragging the mouse over the column of zones to be made null. This is the approach

to define sub-grids, as discussed previously for the creation of attached grids (Section 1.2.2.3) and

interfaces (Section 1.2.2.4).

New elastic or Mohr-Coulomb materials are created in the Define Material dialog. Figure 1.37

shows the Define Material dialog, opened in the Assign tool by pressing the Create button. Within

this dialog, you can assign a classification and material name, prescribe elastic or Mohr-Coulomb

constitutive model type and assign material properties. The classification name is used to help

identify materials within a Material Database; the database is described below in Section 1.2.3.2.

If only a few materials are prescribed for a model, then the classification may not be needed and can

be left blank. The dialog in Figure 1.37 creates a silty sand material and assigns a Mohr-Coulomb

material model with elastic and plastic properties. Note that the dialog provides the option to assign

either bulk and shear moduli or elastic (Youngs) modulus and Poissons ratio. The alternative

elastic properties are calculated when the Alternate box is checked.

Figure 1.37 Define Material dialog in the

Assign

tool

* Note that a model created with one of the Build tools can consist of null-material zones as well as

elastic-material zones. You can distinguish the null and elastic zones in a model by switching the

model view from x-y space to i-j space. This is done with a right-click in the model view to

open the model-view pop-up menu (see Section 1.4.1.1), and then selection of IJ Space . The model

view will switch to i-j space and any null zones will be visible.

FLAC Version 5.0

1 - 38

When OK is pressed, the material is created and the material name is added to the material List.

Clone

and Edit buttons are also provided to facilitate creation and modification of several materials.

Delete

The

button will delete a selected material from the material list.

After all materials required for the model have been created, they can be assigned to the grid, using

mode (1), (2), (3) or (4), described above. Figure 1.38 illustrates the assignment of two materials

in three layers in a model.

Figure 1.38 Assign materials using the

Layer

mode

When a material is assigned, a GROUP command is created to associate a group name with a

material, a MODEL command is created to prescribe the selected constitutive model, and a PROPERTY

command is created to assign the associated material properties. The commands are listed in the

Changes pane in Figure 1.38.

FLAC Version 5.0

FLAC-GIIC Reference

1 - 39

1.2.3.2 Material Database

The material database provided with the Assign tool is accessed with the Database button. The

database contains a list of pre-defined materials based on the material properties tables contained

in Section 3.7 in the Users Guide. The database list is stored with the preference settings in the

STARTUP.GPF file. The database is divided into material groups and listed in a tree structure,

as shown in Figure 1.39. To select a material from the database, select the material name in the list

and then Add . The material name will be added to the Selection pane shown on the left side of the

dialog. For example, the material Soil-Gravel:uniform has been selected in Figure 1.39.

After you have selected the material(s) you wish to use in your model, press OK . The materials in

the Selection pane will be added to the material List in the Assign tool. These materials can then be

assigned to zones using the same procedures described previously.

Figure 1.39 Material database dialog

You can modify the materials in the pre-defined database, or create your own database. Click the

Edit

tab (at the top of the dialog) to edit the currently selected material. For example, Figure 1.40

shows the Edit pane for the Soil-Gravel:uniform material. This panes parameters and behavior are

identical to the Define Material dialog shown previously in Figure 1.37.

FLAC Version 5.0

1 - 40

Figure 1.40

Edit

tab in the Material database dialog

Make changes to a material in the Edit pane and press Apply at the bottom of the tool to update the

material. The Create and Clone buttons at the bottom of the Selection pane are used to create new

materials to add to the database. Copy->Database adds the material to the database under the specified

classification name. The material is removed from the Selection pane using the Remove button.

The Save , Append and Load buttons beneath the material tree (in Figure 1.39) are used to save-to-file,

append to, or load-from-file the database that you create. The Delete button allows you to delete

materials from the database. A user-created database is given the extension .GMT when it is

saved in a selected directory using the Save button.

FLAC Version 5.0

FLAC-GIIC Reference

1.2.3.3

Cut&Fill

1 - 41

Tool

The Cut&Fill tool is used, in conjunction with the Assign tool, for the case in which either elastic

or Mohr-Coulomb material is added to the model (fill material) or subtracted from the model

(excavated material) during different stages of the analysis e.g., adding embankment lifts in the

construction of an earth dam. Note that this tool only applies to elastic or Mohr-Coulomb materials

created with the Assign tool. The Cut&Fill tool cannot be used, at this time, with advanced material

models assigned with the Model tool. The tool is shown in Figure 1.41.

Figure 1.41

Cut&Fill

tool

After materials are created in the Assign tool, these materials will be listed in the List pane of the

Cut&Fill

tool, as shown in Figure 1.41. A material is excavated by selecting the material name in

the material List and then pressing Excavate . Alternatively, you can right-click on the material in the

model view; a pop-up menu will then open and you can select Excavate . If the Show excavations? box is

checked, a shaded region will be shown in the model view to help identify which materials have

been excavated.

In order to fill an excavated region, highlight the excavated material name in List and click on Fill .

You can also right-click on the excavated material to select Fill on the pop-up menu. In Figure 1.41,

four materials (Layer 1 through Layer 4) have been excavated, and Layer 1 has been filled. The

associated MODEL commands are listed in the Changes pane in the Cut&Fill tool when the material

is either excavated or filled. Note that all material regions in the FLAC grid must be defined before

the FLAC calculation is started. If materials are to be added at a later stage of an analysis, they can

be nulled (excavated) before beginning the calculation and then added (filled) at the later stage.

FLAC Version 5.0

1 - 42

1.2.3.4

GWProp

Tool

The GWProp tool is used to set the porosity and permeability properties for the groundwater-flow

configuration (when CONFIG gw is specified). The tool is shown in Figure 1.42. Zones are selected

to assign the groundwater properties in one of four ways, as described previously in Section 1.2.3.1.

After the zone selection is made, a Model Groundwater properties dialog will open, as shown

in Figure 1.42. Either constant values for porosity and (isotropic or anisotropic) permeability, or

values that vary as a function of volumetric strain, can be specified. See the PROPERTY command in

Section 1 in the Command Reference for a description of the porosity and permeability properties.

The Biot coefficient is also set in this tool, if Set Biot on? is selected in the GW (Flow) Settings dialog

accessed from the GW tool in the Settings tab. See Section 1.2.7.3.

Figure 1.42

FLAC Version 5.0

GWProp

tool

FLAC-GIIC Reference

1.2.3.5

Model

1 - 43

Tool

All material constitutive models are available through the GIIC if the Include Advanced Constitutive Models?

box is checked in the Models Options dialog. Note that this option can be turned on at any stage of

the FLAC analysis. When this box is checked, the Model and Property buttons are added to the Material

tool bar.

The constitutive models are divided into seven groups and accessed by clicking on one of the radio

buttons: Null , Elastic , Plastic , Creep , Dynamic , User Fish or User C++ . Note that the Creep button, the

Dynamic

button and the User C++ button will only be visible if the creep-analysis mode, the dynamicanalysis mode or the C++ user-defined model mode, respectively, is checked in the Model Options

dialog. The User Fish button is included after a FISH constitutive model is called into FLAC. (See

Section 1.2.3.7 for information on implementing FISH constitutive models in FLAC.) The User C++

button is included after a C++ user-defined model is called into FLAC. (See Section 1.2.3.8 for

information on implementing C++ user-defined models.) Figure 1.43 shows the Model tool with all

constitutive models available.

Figure 1.43

Model

tool

When you select a radio button, a list of constitutive models will be shown in the bottom-right corner

of the Model tool. For example, the Plastic radio button is checked, and six of the eight plasticity

models are visible, in Figure 1.43.

In order to assign a constitutive model to the FLAC grid, first select one of the models. The

ubiquitous-joint model is selected in Figure 1.43. A constitutive model is assigned to zones in a

FLAC Version 5.0

1 - 44

FLAC model in one of four ways, as explained previously in Section 1.2.3.1. When the assignment

is made (for example, by pressing SetAll ), a properties dialog will open. The Model ubiquitous

properties dialog is shown in Figure 1.43. After entering the properties in the dialog, press OK and

a MODEL and PROPERTY command will be created and shown in the Changes pane. A group name

can be associated with the constitutive model for the selected zone range. Note that the group name

must be assigned before the zone range is selected. For example, the group name bedded shale is

associated with the ubiquitous-joint model before SetAll is pressed. A GROUP command is then

also created when OK is pressed in the properties dialog. After all constitutive models have been

assigned to the FLAC grid, press Execute to send the commands to FLAC and return to the main

window. The model-view pane will be updated to show the assigned constitutive models.

1.2.3.6

Property

Tool

The Property tool accesses all material properties associated with the constitutive models provided in

the Model tool. Material properties can be prescribed individually for each zone in a model or over a

region of zones. A linear variation of the property over a given range can also be prescribed, and the

values of the property can be chosen randomly from a normal (Gaussian) distribution. Figure 1.44

shows the Property tool. The cohesion property, used in the ubiquitous-joint model, is highlighted,

and the SetAll button is pressed. This causes a dialog to open to specify a value and optional variation

for the cohesion property. A spatial variation in the y-direction is given for cohesion in Figure 1.44.

When OK is pressed, a PROPERTY command with a var keyword is created. (See Section 1.1.3.4 in

the Command Reference for the definition of var to apply a spatial variation.) See the PROPERTY

command description in Section 1 in the Command Reference for descriptions of the different

ways material properties can be varied.

After the property change or variation has been made, press Execute to send the PROPERTY command(s) to FLAC. If you wish to confirm the action taken with the PROPERTY command, return to

the Property tool, highlight the property in question, and press the Plot values . A contour plot of the

selected property will appear in the model-view of the Property tool. Figure 1.45 shows the contour

plot of cohesion corresponding to the variation assigned in Figure 1.44.

FLAC Version 5.0

FLAC-GIIC Reference

Figure 1.44

1 - 45

Property

tool

Figure 1.45 Plot of variation in cohesion

FLAC Version 5.0

1 - 46

1.2.3.7 FISH Constitutive Models

FISH constitutive models are implemented in FLAC using either the FISH Editor and/or the

Utility FishLib

/

tool. See Section 1.5 for information on creating and executing a FISH function

using the FISH Editor. Section 1.2.6.4 describes the implementation of FISH functions from the

FishLib

tool.

Figure 1.46 shows the FishLib tool from the Utility toolbar. The topmost folder of the tree, Library,

corresponds to the ITASCA\FLAC500\GUI\FISHLIB directory. The subfolders listed in the

tool are identical to the subfolders in the FISHLIB folder. The FISHLIB\ConstitutiveModels

folder contains a set of pre-defined FISH constitutive models. In Figure 1.46, a user-defined model

has been added to the FISH library by first adding the file user-defined.fis to the FISHLIB

folder, then pressing Refresh in the FishLib tool.

Figure 1.46 MDUNCAN.FIS model added to

FishLib

library

The user-defined model can now be loaded into FLAC by pressing the OK button in the FishLib tool.

Once the model is loaded, the User Fish radio button is added to the Model tool. The FISH model

can now be applied to the FLAC grid and material properties assigned in the same manner as that

for the built-in models, as described in Section 1.2.3.5. Figure 1.47 shows the Model user-defined

properties: dialog opened to assign properties for this FISH constitutive model.

FLAC Version 5.0

FLAC-GIIC Reference

Figure 1.47

1 - 47

User Fish

button added to

Model

tool

FLAC Version 5.0

1 - 48

1.2.3.8

LoadModel

Tool

The LoadModel tool is added to the Material tool bar when the CPP UDMs box is checked in the Model

Options dialog. This tool is used to load user-defined models, written in C++ and compiled as DLL

(dynamic link library) files, into FLAC. See Section 4 in Optional Features for instructions on

creating new constitutive models for FLAC. Once you have created a new model as a DLL, press

the LoadModel button to open a dialog and load the model into FLAC. Select the directory in which the

DLL file is located, and click on the DLL file name. This will create a MODEL load command and

load the model into the FLAC executable. The new model can then be assigned to zones in FLAC in

exactly the same way as the built-in models. For example, Figure 1.48 shows the Model tool after a

user-defined model, usermohr.dll, has been loaded. When the model is assigned to zones, a Model

dll usermohr properties: dialog opens, as shown in the figure, to enter properties for this model.

Figure 1.48

FLAC Version 5.0

User C++

models added from

LoadModel

tool

FLAC-GIIC Reference

1.2.3.9

Thermal

1 - 49

Tool

The Thermal tool is added to the Material tool bar when the Thermal box is checked in the Model Options

dialog. The tool is shown in Figure 1.49. This tool assigns thermal models to a FLAC grid. The

models (thermal null, isotropic heat conduction, anisotropic heat conduction and isotropic heat

conduction with temperature-dependent thermal conductivity) are shown in the Thermal Tool list

on the right side of the Thermal tool. If the groundwater-flow configuration is set ( GWFlow checked in

the Model Options dialog), then thermal-GW is added to the Thermal Tool list. In order to assign a

thermal model to the FLAC grid, highlight the model name in the Thermal Tool list, and then use

one of the four methods discussed in Section 1.2.3.1 to assign the model to specific zones. After

the zones are selected, a dialog will open to enter properties corresponding to the chosen thermal

model. For example, in Figure 1.49, the Model th isotropic properties: dialog is shown to assign

properties for the isotropic heat conduction model.

Figure 1.49

Thermal

tool

FLAC Version 5.0

1 - 50

1.2.4

In Situ

Tools

The In Situ tools assign boundary conditions and initial conditions to the FLAC model. There

are four tools to assign these conditions. The Apply tool and the Fix tool set boundary conditions

along the boundary of the model. The Interior tool prescribes an unchanging condition to interior

gridpoints or zones. The Initial tool assigns initial conditions to gridpoints or zones; conditions

can change during the solution process with this tool.

1.2.4.1

Apply

Tool

The Apply tool assigns boundary conditions to the FLAC model. The types of boundary conditions are

listed in the B. C. types pane, an expandable tree shown in Figure 1.50. The boundary conditions

are divided into six groups: Stress, Velocity, Force, Dynamic, Groundwater and Thermal. The

Dynamic, Groundwater and Thermal groups will only be visible if the dynamic analysis mode, the

groundwater flow mode or the thermal analysis mode, respectively, is checked in the Model Options

dialog.

Figure 1.50

FLAC Version 5.0

Apply

tool

FLAC-GIIC Reference

1 - 51

In order to assign a boundary condition, first select the condition in the B. C. types list. For example,

pressure is highlighted in the Stress group in Figure 1.50. After highlighting the condition, click

and drag the mouse along the boundary on which the condition is to be applied. A highlight bar

will appear with a circle denoting the starting gridpoint for the applied condition. Next, press the

Assign

button, which opens an Assign value dialog. Enter the value for the boundary condition and

then press OK to create the APPLY command.

An optional spatial variation can be prescribed in the Assign value dialog when the Variation box is

checked. The spatial variation is assigned using the relation given by Eq. (3.2) in the Users Guide.

If a spatial variation is assigned, an arrow will appear along the selected boundary; the arrow points

in the direction of the most positive value. For example, a variation in the y-direction is specified

for the xx-stress component in Figure 1.51. The arrow is pointing upward in this figure because

the stress varies from a value of -100 at the bottom of the model to zero at the top. (Recall that

negative stresses indicate compression.)

Figure 1.51 Spatial variation in the boundary condition value assigned with

the Apply tool

A history multiplier can also be specified for the boundary condition value in order to apply a timevarying boundary condition. The multiplier can be given as a FISH function, an input history or an

input table. The boundary-condition value in the Value box (or adjusted by the X-Y Variation) in

the Assign value dialog is multiplied by the history multiplier. If a FISH function is the multiplier,

then the function must first be called into FLAC. See Section 1.5 for instructions on using the FISH

Editor to create and execute FISH functions in the GIIC. If the multiplier is an input history, the

history file must be formatted in the form described for the HISTORY read command as given in

FLAC Version 5.0

1 - 52

Section 1 in the Command Reference. If the multiplier is an input table, then the table must be

formatted in the form described for the TABLE command as given in Section 1 in the Command

Reference. See Section 1.2.6.2 for instructions on creating a table. The input history and input

table only apply for the dynamic-analysis option.

Figure 1.52 illustrates the specification of an input history as a multiplier. A file, ACC1.HIS, is

an acceleration record formatted as described for the HISTORY read command. The History radio

button is pressed in the Multiplier pane of the Assign value dialog. The ? button is then pressed

to locate the directory in which the ACC1.HIS file is located. When this file is selected, it is

assigned a history number, and a HISTORY read command is created. This command is then sent to

FLAC and the history file is read into the code. By pressing OK in the Assign value dialog, an APPLY

command is created with the hist keyword. Finally, when Execute is pressed in the Apply dialog, the

APPLY command is sent to FLAC and the GIIC returns to the main window. The HISTORY read and

APPLY commands are now listed in the resource pane.

Figure 1.52 History multiplier assigned with the

Apply

tool

Note that the form of the boundary path (short, long or both) can be selected, and the apply condition

can be removed in the Apply tool. Also, note that a Free-Field button is provided to assign a free-field

boundary condition for dynamic analysis.

FLAC Version 5.0

FLAC-GIIC Reference

1.2.4.2

Fix

1 - 53

Tool

With the Fix tool, velocity, pore pressure, saturation and temperature (and non-wetting pore pressure

and seepage for two-phase flow analysis) can be prevented from changing at selected gridpoints.

This tool is typically used to set mechanical, groundwater or thermal boundary conditions for a

model. For example, if a fixed displacement (i.e., roller or pinned) boundary condition is required,

the appropriate velocities are first initialized (using the Initial tool; note that zero velocity is the

default on start-up) and then the selected boundary gridpoints are fixed to prevent movement.

Figure 1.53 shows the Fix tool.

Figure 1.53

Fix

tool

In order to fix a condition, select the corresponding type (e.g., in Figure 1.53, the X&Y gridpoint

velocity is selected). Then click and drag the mouse over the gridpoints to be fixed. A circle will

appear as the pointer passes over the gridpoint, and a letter designation will appear when the mouse

button is released. In Figure 1.53, the letter B is shown, which designates that the gridpoint is

fixed in both the x- and y-directions. A FIX command will also be created and listed in the Changes

pane. Press Execute to send the FIX command(s) to FLAC. A SetMarked GP button and Set All GP button

are provided to apply the fixity condition to multiple gridpoints. A fixity condition can also be

removed in this tool by first selecting the Free radio button and then dragging the mouse over the

gridpoints to be freed.

FLAC Version 5.0

1 - 54

1.2.4.3

Initial

Tool

Certain gridpoint or zone variables can be assigned initial values using the Initial tool. The gridpoint

variables and zone variables are grouped separately in expandable trees shown in Figures 1.54 and

1.55. In order to assign initial values to a selected variable, first select the variable name. Next,

click and drag the mouse over the gridpoints (or zones) that are to be assigned initial values. For

example, in Figure 1.54, gridpoint pore pressure* is selected (pp), and the mouse is dragged over

the lower seven rows of gridpoints; these gridpoints are then highlighted. Now, press the Assign

button. This opens a dialog to input the initial value. Several options to assign initial values are

available. In order to assign a pore pressure distribution that increases with depth, check the Variation

box and enter the variation according to Eq. (3.2) in the Users Guide. When a spatial variation is

assigned, an arrow will appear over the selected gridpoints; the arrow points in the direction of the

most positive value. A downward arrow is shown in Figure 1.54 for the variation specified in the

dialog. This corresponds to an increasing pore pressure with depth in the model.

Figure 1.54 Assigning gridpoint values with the

Initial

tool

Note that if a variable is to be assigned initial values for all gridpoints in the model, press Assign

immediately after highlighting the variable name. It is not necessary to drag the mouse over all

of the gridpoints. Also, note that once the gridpoints are selected to initialize one variable, those

gridpoints and the selected value and variation will be remembered for the next variable assignment.

* Note that gridpoint pore pressures are initialized when GWFlow is selected in the Model Options dialog.

When GWFlow is not selected, then pore pressures are initialized as zone quantities.

FLAC Version 5.0

FLAC-GIIC Reference

1 - 55

Assigning an initial value for zone variables is performed in the same way as for gridpoint variables.

In this case, zones are highlighted when the mouse is dragged across the model, as shown in

Figure 1.55. This figures illustrates the assignment of a yy-stress distribution, ranging from -107 at

the bottom of the model to zero at the top. The variation is prescribed in accordance with Eq. (3.2)

in the Users Guide. The arrow now points upward in the direction of the most positive value.

Two additional radio buttons are provided on the value assignment dialog. The Add option allows

the specified value, including the variation given, to be added to the existing values at the selected

gridpoints or zones. The Mul option allows the existing value at the gridpoint or zone to be multiplied

by the specified value (including any variations).

When the OK button is pressed in the dialog, an INITIAL command (with optional add or multiply

keywords) is added to the Changes pane. These commands are then sent to FLAC when Execute is

pressed.

Figure 1.55 Assigning zone values with the

Initial

tool

After you have assigned initial values in the FLAC model, you can return to the Initial tool and

check this assignment. By highlighting the variable name and then pressing Plot values , a contour

plot of the values assigned for that variable will be plotted. For example, Figure 1.56 shows the

pore pressure contours for the distribution assigned previously in Figure 1.54.

FLAC Version 5.0

1 - 56

Figure 1.56 Checking assigned values with

Plot values

in the

Initial

tool

A Displmt & Velocity button is also provided in the bottom-right corner of this tool. Press this button whenever you wish to initialize displacements and velocities in a model. This creates two

commands: INITIAL xdisp 0 ydisp 0 and INITIAL xvel 0 yvel 0 to send to FLAC.

FLAC Version 5.0

FLAC-GIIC Reference

1.2.4.4

Interior

1 - 57

Tool

The Interior tool is used to apply mechanical, groundwater and thermal conditions to any interior

gridpoint or zone in the model. Note that these are fixed conditions within the model. The gridpoint

interior conditions and zone interior conditions are grouped separately in expandable trees shown

in Figures 1.57 and 1.58. The application is similar to that for the APPLY tool. Select the interior

condition to be applied and then click and drag the mouse over the selected gridpoints or zones to

apply the condition. Then press Assign to open a dialog to assign the value for the interior condition.

Figure 1.57 illustrates the application of an x-acceleration at one gridpoint in the model, and

Figure 1.58 shows the application of a groundwater well over two zones. Note that the dialog is

identical to that for the APPLY tool. In Figure 1.57, the acceleration is applied with a history multiplier.

In Figure 1.58, the well is applied with a time-varying FISH function. See the discussion for the

APPLY

tool in Section 1.2.4.1 for use of the history and FISH multipliers.

Figure 1.57

Interior

tool for setting gridpoint condition

FLAC Version 5.0

1 - 58

Figure 1.58

FLAC Version 5.0

Interior

tool for setting zone condition

FLAC-GIIC Reference

1.2.5

Structure

1 - 59

Tools

The Structure tools define the geometry, properties, and element and nodal conditions for structural

elements. These tools are activated when the Include Structural Elements? box is checked in the Model

Options dialog. Note that the Structure tool tab can be activated at any time in an analysis; click on

File / Model options to open the Model Options dialog and activate the Structure tools. There are

ten Structure tools. Seven tools, Beam , Liner , Cable , Pile , Rockbolt , Strip and Support , are used to define

the geometry of the structural elements. The Segment tool sets conditions for structural element

segments, and the Node tool sets conditions for structural element nodes. The SEProp tool assigns

properties to the structural elements.

1.2.5.1 Common Attributes and Behaviors of Structural Element Tools

A structural element is defined as a set of two or more nodes with segments between each node.

Nodes are positioned in x-y space by default. The structural element is created with click-and-drag

operation to define a beginning point and an endpoint. A STRUCTURE node x y command(s) is

generated based on the mouse movements. Pressing <Ctrl> while click and dragging will cause

the nodes of a structural element to snap to the nearest gridpoint when adding or moving nodes.

Some tools include a Segments control to add segments (and the correspondingly necessary nodes)

between two defined endpoints. Right-clicking on a defined node will display a pop-up dialog for

numerical (rather than mouse) input of positioning information. All tools have a Clear button that

will remove (erase) any existing structural element within the current instance of the tool (it does

not clear structural elements that were previously defined and executed). All tools have a NewInput

button that will allow numerical (rather than mouse) specification of new structural elements.

1.2.5.2 Common Modes for Defining Structural Elements

Most of the structural element tools utilize a common set of modes when creating and modifying

structural elements. These modes are mutually exclusive (only one mode may be activated at a

time), and they are: Add , Delete , PropID , Move and Pin . Note that the modes only apply to newly

created structural elements in the tool.

FLAC Version 5.0

1 - 60

The Add mode is used to create a new structural element or to add nodes/segments to an existing

structural element. Figure 1.59 shows a pile with 30 segments that has been created by defining

four nodes. Each of the four nodes was clicked while the <Ctrl> button was pressed, which

causes the node to snap to the nearest gridpoint. This is indicated by the X that appears inside

the node box. Note that the Segments property is set to 10, which results in 10 segments appearing

between each of the defined nodes.

Figure 1.59 A pile element is defined

FLAC Version 5.0

FLAC-GIIC Reference

1 - 61

The Delete mode is used to delete one or more nodes; intermediate nodes between defined nodes

are not available to delete. The delete mode works on sections of the element rather than on the

nodes themselves. Hovering over a section of an element will cause that section to be highlighted,

indicating that it will be removed when it is clicked in delete mode (shown in Figure 1.60).

Individual structural element segments can be deleted after the structural element is created. See

the Segment tool in Section 1.2.5.9.

Figure 1.60 Deleting mode: the middle section of the pile element is highlighted as the mouse hovers over it to indicate that it will be removed when the mouse is clicked

FLAC Version 5.0

1 - 62

The Prop ID mode causes the elements property ID to be displayed when the mode is activated.

Clicking on the segment associated with an ID number will open a dialog that may be used to

assign a new number. In Figure 1.61, the identification number P1 corresponds to pile property

identification number 3001. Clicking on the segment allows the identification number to be changed

to P2, which will correspond to ID 3002 identification numbers are added sequentially.

Figure 1.61 Using

FLAC Version 5.0

PropID

mode to display/change identification numbers

FLAC-GIIC Reference

1 - 63

The Move mode is used to move a defined element. The element may be moved by click and dragging

an endpoint or by click and dragging on any part of the element. In Figure 1.62, pile P2 from

the previous figure has been moved by dragging its top node to the location of P1s bottom node.

Holding <Ctrl> while doing so causes the node to snap to the gridpoint at its new location. Since

this position already contains a node, a dialog appears as shown, asking whether the two nodes

should be merged into one. Answering no to the dialog will leave two nodes situated at that

location.

Figure 1.62 Using the move mode to reposition an element

FLAC Version 5.0

1 - 64

The Pin mode is used to establish pin connections. By default, moments develop at nodes connecting

multiple segments of a beam, liner, pile or rockbolt element or elements. As with the Delete mode,

the mouse operation is performed on the segment between nodes rather than directly on the nodes.

Hovering over a segment causes it to be highlighted. Clicking on the segment causes an arrow to

be drawn, indicating a pin connection; a corresponding STRUCT node n pin command is created.

The denoted connection can be removed by clicking on the arrow. Note that structural moments are

not transmitted to gridpoints; thus an element connected to the grid is pin-jointed to the gridpoint

at each connection point. In Figure 1.63, a pin connection is created between the two nodes in the

same location from the previous figure. When one node is pinned to another, the nodes are slaved.

Nodes may also be slaved using the Node tool, described below in Section 1.2.5.10.

Figure 1.63 Creating a pin connection using the

Pin

mode

As mentioned above, the Pile elements may be removed by pressing the Clear button; a new element

may be described numerically in dialogs using the NewInput button. It is important to note that all of

the actions performed in a structural element tool apply to the currently created elements(s). These

actions result in commands that are sent to FLAC when Execute is pressed. It is not possible to return

to the tool and perform operations on previously created elements of that type. The only exception

is that you can create a new element and connect the new end-node to a previously created element

node.

FLAC Version 5.0

FLAC-GIIC Reference

1.2.5.3

The

Beam

Beam

1 - 65

Tool

tool creates beam elements. The tool has two base forms:

Lining

and

Free

In free form, a beam is created, defined by one segment and two nodes, when the mouse is pressed,

dragged and released. Each node, by default, is positioned in x-y space, and a STRUCTURE node n x

y command is generated when the mouse is clicked. Nodes attached to gridpoints using the <Ctrl>

key (as described in the previous section) will generate STRUCTURE node n grid i j commands. It

is possible to change the attachment condition of the node by right-clicking a node. This opens a

Node Parameters dialog that allows you to change the node condition to either free or attach to grid ,

depending on the selected radio button.

Figure 1.64 The Node Parameters dialog is used to change the attachment

condition of a node in the Beam tool

When the beam commands are executed, a series of STRUCTURE node commands are sent to FLAC,

followed by a series of STRUCTURE beam begin node n1 end node n2 prop 1001 commands which

connect all beam nodes to create the beams (the property identification number 1001 is assigned,

by default, to the beam; this may be changed using the PropID mode of the Beam tool).

Multiple beams can be created and connected together, or connected to existing beams or other

elements. If the node of a new element is defined at the location of existing element node, the

existing node will be defined as an end-node for the new beam.

In lining form, a beam may be created along some or all of an internal or external grid boundary. In

addition, this form contains a range of switches that may be set to further define a lining beam.

FLAC Version 5.0

1 - 66

Nodes may be attached in one of three ways: to the grid; to an interface; or to an existing liner or

beam. In the case of a beam lining attached to an interface, it is also possible to create a gap from

the grid at a specified distance. If either to an interface or to a liner/beam is selected, the specification

of the new element will cause an Interface properties dialog to appear to provide the properties

for the interface that is created along with the beam element (this is shown in Figure 1.65). This

dialog is the same as that described in Section 1.2.2.4. When the beam with interface connection

is executed, INTERFACE commands will be generated in addition to the STRUCT beam commands.

Figure 1.65 Creating a lining beam attached to an interface in the

Beam

tool

Using the to an interface mode for assignment of a beam (the option also appears in the liner tool)

is a quick, automatic way to generate both the structural element and the interface. However, it is

possible to separately specify a liner or beam element and an interface and then connect the two.

This process is described in detail in the following section, Section 1.2.5.4.

Toggling the Long check box will cause the tool to define an element using the longest path between

starting point and endpoint. As a result, a single click on a point will specify a lining along the

entire boundary selected. Clicking on a point and dragging will first line the entire boundary and

then erase the element along the direction of the dragging motion.

FLAC Version 5.0

FLAC-GIIC Reference

1 - 67

1.2.5.4 Connecting Beams to Grids Using an Interface

Beams can interact with the grid or with other beams by placing an interface between the beam and

the grid or between two beams. For example, the recommended approach to simulate a retaining

wall is to represent the wall by beam elements with the soil/wall interaction represented by an

interface. This model can be created easily by using the Beam tool in Lining mode, as described in

the previous section. However, it could also be created manually, as follows. This procedure is

presented as a reference in the event that an interface connection that the Beam tool cannot address

is required.

The wall is first created in the Beam tool as a beam with seven segments located as shown in

Figure 1.66. Note that the end-nodes of the beam are positioned at the same locations as the

gridpoints at the top and bottom of the wall; however, the nodes are not connected to the gridpoints.

Figure 1.66 Create wall as beam elements in

Beam

tool

After creating the wall with beam elements, the soil/wall interface is created with the Alter / Interface

tool. Note that the connection of the structural element nodes to the interface nodes is orderdependent. The active side of the beam elements is on the left of the direction in which the

interface nodes are assigned. In other words, the contacting grid must be approaching from the left.

In this example, the A-side of the interface is attached to the beam nodes. In Figure 1.67, A-side and

Beam

are selected. Clicking and dragging from the top beam segment to the bottom beam segment

causes a circle to appear over the beam segments to indicate that the beam is being connected to

the interface. When the mouse button is released, a hatched pattern will appear on one side of the

FLAC Version 5.0

1 - 68

beam elements; this indicates the active side of the beam. (Note that the direction of the active side

can be reversed by pressing the Reverse Beam button.)

Figure 1.67 Attach A-side of interface to beam nodes in the

Interface

tool

The B-side is connected to the grid by checking the B-side and Grid buttons and clicking and dragging

the mouse from the top gridpoint to the bottom gridpoint that will be interacting with the beam. A

bar will appear along the grid when the mouse button is released, as shown in Figure 1.68. Finally,

press the Assign button to assign interface properties, and then Execute to send the created INTERFACE

commands to FLAC.

If the wall is embedded on both sides within the grid (e.g., an embedded sheetpile wall), then

interfaces must be attached to both sides of the beam element. The same procedure as before is

followed to attach the interface between the beam nodes and the gridpoints. Remember that the

active side of the beam is reversed when the second interface is connected. It is recommended that

the Retaining wall, 2 interfaces in the Build / Library tool be used as a template to create a model with

an embedded wall.

FLAC Version 5.0

FLAC-GIIC Reference

Figure 1.68 Attach B-side of interface to gridpoints in the

1.2.5.5

Liner

1 - 69

Interface

tool

Tool

The liner tool behaves in all respects like, and contains identical controls to, the Beam tool when it is

in the lining form. The difference between the tools is the difference between the element types:

beam elements and liner elements have different element behaviors and have different methods of

interacting with the FLAC grid. See Sections 1.2 and 1.3 in Structural Elements to understand

the differences between these element types.

FLAC Version 5.0

1 - 70

1.2.5.6

Cable

Tool

A cable is specified by defining two end-nodes positioned in x-y space; and the cable consists of 10

segments according to the tools default segments setting. It is recommended that the number of

segments be chosen such that there is approximately one cable node located within every zone along

the length of the cable. For example, Figure 1.69 shows a cable consisting of five segments, passing

though five zones in the model. When the cable is created, STRUCT node commands define the

cable end-nodes, and a STRUCTURE cable begin node n1 end node n2 seg m prop 2001 command

defines the cable. The property identification number 2001 is assigned, by default, to the cable.

Figure 1.69

Cable

tool

In addition to the common Add , PropID , Move and Delete modes, the cable tool may be pre-tensioned

by checking the Tension radio button and then clicking on the element. This will cause a Pretension

cable dialog to open so that a pre-tension axial force can be assigned.

Cables can be connected to each other, or connected to other existing elements. When cables are

connected to other elements they share the same node.

FLAC Version 5.0

FLAC-GIIC Reference

1.2.5.7

Pile

Rockbolt

1 - 71

, and

Strip

Tools

As was seen earlier with the Liner tool and the Beam tool in Lining form, the Pile , Rockbolt , and

Strip

tools behave the same in all respects and contain identical controls. The tools are different

because they define different element types: pile, rockbolt, and strip elements have different element

behaviors and have different methods of interacting with the FLAC grid. See Sections 1.5, 1.6 and

1.7 in Structural Elements to understand the differences between these element types. The use of

the Pile tool is described below but the description is fully applicable to the Rockbolt and Strip tools

as well.

A pile is specified by defining two end-nodes positioned in x-y space; the pile consists of 10 segments

according to the tools default segments setting. It is recommended that the number of segments

be chosen such that there is approximately one pile node located within every zone along the length

of the pile. For example, Figure 1.70 shows two piles, each consisting of 10 segments, passing

though 11 zones in the model. When the pile is created, STRUCT node commands define the pile

end-nodes, and a STRUCTURE pile begin node n1 end node n2 seg m prop 3001 command defines

the pile. The property identification number 3001 is assigned, by default, to the pile.

Figure 1.70

Pile

tool

Piles, rockbolts, and strips can be connected to each other or to other elements. When one of these

elements is connected to another element, they share the same node. Pile, rockbolt, and strip nodes

cannot be connected to existing cable nodes.

FLAC Version 5.0

1 - 72

1.2.5.8

Support

Tool

The Support tool creates support elements. Supports are added to the FLAC model by positioning

and left-clicking the mouse at the location corresponding to the central point of the support. The

left-click will open a Support Geometry Parameters dialog that allows the user to change the

geometry (i.e., inclination angle, position, width and segment number) of the support. It should be

noted that certain conditions must be satisfied to generate support elements. Otherwise, a warning

message will be issued from the GIIC. Detailed constraints on support creation can be found in the

Command Reference for the STRUCT support command.

Figure 1.71

Support

tool

When the geometry dialog is confirmed, the support will be generated virtually. At this point,

mouse-dragging or right-clicking on the support to open the geometry dialog again can change the

support geometry and position, if the Move radio button has been selected. Support elements may be

deleted by left-clicking the support with the Delete radio button selected. The support property ID

can be changed by checking the PropID radio button and right-clicking on the support. When Execute

is pressed, a series of STRUCT support (xc, yc) width value seg ns angle value prop np commands

will be sent to FLAC.

FLAC Version 5.0

FLAC-GIIC Reference

1.2.5.9

Segment

1 - 73

Tool

The Segment tool allows you to either delete individual structural element segments or define plastic

hinges at nodes connecting element segments. Element segment numbers are shown when you

enter this tool. Check the Delete radio button and click on the element segments you wish to delete.

Check the Hinge button and click and drag the mouse over the segments to be connected by plastic

hinges. For example, in Figure 1.72, the mouse is dragged from segment 21 to segment 23 to assign

plastic hinges to the connecting nodes. Note that the STRUCT hinge 21 23 command is created as a

result of this operation.

Figure 1.72

Segment

tool

FLAC Version 5.0

1 - 74

1.2.5.10

Node

Tool

Structural node conditions are specified with the Node tool. Structural node numbers are shown when

you enter this tool. Click on a node number to open a dialog of conditions for that number. The

translational and rotational velocity components can be initialized (set values under Initial Velocity )

and fixed (check boxes under Fix ). Loads and moments can be assigned (set values under Load ),

and nodes can be slaved to other nodes (check boxes under Slave ).

For example, in Figure 1.73, a vertical load is applied to node 25 and node 26. The dialog for

Node:26 is shown in the plot.

Figure 1.73

Node

tool

In Figure 1.73, node 23 is slaved to node 1. Note that a + sign is shown with the node numbers

in the Node tool if two nodes are slaved e.g., 1 + 23. The Node tool dialog may be used to

slave nodes together (using the Slave section of the dialog). Nodes may also be slaved together

when the structural element containing the node is defined, using the Pin mode described earlier in

Section 1.2.5.2.

FLAC Version 5.0

FLAC-GIIC Reference

1 - 75

The operations described above are for the Individual mode. The modes Range and All allow

the user to change or initialize conditions for many nodes in one operation. For example, the Node

Range Edit dialog (shown in Figure 1.74) can be opened by clicking nodes 12 and 16 sequentially

in Figure 1.73. Any subsequent confirmed changes in this dialog will apply to nodes 12 through 16.

Mode All will bring out Node Range Edit with all existing structural nodes and apply subsequent

operations to all of them.

Figure 1.74 The Node Range Edit dialog