Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Yarnconditioning 150612160000 Lva1 App6891

Caricato da

dineshv74Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Yarnconditioning 150612160000 Lva1 App6891

Caricato da

dineshv74Copyright:

Formati disponibili

Advanced Yarn Manufacturing

Azmir Latif, MSc in textile Engineering

Yarn conditioning

In which process yarn is conditioned for better performance (such as strength, serviceability,

luster, handle etc) is called yarn conditioning. Textile fibers are subjected to various physical

operations to make in to a yarn. For example cotton fiber passes through opening, carding,

drawing and spinning to become a yarn. During these phases the original moisture content on the

fiber would have been lost and some static electricity would be carried by the fiber. The amount

of static current carried by yarn changes from fiber to fiber. Similarly the strength of any fiber

depends up on how close the present moisture content is to the original natural value.

Similarly some high twist yarn would tend to lose its twist as and when it is allowed freely,

making a lengthwise elongation.

Some fibers would tend to shrink when exposed to hot atmosphere or any treatment that involves

heat and hence higher temperature. For example polyamide, polyester etc.Some blends like

Cotton/Lycra, Viscose/Lycra require conditioning to make the width the fabric stable.

So all the above said factors, if not addressed properly would reflect badly on the final quality of

yarn or fabric.

Moisture in atmosphere has a great impact on the physical properties of textile fibres and yarns.

Relative humidity and temperature will decide the amount of moisure in the atmosphere. High

relative humidity in different departments of spinning is not desirable. It will result in major

problems. But on the otherhand, a high degree of moisture improves the physical properties of

yarn. Moreover it helps the yarn to attain the standard moisture regain value of the fibre. Yarns

sold with lower moisture content than the standard value will result in monetary loss. Therefore

the aim of CONDITIONING is to provide an economical device for supplying the necessary

moisture in a short time, in order to achieve a lasting improvement in quality.

The relative humidity in turn affects the properties of the fibre via the moisture content of the

cotton fibre. The fibre strength and elasticity increase proportionately with the increase in

humidity. If the water content of the cotton fibre is increased the fibre is able to swell, resulting

in increased fibre to fibre friction in the twisted yarn structure. This positive alteration in the

properties of the fibre will again have a positive effect on the strength and elasticity of the yarn.

A process that addresses all the above parameters is called CONDITIONING. Conditioning

process differs from fiber to fiber.

So conditioning is a preliminary process in any processing that improves and maintains the

quality of yarn.

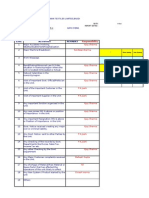

Conditioning may be done in yarn stage on perforated paper or plastic cones/cheeses in an Auto

Clave or Horizontal beam dyeing machine as shown above.

Conditioning Process for various yarns:

Advanced Yarn Manufacturing

Azmir Latif, MSc in textile Engineering

1) 100% Polyester yarn: Load the yarn in the form cones wound on plastic cones, in to a beam

dyeing machine. Introduce steam and raise the temperature to 100C at 3C per minutes. Steam

for 15 minutes at 100C followed by 15 minutes cooling = 1 cycle. Repeat the cycle for 4 times.

2) 100% Nylon: Load the yarn in the form cones wound on plastic cones, in to a beam dyeing

machine. Introduce steam and raise the temperature to 100C at 3C per minutes. Steam for 15

minutes at 100C followed by 15 minutes cooling to a temperature of 50C = 1 cycle. Repeat the

cycle for 4 times.

3) Silk yarn: Load the yarn in the form cones wound on plastic cones, in to a beam dyeing

machine. Introduce steam and raise the temperature to 70C at 3C per minutes. Steam for 15

minutes at 70C followed by 15 minutes cooling to a temperature for 30C = 1 cycle. Repeat the

cycle for 4 times.

4) Cotton/Lycra (40's Lycra) or Viscose/Lycra (60's): Conditioning the yarn as mentioned for

silk.

The following effects would be envisaged by steam-conditioning of yarn:

Twist Setting - Preventing Snarling (yarn loops)

Better Dye affinity - Eliminating static electricity

Influencing the Cloth handle - Preventing crease-proneness

High bulking - Humidifying

Dye - fixing - De-crinkling

Determining residual boiling shrinkage.

The effects of yarn conditioning on yarn properties of both ring spun and open end 100% cotton

and cotton/polyester yarns and the resultant weaving

Because of the tremendous productivity and speed, air-jet weaving machines are becoming more

evident in today's textile world. However, these increased speeds place greater stresses on filling

and warp yarns. The process of conditioning yarn offers one possible method for enhancing yarn

performance on today's high speed weaving machines. This research was conducted to determine

the effects of yarn conditioning on yarn properties, weaving stop levels, and dye uptake

performance. Four types of yarns were used in this research. They were: 13.5/1 100% cotton and

cotton/polyester ring spun, 11.0/1 100% cotton open-end, and 12.0/1 cotton/polyester open-end

yarn. Also, a 40.0/1 100% cotton ring spun yarn was used for warp yarn. The yarns were

conditioned on two types of conditioners. One conditioner used a indirect steam system and the

other used a direct steam system. Two temperature levels of 50-55 degrees Celsius and 75-80

degrees Celsius were used in both types of conditioners. The conditioned yarns were tested for

single-end strength, single-end elongation, elasticity, torque (liveliness), and hairiness. Also,

unconditioned yarns of the same type were tested to provide a baseline for comparison. This

research also examined how yarn conditioning effects slashing parameters. The 40.0/1 100%

Advanced Yarn Manufacturing

Azmir Latif, MSc in textile Engineering

cotton ring spun yarns were slashed and tested for size pickup, encapsulation, penetration, and

tensile properties. Finally, the yarns used for warp and filling were knitted into socks and then

dyed. The purpose of this was to determine the effect of yarn conditioning on dye uptake and

delta E properties. The 13.5/1 100% cotton ring spun yarns and the 12/1 cotton/polyester openend yarns were woven as filling on air-jet weaving machines. The warp yarns were also woven

on airjet machinery. All weaving trials used a plain oxford weave. The yarn tests results revealed

that yarn conditioning did not affect strength, elongation, or elasticity. There were some

instances when yarn conditioning increased yarn hairiness, especially for ring spun yarns. One of

the most consistent findings of this research was that conditioning yarn on either system at either

temperature level, significantly reduced yarn liveliness. Results indicated that the indirect steam

system, operated at a 75-80 degrees Celsius temperature level, exhibited the most reduction in

yarn liveliness. The filling stop trials indicated that conditioned yarns wove at a lower stop level

than unconditioned yarn. However, only yarns conditioned on the indirect steam system, at 75-80

degrees Celsius, wove significantly better at the 95 % confidence level. This research also

showed that filling stop levels with ring spun yarn are affected to a greater degree than open end

yarns. Slashing procedures were kept consistent throughout the trial. Yarn conditioning did not

affect any of the slashing parameters tested. Because of this, the conditioned warp yarns did not

weave at a lower warp stop level. The dye uptake trials revealed that conditioned yarns absorb

less dye than unconditioned yarn. The difference in dye uptake was great enough to result in

visible differences, as indicated by the Delta E values. There were also dye uptake differences

between type of conditioner and temperature used. The 100% cotton yarns exhibited the greatest

differences in dye uptake. This is contributed to changes in the crystallinity of the cotton fiber

when the heat and moisture of yarn conditioning are applied.

Yarn Conditioning Process

High speed spinning machines generate more friction thus giving additional heat to the yarn and

as a result of such heat transfer the yarn moisture content is vaporized. Rising speeds in spinning

result in decreased yarn quality for other processes and it is well known that dry yarns have

worse properties. For quality reasons it is absolutely important to have even distribution of this

recuperated moisture throughout the entire yarn package. Only the vacuum technology provides

the conditions for the required moisture regain. This paper attempts to comprehensively review

the yarn conditioning mechanism, process parameters of conditioning and applications of yarn

conditioning.

Moisture in atmosphere has a great impact on the physical properties of textile fibres and yarns.

A high degree of moisture improves the physical properties of yarn and it helps the yarn to attain

the standard moisture regain value of the fibre. Yarns sold with lower moisture content than the

standard value will result in monetary loss. Therefore the aim of yarn conditioning is to provide

an economical device for supplying the necessary moisture in a short time, in order to achieve a

lasting improvement in quality.

In these days there is a dramatic change in the production level of weaving and knitting

machines, because of the sophisticated manufacturing techniques. Yarn quality required to run

on these machines is extremely high. In order to satisfy these demands without altering the raw

material, it is possible to make use of the physical properties inherent in the cotton fibres. Cotton

Advanced Yarn Manufacturing

Azmir Latif, MSc in textile Engineering

fiber is hygroscopic material and has the ability to absorb water in the form of steam. It is quite

evident that the hygroscopic property of cotton fibers depends on the relative humidity. The

higher the humidity is, more the moisture absorption. The increase in the relative atmospheric

humidity causes a rise in the moisture content of the cotton fiber.

The fibre strength and elasticity increase proportionately with the increase in humidity. If the

water content of the cotton fibre is increased, the fibre is able to swell, resulting in increased

fibre to fibre friction in the twisted yarn structure. This positive alteration in the properties of the

fibre will again have a positive effect on the strength

and elasticity of the yarn.

Problems in conventional yarn conditioning

method

The standard conventional steaming treatment for

yarn is chiefly used for twist setting to avoid snarling

in further processing. It does not result in lasting

improvement in yarn quality. The steaming process

may fail to ensure even distribution of the moisture,

especially on cross-wound bobbins (cheeses) with

medium to high compactness (Fig. 1).

The absence of vacuum in conventional conditioning chambers prevents Conventional

homogeneous penetration. The outer layers of the package are also too moist and the transition

from moist to dry yarn gives rise to substantial variations in downstream processing of the

package, both with regard to friction data and strength.

Since the moisture is applied superficially in the wet steam zone or by misting with water jets, it

has a tendency to become re-adjusted immediately to the ambient humidity level owing to the

large surface area. Equipment of this kind also prevents the optimum flow of goods and takes up

too much space.

CONTEXXOR conditioning process by Xorella

The thermal conditioning process of the yarn

according to the CONTEXXOR process developed

by Xorella, is a new type of system for conditioning

the yarn package (Fig. 2). Thermal conditioning

uses low-temperature saturated steam in vacuum.

With the vacuum principle and indirect steam, the

yarn is treated very gently in an absolutely saturated

steam atmosphere. The vacuum first removes the air

Advanced Yarn Manufacturing

Azmir Latif, MSc in textile Engineering

pockets from the yarn package to ensure accelerated steam penetration and also removes the

atmospheric oxygen in order to prevent oxidation. The conditioning process makes use of the

physical properties of saturated steam or wet steam (100% moisture in gas-state). The yarn is

uniformly moistened by the gas. The great advantage of this process is that the moisture in the

form of gas is very finely distributed throughout the yarn package and does not cling to the yarn

in the form of drops. This is achieved in any cross-wound bobbins, whether the yarn packages

are packed on open pallets or in cardboard boxes.

Effect of conditioning process parameters on yarn properties

Although yarn conditioning machine can add the moisture of yarn, one must consider different

raw material and yarn counts to make different yarn conditioning programs. In spite of higher

moisture, if there is high vacuum condition, the low quality of raw cotton, coarse count and

higher ratio of short fibre would make yarn over relaxed and thus will have less strength. Thus

cotton yarn less than Ne 21s, needs less vacuum, low steam temperature, longer heating up time

and constant temperature. For PC or pure polyester fibre as well as combed yarn. It requires high

vacuum degree and high steam temperature. The time for heating up and constant temperature is

related to the actual twist but maximum should not exceed 70 minutes.

Steam temperature is set according to the types of fibers. If cotton fiber is conditioned under 100

for 20 days, it would have only 92% strength left, but polyester fibre under the same conditions

would retain 100% strength. For different fibers, there is a big difference in the flow temperature,

fusion, resolution and other index of thermo logy. Maximum temperature for cotton fiber in yarn

conditioning machine should not exceed 85 but pure polyester could reach 140. Otherwise it will

have negative effects on breakage strength and colors.

P. V. Kadole et al found that, the cycle with first cycle temperature 58C - 05 min. and second

cycle temperature 62C - 25 min. (with total time for the cycle 55 min.) gives optimized yarn

properties for 20KW (4.26 TM), 20KH (3.78) waxed, 20 CH waxed. (3.6 TM) yarns. They also

stated that in case of conditioning waxed and unwaxed yarn simultaneously with same

programme, care should be taken while selecting maximum temperature in second cycle. Always

it should be less than melting point of the wax. They showed that the combined programme helps

in achieving best yarn results at low power cost and higher production rate.

Sibel Sardag et al studied the effects of vacuum steaming process parameters (temperature and

duration) on tenacity properties of 1 00 % cotton and 100 % viscose yarns. For this purpose, the

yarns with different twist coefficients and numbers were twisted and exposed to vacuum

steaming at different temperatures and for durations appropriate to their raw material properties.

Tenacity properties of the yarns were measured before and after vacuum steaming. They found

that vacuum steaming temperature has significant effect on tenacity properties of 100% cotton

and 100 % viscose yarns but vacuum steaming duration has been found to be statistically

insignificant on tenacity properties of cotton yarns, and viscose yarns.

In another study, these authors showed that tenacity, elongation at break (in per cent), and work

of rupture of 30 tex and 20 tex PES/viscose yarns were to be enhanced due to heat-setting. They

also showed that the tenacity and elongation at break values of the yarns decreased after dyeing;

Advanced Yarn Manufacturing

Azmir Latif, MSc in textile Engineering

however, these values are still high when compared with those of the pre-heat setting. The

increase of temperature from 90C to 110C caused a decrease in the strength values of the yarns.

For this reason, they considered the heat- setting at 90C to be sufficient to enhance the strength

properties of PES/viscose yarns - consisting of 67% PES and 33% viscose.

Yarn conditioning machine does improve the CV of yarn and also it does not make it worse. It is

the fact that CV and neps of yarn detected by yarn evenness tester is raised rapidly for yarn, just

taken from the yarn conditioning machine. However, leaving it for 24 hours, later the data will

remain as before. The reason is after processing, a part of water gets into the inner core of yarn

and becomes relatively steady crystal water, and water attached to the surface of yarn becomes

unsteady. The difference in each part of the surface water would result in different dielectric

coefficient, which makes the yarn evenness tester give inaccurate results.

In case of cotton fiber, absorption of moisture is delayed after processing in the yarn

conditioning machine. It is therefore, better to pack or use the yarn after 30 minutes rest in the

yarn stock room. This would allow enough time for the surface water to evaporate and also to

retain the same moisture level both inside and outside of the yarn. The yarn that has been

processed in the yarn conditioning machine should not be mixed with the one which has not been

processed; otherwise, there will appear long and narrow shadow on the final product after

dyeing, especially for knitted fabric.

Major applications of the yarn conditioning

In spinning process yarn conditioning machine is used to adjust the moisture of yarn and to

improve efficiency in the next process. After processing, when the moisture level of yarn would

reach about 8.5 %, strength and elongation can be increased greatly, which help the performance

at processing line. The dealing of cone yarn would improve the efficiency on winding, doubling

and twisting and also reduce the yarn hairiness. It will be also helpful to improve warping

efficiency and to reduce the defects from rewinding and warping. Owing to the conformity of

moisture of the yarn, the efficiency of sizing and weaving will also improved ensuring the

quality of the final fabric.

The yarns after processing by yarn conditioning machine would improve the working process as

well as the quality of final fabric. Because of fixed twisting and shaping of the yarn, it will give

equal height of rising and looping, reduce the unwinding tension, stable the structure and size of

the end fabric and give better appearance. Especially it is the key process for setting the seamless

underclothes. The process of conditioning will not only stabilize the twist, but also fully relax the

yarn to reduce the shrinkage of final product.

In dyeing industry, processing after yarn conditioning machine can remove the stress on grey

fabric, which will be helpful for uniform absorption of dyes to obtain bright color as well as

uniform shade of the fabric. In garment industry, yarn conditioning machine can make fabric

with stable size, reducing the shrinkage and improving the quality. Processing yarn, especially

Advanced Yarn Manufacturing

Azmir Latif, MSc in textile Engineering

the chemical fiber, in the conditioning machine can greatly improve the quality and appreciation

of product.

Conclusion

Textile market is becoming sensitive buyer's market. Weaver is demanding dimensioned quality

with consistency from spinners. Therefore in order to satisfy these demands without altering the

raw material; the hygroscopic nature of cotton fibers can be used. Therefore most of the spinning

mills are now going for YCP. These modern YCP gives us even penetration of steam into all the

layers of yarns on cone & ensures even conditioning effect throughout the package. The yarn

conditioning plant supply the yarn with increased strength & elongations, that have reduced

snarling of yarn, improved working at post spinning processes like warping, weaving, knitting,

etc. Yarn conditioning reduces invisible loss to the spinners. Though its initial cost of investment

is high, but its payback period is very less.

Potrebbero piacerti anche

- Objects of Conditioning Are As FollowsDocumento7 pagineObjects of Conditioning Are As FollowssachinnmimsNessuna valutazione finora

- Unimix LB7 4Documento2 pagineUnimix LB7 4MY Lê Thị Trà100% (2)

- Ring Frame - Technological AspectsDocumento43 pagineRing Frame - Technological AspectsAliAhmad50% (2)

- Compact SpinningDocumento15 pagineCompact SpinningCẩm TúNessuna valutazione finora

- F CA-drawframes Combingsection Lowres MarzoliDocumento32 pagineF CA-drawframes Combingsection Lowres MarzoliAshiqueNessuna valutazione finora

- Effect of Changing Arm Pressure of Draft PDFDocumento11 pagineEffect of Changing Arm Pressure of Draft PDFNeelakandan DNessuna valutazione finora

- U Z HL400 HairinessDocumento16 pagineU Z HL400 HairinessarunmythreyeeNessuna valutazione finora

- F CA-blowroom Lowres MarzoliDocumento28 pagineF CA-blowroom Lowres MarzoliAshiqueNessuna valutazione finora

- Training Report of Gcti Tarinees MS WORDDocumento55 pagineTraining Report of Gcti Tarinees MS WORDAakash NagpalNessuna valutazione finora

- PROCESS CONER II OPERATION AND MAINTENANCE GUIDEDocumento24 paginePROCESS CONER II OPERATION AND MAINTENANCE GUIDEMd Hanif SonketNessuna valutazione finora

- Weft & Warp TensionDocumento8 pagineWeft & Warp Tensionnemat2008Nessuna valutazione finora

- Frequency Cleaning / Inspection Points Lubricating Points Type of LubricantDocumento3 pagineFrequency Cleaning / Inspection Points Lubricating Points Type of LubricantKrishnamurthy NatarajanNessuna valutazione finora

- ITMA 2019 Highlights New Textile Machinery InnovationsDocumento8 pagineITMA 2019 Highlights New Textile Machinery InnovationsPadmanaban PasuvalingamNessuna valutazione finora

- Lenzing Tencel - Courtesy: LenzingDocumento38 pagineLenzing Tencel - Courtesy: LenzingSENTHIL KUMARNessuna valutazione finora

- Air Jet Spinning of Cotton YarnsDocumento9 pagineAir Jet Spinning of Cotton YarnsUsman GillNessuna valutazione finora

- Yarn Specs - USTERDocumento24 pagineYarn Specs - USTERZubairShafqat50% (2)

- Highly Efficient LMW Ringframe MachineDocumento16 pagineHighly Efficient LMW Ringframe MachineSudheer Singh chauhanNessuna valutazione finora

- LMW Spinpact CompactDocumento8 pagineLMW Spinpact CompactMY Lê Thị TràNessuna valutazione finora

- Airjet PracDocumento12 pagineAirjet PracJunaid SuhailNessuna valutazione finora

- (Woodhead Publishing India in Textiles) Bhattacharya, Someshwar S. - Shaikh, Tasnim N - Engineering Techniques of Ring Spinning-Woodhead Publishing India PVT LTD (2016)Documento223 pagine(Woodhead Publishing India in Textiles) Bhattacharya, Someshwar S. - Shaikh, Tasnim N - Engineering Techniques of Ring Spinning-Woodhead Publishing India PVT LTD (2016)Fathimatuz ZahroNessuna valutazione finora

- LycraDocumento7 pagineLycraFiaz juttNessuna valutazione finora

- Recent Development of Circular KnittingDocumento32 pagineRecent Development of Circular KnittingHarshitha A100% (1)

- Evaluation of yarn diameter and its effect on fabric qualityDocumento8 pagineEvaluation of yarn diameter and its effect on fabric qualitySabeeh Ul HassanNessuna valutazione finora

- Defects and Quality Optimisation of Core-Spun Yarn Containing SpandexDocumento9 pagineDefects and Quality Optimisation of Core-Spun Yarn Containing SpandexMohammed Atiqul Hoque Chowdhury100% (1)

- Study of Loop Formation Process On 1x1 V-Bed Rib Knitting MachineDocumento12 pagineStudy of Loop Formation Process On 1x1 V-Bed Rib Knitting MachineIAEME PublicationNessuna valutazione finora

- Modern Developments in WeavingDocumento13 pagineModern Developments in WeavingRakeahkumarDabkeyaNessuna valutazione finora

- Effect of Twist On Yarn PropertiesDocumento5 pagineEffect of Twist On Yarn PropertiesAbdulqadeerNessuna valutazione finora

- Mercerizing Cellulose Fibres: Effects and ProcessDocumento5 pagineMercerizing Cellulose Fibres: Effects and ProcessMohammed Atiqul Hoque ChowdhuryNessuna valutazione finora

- Spinning Solutions: Digitization - Automation - SustainabilityDocumento12 pagineSpinning Solutions: Digitization - Automation - SustainabilitySundar Veerasamy100% (1)

- Ring Spinning Vs All Technologies Part 2Documento29 pagineRing Spinning Vs All Technologies Part 2SOhaib KazmeNessuna valutazione finora

- Fibrograph Method PDFDocumento4 pagineFibrograph Method PDFMd Amir HossainNessuna valutazione finora

- Spinpact Fine Tuning HandbookDocumento10 pagineSpinpact Fine Tuning Handbookselvakumar100% (1)

- SpinningDocumento141 pagineSpinningKathirrveluSubramainanNessuna valutazione finora

- Compact Yarn: S.M. Farhana Iqbal Associate Prof. ButexDocumento22 pagineCompact Yarn: S.M. Farhana Iqbal Associate Prof. ButexSadia TabassumNessuna valutazione finora

- A Internship Report in Brabch Textile Technology For Diploma Holders.Documento54 pagineA Internship Report in Brabch Textile Technology For Diploma Holders.Pawan Kumar RajputNessuna valutazione finora

- Uster Statistics-50s CBD Compact ConeDocumento6 pagineUster Statistics-50s CBD Compact Coneselvapdm100% (1)

- Spirality of Single Jersey Knitted FabricDocumento13 pagineSpirality of Single Jersey Knitted FabricKazi Saiful IslamNessuna valutazione finora

- Indian Journal Examines Spirality in Weft-Knitted FabricsDocumento5 pagineIndian Journal Examines Spirality in Weft-Knitted FabricsObak Prithibi100% (1)

- Recent Developments in Compact SpinningDocumento17 pagineRecent Developments in Compact SpinningsuganNessuna valutazione finora

- Gujarat Technological University: W.E.F. AY 2018-19Documento2 pagineGujarat Technological University: W.E.F. AY 2018-19Rushi TannaNessuna valutazione finora

- Vortex FDocumento2 pagineVortex FNipu SenNessuna valutazione finora

- Study of Structure and Properties of Air Jet Textured YarnDocumento15 pagineStudy of Structure and Properties of Air Jet Textured Yarnpraveen kumarNessuna valutazione finora

- Cost Analysis: Quality Comes First, Rest Are ConsequencesDocumento5 pagineCost Analysis: Quality Comes First, Rest Are ConsequencesAl AminNessuna valutazione finora

- Publications: Fibre & YarnDocumento14 paginePublications: Fibre & YarnvigneshbalajirsNessuna valutazione finora

- Friction SpinningDocumento39 pagineFriction SpinningPåñdît ẞhyãmãñtãk MãñîNessuna valutazione finora

- Mechanical Properties of Weft Knitted FabricsDocumento6 pagineMechanical Properties of Weft Knitted FabricsAhmad SamerNessuna valutazione finora

- Analysis of The Imperfection Index (Ipi) Value of Carded Yarn Produced by Using Different Diameter Spacers On The Ring Frame Spinning MachineDocumento7 pagineAnalysis of The Imperfection Index (Ipi) Value of Carded Yarn Produced by Using Different Diameter Spacers On The Ring Frame Spinning MachineUtsho ParvezNessuna valutazione finora

- Study On CCI Warping Machine.Documento5 pagineStudy On CCI Warping Machine.Naimul HasanNessuna valutazione finora

- Compact SpinningDocumento17 pagineCompact SpinningRana Kashif TahirNessuna valutazione finora

- 5-6 Winding Part 2Documento28 pagine5-6 Winding Part 2Md. Towfiq ImrozNessuna valutazione finora

- Man Made Fiber Textile ProcessDocumento39 pagineMan Made Fiber Textile ProcessGarmentLearnerNessuna valutazione finora

- Yarn Winding: Past, Present and FutureDocumento29 pagineYarn Winding: Past, Present and Futurefatimasajjad354100% (1)

- Study On Sizing Practices in Bangladeshi Weaving MillsDocumento41 pagineStudy On Sizing Practices in Bangladeshi Weaving MillsSubrata Majumder50% (2)

- Carr and Latham's Technology of Clothing ManufactureDa EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerValutazione: 4 su 5 stelle4/5 (1)

- Modern Cotton Spinning Machinery, Its Principles and ConstructionDa EverandModern Cotton Spinning Machinery, Its Principles and ConstructionNessuna valutazione finora

- Low Toxicity Biodegradable Salt Substitute For Dyeing TextilesDocumento8 pagineLow Toxicity Biodegradable Salt Substitute For Dyeing Textilesdineshv74Nessuna valutazione finora

- Horsepower To Kilowatt (HP To KW) and KW To HP (Kilowatts To MeDocumento2 pagineHorsepower To Kilowatt (HP To KW) and KW To HP (Kilowatts To Medineshv74Nessuna valutazione finora

- Inland Surface Water CategoriesDocumento1 paginaInland Surface Water Categoriesdineshv74Nessuna valutazione finora

- VIBRANT GUJARAT ENVIRONMENT SECTOR PROFILEDocumento28 pagineVIBRANT GUJARAT ENVIRONMENT SECTOR PROFILEdineshv74Nessuna valutazione finora

- Working with Plaid FabricsDocumento7 pagineWorking with Plaid Fabricsdineshv74Nessuna valutazione finora

- Hazardous Materials: Toxic Substances Hazardous SubstancesDocumento8 pagineHazardous Materials: Toxic Substances Hazardous Substancesdineshv74Nessuna valutazione finora

- Calorific Value of CoalDocumento8 pagineCalorific Value of Coaldineshv74Nessuna valutazione finora

- Burlap and Soil Saver Products Jute Erosion Control Mesh JutDocumento7 pagineBurlap and Soil Saver Products Jute Erosion Control Mesh Jutdineshv74Nessuna valutazione finora

- Compressed Air RulesDocumento2 pagineCompressed Air RulesJosé Manuel Martínez GarzaNessuna valutazione finora

- Calorific Value of Coal PDFDocumento10 pagineCalorific Value of Coal PDFdineshv74Nessuna valutazione finora

- Power PlantDocumento15 paginePower PlantBuckshu PhdNessuna valutazione finora

- Unit 2 58Documento63 pagineUnit 2 58Suresh Babu DNessuna valutazione finora

- Boody Bamboo Information PDFDocumento4 pagineBoody Bamboo Information PDFdineshv74Nessuna valutazione finora

- Seven Spiritual Laws of Success 1215441970083150 8Documento19 pagineSeven Spiritual Laws of Success 1215441970083150 8dineshv74Nessuna valutazione finora

- Wings of Fire by APJ Abdul KalamDocumento15 pagineWings of Fire by APJ Abdul Kalamdineshv74Nessuna valutazione finora

- 3-Other Dyes and Reactive DyesDocumento8 pagine3-Other Dyes and Reactive DyesxtrayangNessuna valutazione finora

- Apjkalam 150809093213 Lva1 App6892Documento28 pagineApjkalam 150809093213 Lva1 App6892dineshv74Nessuna valutazione finora

- Chemical Finishing of Textiles PDFDocumento286 pagineChemical Finishing of Textiles PDFdineshv7450% (2)

- 3-Other Dyes and Reactive DyesDocumento8 pagine3-Other Dyes and Reactive DyesxtrayangNessuna valutazione finora

- Theory of Reactive DyeingDocumento22 pagineTheory of Reactive Dyeingmrsohel_tex100% (5)

- 0fcfd50866f4ca1a19000000 PDFDocumento14 pagine0fcfd50866f4ca1a19000000 PDFdineshv74Nessuna valutazione finora

- RFT in Reactive DyeingDocumento24 pagineRFT in Reactive DyeingRezaul Karim Tutul100% (9)

- 0fcfd50866f4ca1a19000000 PDFDocumento14 pagine0fcfd50866f4ca1a19000000 PDFdineshv74Nessuna valutazione finora

- 3-Other Dyes and Reactive DyesDocumento8 pagine3-Other Dyes and Reactive DyesxtrayangNessuna valutazione finora

- Textile Processing Chemistry: Lecture 2Documento11 pagineTextile Processing Chemistry: Lecture 2Ankur SrivastavNessuna valutazione finora

- 138178Documento59 pagine138178dineshv74Nessuna valutazione finora

- 3-Other Dyes and Reactive DyesDocumento8 pagine3-Other Dyes and Reactive DyesxtrayangNessuna valutazione finora

- Salt Trolley Design Sheet1Documento1 paginaSalt Trolley Design Sheet1dineshv74Nessuna valutazione finora

- Daily Report FormatDocumento4 pagineDaily Report Formatdineshv74Nessuna valutazione finora

- Sports AcousticsDocumento43 pagineSports Acousticssiddhant raoNessuna valutazione finora

- Presentation 1Documento26 paginePresentation 1Vaibhav Hireraddi100% (1)

- Planning Installation and Configuration Guide For Windows PDFDocumento228 paginePlanning Installation and Configuration Guide For Windows PDFmmilovanmNessuna valutazione finora

- Sri Lanka's Mineral Resources Can Enrich Country's CoffersDocumento139 pagineSri Lanka's Mineral Resources Can Enrich Country's CoffersPrashan Francis100% (3)

- Data Sheet 2.07 Issue A: Water Flow Detector Model: WFDENDocumento2 pagineData Sheet 2.07 Issue A: Water Flow Detector Model: WFDENOvidiu GavrilasNessuna valutazione finora

- Got 1000 Connect To Alpha 2Documento42 pagineGot 1000 Connect To Alpha 2supriyo110Nessuna valutazione finora

- Megger FORMDocumento1 paginaMegger FORMCOSMOPOLITAN M&ENessuna valutazione finora

- Serospin Operating Manual 20100407Documento19 pagineSerospin Operating Manual 20100407Verdana50% (2)

- Case CX210B Mine Crawler Excavator Tier 3 Parts Manual PDFDocumento701 pagineCase CX210B Mine Crawler Excavator Tier 3 Parts Manual PDFJorge Martinez100% (3)

- Ring OnlyDocumento2 pagineRing Onlyapi-3834777Nessuna valutazione finora

- Enzymatic Browning and Its Prevention-American Chemical Society (1995)Documento340 pagineEnzymatic Browning and Its Prevention-American Chemical Society (1995)danielguerinNessuna valutazione finora

- Oneccc Detection Assignment Grupo1.Ipynb - ColaboratoryDocumento9 pagineOneccc Detection Assignment Grupo1.Ipynb - ColaboratoryAna VelezNessuna valutazione finora

- JAN LOHFELDT vs. NEDBANK LTD - Cape Town High Court Judge Goliath (24.02.2014) & Judge Zondi (25.02.2014)Documento24 pagineJAN LOHFELDT vs. NEDBANK LTD - Cape Town High Court Judge Goliath (24.02.2014) & Judge Zondi (25.02.2014)willNessuna valutazione finora

- ASTM D 2726 - 05a Standard Test Method For Bulk Specific Gravity and DensityDocumento4 pagineASTM D 2726 - 05a Standard Test Method For Bulk Specific Gravity and DensityAzlan AbdNessuna valutazione finora

- Chapter 1 Engineering ManagementDocumento4 pagineChapter 1 Engineering ManagementGeorge Russell80% (5)

- Simple LED Flasher CircuitsDocumento5 pagineSimple LED Flasher CircuitsVivek BNessuna valutazione finora

- Elcometer Wet-Film Gage 115 Spec SheetDocumento2 pagineElcometer Wet-Film Gage 115 Spec SheetMary CasillasNessuna valutazione finora

- Op-Amp Comparator: Astable (Or Free-Running) Multivibrators Monostable MultivibratorsDocumento5 pagineOp-Amp Comparator: Astable (Or Free-Running) Multivibrators Monostable MultivibratorsYuvaraj ShanNessuna valutazione finora

- Captain Marvel (DC Comics) : Shazam! Navigation SearchDocumento34 pagineCaptain Marvel (DC Comics) : Shazam! Navigation SearchAce Orense Cupid Uranus Ace Sphinx Galzu Acetr444 son of Multiverses Chaos Gaeia Eros ACETR444Nessuna valutazione finora

- Qanooneislamorcu 00 JafaDocumento646 pagineQanooneislamorcu 00 JafaawNessuna valutazione finora

- Operation Manual: Impedance Audiometer AT235hDocumento102 pagineOperation Manual: Impedance Audiometer AT235hmendezoswaldoNessuna valutazione finora

- The War Archives - Machinery of Conflict. British Military Trucks of WWIIDocumento84 pagineThe War Archives - Machinery of Conflict. British Military Trucks of WWIISebastijan Kerše100% (10)

- 06 Scaffold Erection and Dismantling (JHA-JSA)Documento4 pagine06 Scaffold Erection and Dismantling (JHA-JSA)AmanNessuna valutazione finora

- Nursing Care Plan For HypertensionDocumento5 pagineNursing Care Plan For HypertensionJessy MalloNessuna valutazione finora

- Product Information: Traffic Management AccessoryDocumento12 pagineProduct Information: Traffic Management AccessoryCORAL ALONSONessuna valutazione finora

- Esquematicos CaterpillarDocumento9 pagineEsquematicos Caterpillarluis alberto rodriguez100% (1)

- CPE PRACTICE TEST 2 READINGDocumento4 pagineCPE PRACTICE TEST 2 READINGHong Anh0% (1)

- ImmortalDocumento4 pagineImmortalMaNithyaVishalanandaNessuna valutazione finora

- Network FYPDocumento3 pagineNetwork FYPla tahzanNessuna valutazione finora

- Satellite Communication Uplink Transmitter Downlink Receiver and TransponderDocumento2 pagineSatellite Communication Uplink Transmitter Downlink Receiver and TransponderTHONTARADYA CHANNELNessuna valutazione finora