Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sae J287 1988 PDF

Caricato da

Jason RogersTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sae J287 1988 PDF

Caricato da

Jason RogersCopyright:

Formati disponibili

400 Commonwealth Drive, Warrendale, PA 15096-0001

SURFACE

VEHICLE

RECOMMENDED

PRACTICE

Submitted for recognition as an American National Standard

REAF.

JUN88

J287

Issued

Reaffirmed

1976-07

1988-06

Superseding J287 FEB80

(R) DRIVER HAND CONTROL REACH

ForewordThis document has not changed other than to put it into the new SAE Technical Standards Board

Format.

1.

ScopeThis recommended practice describes boundaries of hand control locations that can be reached by

desired proportions of different driver populations in passenger cars, multi-purpose passenger vehicles, and

light and medium trucks. This practice is not applicable to heavy trucks.

1.1

IntroductionThe description of driver hand control reach envelopes was developed using data acquired

from test subjects performing reach tasks in test fixtures simulating a range of actual vehicle configurations

(Reference 1 and 21). The test subjects included equal numbers of men and women selected to represent the

(United States) driving population on the basis of stature and age, and were tested both with and without

upper torso three-point restrain (a diagonal non-extending shoulder strap attached separately to the lap belt,

that is, not a continuous loop). The envelopes constructed using the non-extending shoulder and lap belt are

meant to define a restrained reach and the envelopes constructed using the lap belt only will describe an

unrestrained upper torso hand reach. The hand reach envelopes are three-dimensional surfaces described in

table form and can be referenced to a particular vehicle seating configuration according to procedures

described in Sections 5 and 6. Only the 95% boundaries are presented in the tables.

2.

References

2.1

Applicable PublicationsThe following publications form a part of the specification to the extent specified

herein. Unless otherwise indicated the latest revision of SAE publications shall apply.

2.1.1

SAE PUBLICATIONSAvailable from SAE, 400 Commonwealth Drive, Warrendale, PA 15096-0001.

1.

2.

3.

4.

SAE J182aMotor Vehicle Fiducial Marks

SAE J826 MAY87Devices for Use in Defining and Measuring Vehicle Seating Accommodation

SAE J1100 JUN84Motor Vehicle Dimensions

D. Hammond and R. Roe, SAE Controls Reach Study. Paper 720199 presented at SAE Automotive

Engineering Congress and Exposition, Detroit, January 1972.

5. D. Hammond, D. Maurer, and L. Razgunas, Controls ReachThe Hand Reach of Drivers. Paper

750357 presented at SAE Automotive Congress and Exposition, Detroit, February 1975.

6. R. W. Roe, Reach to Other Types of Controls. Minutes of meeting of Design Devices Subcommittee,

SAE Human Factors Engineering Committee, April 18, 1972.

1. See References Section under Applicable Publications for References.

SAE Technical Standards Board Rules provide that: This report is published by SAE to advance the state of technical and engineering sciences. The use of this report is entirely

voluntary, and its applicability and suitability for any particular use, including any patent infringement arising therefrom, is the sole responsibility of the user.

SAE reviews each technical report at least every five years at which time it may be reaffirmed, revised, or cancelled. SAE invites your written comments and suggestions.

QUESTIONS REGARDING THIS DOCUMENT: (412) 772-8512 FAX: (412) 776-0243

TO PLACE A DOCUMENT ORDER; (412) 776-4970 FAX: (412) 776-0790

SAE WEB ADDRESS http://www.sae.org

Copyright 1988 Society of Automotive Engineers, Inc.

All rights reserved.

Printed in U.S.A.

SAE J287 Reaffirmed JUN88

2.2

2.2.1

Related PublicationsThe following publications are provided for information purposes only and are not a

required part of this document.

SAE PUBLICATIONSAvailable from SAE, 400 Commonwealth Drive, Warrendale, PA 15096-0001.

SAE J1052 MAY87Motor Vehicle Driver and Passenger Head Position

SAE J1516 M AR90Accommodation Tool Reference Point

SAE J941 JUN92Motor Vehicle Drivers Eye Locations

3.

Definitions

3.1

Driver Hand Reach CapabilityThe maximum reach capability of drivers in a simulated driving situation with

the non-reaching hand on the steering wheel and the right foot on the accelerator pedal.

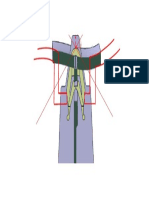

3.2

Basic Reach TaskThe hand reach to a forward mounted control with the control held in a three-finger grasp.

See Figure 1.

FIGURE 1

3.3

Hand Reach EnvelopesGeometric description of the hand reach capability for a specified proportion of a

driver population and type of torso restraint system. The contour of the hand reach envelope refers to the

geometric center of the control knob face. If the control knob face is at, or rearward of, the contour, it is

estimated that at least the specified proportion of the indicated driver population can reach and operate the

control. (See Reference1.)

-2-

SAE J287 Reaffirmed JUN88

3.4

Hand Reach Reference Plane (HR Plane)A vertical reference plane extending laterally across the vehicle

used to properly position the hand reach envelopes with respect to the geometry of the vehicle seating

configuration. The horizontal location of the HR plane rearward of the Accelerator Heel Point is determined by

application of the General Package Factor (G) as shown below:

HR = 786 ( 99 ) G, mm

3.5

(Eq. 1)

Interior DimensionsAll interior dimensions referred to in this recommended practice, except where noted,

are defined in SAE J1100aMotor Vehicle Dimensions. All dimensions are defined normal to the threedimensional reference system of the vehicle loaded to design load weight and oriented to a ground reference

plane using fiducial marks as described in SAE J182aMotor Vehicle Fiducial Marks.

The characteristics of seat geometry are described in terms of the two- and three-dimensional H-point devices

with 95 percentile leg length adjustments as described in SAE J826Devices for Use in Defining and

Measuring Vehicle Seating Accommodation. The interior dimensions are measured with the front seat in the

rearmost normal driving position as specified by the manufacturer. All other adjustable features, such as

steering wheel, seat height, or tilt adjustment for the seat back or seat cushion, are also located as specified by

the manufacturer, and if not specified will be positioned at a normal driving position.

3.5.1

GENERAL PACKAGE FACTOR (G)An algebraic equation that expresses and summarizes the geometry of a

particular vehicle seating configuration in terms of a single index value. See Figures 2 and 3. The range of

package dimensions for which this recommended practice is applicable is shown below:

TABLE 1

L40 Back angle-front

9.0 deg

H30 Vertical SgRP to heel pt

130 mm to 520 mm

33.0 deg

L23 Horizontal Hpt travel, SgRP

130 mm nominal

W9 Steering wheel diameter

330 mm to 600 mm

H18 Steering wheel angle

10.0 deg to 70.0 deg

L11 Horizontal steering wheel center 660 mm to 152 mm

H17 Vertical steering wheel center

530 mm to 838 mm

3.5.2

CENTERLINE OF OCCUPANT (C/LO)Centerline of occupant is the Y coordinate of the H-point and is

represented by the centerplane of the occupant or H-point machine in each designated seating position.

3.5.3

ACCELERATOR HEEL POINT (AHP)Accelerator heel point is located at the intersection of the two- or threedimensional device heel point and the depressed floor covering with the shoe on the undepressed

accelerator pedal and the foot angle at a minimum of 87 deg. For vehicles with SgRP to heel (H30) greater

than 457 mm, the accelerator pedal may be depressed as specified by the manufacturer. If the depressed

pedal is used, the foot must be flat on the accelerator pedal.

-3-

SAE J287 Reaffirmed JUN88

FIGURE 2

FIGURE 3

-4-

SAE J287 Reaffirmed JUN88

4.

Field of Application

4.1

This practice is primarily directed towards the initial design stages of a new vehicle program, where reference

to H-point or Rearmost H-point implies Rearmost Design H-point or Seating Reference Point (SgRP). Its

application for checking purposes in actual vehicles and prototype seat models will take into account an

allowable tolerance for actual H-point.

4.2

The hand reach envelopes are directly applicable to left hand drive motor vehicles designed for seated

operators in full width or single width seats having fore and aft seat adjustment approximately horizontal.

Application to right hand drive vehicles is assumed to be symmetrically opposite.

4.3

The hand reach envelopes are directly applicable for a three-finger grasping reach to a forward mounted

control knob of 25 mm diameter maneuvered horizontally in the fore-aft direction. The hand reach envelopes

are also applicable to other types of reach to forward controls by using an appropriate adjustment factor that

will account for the mode of operation at the control.

4.3.1

EXTENDED FINGER OPERATED CONTROLAn adjustment factor of 50 mm is added to the tabled values of the

reach envelope in order to describe the center of the finger pad contact surface which will be within the reach

of drivers.

4.3.2

FULL HAND GRASPED CONTROLSAn adjustment factor of 50 mm is subtracted from the tabled values of the

reach envelope in order to describe the center of the face of the control knob which will be within the reach of

drivers.

5.

Required Characteristics

5.1

The ranges of the interior dimensions for which this recommended practice is applicable are described in 3.5.

5.2

The envelopes describe the boundaries of control locations that can be reached by at least 95% of certain

driver populations that include mixtures of 50/50, 75/25, and 90/10 male to female driver population ratios. The

envelopes for each of these categories are described as referenced in a fore and aft direction to specified

seating coordinates. The envelopes extend from 400 mm outboard to 600 mm inboard of operator centerline

and from -100 mm below H-point to 800 mm above H-point. See Figure 4.

-5-

SAE J287 Reaffirmed JUN88

FIGURE 4

5.3

Hand reach envelopes are provided in the attached tables for seven different seating configurations, three male

to female driver population ratios and two types of restraint systems which account for drivers wearing a lap

belt only permitting a free upper torso and unrestrained reach; and secondly, both lap and shoulder belt

permitting only a restrained reach. The selection of an envelope for a vehicle is based on the calculated value

of the General Package Factor (G), identification of the male to female driver population appropriate for the

vehicle, and the identification of the appropriate restraint system. The General Package Factor (G) is

calculated using the dimensions describing the vehicle seating configuration as shown in Figures 2 and 3.

5.4

The Hand Reach Envelop is located in the vehicle by employing a relationship that utilizes the value of the

General Package Factor (G). The horizontal component of the envelopes is measured as a distance forward of

a Hand Reach Reference Plane. The fore and aft location of this plane rearward from the Accelerator Heel

Point is determined from the value of the General Package Factor (G) as shown in 3.4.

6.

Procedure for Using the Hand Reach Envelopes

6.1

The envelopes are located in the vehicle according to a set of orthogonal reference planes: A horizontal

elevation reference plane through the H-point of the rearmost normal driving position, the lateral HR plane, and

a vertical plane extending along the C/LO. See Figure 4.

6.1.1

Establish a reference origin.

6.1.1.1

Specify the dimensions describing the geometry of the vehicle seating configuration and calculate the

value of the General Package Factor (G) as described in Figure 3.

6.1.1.2

Calculate HR from the value of the General Package Factor (G) as shown in 3.4.

6.1.1.2.1

If (HR-L53) is less than zero, then the hand reach reference plane is located longitudinally at a distance

(HR) rearward of the Accelerator Heel Point.

6.1.1.2.2

IF (HR-L53) is greater than zero, the hand reach reference plane is located longitudinally at the H-point

of the rearmost normal driving position.

-6-

SAE J287 Reaffirmed JUN88

6.1.2

Identify the appropriate hand reach envelope.

6.1.2.1

Referring to the attached tables, identify the hand reach envelope appropriate for the value of the General

Package Factor (G) calculated for this vehicle, the specified driver population, and the appropriate type of

restraint system.

6.1.2.2

Determine the lateral locations of the controls of interest. These locations will be described as lateral

locations from the (C/LO). Determine the height of the control above the horizontal elevation reference

plane described in 6.1.

6.1.3

Determine if the control is within reach.1

1. The blank areas in the hand reach tables are regions where hand reach was not measured or where design limit values could not be established. The gray areas are regions where the difference between the hand reach model and the observed design limit values exceeded 25 mm.

The reach values shown in these areas should be used cautiously.

-7-

SAE J287 Reaffirmed JUN88

-8-

SAE J287 Reaffirmed JUN88

-9-

SAE J287 Reaffirmed JUN88

-10-

SAE J287 Reaffirmed JUN88

-11-

SAE J287 Reaffirmed JUN88

-12-

SAE J287 Reaffirmed JUN88

-13-

SAE J287 Reaffirmed JUN88

-14-

SAE J287 Reaffirmed JUN88

-15-

SAE J287 Reaffirmed JUN88

-16-

SAE J287 Reaffirmed JUN88

-17-

SAE J287 Reaffirmed JUN88

-18-

SAE J287 Reaffirmed JUN88

-19-

SAE J287 Reaffirmed JUN88

-20-

SAE J287 Reaffirmed JUN88

-21-

SAE J287 Reaffirmed JUN88

-22-

SAE J287 Reaffirmed JUN88

-23-

SAE J287 Reaffirmed JUN88

-24-

SAE J287 Reaffirmed JUN88

-25-

SAE J287 Reaffirmed JUN88

-26-

SAE J287 Reaffirmed JUN88

-27-

SAE J287 Reaffirmed JUN88

-28-

SAE J287 Reaffirmed JUN88

-29-

SAE J287 Reaffirmed JUN88

-30-

SAE J287 Reaffirmed JUN88

-31-

SAE J287 Reaffirmed JUN88

-32-

SAE J287 Reaffirmed JUN88

-33-

SAE J287 Reaffirmed JUN88

-34-

SAE J287 Reaffirmed JUN88

-35-

SAE J287 Reaffirmed JUN88

-36-

SAE J287 Reaffirmed JUN88

-37-

SAE J287 Reaffirmed JUN88

-38-

SAE J287 Reaffirmed JUN88

SAE J287 Reaffirmed JUN88

-40-

SAE J287 Reaffirmed JUN88

-41-

SAE J287 Reaffirmed JUN88

-42-

SAE J287 Reaffirmed JUN88

-43-

SAE J287 Reaffirmed JUN88

-44-

SAE J287 Reaffirmed JUN88

-45-

SAE J287 Reaffirmed JUN88

-46-

SAE J287 Reaffirmed JUN88

-47-

SAE J287 Reaffirmed JUN88

-48-

SAE J287 Reaffirmed JUN88

7.

Notes

7.1

Marginal IndiciaThe change bar (l) located in the left margin is for the convenience of the user in locating

areas where technical revisions have been made to the previous issue of the report. An (R) symbol to the left

of the document title indicates a complete revision of the report.

PREPARED BY THE SAE HUMAN ACCOMMODATION AND DESIGN DEVICES SUBCOMMITTEE

AND SPONSORED BY THE SAE HUMAN FACTORS COMMITTEE

-49-

SAE J287 Reaffirmed JUN88

RationaleSAE J287, revised February 1980, still provides the latest criteria on driver hand reach

capabilities. Considerations are being made to simplify the hand reach reference plane (HR plane)

procedure using SAE J1516Accommodation Tool Reference Point. This future update must be made

concurrent with other accommodation tool practices, SAE J941 and SAE J1052.

Relationship of SAE Standard to ISO StandardNot applicable.

ApplicationThis recommended practice describes boundaries of hand control locations that can be reached

by desired proportions of different driver populations in passenger cars, multi-purpose passenger

vehicles, and light and medium trucks. This practice is not applicable to heavy trucks.

Reference Section

SAE J182aMotor Vehicle Fiducial Marks

SAE J826 MAY87Devices for Use in Defining and Measuring Vehicle Seating Accommodation

SAE J1100 JUN84Motor Vehicle Dimensions

D. Hammond and R. Roe, SAE Controls Reach Study. Paper 720199 presented at SAE Automotive

Engineering Congress and Exposition, Detroit, January 1972.

D. Hammond, D. Maurer, and L. Razgunas, Controls ReachThe Hand Reach of Drivers. Paper

750357 presented at SAE Automotive Congress and Exposition, Detroit, February 1975.

R. W. Roe, Reach to Other Types of Controls. Minutes of meeting of Design Devices Subcommittee,

SAE Human Factors Engineering Committee, April 18, 1972.

Developed by the SAE Human Accommodation and Design Devices Subcommittee

Sponsored by the SAE Human Factors Committee

Potrebbero piacerti anche

- SAEJ1050Documento24 pagineSAEJ1050Karen StillNessuna valutazione finora

- SAE J1052 Motor Vehicle Driver and Passenger Head PositionDocumento13 pagineSAE J1052 Motor Vehicle Driver and Passenger Head PositionWilliam Venegas100% (1)

- Sae J826-2008Documento32 pagineSae J826-2008facu19840% (1)

- SAEJ198v001 PDFDocumento12 pagineSAEJ198v001 PDFandrefs7Nessuna valutazione finora

- Hyperlogic Heavy Metal 120x60 Skid System Quick Start Installation InstructionsDocumento17 pagineHyperlogic Heavy Metal 120x60 Skid System Quick Start Installation Instructionsapi-247828287Nessuna valutazione finora

- Simulation of Biaxial Wheel Test and Fatigue Life Estimation ConsideringDocumento9 pagineSimulation of Biaxial Wheel Test and Fatigue Life Estimation Consideringesmaeel ghafari100% (1)

- Handwheel To Road Wheel 730039V001Documento79 pagineHandwheel To Road Wheel 730039V001Dinesh Maheshwari100% (1)

- Booking Confirmation For Process Number 123782146Documento2 pagineBooking Confirmation For Process Number 123782146Jason RogersNessuna valutazione finora

- Crash Analysis 240509Documento39 pagineCrash Analysis 240509Jason RogersNessuna valutazione finora

- Digital Control System Analysis and Design 4th Edition by Phillips ISBN Solution ManualDocumento46 pagineDigital Control System Analysis and Design 4th Edition by Phillips ISBN Solution Manualraymond100% (23)

- HSM Info and CommandsDocumento17 pagineHSM Info and CommandsapmountNessuna valutazione finora

- Surface Vehicle Recommended Practice: Reaf. MAR90Documento11 pagineSurface Vehicle Recommended Practice: Reaf. MAR90WVPNessuna valutazione finora

- Sae J287 1988Documento50 pagineSae J287 1988bmartii100% (1)

- NX General PackagingDocumento4 pagineNX General PackagingRama BaruvaNessuna valutazione finora

- Surface Vehicle Recommended PracticeDocumento8 pagineSurface Vehicle Recommended Practicewilian_coelho3309Nessuna valutazione finora

- Surface Vehicle Recommended Practice: CAD Model For SAE J826 3-D H-Point MachineDocumento6 pagineSurface Vehicle Recommended Practice: CAD Model For SAE J826 3-D H-Point MachineNacho EuclidesNessuna valutazione finora

- Ergonomic Analysis of Motor VehiclesDocumento14 pagineErgonomic Analysis of Motor VehiclesdeyeNessuna valutazione finora

- Ergo HF 3Documento14 pagineErgo HF 3Marko BrkicNessuna valutazione finora

- RamsisDocumento10 pagineRamsishaw_gamerNessuna valutazione finora

- SAEJ1512 V 001Documento2 pagineSAEJ1512 V 001koalaboiNessuna valutazione finora

- Catia V5 Interview QuestionsDocumento2 pagineCatia V5 Interview Questionspriyankar007Nessuna valutazione finora

- Design and Crash Analysis of Passenger Car Frontal Bumper Beam Using Hypermesh and RadiossDocumento5 pagineDesign and Crash Analysis of Passenger Car Frontal Bumper Beam Using Hypermesh and RadiossAnup M UpadhyayaNessuna valutazione finora

- Saej 4003 V 001Documento42 pagineSaej 4003 V 001kyletgerberNessuna valutazione finora

- Vehicle Occupant PackagingDocumento12 pagineVehicle Occupant Packagingkalpesh.kkj100% (1)

- Design Driver Space For Large CarDocumento13 pagineDesign Driver Space For Large Cardhana555100% (1)

- Automotive Storage and PackagingDocumento68 pagineAutomotive Storage and PackagingViswanath AdithamNessuna valutazione finora

- International: 400 Cammonweal!H Drive. Warrendale. Pa 1Soss-Ooo1Documento21 pagineInternational: 400 Cammonweal!H Drive. Warrendale. Pa 1Soss-Ooo1WVPNessuna valutazione finora

- ISO 5700-2013 - Tractors For Agriculture and Forestry - Roll-Over Protective Structures - Static Test Method and AcceptanceDocumento44 pagineISO 5700-2013 - Tractors For Agriculture and Forestry - Roll-Over Protective Structures - Static Test Method and AcceptanceMohanrajMJNessuna valutazione finora

- SAE Seat Design OverviewDocumento16 pagineSAE Seat Design OverviewGuilherme PfeilstickerNessuna valutazione finora

- Surface Vehicle Recommended PracticeDocumento3 pagineSurface Vehicle Recommended PracticeVIGNESH KUMARNessuna valutazione finora

- ErgonomicsDocumento12 pagineErgonomicsBhavesh ShimpiNessuna valutazione finora

- Ergonomics Automotive PDFDocumento2 pagineErgonomics Automotive PDFCathyNessuna valutazione finora

- Pedestrian Safety ANSA mETA v2Documento3 paginePedestrian Safety ANSA mETA v2samisdr3946Nessuna valutazione finora

- 'Internship Report ' Seating SystemDocumento31 pagine'Internship Report ' Seating SystemMr NobodyNessuna valutazione finora

- Auto ErgonomicDocumento4 pagineAuto ErgonomicAnshul BediNessuna valutazione finora

- Ergonomics of Car Packaging Part 1Documento2 pagineErgonomics of Car Packaging Part 1Ejan AdinNessuna valutazione finora

- Surface Vehicle Standard: Coolant System HosesDocumento18 pagineSurface Vehicle Standard: Coolant System HosesAdriana SukmanaputraNessuna valutazione finora

- Techniques For Engine Mount Modeling and OptimizationDocumento164 pagineTechniques For Engine Mount Modeling and OptimizationSwapnil NarnavareNessuna valutazione finora

- Surface Vehicle Recommended Practice: (R) Biaxial Wheel Fatigue TestDocumento23 pagineSurface Vehicle Recommended Practice: (R) Biaxial Wheel Fatigue TestAdriana SukmanaputraNessuna valutazione finora

- Seat-Antisubmarine Performance SeatDocumento5 pagineSeat-Antisubmarine Performance SeatKarthik IyerNessuna valutazione finora

- Tractor Traction Wheels TyresDocumento14 pagineTractor Traction Wheels Tyresmehmed şahinNessuna valutazione finora

- 2005mustang SpecsDocumento37 pagine2005mustang SpecsTetsunari KodaNessuna valutazione finora

- Structural Optimization Automotive Chassis Heavy VehicleDocumento16 pagineStructural Optimization Automotive Chassis Heavy VehicleAnurag Singh PatelNessuna valutazione finora

- Ensayo de Asientos Segun SaeDocumento11 pagineEnsayo de Asientos Segun SaecawidNessuna valutazione finora

- Iso 3958Documento6 pagineIso 3958Eduardo AlfaroNessuna valutazione finora

- Double WishboneDocumento6 pagineDouble WishboneRian SteveNessuna valutazione finora

- Ada 431130Documento18 pagineAda 431130Tarık OlğarNessuna valutazione finora

- Surface Vehicle Recommended Practice: Driver Hand Control ReachDocumento31 pagineSurface Vehicle Recommended Practice: Driver Hand Control ReachTolga PekruNessuna valutazione finora

- BLN 9885BDocumento32 pagineBLN 9885Bseaqu3stNessuna valutazione finora

- SAEJ198 V 001Documento12 pagineSAEJ198 V 001Nijanthan G. VasudevanNessuna valutazione finora

- E1448Documento8 pagineE1448DannyChaconNessuna valutazione finora

- Economic Solution For Data Acquisition in A Formula SAE Race CarDocumento6 pagineEconomic Solution For Data Acquisition in A Formula SAE Race CarmclarenrulzNessuna valutazione finora

- Selección de BandasDocumento84 pagineSelección de Bandasrod3662Nessuna valutazione finora

- IJSTM17451382214600Documento14 pagineIJSTM17451382214600Viraj GaonkarNessuna valutazione finora

- Ais 018 2Documento15 pagineAis 018 2senguttuvelNessuna valutazione finora

- GFP21 TorsionalVibrationAnalysisDocumento4 pagineGFP21 TorsionalVibrationAnalysisRonald GeorgeNessuna valutazione finora

- R04706112117 PDFDocumento6 pagineR04706112117 PDFSantiago UrgilesNessuna valutazione finora

- V Belt Drive Selection HandbookDocumento84 pagineV Belt Drive Selection Handbookkripto uzmanıNessuna valutazione finora

- Steering StandardDocumento7 pagineSteering StandardAbinash KumarNessuna valutazione finora

- Design and Development of Hydro-Pneumatic Suspension SystemDocumento11 pagineDesign and Development of Hydro-Pneumatic Suspension SystemzhenyupanNessuna valutazione finora

- Design and Wind-Tunnel Analysis of A Fully Adaptive Aircraft ConfigurationDocumento9 pagineDesign and Wind-Tunnel Analysis of A Fully Adaptive Aircraft ConfigurationRicardo MinetteNessuna valutazione finora

- Car Templates 1Documento72 pagineCar Templates 1Anand KiranNessuna valutazione finora

- Car TemplatesDocumento68 pagineCar TemplatesFarhang Mohamadi100% (3)

- 5 - 15 - 2008 - 3 - 52 - 00 - PM86 Ais-097Documento18 pagine5 - 15 - 2008 - 3 - 52 - 00 - PM86 Ais-097Alexandru IordacheNessuna valutazione finora

- Sae Technical Paper Series: Kevin O'DeaDocumento17 pagineSae Technical Paper Series: Kevin O'DeaAmudha SivakumarNessuna valutazione finora

- Client Information - ZF INDIA PRIVATE LIMITED: Booking ConfirmationDocumento2 pagineClient Information - ZF INDIA PRIVATE LIMITED: Booking ConfirmationJason RogersNessuna valutazione finora

- HDFC ERGO General Insurance Company Limited: Policy No. 2320 1001 7259 2300 000Documento3 pagineHDFC ERGO General Insurance Company Limited: Policy No. 2320 1001 7259 2300 000Jason RogersNessuna valutazione finora

- Letter 1Documento1 paginaLetter 1Jason RogersNessuna valutazione finora

- HDFC ERGO General Insurance Company Limited: Policy No. 2320 1001 7259 2300 000Documento2 pagineHDFC ERGO General Insurance Company Limited: Policy No. 2320 1001 7259 2300 000Jason RogersNessuna valutazione finora

- HDFC ERGO General Insurance Company Limited: Policy No. 2320 1001 7259 2300 000Documento3 pagineHDFC ERGO General Insurance Company Limited: Policy No. 2320 1001 7259 2300 000Jason RogersNessuna valutazione finora

- HDFC ERGO General Insurance Company Limited: Policy No. 2320 1001 7259 2300 000Documento2 pagineHDFC ERGO General Insurance Company Limited: Policy No. 2320 1001 7259 2300 000Jason RogersNessuna valutazione finora

- Mohammad Mohiuddin: What'S The Balance On My Card?Documento3 pagineMohammad Mohiuddin: What'S The Balance On My Card?Jason RogersNessuna valutazione finora

- Powder CoatingDocumento36 paginePowder CoatingJason Rogers100% (1)

- Itp Piping PDFDocumento4 pagineItp Piping PDFdashNessuna valutazione finora

- Receipt 9862882Documento1 paginaReceipt 9862882Jason RogersNessuna valutazione finora

- Care-Reimbursement Claim FormDocumento11 pagineCare-Reimbursement Claim FormJason RogersNessuna valutazione finora

- HYD JD Lead Vehicle DesignerDocumento2 pagineHYD JD Lead Vehicle DesignerJason RogersNessuna valutazione finora

- Automotive Paint Michael OlveraDocumento7 pagineAutomotive Paint Michael OlveraJason RogersNessuna valutazione finora

- Application Note: Antenna Fundamentals: DiscussionDocumento4 pagineApplication Note: Antenna Fundamentals: DiscussioncorsairsanNessuna valutazione finora

- Bank ChequeDocumento1 paginaBank ChequeJason RogersNessuna valutazione finora

- Wajdi A. S. Khamayseh CV: Objectives and Resume SummaryDocumento5 pagineWajdi A. S. Khamayseh CV: Objectives and Resume SummaryJason RogersNessuna valutazione finora

- Tool TestDocumento2 pagineTool TestJason RogersNessuna valutazione finora

- Sae J449a 1963Documento4 pagineSae J449a 1963Jason RogersNessuna valutazione finora

- Market Study of Paint IndustryDocumento9 pagineMarket Study of Paint IndustryJason RogersNessuna valutazione finora

- Clip Tower Cut OutsDocumento1 paginaClip Tower Cut OutsJason RogersNessuna valutazione finora

- By Authority of Legally Binding Document: The United States of AmericaDocumento10 pagineBy Authority of Legally Binding Document: The United States of AmericaJason RogersNessuna valutazione finora

- Parallel ArchitecturesDocumento56 pagineParallel ArchitectureskalscribNessuna valutazione finora

- Sae J902a 1967Documento5 pagineSae J902a 1967Jason RogersNessuna valutazione finora

- Part and Mold Design Guide (2005)Documento174 paginePart and Mold Design Guide (2005)naitikpanchal100% (4)

- Designing Plastic Components - QMRplasticsDocumento10 pagineDesigning Plastic Components - QMRplasticsClara PereiraNessuna valutazione finora

- Workholding 1 321methodDocumento31 pagineWorkholding 1 321methodJason RogersNessuna valutazione finora

- Transmission 240509Documento25 pagineTransmission 240509Jason RogersNessuna valutazione finora

- Chapter 1-Part 1: Half-Wave RectifiersDocumento50 pagineChapter 1-Part 1: Half-Wave RectifiersWeehao SiowNessuna valutazione finora

- PumpsDocumento8 paginePumpskannagi198Nessuna valutazione finora

- Digital Microelectronic Digital Microelectronic Circuits Circuits ( (Documento24 pagineDigital Microelectronic Digital Microelectronic Circuits Circuits ( (Gowtham HariNessuna valutazione finora

- Experiment: Measurement of Power in Three Phase Balanced LoadDocumento2 pagineExperiment: Measurement of Power in Three Phase Balanced LoadTripti GuptaNessuna valutazione finora

- AC Commutator Motors Repulsion Series Motor UniversalDocumento3 pagineAC Commutator Motors Repulsion Series Motor UniversalwhrferNessuna valutazione finora

- Norma JIC 37Documento36 pagineNorma JIC 37guguimirandaNessuna valutazione finora

- UserDocumento150 pagineUserRahul ShardhaNessuna valutazione finora

- 6 DZM 24Documento1 pagina6 DZM 24Wai Phyoe AungNessuna valutazione finora

- HVAC Control in The New MillenniumDocumento389 pagineHVAC Control in The New Millenniumnicky1213aNessuna valutazione finora

- Uncertainty in Tensile TestDocumento11 pagineUncertainty in Tensile TestDavidAlejandroGaonaNessuna valutazione finora

- KPS Alignment Procedure & FormulaDocumento4 pagineKPS Alignment Procedure & FormulaWidhyatmika RestuNessuna valutazione finora

- Act MCQDocumento10 pagineAct MCQKARTHICKNessuna valutazione finora

- Control Systems Design ProjectDocumento3 pagineControl Systems Design ProjectHasan ÇalışkanNessuna valutazione finora

- A Study of Metro Manilas Public Transportation SeDocumento19 pagineA Study of Metro Manilas Public Transportation Segundranken08Nessuna valutazione finora

- Practical Exercise 02Documento17 paginePractical Exercise 02FeRro ReniNessuna valutazione finora

- Engineering Materials CE-105: ConcreteDocumento27 pagineEngineering Materials CE-105: Concretenasir khanNessuna valutazione finora

- Resultat 50 Infos - KrnageDocumento1 paginaResultat 50 Infos - Krnagesarbalice39Nessuna valutazione finora

- ASAM XIL Release-Presentation V2-2-0Documento34 pagineASAM XIL Release-Presentation V2-2-0Arsalan KhanNessuna valutazione finora

- No Load Test: ObjectiveDocumento5 pagineNo Load Test: ObjectiveyashNessuna valutazione finora

- Molten Salt Heat Storage PDFDocumento20 pagineMolten Salt Heat Storage PDFchuckhsu1248Nessuna valutazione finora

- A Compendium of Blog Posts On Op Amp Design Topics: by Bruce TrumpDocumento37 pagineA Compendium of Blog Posts On Op Amp Design Topics: by Bruce TrumpJustine ManningNessuna valutazione finora

- 3Documento8 pagine3K@mR@N D@uD P@nHw@RNessuna valutazione finora

- API TutorialDocumento22 pagineAPI TutorialKomarudinNessuna valutazione finora

- Choking vs. Clutch Performance: A Study of Sport Performance Under PressureDocumento19 pagineChoking vs. Clutch Performance: A Study of Sport Performance Under Pressuremensrea0Nessuna valutazione finora

- First Quarter Summative Test in Math 7Documento2 pagineFirst Quarter Summative Test in Math 7Lemanuel097 FloresNessuna valutazione finora

- Wear and Corrosion Properties of AISI 420 Martensitic Stainless Steel Treated by Active Screen Plasma Nitriding PDFDocumento9 pagineWear and Corrosion Properties of AISI 420 Martensitic Stainless Steel Treated by Active Screen Plasma Nitriding PDFsaltbathNessuna valutazione finora

- Software Testing Lab Manual 3Documento50 pagineSoftware Testing Lab Manual 3Arya RajuNessuna valutazione finora