Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Objectives: The Aggregate Impact Value Is Recommended Values

Caricato da

Mohamad Zahir RazakTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Objectives: The Aggregate Impact Value Is Recommended Values

Caricato da

Mohamad Zahir RazakCopyright:

Formati disponibili

CEG552

HIGHWAY & TRAFFIC ENGINEERING

AGGREGATE IMPACT TEST

OBJECTIVES

The objective of this study is to assess the

resistance of an aggregate to mechanical

degradation by the Aggregate Impact Test.

PROCEDURES

The apparatus consists of a steel test

mould with a falling hammer. The

hammer slides freely between vertical

guides so arranged that the lower part of

the hammer is above and concentric with

the mould.

INTRODUCTION

When a road aggregate has been manufacture to a specified grading it is

stockpiled, loaded into trucks, transported, tipped, spread and compacted. If the

aggregate is weak, some degradation may take place and result in a change in

grading and the production of excessive and undesirable fines. Thus, an

aggregate complying with a specification at the quarry may fail to do so when it

is in the pavement. Granular base layers and surfacings are subjected to

repeated loadings from truck tyres and the stress at the contact points of

aggregate particles can be quite high. These crushing tests can reveal

aggregate properties subject to mechanical degradation of this form.

DISCUSSION

1.

Prepare the material that is the

aggregate passing a 12.70mm sieve and

retained on a 9.52mm sieve. It shall be

clean and dry (wash if necessary) but it

must not be dried for longer than 4 hours

not at a temperature higher than 110 C

otherwise certain aggregates may be

damaged.

2.

Place the whole of the test sample

(mass A) in the steel mould into three

layers and compact the sample by a single

tamping of 25 strokes of the tamping rod.

3.

Deliver 15 blows of the hammer

dropping 381mm on the test sample, each

should be delivered at an interval not less

than one second.

4.

Sieve the crushed aggregate over a

2.36mm sieve.

5.

Weigh the fraction passing 2.36mm

to the nearest 0.1 g (mass B).

6.

Weigh the fraction retained on the

sieve (mass C). If the {A-(B+C)} > 1gram,

the result shall be discarded and a fresh

test made.

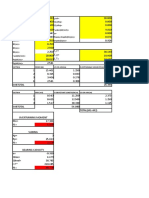

RESULT

Mass A = 281.4g

Mass B= 68.9g

Mass C= 211.6g

AIV=

The size of aggregates that used is 10mm with total weight of 2.5kg. The

Aggregate Impact Value is 24.48 % which is the recommended values is

between 20-30% . The classification is satisfactory for road surfacing.

Specified limits of percent aggregate impact value for different type of road

construction by Indian Road Congress is given for Aggregate Impact Value

not mora than 30 is bituminous surface dressing, penetration madacam,

x 100 %

68.9

281.4

x 100 % = 24.48 %

REFERENCE

1.

CONCLUSION

B

A

B+C= 280.5g

A-(B+C)= 281.4-280.5

=0.9 < 1g

2.

Ref. Standard Procedure:

Arahan Teknik (Jalan) 5/85

SS (1974). SS73:1974

Specification for methods for

sampling and testing of

mineral aggregates, sand

and fillers- Determination of

aggregate impact value,

aggregate crushing value

and ten percent fines value.

Singapore Standard,

Singapore.

Potrebbero piacerti anche

- Lecture Notes on Reinforced Concrete DesignDa EverandLecture Notes on Reinforced Concrete DesignNessuna valutazione finora

- Ceg552 Highway & Traffic Engineering Aggregate Impact Test Open Ended Lab Level 1 PreambleDocumento2 pagineCeg552 Highway & Traffic Engineering Aggregate Impact Test Open Ended Lab Level 1 Preamblenur syafieraNessuna valutazione finora

- Civil Vii Pavement Materials and Construction 10cv763 SolutionDocumento35 pagineCivil Vii Pavement Materials and Construction 10cv763 SolutionSaleem MohammedNessuna valutazione finora

- Ceg552 Highway & Traffic Engineering Practical #4.2: Aggregate Impact Test Open Ended Lab Level 0Documento3 pagineCeg552 Highway & Traffic Engineering Practical #4.2: Aggregate Impact Test Open Ended Lab Level 0saifulsabdinNessuna valutazione finora

- Aiv Test ReportDocumento6 pagineAiv Test Reportrus67% (6)

- Determination of Aggregate CrushingDocumento8 pagineDetermination of Aggregate CrushingPoovan Rajaratnam100% (2)

- TE Lab ManualDocumento104 pagineTE Lab Manualakhila100% (1)

- Lab ReportDocumento65 pagineLab ReportShah RulNessuna valutazione finora

- Aggregate Impact Test: Highway and Traffic Engineering ECG564Documento7 pagineAggregate Impact Test: Highway and Traffic Engineering ECG564SyukrinaNessuna valutazione finora

- Aggregate Impact Value TestDocumento5 pagineAggregate Impact Value TestKimi RusdiNessuna valutazione finora

- Aggregate Impact Value TestDocumento15 pagineAggregate Impact Value Testmd khajaNessuna valutazione finora

- TransportationmmDocumento25 pagineTransportationmmUaj AvhaNessuna valutazione finora

- Tribhuvan University Institute of EngineeringDocumento6 pagineTribhuvan University Institute of EngineeringManjesh MishraNessuna valutazione finora

- Transportation Engineering I Lab ReportsDocumento22 pagineTransportation Engineering I Lab ReportsSushrutNessuna valutazione finora

- Lab Tests On AggregatesDocumento15 pagineLab Tests On AggregatesYohan NyirendaNessuna valutazione finora

- Tranportation All ExperimentDocumento55 pagineTranportation All ExperimentMaiwand KhanNessuna valutazione finora

- For Highway Aggregate Crushing Value Lab Report (Ombz)Documento7 pagineFor Highway Aggregate Crushing Value Lab Report (Ombz)ombani100% (5)

- Transportation Engineering - I: (Laboratory Manual)Documento33 pagineTransportation Engineering - I: (Laboratory Manual)Faizan AlyNessuna valutazione finora

- Impact TestDocumento1 paginaImpact TestMohamad Zahir RazakNessuna valutazione finora

- Aggregate Crushing Value TestDocumento3 pagineAggregate Crushing Value TestCaroline MuthoniNessuna valutazione finora

- (COMPLETE) AIV and AbrasionDocumento10 pagine(COMPLETE) AIV and AbrasionAthirah DinataNessuna valutazione finora

- Adobe Scan 07-Feb-2024Documento2 pagineAdobe Scan 07-Feb-2024rajkumarmeena9462Nessuna valutazione finora

- Test of Aggregate Highway Engineering: Submitted byDocumento12 pagineTest of Aggregate Highway Engineering: Submitted byasad jibraanNessuna valutazione finora

- Test of Aggregate Highway Engineering: Submitted byDocumento12 pagineTest of Aggregate Highway Engineering: Submitted byasad jibraanNessuna valutazione finora

- Aggregates and Cement TestsDocumento31 pagineAggregates and Cement TestsAbdulsamadNessuna valutazione finora

- Transportation Lab ManualDocumento25 pagineTransportation Lab ManualAditi YadavNessuna valutazione finora

- CHAPTER 5 Unbound Pavement MaterialsDocumento26 pagineCHAPTER 5 Unbound Pavement MaterialszakariaNessuna valutazione finora

- Flakiness and Elongation TestDocumento6 pagineFlakiness and Elongation TestnoorshafiqNessuna valutazione finora

- Tre Lab ManualDocumento36 pagineTre Lab ManualRushi NaikNessuna valutazione finora

- Experience & Achievement:: Prof. Rajesh BhagatDocumento53 pagineExperience & Achievement:: Prof. Rajesh BhagatAdityaNessuna valutazione finora

- Highway and Transportation Engineering Lab Manual: June 2016Documento28 pagineHighway and Transportation Engineering Lab Manual: June 2016deepak khudaniaNessuna valutazione finora

- Tests On Aggregate: 1.crushing TestDocumento10 pagineTests On Aggregate: 1.crushing TestzeeshanNessuna valutazione finora

- Statistical Analysis of Tribological Performance of Functionally Graded Copper Composite Using DOEDocumento8 pagineStatistical Analysis of Tribological Performance of Functionally Graded Copper Composite Using DOEZamzam DiamelNessuna valutazione finora

- Tests On Aggregates MirriamDocumento10 pagineTests On Aggregates MirriamAllan SsemujjuNessuna valutazione finora

- PavementDocumento13 paginePavementmohanganeNessuna valutazione finora

- 7 Lab Tests On Aggregate To Check Quality For Use in Road Work - CivilblogDocumento11 pagine7 Lab Tests On Aggregate To Check Quality For Use in Road Work - Civilblogsmallik3Nessuna valutazione finora

- Experiment No 2 Crushing ValueDocumento5 pagineExperiment No 2 Crushing Valuefaiz19aaNessuna valutazione finora

- Assignment 3 Ce20m011Documento10 pagineAssignment 3 Ce20m011Mulani Parvez Raphik ce20m011Nessuna valutazione finora

- Chapter Six Highway Materials FinalDocumento85 pagineChapter Six Highway Materials FinalRahul RajaNessuna valutazione finora

- Aggregate Impact ValueDocumento7 pagineAggregate Impact ValueAisyah Ibrahim84% (25)

- Transportation LabDocumento23 pagineTransportation LabSiddharth kumar SinghNessuna valutazione finora

- LAB LESSON 2 Types of AggregatesDocumento5 pagineLAB LESSON 2 Types of AggregatesajaytrixNessuna valutazione finora

- AivDocumento4 pagineAivSyafiq YapNessuna valutazione finora

- OEL CEG552 Level 1 Aggregate Strength Test - Los Angeles Abrasion TestDocumento3 pagineOEL CEG552 Level 1 Aggregate Strength Test - Los Angeles Abrasion Testdarling you0% (1)

- AIV TestDocumento3 pagineAIV TestismailNessuna valutazione finora

- Determination of Aggregate Crushing ValueDocumento10 pagineDetermination of Aggregate Crushing ValueArivalagan Revichandran100% (1)

- Elongation IndexDocumento17 pagineElongation IndexNurul Ain MohdNessuna valutazione finora

- Unit 2 AggregateDocumento38 pagineUnit 2 Aggregatehrushikesh dhokaleNessuna valutazione finora

- Faculty of Engineering and Built Environment: Name Student's IDDocumento4 pagineFaculty of Engineering and Built Environment: Name Student's IDJonAthan LimNessuna valutazione finora

- Experiment No 02 (A)Documento3 pagineExperiment No 02 (A)Md Sabbir HossainNessuna valutazione finora

- PDHC Paper Solution (Winter 2021) : Q.1 (A) Explain The Term Effective CBR' 03 AnsDocumento38 paginePDHC Paper Solution (Winter 2021) : Q.1 (A) Explain The Term Effective CBR' 03 Ansaarjav112004Nessuna valutazione finora

- Highway Engg Lab ExperimentsDocumento9 pagineHighway Engg Lab Experimentskamalkumarbal77Nessuna valutazione finora

- Laboratory Manual - Tre - 2019-20Documento63 pagineLaboratory Manual - Tre - 2019-2019CE012 Anuraj Sadanand DharmeNessuna valutazione finora

- Highway Enginering TestsDocumento4 pagineHighway Enginering TestsanjaleebrcNessuna valutazione finora

- Transportation Engineering Lab ManualDocumento42 pagineTransportation Engineering Lab Manualउमेश गावंडे89% (9)

- Highway Lab Report (Full) PDFDocumento84 pagineHighway Lab Report (Full) PDFWai KiatNessuna valutazione finora

- Research Article: Dry Sliding Friction and Wear Studies of Fly Ash Reinforced AA-6351 Metal Matrix CompositesDocumento7 pagineResearch Article: Dry Sliding Friction and Wear Studies of Fly Ash Reinforced AA-6351 Metal Matrix CompositesKrishnan VelavanNessuna valutazione finora

- WSDOT FOP For ASTM C 1621/C 1621M: 1. ScopeDocumento8 pagineWSDOT FOP For ASTM C 1621/C 1621M: 1. Scopes s kattiNessuna valutazione finora

- Reinforced Concrete Buildings: Behavior and DesignDa EverandReinforced Concrete Buildings: Behavior and DesignValutazione: 5 su 5 stelle5/5 (1)

- Osd CalculationDocumento7 pagineOsd CalculationMohamad Zahir RazakNessuna valutazione finora

- Box CulvertDocumento3 pagineBox CulvertMohamad Zahir RazakNessuna valutazione finora

- OSD UndergroundDocumento14 pagineOSD UndergroundMohamad Zahir RazakNessuna valutazione finora

- Foundation Ch.8Documento42 pagineFoundation Ch.8Ilham HusseinNessuna valutazione finora

- Cross Section2 ModelDocumento1 paginaCross Section2 ModelMohamad Zahir RazakNessuna valutazione finora

- Retaining Wall Design ExampleDocumento8 pagineRetaining Wall Design ExampleJefferson Nobleza67% (3)

- Drawing ExampleDocumento1 paginaDrawing ExampleMohamad Zahir RazakNessuna valutazione finora

- Slide Presentation Bs and EcDocumento21 pagineSlide Presentation Bs and EcMohamad Zahir Razak100% (2)

- Graf Lusas NewDocumento5 pagineGraf Lusas NewMohamad Zahir RazakNessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 3.technology of PrestressingDocumento16 pagine3.technology of PrestressingMohamad Zahir RazakNessuna valutazione finora

- ᵩsoil= C1 (Kpa) = Q (Kn/M) C2 (Kpa) = ˠWater (Kn/M3) = Α= Passive Depth (D1) (M) = B1 (M) = Depth (D) (M) = B2 (M) = B3 (M) = B4 (M) = ˠSoil (Kn/M3) = Pa (Kn/M) = Pp (Kn/M) =Documento5 pagineᵩsoil= C1 (Kpa) = Q (Kn/M) C2 (Kpa) = ˠWater (Kn/M3) = Α= Passive Depth (D1) (M) = B1 (M) = Depth (D) (M) = B2 (M) = B3 (M) = B4 (M) = ˠSoil (Kn/M3) = Pa (Kn/M) = Pp (Kn/M) =Mohamad Zahir RazakNessuna valutazione finora

- Retaining Wall SpreadsheetDocumento5 pagineRetaining Wall SpreadsheetMohamad Zahir RazakNessuna valutazione finora

- AcknowledgementDocumento2 pagineAcknowledgementMohamad Zahir RazakNessuna valutazione finora

- British Standard CodeDocumento12 pagineBritish Standard CodeMohamad Zahir Razak100% (1)

- British Standard CodeDocumento12 pagineBritish Standard CodeMohamad Zahir Razak100% (1)

- Society UitmDocumento2 pagineSociety UitmMohamad Zahir RazakNessuna valutazione finora

- Lab Report Air ParticleDocumento2 pagineLab Report Air ParticleMohamad Zahir RazakNessuna valutazione finora

- Intro To FEM Lab (Aditional Lab Sheet) - 2Documento5 pagineIntro To FEM Lab (Aditional Lab Sheet) - 2saifulsabdinNessuna valutazione finora

- British Standard CodeDocumento12 pagineBritish Standard CodeMohamad Zahir Razak100% (1)

- Marketing PlanDocumento17 pagineMarketing PlanMohamad Zahir RazakNessuna valutazione finora

- Patching: Fatigue CrackingDocumento4 paginePatching: Fatigue CrackingMohamad Zahir RazakNessuna valutazione finora

- Discussion INDE TRUSSDocumento1 paginaDiscussion INDE TRUSSMohamad Zahir RazakNessuna valutazione finora

- Procedure of TorsionDocumento1 paginaProcedure of TorsionMohamad Zahir RazakNessuna valutazione finora

- Intro Ducti On To Comp: - AssignmentDocumento3 pagineIntro Ducti On To Comp: - AssignmentMohamad Zahir RazakNessuna valutazione finora

- OEL CEG552 Level 2 Texture Depth and Skid ResistanceDocumento1 paginaOEL CEG552 Level 2 Texture Depth and Skid ResistanceMohamad Zahir Razak0% (1)

- OEL CEG552 Level 1 Bitumen TestDocumento4 pagineOEL CEG552 Level 1 Bitumen TestMohamad Zahir RazakNessuna valutazione finora

- Strut StructureDocumento4 pagineStrut StructureMohamad Zahir RazakNessuna valutazione finora

- Flotation Control and OptimisationDocumento11 pagineFlotation Control and OptimisationAmalia PănescuNessuna valutazione finora

- Biophy-Lec (Mod1 - The-Basics) PDFDocumento18 pagineBiophy-Lec (Mod1 - The-Basics) PDFShekinah LeynesNessuna valutazione finora

- Automatic Railway Gate Control by Using Microcontroller - 24 PagesDocumento44 pagineAutomatic Railway Gate Control by Using Microcontroller - 24 PagesSebastin AshokNessuna valutazione finora

- Rieber Sealing in AmericaDocumento10 pagineRieber Sealing in Americaulloap*100% (1)

- Basic Concepts: Introduction To Composite DesignDocumento10 pagineBasic Concepts: Introduction To Composite DesignraviciviltNessuna valutazione finora

- Filetype PDF Photoconduction SemiconductorDocumento2 pagineFiletype PDF Photoconduction SemiconductorGregNessuna valutazione finora

- As 60034.22-2010 Rotating Electrical Machines AC Generators For Reciprocating Internal Combustion (RIC) EnginDocumento8 pagineAs 60034.22-2010 Rotating Electrical Machines AC Generators For Reciprocating Internal Combustion (RIC) EnginSAI Global - APAC100% (1)

- Review Module 24 Geotechnical Engineering 5 Part 2Documento2 pagineReview Module 24 Geotechnical Engineering 5 Part 2John Andre MarianoNessuna valutazione finora

- Thermal Calculation of Heat Exchangers With Simplified Consideration of Axial Wall Heat ConductionDocumento7 pagineThermal Calculation of Heat Exchangers With Simplified Consideration of Axial Wall Heat ConductionA.M.P.P. GUNARATHNANessuna valutazione finora

- SilverThin Slewing Rings and Pinions CatalogDocumento16 pagineSilverThin Slewing Rings and Pinions CatalogGanesh LohakareNessuna valutazione finora

- Chapter 05Documento49 pagineChapter 05bellaNessuna valutazione finora

- Sade-5tnqzd r12 enDocumento9 pagineSade-5tnqzd r12 enPop-Coman SimionNessuna valutazione finora

- ENGINEERING - MATHEMATICS - 2 VTU Syllabus PDFDocumento167 pagineENGINEERING - MATHEMATICS - 2 VTU Syllabus PDFAdarshNessuna valutazione finora

- Dooms Day and Life After Death PDFDocumento289 pagineDooms Day and Life After Death PDFGhulam Mustafa100% (1)

- CPRF Analysis PDFDocumento8 pagineCPRF Analysis PDFMohd FirojNessuna valutazione finora

- Identification of Textile Fiber by Raman MicrospecDocumento9 pagineIdentification of Textile Fiber by Raman MicrospecTesfayWaseeNessuna valutazione finora

- Velocity Analysis and Statics CorrectionsDocumento192 pagineVelocity Analysis and Statics CorrectionsKim PerezNessuna valutazione finora

- Musica Universalis First DraftDocumento78 pagineMusica Universalis First DraftWilliam1091Nessuna valutazione finora

- Thickening Agent - Wikipedia, The Free EncyclopediaDocumento5 pagineThickening Agent - Wikipedia, The Free EncyclopediaJohnNessuna valutazione finora

- Microfluidics Fluid Physics at The Nanoliter Scale PDFDocumento50 pagineMicrofluidics Fluid Physics at The Nanoliter Scale PDFDavid CoralNessuna valutazione finora

- Ionic Equilibrium - 1Documento18 pagineIonic Equilibrium - 1Aditya BajajNessuna valutazione finora

- Chapter - 4 - Design of Footings-2-Isolated FootingDocumento10 pagineChapter - 4 - Design of Footings-2-Isolated FootingAdisalem BelayNessuna valutazione finora

- Mechanical Castings Ppt-2Documento49 pagineMechanical Castings Ppt-2PubgArena 01Nessuna valutazione finora

- Calculating The System HeadDocumento9 pagineCalculating The System HeadSam Wing HongNessuna valutazione finora

- DC 53 CatalogDocumento4 pagineDC 53 CatalogHonza MičkaNessuna valutazione finora

- Workshop 3-3: Rectangular Patch Antenna: Introduction To ANSYS Electronics DesktopDocumento21 pagineWorkshop 3-3: Rectangular Patch Antenna: Introduction To ANSYS Electronics DesktopRodrigoNessuna valutazione finora

- Trial Mix Design Report PDFDocumento38 pagineTrial Mix Design Report PDFTimothy HughesNessuna valutazione finora

- Unit I - Force Analysis (9) : Systems and Tribology ConceptDocumento82 pagineUnit I - Force Analysis (9) : Systems and Tribology ConceptSaranNessuna valutazione finora

- Lifetime Calculation of Irregularly Oscillating Bearings in Offshore WinchesDocumento12 pagineLifetime Calculation of Irregularly Oscillating Bearings in Offshore WinchesNadav SharabiNessuna valutazione finora

- Practice Problems 4 and 5Documento3 paginePractice Problems 4 and 5shuckss taloNessuna valutazione finora