Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ESP Design Calculation PDF

Caricato da

Mohammed Abdul Moied100%(1)Il 100% ha trovato utile questo documento (1 voto)

287 visualizzazioni17 pagineTitolo originale

ESP-Design-Calculation.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

287 visualizzazioni17 pagineESP Design Calculation PDF

Caricato da

Mohammed Abdul MoiedCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 17

Reliable

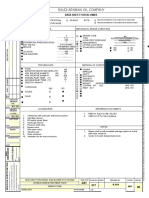

information on well productivity

Fluid rate = input parameter

Selection of ESP highly dependent on the flow

rate

Different pump have different recommended

application ranges

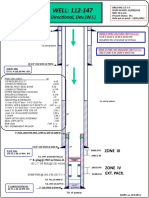

Well Physical Data

Casing & liner sizes, weights and depths

Tubing size, type, weight & thread

Total well depth

Depth of perforation or open hole interval

Well inclination data

Well Performance Data

Tubing head pressure at desired rate (FTHP)

Casing head pressure

Desired liquid production rate

SBHP or static liquid level

FBHP or dynamic liquid level

Productivity data (PI or qmax for the Vogel Model)

1.

2.

2.

Well Performance Data-contd

Gas-oil ratio (GOR)

Water cut or water-oil ratio

Bottomhole temp at desired rate

3.

Fluid properties

Specific or API gravity of produced oil

SG of water

SG of gas

Bubble point pressure

Viscosity of produced oil

PVT data

The specific gravity (SG) need to be known from the water

cut

SG SGwater SGoil

The SBHP need to be known

SBHP 0.433 L perf Lstat SG

Based on the flowing pressure at perforations, the pressure

at pumps intake pressure (PIP) is found from the following

formula, if the fluid gradient in the annulus is known

To check the amount of free gas at the pumps suction

conditions, the solution gas-oil ratio at the pump intake is

calculated from Standings bubble point pressure

correlation:

Oil API

141 .5

131 .5

sg oil@60 F

By comparing above value to the wells producing GOR, it

can be established whether a free gas enters the

submersible pumps.

The liquid volumetric rate to be handled by ESP pump is

found from the water and oil rates.

In the above formula, the oil volume factor can be ontained

from Standing correlation:

To determine number of pump stages, the total

head to be overcome by the ESP pump need to

identified.

This is called Total Dynamic Head (TDH) and is

the sum of the following, all in length units:

Wellhead pressure at the given liquid rate

Net hydrostatic pressure acting on the pump

Frictional pressure drop that occurs in the tubing

string

The second term equals the true vertical depth (TVD) of the

dynamic liquid level, at which the fluid level in the casing

annulus stabilizes while producing the desired liquid rate.

It is easily found from the value of the pump intake

pressure, PIP, assuming that an oil column exists in the

annulus above the pump setting depth:

It should be noted here that the pump is usually set

below this depth in order to provide for a sufficient

submergence required for proper pump

operation.

A rule of thumb value is at least 500 ft of fluid

over the pump (FOP), the other limit being the

depth of the sandface(perforations).

The frictional head loss in the tubing string can be

estimated from Fig A where the head loss for

1,000 ft of pipe length,

is plotted versus

liquid rate. The total loss in the tubing string is

found as:

Now, the TDH is calculated in head (ft) units as follows:

Potrebbero piacerti anche

- Basic Field ServiceDocumento62 pagineBasic Field ServicenofriandiNessuna valutazione finora

- Coatings - Competitive Crossover 2013 R2Documento127 pagineCoatings - Competitive Crossover 2013 R2g_milburnNessuna valutazione finora

- Tubing StringDocumento32 pagineTubing StringKAORU AmaneNessuna valutazione finora

- SS3100 2.375 DHSIT Valve Maintenance Manual Rev 7 10010661Documento54 pagineSS3100 2.375 DHSIT Valve Maintenance Manual Rev 7 10010661Eduardo Oyarzun0% (1)

- Application Engineering: Reda Esp System ComponentsDocumento4 pagineApplication Engineering: Reda Esp System Componentselsayed amerNessuna valutazione finora

- ESP Design Hand CalculationsDocumento17 pagineESP Design Hand CalculationsMuhammad ImranNessuna valutazione finora

- Subsea Chokes BrochureDocumento12 pagineSubsea Chokes Brochureprihartono_diasNessuna valutazione finora

- ESP Systems: History and Leading ManufacturersDocumento12 pagineESP Systems: History and Leading Manufacturersmozhi.shNessuna valutazione finora

- KEY Macromolecules Chart 2015Documento4 pagineKEY Macromolecules Chart 2015Joshua BernilNessuna valutazione finora

- PMP Exam Preparation Plan (Tracking Sheet)Documento6 paginePMP Exam Preparation Plan (Tracking Sheet)Mohammed Abdul MoiedNessuna valutazione finora

- 6.37 Combi Bop ManualDocumento23 pagine6.37 Combi Bop ManualDEATH ASSASSIN GAMERNessuna valutazione finora

- ESP SystemsDocumento22 pagineESP SystemsNabila GhaisaniNessuna valutazione finora

- PoseidonDocumento2 paginePoseidonAlan CordobaNessuna valutazione finora

- The Technically Impossible HolocaustDocumento20 pagineThe Technically Impossible HolocaustHuckelberry100% (2)

- Total Dynamic Head - TDHDocumento37 pagineTotal Dynamic Head - TDHs pNessuna valutazione finora

- Artificial Lift: Abdullah Bin ZiadDocumento39 pagineArtificial Lift: Abdullah Bin ZiadGilbertNessuna valutazione finora

- Bullheading Calculation Example Pressure ScheduleDocumento10 pagineBullheading Calculation Example Pressure ScheduleazizsarshoghNessuna valutazione finora

- ESP Systems EquipmentDocumento28 pagineESP Systems EquipmentAdam Rohman SAZZYSAQQASASHANessuna valutazione finora

- Gas Well De-Watering Techniques Using ESPsDocumento31 pagineGas Well De-Watering Techniques Using ESPsTiffany BarlowNessuna valutazione finora

- ESP Design CalculationDocumento17 pagineESP Design Calculationpeiwen_419100% (3)

- Centurion Pump Line: Unmatched Performance and Abrasion ResistanceDocumento6 pagineCenturion Pump Line: Unmatched Performance and Abrasion ResistancehenbauNessuna valutazione finora

- An Introduction To Drilling: Akshat Tarate Summer Trainee New Builds Division - EOSILDocumento54 pagineAn Introduction To Drilling: Akshat Tarate Summer Trainee New Builds Division - EOSILAkshat Tarate100% (1)

- Workover ProceduresDocumento9 pagineWorkover ProceduresAnonymous eGlNdZNessuna valutazione finora

- Chapter 02Documento199 pagineChapter 02351brendan83% (6)

- Materials of Construction For Pressure VesselsDocumento59 pagineMaterials of Construction For Pressure VesselsVimin Prakash90% (10)

- Gas-Liquid Flow Through Electric Submersible PumpsDocumento8 pagineGas-Liquid Flow Through Electric Submersible PumpspicapicNessuna valutazione finora

- Wellhead - Saquib ErbilDocumento109 pagineWellhead - Saquib ErbilYasir AhmedNessuna valutazione finora

- LPG Handbook PDFDocumento50 pagineLPG Handbook PDFAhmed Sherif100% (1)

- WellheadDocumento2 pagineWellheadRicardo Paz SoldanNessuna valutazione finora

- Burn BodyDocumento32 pagineBurn BodyMahmoud Ahmed Ali AbdelrazikNessuna valutazione finora

- ESP Sizing Example 1Documento6 pagineESP Sizing Example 1Ahmed Ali AlsubaihNessuna valutazione finora

- Dual EspDocumento8 pagineDual EspdoubleulandNessuna valutazione finora

- Detail Specification of Rig Sagar Gaurav: Ongc Videsh Ltd. Out Line Drilling Unit SpecificationDocumento25 pagineDetail Specification of Rig Sagar Gaurav: Ongc Videsh Ltd. Out Line Drilling Unit SpecificationMohitNessuna valutazione finora

- Aerated DrillingDocumento7 pagineAerated DrillingHarisma BagusNessuna valutazione finora

- Genie: Hot Water Driven Vapor Absorption MachineDocumento39 pagineGenie: Hot Water Driven Vapor Absorption MachineObayomi KennyNessuna valutazione finora

- ESP Pumps in Viscous LiquidsDocumento68 pagineESP Pumps in Viscous Liquidsalexis_viteriNessuna valutazione finora

- ESP Reliability Theory and Failure AnalysisDocumento1 paginaESP Reliability Theory and Failure Analysisazareiforoush100% (1)

- 4 PumpsDocumento26 pagine4 PumpsdhasdjNessuna valutazione finora

- Posiset Ds PDFDocumento2 paginePosiset Ds PDFariosabzNessuna valutazione finora

- Amb Jul Aug 2015Documento100 pagineAmb Jul Aug 2015unitymineNessuna valutazione finora

- Esp Design Data SheetDocumento6 pagineEsp Design Data SheetMohamed Abd El-MoniemNessuna valutazione finora

- ESP: Electrical Submersible Pump OverviewDocumento17 pagineESP: Electrical Submersible Pump OverviewMurad AliyevNessuna valutazione finora

- Investigation of ESP PerformanceDocumento12 pagineInvestigation of ESP PerformanceTfay89Nessuna valutazione finora

- Esp System Start-Up, Commissioning and Operation - LastDocumento42 pagineEsp System Start-Up, Commissioning and Operation - LastAnonymous 4hOjnj5100% (1)

- Gas Lift Valve InjDocumento3 pagineGas Lift Valve InjMikhaelrams RamsNessuna valutazione finora

- Membrane EngDocumento5 pagineMembrane EngMeirbekNessuna valutazione finora

- Cabezales Pjs 1sthDocumento3 pagineCabezales Pjs 1sthjairaso2950Nessuna valutazione finora

- Smacna LeakageDocumento10 pagineSmacna Leakagekothat82Nessuna valutazione finora

- Boost Well Production with Gas Lift EquipmentDocumento51 pagineBoost Well Production with Gas Lift EquipmentSufian R EllabbadNessuna valutazione finora

- Primary Checkpoint - Mathematics (0845) October 2015 Paper 2 PDFDocumento16 paginePrimary Checkpoint - Mathematics (0845) October 2015 Paper 2 PDFMohammed Abdul Moied100% (1)

- Ventilation requirements for patient care areasDocumento1 paginaVentilation requirements for patient care areasMohammed Abdul MoiedNessuna valutazione finora

- 5.1-Casing DesignDocumento23 pagine5.1-Casing DesignnabeelkhanNessuna valutazione finora

- Static and Mobile Pressure Vessels Rules OverviewDocumento22 pagineStatic and Mobile Pressure Vessels Rules Overviewsatnam1979100% (1)

- LP-Gas Service Mans ManualDocumento52 pagineLP-Gas Service Mans Manualprocha1100% (1)

- Clinical Chemistry - Theory, Analysis, CorrelationDocumento344 pagineClinical Chemistry - Theory, Analysis, Correlationaristides.quinteroNessuna valutazione finora

- Pertemuan12 ESP 04042016 13042016Documento192 paginePertemuan12 ESP 04042016 13042016Priozky Pratama Purba100% (1)

- Esp SizingDocumento17 pagineEsp SizingAmin ElfatihNessuna valutazione finora

- ESP VSD DesignDocumento21 pagineESP VSD DesignLarasati K Sadewi100% (1)

- 05 - 3 ProtectorsDocumento35 pagine05 - 3 ProtectorsAndre Damara100% (1)

- Increase Pressure Deep Oil WellDocumento97 pagineIncrease Pressure Deep Oil WellVincent J. CataldiNessuna valutazione finora

- Lab 5 Reservoir Fluid StudiesDocumento10 pagineLab 5 Reservoir Fluid StudiesIrwan JanuarNessuna valutazione finora

- Artificial Lift: Electric Submersible Pumps ESPDocumento47 pagineArtificial Lift: Electric Submersible Pumps ESPVlassis SarantinosNessuna valutazione finora

- Well Control EquipmentDocumento18 pagineWell Control Equipmentفؤاد ابوزيدNessuna valutazione finora

- Top Drive System Troubleshooting Guide TDS-9SA/11SADocumento64 pagineTop Drive System Troubleshooting Guide TDS-9SA/11SAMohamed Abdelazim Bakr AdamNessuna valutazione finora

- Gas Lift ValvDocumento2 pagineGas Lift ValvMikhaelrams Rams0% (1)

- Dual ESP Completion SystemDocumento2 pagineDual ESP Completion SystemDenis GontarevNessuna valutazione finora

- ESP Design - Step 4 Total Dynamic HeadDocumento6 pagineESP Design - Step 4 Total Dynamic HeadazareiforoushNessuna valutazione finora

- WELL: 112-147: Directional, Dev. (W.I.)Documento15 pagineWELL: 112-147: Directional, Dev. (W.I.)Mostafa KorttamNessuna valutazione finora

- BOP Drawings by Sections, RevDocumento10 pagineBOP Drawings by Sections, RevberrouiNessuna valutazione finora

- ESPCatalogOCT2013 PDFDocumento218 pagineESPCatalogOCT2013 PDFSteve MarfissiNessuna valutazione finora

- Pds Products HRP ESP PackersDocumento2 paginePds Products HRP ESP PackersfredyNessuna valutazione finora

- Alkhorayef ESP Catalog 2019Documento96 pagineAlkhorayef ESP Catalog 2019rasnowmah2012Nessuna valutazione finora

- Electrical Submersible Pump (ESP) : Components (Equipment Description) PTP-6.1Documento19 pagineElectrical Submersible Pump (ESP) : Components (Equipment Description) PTP-6.1nawarsNessuna valutazione finora

- Surface Well Testing Reporting Format and Standard GD-GL-HAL-SWT-601Documento10 pagineSurface Well Testing Reporting Format and Standard GD-GL-HAL-SWT-601Said100% (1)

- GE - ESP BrochureDocumento16 pagineGE - ESP Brochureandreé VillalobosNessuna valutazione finora

- 9 Surface Equipment PDFDocumento47 pagine9 Surface Equipment PDFAli AliNessuna valutazione finora

- PM RoleDocumento4 paginePM Rolesukrit dobhalNessuna valutazione finora

- Tricks of The TradeDocumento4 pagineTricks of The TradeMohammed Abdul MoiedNessuna valutazione finora

- Scrum Flow: Process ChartDocumento2 pagineScrum Flow: Process ChartJean BazanNessuna valutazione finora

- Global Travel Restrictions 20200224Documento11 pagineGlobal Travel Restrictions 20200224Anil GargNessuna valutazione finora

- Covid-19 Form All Sub Specialties in Medicine (Notes by Areez)Documento1 paginaCovid-19 Form All Sub Specialties in Medicine (Notes by Areez)Mohammed Abdul MoiedNessuna valutazione finora

- Project Communications ManagementDocumento1 paginaProject Communications ManagementMUHAMMAD ALI HAFEEZNessuna valutazione finora

- Project Management Body of Knowledge (Pmbok® Guide) : Date Source of Study Reading ExerciseDocumento2 pagineProject Management Body of Knowledge (Pmbok® Guide) : Date Source of Study Reading ExerciseMohammed Abdul MoiedNessuna valutazione finora

- Blower Data Sheet-Aeration TankDocumento1 paginaBlower Data Sheet-Aeration TankMohammed Abdul MoiedNessuna valutazione finora

- 10 Project Communications Management TermsDocumento4 pagine10 Project Communications Management Termsravish katariaNessuna valutazione finora

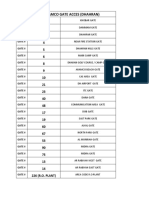

- Saudi Aramco Gate Access LocationsDocumento1 paginaSaudi Aramco Gate Access LocationsMohammed Abdul MoiedNessuna valutazione finora

- Project Communication ManagementDocumento4 pagineProject Communication ManagementwondeNessuna valutazione finora

- Canadian ImmigrationDocumento4 pagineCanadian ImmigrationMohammed Abdul MoiedNessuna valutazione finora

- Errata Rectangular Industrial Duct Construction StandardsDocumento1 paginaErrata Rectangular Industrial Duct Construction StandardsscoutjohnyNessuna valutazione finora

- NarrativeDocumento4 pagineNarrativeMohammed Abdul MoiedNessuna valutazione finora

- New Doc 2019-01-07 12.27.44Documento16 pagineNew Doc 2019-01-07 12.27.44Mohammed Abdul MoiedNessuna valutazione finora

- NarrativeDocumento4 pagineNarrativeMohammed Abdul MoiedNessuna valutazione finora

- New Doc 2018-12-11 08.00.26 PDFDocumento14 pagineNew Doc 2018-12-11 08.00.26 PDFMohammed Abdul MoiedNessuna valutazione finora

- Sound PDFDocumento18 pagineSound PDFMohammed Abdul MoiedNessuna valutazione finora

- Earth and BeyondDocumento12 pagineEarth and BeyondMohammed Abdul MoiedNessuna valutazione finora

- New Doc 2019-01-21 08.29.04 PDFDocumento13 pagineNew Doc 2019-01-21 08.29.04 PDFMohammed Abdul MoiedNessuna valutazione finora

- CamScanner Scanned Document PagesDocumento14 pagineCamScanner Scanned Document PagesMohammed Abdul MoiedNessuna valutazione finora

- New Doc 2019-01-21 08.29.04Documento13 pagineNew Doc 2019-01-21 08.29.04Mohammed Abdul MoiedNessuna valutazione finora

- Readme PDFDocumento1 paginaReadme PDFMohammed Abdul MoiedNessuna valutazione finora

- Specification For Pipeline Valves - AP SPEC 6D PDFDocumento100 pagineSpecification For Pipeline Valves - AP SPEC 6D PDFMohammed Abdul MoiedNessuna valutazione finora

- Cell LineDocumento12 pagineCell LineLuis PhillipsNessuna valutazione finora

- Ch11EN Fluid Unit Flow PathDocumento1 paginaCh11EN Fluid Unit Flow PathHermeson SantiagoNessuna valutazione finora

- T50 300 Xl092grexbDocumento3 pagineT50 300 Xl092grexbSykat ZamanNessuna valutazione finora

- EDXRF Analysis of Polymer Films Thickness and CompositionDocumento2 pagineEDXRF Analysis of Polymer Films Thickness and CompositionnadiarhNessuna valutazione finora

- Kanthal Appliance Heating Alloys Handbook PDFDocumento33 pagineKanthal Appliance Heating Alloys Handbook PDFwillwNessuna valutazione finora

- Universitas Ahmad Dahlan - JellyDocumento15 pagineUniversitas Ahmad Dahlan - JellyMaqfirotul LailyNessuna valutazione finora

- Manufacturing Ammonia Using The Haber Process: BSC IllDocumento8 pagineManufacturing Ammonia Using The Haber Process: BSC Illdigukharade9848Nessuna valutazione finora

- AQUACID 101 EX Lote 1020015695 & BPY0021-01Documento1 paginaAQUACID 101 EX Lote 1020015695 & BPY0021-01Julio . CNessuna valutazione finora

- Stitute: NCERT Solution For Class 10 Science Chapter 2 Acids, Bases and SaltsDocumento8 pagineStitute: NCERT Solution For Class 10 Science Chapter 2 Acids, Bases and SaltsSuneethaNessuna valutazione finora

- RT One Touch AltDocumento2 pagineRT One Touch AltsobheysaidNessuna valutazione finora

- Plastics: Name: Taaha Muzaffar Imam ROLL NO.: 19011AA002 Sem/Sec: Ii/A Branch: B.Arch College: Spa' JnafauDocumento5 paginePlastics: Name: Taaha Muzaffar Imam ROLL NO.: 19011AA002 Sem/Sec: Ii/A Branch: B.Arch College: Spa' JnafauTaaha Muzaffar ImamNessuna valutazione finora

- Backup Rings Respaldo de OringsDocumento8 pagineBackup Rings Respaldo de OringsRPINILLA (EICO S.A.)Nessuna valutazione finora

- Chemistry Investigatory ProjectDocumento10 pagineChemistry Investigatory ProjectAjay ChauhanNessuna valutazione finora

- Setting up PCR for D1S80 VNTR Analysis from Buccal Cell DNADocumento10 pagineSetting up PCR for D1S80 VNTR Analysis from Buccal Cell DNAmmarrinnaNessuna valutazione finora

- OLEDreport PDFDocumento26 pagineOLEDreport PDFStanimir YordanovNessuna valutazione finora

- June 2017 (v1) QP - Paper 6 CIE Biology IGCSEDocumento12 pagineJune 2017 (v1) QP - Paper 6 CIE Biology IGCSEbandana dekaNessuna valutazione finora

- Recycling OF Aluminum Salt Cake: ANL/CP - 73449 DE92 003408Documento20 pagineRecycling OF Aluminum Salt Cake: ANL/CP - 73449 DE92 003408Vijaykumar SharmaNessuna valutazione finora

- Static ElectricityDocumento9 pagineStatic ElectricityEssraa KhamisNessuna valutazione finora

- TebuconazoleDocumento195 pagineTebuconazoleKen EspinoNessuna valutazione finora

- Formulation and Evaluation of Orally Disintegrating Tablets of SertralineDocumento7 pagineFormulation and Evaluation of Orally Disintegrating Tablets of SertralineDinesh BabuNessuna valutazione finora