Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Catalytic Hydrogenation PPD

Caricato da

shujia_yapCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Catalytic Hydrogenation PPD

Caricato da

shujia_yapCopyright:

Formati disponibili

Articles

Indian Journal of Chemical Tech nology

Vol. 10, November 2003, pp. 627-631

Catalytic hydrogenation of p-nitroaniline and 2-methoxy-5-nitroaniline

Sunil P Bawane & Sudhirprakash B Sawant*

Un iversity Institute of Chemical Tec hnology, University of Mumbai , Matunga, Mumbai 400 019, India

Received 27 August 2002; revised received 3 1 March 2003; accepted 28 April 2003

Catalytic hydrogenation of p-nitroaniline (PNA)' to p-phenylenediamine (PPD) was carried out in methanol

using 5% Pd/C as a catalyst at h~drogen pressures in the range of200-1000 kPa, reaction temperatures 313-333 K,

catalyst loadings 200-500 mg dm and PNA concentrations 0.3-1.02 mol dm"3 Catalytic hydrogenation of 2-methoxy5-nitroaniline (MNA) to 4-methoxy-1,3, benzenediamine (MBD) was carried out in dimethylformamide as a solvent

using 5% Pd/C as catalyst at hydrogen pressures 1000-2000 kPa, reaction temperatures 413-433 K, catalyst loadings

200-600 mg dm"3 and MNA concentrations 0.22-1.7 mol dm3 Speed of agitation beyond 17 rps had no effect on the

progress of the reaction. The study shows that PNA and MNA can be selectively hydrogenated to PPD and MBD,

respectively and the initial rate of hydrogenations showed first order dependence on the reactant concentration,

hydrogen partial pressure, and the catalyst loading for both the reactions. The activation energies for the catalytic

hydrogenation ofPNA and MNA were found to be 37.26 and 93.73 kJ mor 1, respectively.

The hydrogenation of nitro aromatic compound to the

corresponding anilines is an example, where, a

process change is necessary for prevention of

environ mental pollution. Reduction using iron-acid,

sulphides or polysu lphides is known to generate

substan tial waste. Therefore, catalytic hydrogenation

is the method of choice for the large-scale

manufacture of many aromatic and aliphatic amines

from the corresponding nitro compounds. The

objective of the present work was to study the

catalytic hydrogenation of p- nitroani line (PNA) topphenylenediamine

(PPD)

and

2-methoxy-5nitroaniline (MNA) to 4-methoxy-1,3, benzenediamine (MBD) using 5 % palladi um on carbon

catalyst under a wide range of operating conditions.

PPD is useful in the photographic and dye industri es

and widely used as antioxident and antiozonants for

elastomers, plastics and petroleum products. MBD is

used as an intermediate in the dyes industry. Various

methods have been described in the literature for the

sy nthesis of PPD 1. 10 . However, very limited kinetic

information concerning the hydrogenation reaction of

PNA to PPD has been published. Practically no

literature is available regarding the catalytic

hydrogenati on of MNA to MBD . The synthesis of

MBD by catal ytic hydrogenation of 2,4-dinitroanisole

using Pd/C as a catalyst has been reported 11

*For correspondence (E- mail : s bs@ udct.e rn et. in ;

Fax: +91-22-24145614)

Experimental Procedure

Materials

PNA and MNA were obtai ned from Arati

Industries Ltd, Mumbai, India. Methanol and

dimethylformamide used were of laboratory reagent

grade and obtained from s. d. fine chemicals Ltd.,

Mumbai, Indi a. Hydrogen (purity, 99.98%) was

obtained from Indi a Oxygen Limited, Mumbai , India

and used as such. Commercially prepared 5 % Pd/C

was obtained from Parekh Platinum Ltd, Mumbai,

Indi a.

Method

Experiments were carried out in an autoclave

(diameter = 65 mm, 100 mL capacity). The reactor

had provisions for automatic te mperature control,

variab le agitatio n speed, a safety rupture disk and the

sampl in g of the liquid phase. Methanol and

dimethylformamide were used as a solvent for the

catalytic reduction of PNA and MNA, respectively.

The appropriate quantities of the reactant, the solvent

and the catalyst were added to the clean and dry

autoc lave. Before heating the autoclave to the

required temperature, it was repeatedly purged first

with nitrogen and then with hydrogen at room

temperature without stirring. Once the required

temperature was reached, it was pressurized with

hyd rogen to get the desired partial pressure of

hyd rogen and stirring was started. As the reaction

Articles

Indi an J. Chern. Techno!., November 2003

proceeded, the hydrogen consumed was made up , so

as to maintain a constant pressure. Samples (2-3 mL)

were withdrawn through the sampl e outlet at regular

time intervals and analyzed on a GC using a SS

column, which was 2 m long and packed with 5 % SE30 on chromosorb WHP materi al. The conditions of

analysis for both the reaction mi xtures were: FID

temperature: 573 K; injection temperature: 573 K;

co lumn temperature: 443 K; carri er gas, N2 : 1.9x 10-5

m3 min-' .

80

a..

c

0

v;

(jj

>

c

40

0

()

Results and Discussion

The stoichi ometric reacti ons in volved in

catalytic hydrogenation of PNA and MNA are:

60

20

the

(1)

3 H2

____.

PNA

600 .

1200

1800

2400

Time,(s)

+

PPD

Fig. !-Effect of impeller speed on the conversion of PNA

I 0 rps

0 17 rps

x 24 rps

Reacti on temperature: 333 K ; Hydrogen partial pressure:

1000 kPa; Catalyst loading: 360 mg dm-3 ; PNA co nce ntration: 0.6

mo l dm-3

(2)

80

~

::2

60

c:

0

'(ii

MNA

MBD

Qj

>

c:

40

()

Initial experiments on catalytic hydrogenation of

PNA and MNA were carried out to establish the

material balance of reactants consumed and products

formed and the balance to the ex tent of minimum

98% as per the stoichiometry given by reaction l and

2 was established for the organi c reactants and

products . For kinetic experiments, progress of the

reaction was monitored by analyzing the reaction

mixture and calcul ating the moles of the reactants

consumed as a function of time in each run. Based on

the moles of reactants consumed, the initial rates were

calc ul ated graphicall y usi ng third o rder pol y no mi al

equation.

Effect of speed of agitation

The effect of impeller speed o n the convers ion of

PNA and MN A in the range 10-24 rps is show n in

628

~

0

20

0

0

1200

2400

3600

4800

Time, (s)

Fig . 2- Effect of impeller speed on the conversion of MNA

I 0 rps

0 17 rps

x 24 rps

Reacti o n temperature: 433 K; Hydrogen partial pressure:

2000 kPa; Catalyst loading: 600 mg dm- 3 ; MNA co ncentration:

0.22 mol dm-3

Figs I and 2, respectively . The conversion was found

to increase when the speed increases from 10 to 17

rps. This indicates that gas to liquid and/or liquid to

solid mass transfer resistance is significant between

10-17 rps. The impell er speed was not observed to

have any effect on the convers ion after 17 rps,

Articles

Bawane & Sawant: Catalytic hydrogenation of p-nitroaniline and 2-methoxy-5-nitroaniline

indicating absence of external

mass-transfer

limitation, beyond the speed of agitation of 17 rps.

Effect of catalyst loading

The catalyst loading was varied between 200 to 500

mg dm3 for the catalytic hydrogenation of PNA and

200 to 600 mg dm- 3 for the catalytic hydrogenation of

MNA. The initial rate of reaction was found to

increase linearly with the catalyst loading.

Effect of hydrogen partial pressure

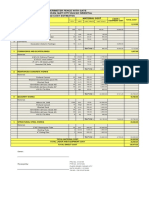

Table !--Optimum conditions for the catalytic hydrogenation of

PNAand MNA

Parameter

Substrate concentration

(mol dm-3)

Temperature (K)

Hydrogen partial press ure

(kPa)

Catalyst loading

(mg dm"3 )

Time for complete

conversion (s)

Seeed (res)

PNA

hydrogenation

MNA

hydrogenation

0.6

0.22

333

433

1000

2000

360

600

2400

5800

24

24

The effect of hydrogen partial pressure was studied

in the range of 200-1000 kPa for the catalytic

reduction of PNA and in the range of 1000-2000 kPa

for the catalytic hydrogenation of MNA. The rate was

found to increase linearly with the hydrogen partial

pressure. The result indicates first order dependence

of the initial rate of reaction on the hydrogen partial

pressure

The rate equation for the catalytic hydrogenation of

PN A when the surface reaction between the adsorbed

species controls the progress of the reaction can be

written as,

Effect of reactant concentration

fj =Ki a pc *H, c *PNA

(1 )

CH, HC*H,

(2)

CPNA HC*PNA

(3)

C *H, =KaCH,

(4)

The reactant concentration was varied from 0 .31.02 mol dm3 for the catalytic hydrogenation of PNA

and from 0.22-1.7 mol dm3 for the catalytic

hydrogenation of MNA . The initial rate was found to

increase with increasing the reactant concentration

and showed a first order dependence on the reactant

concentration .

K \ c PNA

(5)

'i =KiapKaK\ CH, C PNA

(6)

c PNA =

. . . (7 )

Effect of temperature

The

reactions

were

studied

at

different

temperatures in the range of 313-323 K for the

catalytic hydrogenation of PNA and in the range of

413-433 K for the catalytic hydrogenation of MNA. It

was found that the initial rate of catalytic

the

hydrogenation

increases

with

increasing

temperature.

The optimum reaction conditions to get maximum

hydrogenation of PNA and MNA are li sted in

Table I. All the experim ents were carri ed out to

eliminate the external mass- transfer res istances by

operating at hi gh impeller speed (24 rps). It was found

that temperature has stro ng effect on th e initi al rate of

the reacti on and initial rate of reacti o n vari es linearly

with the hydrogen parti al pressure as we ll as with the

reactant concentrati on. Intraparti cle d iffusion was

12

eliminated by usi ng very fin e catalyst particles

Hence, on the basis of above observations it can be

assumed that surface reacti on is the rate-contro ll ing

step.

Taking the initial values,

cH cPNAo

... (8)

2.,

. . . (9)

where,

Solubili ty of hydrogen in

methano l and

dimeth ylformamide was estimated by a correlati on for

hydrogen so lubility given by Shaw 13 .

The Arrheniu s pl ot of In k 1 versus liT gave a

straight line as shown in Fig. 3, and an activati on

629

Articles

Indi an J. Chern. Techno!., November 2003

-3.1 , - - - - - - - - - - - - - - - - - - ;

... (II)

-3.3

Taking the initial values,

-3.5

... (12)

.:Z

.s

CH 2o CM NAo

-3.7

... (13)

-3.9

-4.1 -+-------r------.----------r'

2.9

3

3.1

3.2

where,

( Iff)* 10+3 (K- 1)

Fig. 3---Arrhenius plot for the catal ytic hydrogenation of PNA

PNA concentration: 0.6 mol dm.3 ; Hydrogen parti al pressure:

1000 kPa; Agitation speed: 24 rps; Catalyst loading : 360 mg dm3

4,------------------

The Arrhenius plot of In k 2 versus liT gave a

straight line (Fig. 4), and value of activation energy as

93.73 kJ mor' for catalytic hydrogenation of MNA.

These high values of activation energies indicate that

the reactions are kinetically controlled.

Conclusion

4 .8

-5.2

-5.6

~+-----.----.-----.----~

2.28

2.32

2.38

2.4

2.44

(Iff)* 10+3 (K 3 )

Fig. 4-Arrhenius plot for the catalytic hydrogenation of MN A

MNA concentrati on: 0.22 mol dm.3 ; Hydrogen partial pressure:

3

2000 kPa; Agitation speed: 24 rps; Catalyst loading: 600 mg dm

energy of 37 .26 kJ mor' for catalytic hydrogenation

ofPNA.

Similarly, the rate equation for the catalytic

hydrogenation of MNA, when the surface reaction

between the adsorbed species controls the progress of

the reaction , can be written as,

... (10)

630

p-nitroaniline and 2-methoxy-5-nitroaniline can be

selectively hydrogenated to p-phenyle nediarnine and

4-methoxy 1,3, benzenediamine, respectively using

5% Pd/C as a catalyst. The initial rate of

hydrogenation had first order dependence with respect

to the reactant concentration, hydrogen partial

pressure, and the catalyst loading for both the

reactions . The activation energies for the catalytic

hydrogenation of p -nitroaniline and 2-methoxy-5nitroaniline were found to be 37.26 and 93.73 kJ

mol- 1, respectively.

Nomenclature

3

CrNAo

=initi al concentration of PNA, mol dm"

CPNA

=liquid phase concentration of PNA, mo l dm3

c;NA

=adsorbed concentration of PNA, mol dm3

3

C MNAo

=initi al concentration ofMNA, mol dm

CMNA

=l iquid phase concentration of MNA, mol dm

cMNA

=adso rbed concentration of MNA, mo l dm

C11 ,

= concentration of hydrogen in liquid phase, mol dm3

C' 11 , = adsorbed concentrati on of hydrogen, mo l dm3

C11 20 =initial concentration of hydrogen in liqu id phase, mol

dm3

= rate of the catalytic hydrogenation of PNA. mol dm3 s- 1

Bawane & Sawant: Catalytic hydrogenation of p-nitroaniline and 2-methoxy-5-nitroaniline

"o

K,

=initial rate of catalytic hydrogenation of PNA, mol

dm-3 s- 1

=rate of the catalytic hydrogenation of MNA, mol

dm-3 s-1

=initial rate of catalytic hydrogenation of MNA, mol

dm- 3 s 1

=rate constant for catalytic hydrogenation of PNA

K2

= rate constant for catalytic hydrogenation of MN A

r2

r20

K, ,K',,K'2 =equilibrium constants

aP

= specific surface area of the catalyst, m2 m3

Shigeo Y, Tsukasa T, Takafumi A, Eiji S & Hiroyuki H, Jpn

Kokai Tokkyo Koho Jp, 62 (1985) 12; Chern Abstr, 107

(1987) 96425 .

Tsukasa T, Takafumi A, Shigeo Y & Hiroyuki H, Jpn Kokai

Tokkyo Koho Jp, 62 (1987) 7; Chern Abstr, 107 (1987 )

218216.

Tsukasa I, Jpn Kokai Tokkyo Koho Jp, 60 (1984) 3; Chern

Abstr, 104 (1986) 50637.

Kataoka H, Jpn Kokai Tokkyo Koho Jp, 59 (1983) 5; Chern

Abstr, 101 (1984) 170869.

Atsuo M, Kiichi F & Hiroshigeo M, Jpn Kokai Tokkyo Koho

Jp, 78 (1977) 7; Chern Abstr, 90 (1979) 103596.

10

Kiichi F & Atsuo M, Jpn Kokai Tokkyo Koho Jp, 79 (1977)

4; Chern Abstr, 90 ( 1979) 203661.

11

Zhao X, Xing C & Lubai C, Jingxi Huagong , 14 (1997) 41 ;

Chern Abstr, 127 ( 1997) 331240.

12

Ramchandra P A & Chaudhari R V, Three Phase Catalytic

Reactors (Gordon and Breach Science Publication, New

York), 1983.

13

Shaw J M, Can J Chern Eng, 65 (1987) 293.

References

I

2

Sarmah P & Barua N C, Tetrahedran Lett, 31 (1990) 4065.

Sivanandaiah K M, Guresiddappa S & Gowda D C, Indian J

Chern, 24B (1985) 1185.

Hideki M, Takeshi N, Masaru W & Teruyuki N, Jpn Kokai

Tokkyo Koh o Jp, 05 (1992) 4; Chern Abstr, 121 ( 1994)

108192.

Kitayama T, Kenji H, Naoki A, Kyoshi N, Akihiro 0 &

Hiroyuki A, Jpn Kokai Tokkyo Koho Jp , 003 (1989) 6; Chern

Abstr, 115 (1991) 159996.

Articles

631

Potrebbero piacerti anche

- Kinetic Studies On Catalytic Decomposition of Methane To Hydrogen and Carbon Over Ni/Tio CatalystDocumento7 pagineKinetic Studies On Catalytic Decomposition of Methane To Hydrogen and Carbon Over Ni/Tio CatalystAaLee IsaisNessuna valutazione finora

- Gas-Phase Hydroformylation of Propene Over Silica-Supported PPH - Modified Rhodium CatalystsDocumento9 pagineGas-Phase Hydroformylation of Propene Over Silica-Supported PPH - Modified Rhodium CatalystsIlireaNessuna valutazione finora

- Catalytic Dehydrogenation of Z-Butanol With Zno and CuoDocumento4 pagineCatalytic Dehydrogenation of Z-Butanol With Zno and CuoRosy Vargas CaroNessuna valutazione finora

- Cjce 22656Documento6 pagineCjce 22656Tua HalomoanNessuna valutazione finora

- Electronic Supplementary Information: S1.1Preparation of CatalystsDocumento9 pagineElectronic Supplementary Information: S1.1Preparation of CatalystsGovind ManglaniNessuna valutazione finora

- Propane Dehydrogenation in Modified Membrane Porous ReactorDocumento7 paginePropane Dehydrogenation in Modified Membrane Porous ReactorNoezran AzwarNessuna valutazione finora

- Catalytic Oxidation of Benzene To Maleic Anhydride in A Continuous Stirred Tank ReactorDocumento7 pagineCatalytic Oxidation of Benzene To Maleic Anhydride in A Continuous Stirred Tank ReactorMirko GraneseNessuna valutazione finora

- JAPS v119 1827 2011Documento8 pagineJAPS v119 1827 2011newton_86Nessuna valutazione finora

- International Journal of Chemtech Research: J.G. ManjunathaDocumento11 pagineInternational Journal of Chemtech Research: J.G. ManjunathaAmrAliNessuna valutazione finora

- Plug Flow ReactorDocumento9 paginePlug Flow ReactorTajTajNessuna valutazione finora

- Liquid Phase Hydrogenation of Dimethyl Nitrobenzene Over Nickel CatalystsDocumento6 pagineLiquid Phase Hydrogenation of Dimethyl Nitrobenzene Over Nickel CatalystsIJARP PublicationsNessuna valutazione finora

- Doppler Coefficient of Reactivity - Benchmark Calculations For Different Enrichments of Uo2 - Thilagam Sunil Sunny SubbaiahDocumento10 pagineDoppler Coefficient of Reactivity - Benchmark Calculations For Different Enrichments of Uo2 - Thilagam Sunil Sunny SubbaiahNadia Belen JuarezNessuna valutazione finora

- Carbonilación Del MetanolDocumento17 pagineCarbonilación Del MetanolPedro JuanNessuna valutazione finora

- Hidrogenation of NitrobenzeneDocumento6 pagineHidrogenation of NitrobenzenejinmgNessuna valutazione finora

- Performance of Thermal Energy Storage Unit Using Solid Ammoniated Salt (Cacl - NH System)Documento6 paginePerformance of Thermal Energy Storage Unit Using Solid Ammoniated Salt (Cacl - NH System)ajayNessuna valutazione finora

- Calculation of Material Balance For Catalytic Reforming of Naphtha FractionsDocumento4 pagineCalculation of Material Balance For Catalytic Reforming of Naphtha FractionsMai Ngoc Chien100% (4)

- Isooctyl Mercaptan PDFDocumento9 pagineIsooctyl Mercaptan PDFGilar GumelarNessuna valutazione finora

- S A M S AC R P: Hortcut Pproach T O Odeling A N D Imulation O F Atalytic Eforming RocessDocumento6 pagineS A M S AC R P: Hortcut Pproach T O Odeling A N D Imulation O F Atalytic Eforming RocessLuis Enrique Jiménez GonzálezNessuna valutazione finora

- Catalyzed Decomposition of Hydrogen PeroxideDocumento5 pagineCatalyzed Decomposition of Hydrogen PeroxideDennis WrinNessuna valutazione finora

- Thermodynamic Properties of Methanol in The CriticDocumento42 pagineThermodynamic Properties of Methanol in The CriticNiken SitoresmiNessuna valutazione finora

- Hydrocarbon Sythesis From Syngas by Very High Pressure PlasmaDocumento8 pagineHydrocarbon Sythesis From Syngas by Very High Pressure PlasmaIsmail RahimNessuna valutazione finora

- 2004 Methanol Steam Reforming Over CuZnOAl2O3 Catalyst Kinetics and Effectiveness FactorDocumento11 pagine2004 Methanol Steam Reforming Over CuZnOAl2O3 Catalyst Kinetics and Effectiveness FactorChauNessuna valutazione finora

- Kinetics and Slurry-Type Reactor Modelling During Catalytic Hydrogenation of O - Cresol On Ni/SioDocumento11 pagineKinetics and Slurry-Type Reactor Modelling During Catalytic Hydrogenation of O - Cresol On Ni/Sioحسن محمدNessuna valutazione finora

- Keane 1999Documento11 pagineKeane 1999sj singhNessuna valutazione finora

- Kinetics of Palladium Catalysed Partial Oxidation of MethaneDocumento7 pagineKinetics of Palladium Catalysed Partial Oxidation of Methanevishalvilvas85Nessuna valutazione finora

- Simultaneous Reaction-Deactivation Kinetics in N-Octane and Methylcyclopentane Reforming Reactions On Platinum-Containing CatalystsDocumento18 pagineSimultaneous Reaction-Deactivation Kinetics in N-Octane and Methylcyclopentane Reforming Reactions On Platinum-Containing CatalystsLuis Enrique Jiménez GonzálezNessuna valutazione finora

- Determining Ni With DimethylglyoximeDocumento5 pagineDetermining Ni With Dimethylglyoxime아미르Nessuna valutazione finora

- Badiea S. Babaqi A.2018.01.025Documento17 pagineBadiea S. Babaqi A.2018.01.025Badis GueloulNessuna valutazione finora

- 1,8 Methane DiamineDocumento7 pagine1,8 Methane DiamineradhwaNessuna valutazione finora

- Selective Hydrogenation of Methyl Acetylene and Propadiene in An IndustrialDocumento7 pagineSelective Hydrogenation of Methyl Acetylene and Propadiene in An IndustrialAdrian Fernandez BelloNessuna valutazione finora

- Intrinsic and Global Reaction Rate of Methanol Dehydration Over 7-A1203 PelletsDocumento6 pagineIntrinsic and Global Reaction Rate of Methanol Dehydration Over 7-A1203 PelletsHectorNessuna valutazione finora

- Disomma 2012Documento7 pagineDisomma 2012Norma JenarezNessuna valutazione finora

- Hydrogenation of Nitrobenzene To P-Aminophenol in A Four-Phase Reactor Reaction Kinetics and Mass Transfer EffectsDocumento6 pagineHydrogenation of Nitrobenzene To P-Aminophenol in A Four-Phase Reactor Reaction Kinetics and Mass Transfer EffectsHeylenLoperaNessuna valutazione finora

- Atilhan 2010Documento7 pagineAtilhan 2010KHƯƠNG TRẦN HOÀNGNessuna valutazione finora

- Sintesis de Polimero SemiconductorDocumento7 pagineSintesis de Polimero SemiconductorELOISA ADELAIDA VALADEZ AVINANessuna valutazione finora

- CC3 Mechanism and ModellingDocumento4 pagineCC3 Mechanism and ModellingRubesh KumarNessuna valutazione finora

- NS Distillation 1979Documento9 pagineNS Distillation 1979FizzerNessuna valutazione finora

- Catalytic Reforming of Methane With Carbon Dioxide Over Nickel Catalysts II. Reaction KineticsDocumento26 pagineCatalytic Reforming of Methane With Carbon Dioxide Over Nickel Catalysts II. Reaction KineticsDiego LVNessuna valutazione finora

- Methane Catalytic Pyrolysis by Microwave and Thermal Heating Over Carbon Nanotube-Supported Catalysts: Productivity, Kinetics, and Energy E CiencyDocumento13 pagineMethane Catalytic Pyrolysis by Microwave and Thermal Heating Over Carbon Nanotube-Supported Catalysts: Productivity, Kinetics, and Energy E Ciencyc675jjNessuna valutazione finora

- Catalytic Reforming of Heavy Naphtha, Analysis and SimulationDocumento19 pagineCatalytic Reforming of Heavy Naphtha, Analysis and SimulationTHE SEZARNessuna valutazione finora

- Rochelle 2010 q1 Research ReportDocumento887 pagineRochelle 2010 q1 Research ReportKvspavan KumarNessuna valutazione finora

- Critical Properties of Hydrogen Peroxide Determined From Direct MeasurementsDocumento8 pagineCritical Properties of Hydrogen Peroxide Determined From Direct MeasurementsMarcelo Sebastian HerreraNessuna valutazione finora

- Teknologi Reaktor Nuklir: Jurnal Tri Dasa MegaDocumento4 pagineTeknologi Reaktor Nuklir: Jurnal Tri Dasa MegaMegaNessuna valutazione finora

- Temperature-Responsive Polymers: Chemistry, Properties, and ApplicationsDa EverandTemperature-Responsive Polymers: Chemistry, Properties, and ApplicationsNessuna valutazione finora

- SI Catalytic N2 to-NH3 Conversion by Fe at Lower Driving ForceDocumento29 pagineSI Catalytic N2 to-NH3 Conversion by Fe at Lower Driving ForceJoseph KfouryNessuna valutazione finora

- Kinetic Modeling and Simulation of The Selective Hydrogenation of The C - Cut of A Thermal Cracking UnitDocumento8 pagineKinetic Modeling and Simulation of The Selective Hydrogenation of The C - Cut of A Thermal Cracking UnitAdrian Fernandez BelloNessuna valutazione finora

- Mechanistic Investigation of Methane Steam Reforming Over Ce-Promoted Ni/SBA-15 CatalystDocumento12 pagineMechanistic Investigation of Methane Steam Reforming Over Ce-Promoted Ni/SBA-15 CatalystDanCosminNessuna valutazione finora

- Tar Reforming Under A Microwave Plasma TorchDocumento8 pagineTar Reforming Under A Microwave Plasma Torchanura7Nessuna valutazione finora

- Synthesis of Epichlorohydrin (Kinetic)Documento6 pagineSynthesis of Epichlorohydrin (Kinetic)maxilencinaNessuna valutazione finora

- Applied Catalysis Volume 69 Issue 1 1991 [Doi 10.1016%2Fs0166-9834%2800%2983297-2] Jean Bandiera; Claude Naccache -- Kinetics of Methanol Dehydration on Dealuminated H-mordenite- Model With Acid and Basic Active CeDocumento10 pagineApplied Catalysis Volume 69 Issue 1 1991 [Doi 10.1016%2Fs0166-9834%2800%2983297-2] Jean Bandiera; Claude Naccache -- Kinetics of Methanol Dehydration on Dealuminated H-mordenite- Model With Acid and Basic Active CePuji LestariNessuna valutazione finora

- 686184: Reactor optimisation and sensitivity: r P k a H k a H k a H kC ε FDocumento5 pagine686184: Reactor optimisation and sensitivity: r P k a H k a H k a H kC ε FM-poe MampshikaNessuna valutazione finora

- Low Temperature MethanolDocumento4 pagineLow Temperature MethanolTORREZ35Nessuna valutazione finora

- 2-Benrabbah - Plasma - DBD..Plasma DBD Activated Ceria-Zirconia-PromotedDocumento18 pagine2-Benrabbah - Plasma - DBD..Plasma DBD Activated Ceria-Zirconia-Promotedfarah al-sudaniNessuna valutazione finora

- Synthesis and Temperature-Responsive Behavior of N-Vinylcaprolactam-Grafted NRDocumento16 pagineSynthesis and Temperature-Responsive Behavior of N-Vinylcaprolactam-Grafted NRNGUYỄN HOÀNG LINHNessuna valutazione finora

- Art:10.1007/s11746 007 1120 yDocumento7 pagineArt:10.1007/s11746 007 1120 yFelipe JimenezNessuna valutazione finora

- Global Kinetics of Direct Dimethyl Ether Synthesis Process From Syngas in Slurry Reactor Over A Novel Cu ZN Al ZR Slurry CatalystDocumento7 pagineGlobal Kinetics of Direct Dimethyl Ether Synthesis Process From Syngas in Slurry Reactor Over A Novel Cu ZN Al ZR Slurry Catalystkrishna_nimeshNessuna valutazione finora

- PresenationDocumento22 paginePresenationpradipmane560Nessuna valutazione finora

- LBNL 54187Documento19 pagineLBNL 54187Mohammed AlShammasiNessuna valutazione finora

- Experiments in Physical Chemistry: Second Revised and Enlarged EditionDa EverandExperiments in Physical Chemistry: Second Revised and Enlarged EditionNessuna valutazione finora

- A Modern Course in Statistical PhysicsDa EverandA Modern Course in Statistical PhysicsValutazione: 3.5 su 5 stelle3.5/5 (2)

- Iglidur X - The High-Tech Problem SolverDocumento12 pagineIglidur X - The High-Tech Problem Solvergoooga299Nessuna valutazione finora

- Samtec ASP 134488 01 DatasheetDocumento4 pagineSamtec ASP 134488 01 DatasheetamiteshtripathiNessuna valutazione finora

- Self Consolidating ConcreteDocumento2 pagineSelf Consolidating ConcreteaaNessuna valutazione finora

- Manual Intruction BathycorrometerDocumento12 pagineManual Intruction BathycorrometerIwan ChurniawanNessuna valutazione finora

- Hydro Test ProcedureDocumento17 pagineHydro Test Procedureyaser elgoharyNessuna valutazione finora

- Rigging JSA SafetyDocumento5 pagineRigging JSA SafetyaQiLGunawanNessuna valutazione finora

- Farrat Plate BrochureDocumento12 pagineFarrat Plate BrochureShaneLinehanNessuna valutazione finora

- Fa 4 STS (Ged104) Subsec 2Documento2 pagineFa 4 STS (Ged104) Subsec 2Elmoe VillanuevaNessuna valutazione finora

- Textile Finishing IntroductionDocumento14 pagineTextile Finishing IntroductionSENTHIL KUMAR100% (6)

- Determination of % Available Chlorine in Bleaching PowderDocumento10 pagineDetermination of % Available Chlorine in Bleaching PowderABHILASHA MISHRA0% (1)

- HT 521 86151 307 ENDocumento5 pagineHT 521 86151 307 ENEdward AguillónNessuna valutazione finora

- Standpipe Piezometer: Typical InstallationDocumento2 pagineStandpipe Piezometer: Typical InstallationGauri 'tika' Kartika0% (1)

- Material Safety Data Sheet (MSDS) : EMERGENCY: 800-424-9300Documento3 pagineMaterial Safety Data Sheet (MSDS) : EMERGENCY: 800-424-9300Darius DsouzaNessuna valutazione finora

- Textile Colors: For A Colorful WorldDocumento12 pagineTextile Colors: For A Colorful WorldSamuel VanoostenNessuna valutazione finora

- Cold Rolled CR Structural S CM350-G® Steel: General Description Typical UsesDocumento2 pagineCold Rolled CR Structural S CM350-G® Steel: General Description Typical UsesBaziNessuna valutazione finora

- Effect of Indium Doping On Physical Properties of Nanocrystallized SNS Zinc Blend Thin Films Grown by Chemical Bath Deposition.Documento1 paginaEffect of Indium Doping On Physical Properties of Nanocrystallized SNS Zinc Blend Thin Films Grown by Chemical Bath Deposition.atswallaNessuna valutazione finora

- CPP MSDSDocumento4 pagineCPP MSDSevyNessuna valutazione finora

- EstimateDocumento1 paginaEstimateAlemar Soriano MalintadNessuna valutazione finora

- 1 - Catalogo Deionizador Qw-48Documento92 pagine1 - Catalogo Deionizador Qw-48Edgar Muñoz100% (1)

- Power Systems, Inc.: Owner's ManualDocumento64 paginePower Systems, Inc.: Owner's ManualAndrew67% (3)

- Tender Specification Trimdec - Coastel (Ultra)Documento1 paginaTender Specification Trimdec - Coastel (Ultra)Dushan Lalithya Gamaethige100% (1)

- Crane & Grab PMSDocumento8 pagineCrane & Grab PMSSukhvinder SinghNessuna valutazione finora

- TF: Textile Engineering and Fibre Science: WronaDocumento16 pagineTF: Textile Engineering and Fibre Science: WronaChandra Deep MishraNessuna valutazione finora

- TalbrosDocumento26 pagineTalbrossk9568270% (1)

- Operation and Service Manual For Hermetic Utimeter Gtex ChemDocumento78 pagineOperation and Service Manual For Hermetic Utimeter Gtex ChemMAXNessuna valutazione finora

- American Woodworker - 129 (July 2007)Documento68 pagineAmerican Woodworker - 129 (July 2007)Emilian Baluta100% (3)

- DD Folio p01170 CC TuxpanDocumento102 pagineDD Folio p01170 CC TuxpanErnesto VazquezNessuna valutazione finora

- p1475 MisumiDocumento1 paginap1475 MisumidmalfazNessuna valutazione finora

- Prism Cryogenic Oxygen Generators: Reliable On-Site SupplyDocumento4 paginePrism Cryogenic Oxygen Generators: Reliable On-Site SupplyEdwin RosasNessuna valutazione finora

- List of e Waste Collection PointsDocumento13 pagineList of e Waste Collection PointssaikidgoNessuna valutazione finora

![Applied Catalysis Volume 69 Issue 1 1991 [Doi 10.1016%2Fs0166-9834%2800%2983297-2] Jean Bandiera; Claude Naccache -- Kinetics of Methanol Dehydration on Dealuminated H-mordenite- Model With Acid and Basic Active Ce](https://imgv2-2-f.scribdassets.com/img/document/249493359/149x198/d00c274c1f/1418028470?v=1)