Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Design of Embedded Motor Protections

Caricato da

shalu29Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Design of Embedded Motor Protections

Caricato da

shalu29Copyright:

Formati disponibili

215

CHAPTER 7

DESIGN AND IMPLEMENTATION OF

EMBEDDED MOTOR PROTECTION SCHEME

7.1

INTRODUCTION

The three phase squirrel cage induction motors are widely used in

industries due to their reliability, low cost and robustness and hence treated as

work horses of industry. But the possibility of faults is unavoidable. Two

kinds of faults occur on induction motors: mechanical or electrical ones.

Measurement of signals such as currents, voltages, speed, vibrations and

temperature can supply relevant information about faults. This thesis deals

with the diagnosis of electrical faults by mean of current and voltage

measurements only. Motors are critical components for electrical utilities and

process industries. A motor failure can result in the shut down of a generating

unit or production line or require that redundant plant be utilized to

circumvent the problem. Whatever be the consequences of failure, such

events are undesirable since they constitute a decrease in overall system

reliability and additional demands on manpower, finance and time in order to

rectify the problems.

On line detection of the electrical failure mode in its earliest stage is

crucial to promote safe and economical use of ac machines in industrial

applications. Fault location would not only increase the speed of the repairs,

but would also permit more optimal scheduling of the repair outage.

216

Protective functions of an induction motor are mainly intended to prevent

over heating of its windings. Due to electrical faults there is increasing in

overheating of the windings.

This thesis describes a method to detect and protect faults in a

squirrel cage induction motor that does not require any special sensors. Only

conventional current and voltage transformers are used. The method is very

sensitive, fast and detects faults while running and before start. The method is

verified by a microprocessor based prototype.

7. 2

ON LINE MONITORING AND FAULT DETECTION

Three phase induction motors are the most widely used electrical

machines in industry. In an industrialized nation, they can typically between

40 to 50% of all the generated capacity of that country. Reliability based

maintenance (RBM) and condition based maintenance (CBM) strategies are

now widely used by industry and health monitoring of electrical drives is a

major feature in such progress. Many operators use CBM strategies in parallel

with conventional planned maintenance schemes. This can reduce unexpected

failures and downtime, increase the time between planned shutdowns for

standard maintenance, reduce maintenance and operational costs. The

operation of electrical machines in an unsafe condition can also be avoided.

There are various factors that need to be considered when selecting

the most appropriate monitoring technique for application in the industrial

environment and given below:

i)

Sensor should be noninvasive.

ii)

Sensor and instrumentation system must be reliable.

iii)

The diagnostics must be reliable.

217

iv)

The severity of the problem should be quantified.

v)

Estimation of remaining run-life referred to as Prognosis

should be given.

vi)

A prediction of the fundamental cause of the problem, referred

to as root cause analysis (RCA) should be provided via online information from sensors etc.

Induction motor performance can be greatly enhanced through the

use of condition monitoring and diagnostics. These are important issues in

power and power electronic systems since they can greatly improve

reliability, availability and maintainability in a wide range of sensitive

applications. Furthermore, the addition of condition monitoring functions to

existing systems need not be expensive or complicated. Existing sensors and

hardware can provide a vast array of system information that has traditionally

not been used.

Traditional monitoring of motors consists only of protection. This

means that typically, a motor is protected from an overload condition by an

overload relay that monitors the current and estimates the temperature of the

machine windings usually in a very crude way. Only in expensive or sensitive

load applications the condition monitoring is extended to include fault

prediction. Traditionally sensors are added to motors to detect specific faults.

Fault prediction system indicates any failure occur in the motor

prior to shut down so that the preventive maintenance can be performed

easily. Protection and fault prediction therefore are philosophically quite

different. When both are used with sensible preventative maintenance, low

operating costs and high availability rates can both be achieved.

In the

developed embedded protection scheme, both fault detection and protection

are combined in one assembly.

218

7.3

MOTOR PROTECTION SYSTEM

7.3.1

General Requirements

Motor protection should be simple and economical. Cost of

protective system should be within 5% of motor cost. The motor protection

should not operate during starting and permissible overloads. The choice of

motor protection scheme depends upon the following:

i)

Size of motor, rated kW.

ii)

Type: squirrel cage or wound rotor.

iii)

Type of starter, switchgear and control gear.

iv)

Cost of motor and driven equipment.

v)

Importance of process, whether essential service motor or not?

vi)

Type of load, starting currents, possible abnormal conditions

etc.

7.3.2

Occurrences of faults during operation

The occurrences of faults in induction motor during operation are

summarized below:

i)

Prolonged overloading: It is caused by mechanical loading

and short time cyclic overloading.

ii)

Single phasing: One of the supply lines gets disconnected due

to blowing of a fuse or open circuit in one of the three supply

connections.

iii)

Stalling: If the motor does not start due to excessive load, it

draws heavy current. It should be immediately disconnected

from supply.

219

iv)

Stator earth faults: Faults in motor winding are mainly

caused by failure of insulation due to temperature rise.

v)

Phase to phase faults: These are relatively rare due to enough

insulation between phases. Earth faults are relatively more

likely occurring faults.

vi)

Inter-turn faults: These grow into earth faults. No separate

protection is generally provided against inter-turn faults.

vii) Rotor faults:

These are likely to occur in wound rotor

motors, due to insulation failure.

viii) Failure of bearing: This will cause locking up of rotor. The

motor should be disconnected. Bearing should be replaced.

ix)

Unbalanced supply voltage: This will cause heating up of

rotor due to negative sequence currents in motor stator

winding.

x)

Supply under voltage: The under voltage supply cause

increase in motor current for the same load.

xi)

Fault in starter or associated circuit: The choice of

protection for a motor depends upon the size of the motor, its

importance in the plant and nature of load.

7.3.3

Protection of Low Voltage Induction Motor

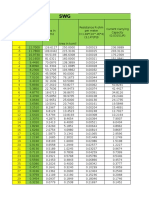

These are most widely used industrial motors. Table 7.1 shows the

protection chart for induction motors used in industries. Table 7.1 shows that

separate devices are used for protecting individual faults. Instead of it, if a

common, single protecting device is used to protect all the above faults then it

will be very economical protection for low voltage motors. Considering the

above, a low cost, integrated, digital protection scheme is developed and

implemented in this thesis.

220

Table 7.1 Protection chart for induction motors

Abnormal

Condition

Alternate forms of

protection from which

Remarks

choice is made

Overloads

Over load release

Thermal overload relays

Over load protection give for almost all motors

should not trip during starting currents

Inverse over current relays

Miniature circuit breaker

with build in trip coils

Phase faults and HRC fuses

earth faults

High set instantaneous

Over current relays

Differential protection becomes economical for

motors above about 1000 kW. Below this, high

set instantaneous protection is preferred

Differential protection

Under voltage

Unbalanced

voltage

Under voltage release

Under voltage release incorporated with every

starter

Under voltage relays

Under voltage relay is used in certain

applications.

Negative phase sequence Only in special applications

relays

Reverse phase Phase reversal protection Generally at supply point

sequence

Prevents reversal of running.

Single phasing Usual thermal overload Recently developed static single phasing

relays

devices becoming popular

Special

single

phase Unbalance protection

preventer

Stalling

Thermal Relays

Instantaneous Trips

Instantaneous O.C. Relays

Rotor Faults

Instantaneous over current Only for wound rotor motors

relays

Switching

surges

RC surge suppressor

100ohm, 0.1A connected between phase and

ground.

221

7.3.4

Evolution of Protective Relays

Historically, the hardware evolution of protective relays experienced

three technologies as shown in Figure 7.1. Electromechanical relays work on

the principle of magnetic fields revolving the internal disks in the relay. If the

current was high enough for specific period of time the disks would rotate to

trip the circuit. Although this was an effective relay, it had some drawbacks.

Since it was susceptible to mechanical failure and trip time were determined

by the physical properties of the disk which are size, weight and resistance.

Electromechanical relays

Early 20th century to

present day

Solid state relays

1960s to 1980s

Digital relays

1980s to present day

Figure 7.1 Evaluation of protective relays

Present day, solid state analog relays are technically outdated

because they are missing a number of additional features on demand today.

Some of its problems are lack of flexibility, limited accuracy and limited

dynamic range, metering and curve, communication impossible, large size

and difficult to find necessary components. Due to these disadvantages,

digital relays were employed to develop new products with improved

flexibility to meet specific customer requirements.

Digital Relays are based on digital signal processing. The voltage

and current are converted to discrete data and then relevant algorithms are

used to calculate the result for protection. In order to detect and isolate the

fault accurately and quickly, voltage and current data need to be acquired at

high speed on large number of input data in real time. Most of the digital

protection relays designers concerned about the trade off in using FPGA

222

based or microcontroller (MC) based relays. Although FPGA based relay

offers better cost over performance ratio, the microcontroller based relay

offers better price with acceptable performance. When compared with

electromechanical relays many more features are included in the modern

microcontroller based motor protection device. The mean time to repay

(MTTR) for microcontroller based relays is likely to be much better than its

electro mechanical counterpart.

7.3.5

Merits and Demerits of Microcontroller Based Relay

Microcontroller based relays are able to process the measured data

(i.e current, voltage, status indication etc) in many different ways. Registered

data in the relay can be sent through a communication network to the

operation / engineering head quarters for continuous monitoring or fault

analysis. The relays together with CTs and VTs can therefore be utilized by

other departments (maintenance, planning, etc.,) in addition to the main task

of motor protection.

The merits and demerits of microcontroller relays compared to

electro mechanical relays are given below:

Merits of Microcontroller based Relays

i)

Lower cost, especially when many functions are used

ii)

Less wiring, lower installation costs

iii)

Self checking diagnostics

iv)

Immediate alarm for most component failures

v)

Greater flexibility to implement custom protection schemes

vi)

Digital fault recording capabilities for post-fault analysis

vii)

Event recording capabilities for post-fault analysis

223

viii) Ability to dynamically change protection schemes

ix)

Less routine maintenance testing required.

Demerits of Microcontroller based Relays

7.4

i)

Generally more susceptible to surge-related failures.

ii)

Generally less able to tolerate high temperatures.

iii)

More numerous and complex settings.

iv)

Test switches are usually not integral to the relay.

SALIENT FEATURES OF THE DEVELOPED PROTECTION

SYSTEM

Features of the developed protection system are given below:

i)

Protection of motors and equipments from operator abuse.

ii)

Protection of personnel from shock hazards due to winding

shorts or earth leakage current from moisture.

iii)

Complete protection is provided using both voltage and

current measurements. Thus allowing maximum motor

utilization with minimum down time for all AC motors.

iv)

Fault prediction and protection is combined together.

v)

Knowledge of detailed machine or bearing parameters are not

necessary

7.5

OVERALL BLOCK DIAGRAM

The overall block diagram of the proposed motor protection system

is shown in Figure 7.2. PIC16F877 block stands for PIC16F877 chip, which is

developed by Microchip Co. US. Since it adopts RISC (Reduced Instruction

224

Set Computing) as kernel structure, it behaves more excellent than the

average 8-bit single chip. Meanwhile, it is easy to learn and supports ICD (In

Circuit Debug). Voltage and current measuring circuit blocks stand for

relative measuring circuits. The measured results are transmitted to

corresponding pins of PIC chip through interface circuit, which is designed to

interface the measuring circuit and microcontroller.

Figure 7.2 Overall block diagram of protection system for three

phase induction motor

Protecting circuit block represents the corresponding protecting

circuit. Once needed, the microcontroller will output an operating signal, the

protecting devices act immediately and correctly to protect the motor, by

operating the drive circuit. The keyboard block and display block are also

given. User can use keyboard to set the reference values and observe the fault

status of the motor through display block.

The setup consists of current transformer, potential transformer, and

relay and contactor unit along with PIC microcontroller. Initially, PIC micro

225

controller is programmed using MPLAB development tool based on the

values obtained from fault analysis shown in Table 7.2. Once micro controller

is programmed the complete hardware setup is developed as shown in

Figure 7.2. The current transformer (CT) and potential transformer (PT) are

used for monitoring line current and line voltage under running condition.

The data gathered from current transformer (CT) and potential

transformer (PT) are transferred to the micro controller digitally by passing

through the current and voltage measuring circuits. The PIC 16F877 micro

controller having in build analog to digital (ADC) converter. So, no need of

external ADC unit. Normally PIC microcontroller A/D converter (ADC) is

capable of processing an input, which is less than 5V signal. So, sensors

should be selected as per the controller design value.

The needed comparisons are made in micro controller according to

limit values, which are previously entered or programmed. When an

unexpected situation is encountered, the motor is being stopped by means of

the control signal. The reference values of the motor are entered through the

keypad and the output values such as load current, type of fault, etc., are

displayed using a LED seven segment display unit. The motor parameters

like the full load current in amperes, service factor and class of motor, etc.,

are needed to be entered into the relay programming unit to automatically

calculate the correct motor protection curve.

The following protective functions are provided by this system:

i)

Over load / Over current (OL)

ii)

Voltage unbalance (UB)

iii)

Under voltage (UV)

iv)

Over voltage(OV)

226

v)

Phase reversal (PR)

vi)

Single phasing (SP)

vii)

Current unbalance (CU)

viii) Locked rotor(LR)

7.6

ix)

Instantaneous current (IC)

x)

Stall (ST)

OBSERVATIONS FROM FAULT ANALYSIS

The simulation results of the fault motor and healthy motor are in

agreement with the reported results using test set up. Based on the results of

this study, the condition monitoring of induction machines is proposed.

Table 7.2 shows the value obtained from electrical fault analysis of induction

motor and their permissible value, which is used for hardware implementation

of protection system.

Table 7.2 Observations from fault analysis

Faults

Unbalanced Supply

Voltage

Current Unbalance

1% to 5%

1% to 5%

Up to 45%

Over current

2 Times rated current

Frequency

Up to 60 Hz

Motor will run up to 75 %

of its rated Load.

Motor will run in reverse

direction

Upto 30%

Upto 20%

Upto 2A

Up to 40%

1.5 Times rated

current

------

Single Phasing

Phase Reversing

Under Voltage

Over Voltage

Ground Fault

Tolerable Value

Permissible Value

Not Permitted

Not Permitted

Upto 20%

Upto 10%

Upto 1 A

227

7.7

CHARACTERISTICS OF MOTOR PROTECTION RELAY

To evaluate the more protection needs, there are many important

characteristics that need to be considered:

i)

The starting current of a motor remains constant until near

running speed, where it drops to the running current level.

ii)

The starting current does not change with the type of load on

the motor, but the time duration changes according to the

inertia of the driven load.

iii)

It takes between 25 and 30 sec for a typical motor winding to

reach a 140C rise over ambient temperature at locked rotor

current condition.

iv)

The heat transfer rates from winding to housing and from

housing to free air are different when the motor is running and

when it is stopped.

v)

The time constant of the motor depends on its size.

vi)

During transient conditions, such as during a motor start, there

is a sudden increase in the motor winding temperature.

vii) Current phase unbalance or phase loss causes additional heat

built up in the motor winding.

This generated heat is

proportional to the size of the motor.

viii) Ground faults in the winding should be cleared quickly to

minimize equipment damage and without affecting the rest of

the power system.

ix)

The motor with 1.15 service factor has a higher full load

current than the same motor with 1.00 service factor, even

though the starting current is the same.

x)

The ratio of starting current to the full load current is higher

for energy efficient than standard efficiency motors.

228

The characteristic of the motor application are shown in Figure 7.3

with the starting current of an induction motor. In the motor application,

definite time and instantaneous elements provide protection for faults in the

motor leads and internal faults in the motor itself. A definite time setting of

about 6 cycles allows the pickup set to 1.2 to 1.5 times locked rotor current to

avoid tipping on the initial inrush current. The instantaneous element can then

be set at twice the locked rotor current for fast clearing of high fault currents.

Figure 7.3 Motor Characteristics

7.8

HARDWARE DESCRIPTION

The Microcontroller based motor protection system combines

control, monitoring and protection function of induction motor from incipient

faults in one assembly setup. The system provides unbalanced supply voltage,

over current / overload, Phase reversing, single phasing, under and over

voltage and ground fault protection schemes. The controller of the system is

implemented using PIC 16F877 microcontroller.

The input data (Limit

values) to the system is given through the keypad. LED Seven Segment

display unit is used as an output device to display the output data, warning

229

message and fault condition. The system works with any motor design with

high degree of accuracy. The method is very sensitive, fast and detects faults

while running and before start. The prototype model is developed and tested

on a three phase induction motor with rated current of 5A and the test results

are satisfying the design criteria.

The maximum allowable under voltage unbalance and over voltage

unbalance is 5%. When the limits are exceeded, controller generates trip

signal, which in turn switch off the induction motor and display warning

message as unbalanced voltage fault and hence induction motor is protected

from heavy unbalancing condition. Similarly other faults are monitored and

induction motor is protected from those faults. The overall circuit diagram of

the protection scheme is shown in Figure 7.4.

The device has two modes of operation setting mode and monitoring

mode. If the device is on setting mode, the user is able to adjust the parameter

according to his application; else the device will be on monitoring mode were

the three phase motor currents and voltages are monitored by current

transformers (CT) and voltage transformers (PT). CT outputs (distorted sine

wave signal proportional to the load current) and PT outputs (voltages) are fed

the low pass filter module. LPF filters the 13th harmonics and above. RMS

module converts the waveforms to DC proportional to its RMS value. The

digitized signals are used to check all the protection schemes taking into

consideration of the users adjusted values.

Figure 7.4 Over all circuit diagram of the protection scheme

230

231

7.8.1

Power Supply

Circuit diagram of a typical power supply used in this system is

shown in Figure 7.5. The transformer steps down the ac voltage to the level of

the desired dc output. A diode rectifier then provides a full-wave rectified

voltage that is initially filtered by a simple capacitor filter to produce a dc

voltage. This resulting dc voltage is given to the IC voltage regulator circuit

which provides a dc voltage with less ripple and constant dc value.

Figure 7.5 Circuit diagram of power supply

7.8.2

Current and potential transformers

phase supply line. The turn ratio used for current transformer used here is

1000:1 A. The potential transformer is used to monitor the input three phase

supply voltage. The turns ratio of potential transformer used in this system is

400: 5V. This transformer will give the output in the range of 5V to the

voltage sensing circuits.

Fig.10.4 Over all Circuit Diagram of

The current transformer is used to monitor input current of three

232

7.8.3

Current and voltage sensing circuits

The current sensing circuit using LM 358 is shown in Figure 7.6. The

output from the current transformer is measured by this current sensing unit.

The output range of current sensing unit is from 0 V to 5V. The three phase

supply voltage is monitored by potential transformer, whose output is sensed

and measured by voltage sensing circuit as shown in Figure 7.7.

Figure 7.6 Current sensing circuit using LM 358

Figure 7.7 Voltage sensing circuit using LM 358

233

7.8.4

Zero Crossing Detectors

The zero crossing detectors are used in protection system to identify

the phase reversing fault which occurs in supply side. Figure 7.8 shows the

zero crossing detector using LM 358 IC. The input from current transformer

is applied to RC ladder filter circuit. Then filtered output is given to IC LM

358, which is low power dual operational amplifier. The phase reversing fault

is identified when any two of three phases RYB is reversed, then zero

crossing detector will measure this effect and pass information to micro

controller which in turn generate trip signal to relay unit.

Figure 7.8 Zero Crossing Detector

7.8.5

Specifications of Induction Motor

The three phase squirrel cage induction motor under test has the

following specifications.

i)

Power rating

2.2 KW

ii)

Line Voltage

400 V

iii)

Rated current

4.6A

iv)

Frequency

50Hz

v)

Number of Poles

vi)

Rated Speed

1440 rpm

234

7.8.6

vii) Connection

Delta

viii) Class Type

PIC 16F877 Microcontroller

The embedded micro controller used for protection system is PIC

16F877. This micro controller having inbuilt flash memory and ADC. The

micro controller has the following core and peripheral features:

i)

Microcontroller Core Features

High-performance RISC CPU

Only 35 single word instructions to learn

Operating speed: DC - 20 MHz clock input

Up to 8K x 14 words of FLASH Program Memory

Up to 368 x 8 bytes of Data Memory (RAM)

Up to 256 x 8 bytes of EEPROM data memory

Direct, indirect and relative addressing modes

Power-on Reset (POR), Power-up Timer (PWRT) and

Oscillator

Start-up Timer (OST)

Watchdog Timer (WDT) with its own on-chip RC

Programmable code-protection

Power saving SLEEP mode

Low-power,

technology

high-speed

CMOS

FLASH/EEPROM

235

Wide operating voltage range: 2.0V to 5.5V

Commercial and Industrial temperature ranges

Low-power consumption

ii)

Peripheral Features

Timer 0: 8-bit timer/counter with 8-bit pre scalar

Timer 1: 16-bit timer/counter with pre scalar, can be

incremented during sleep via external crystal/clock

Timer 2: 8-bit timer/counter with 8-bit period register, pre

scalar and post scalar

7.8.7

Two Capture, Compare, PWM modules

10-bit multi-channel Analog-to-Digital converter

Brown-out detection

Relay Unit

A relay is a switch operated by electromagnetic principle. When the

controlling current flows through the coil, the soft iron core is magnetized and

attracts the L-shaped soft iron armature. This rocks on its pivot and opens,

closes or changes over the electrical contacts in the circuit being controlled.

In this protection system, DC 12 V, 10 A relay is used.

The proposed system uses normally opened type relay. When the

controller output from the microcontroller is high the relay is energized.

When the controller output from the micro controller is low the relay is

reenergized. Therefore, according to the controller output the valve will open

or close and thus level is maintained.

236

7.9

DESIGN CYCLE FOR DEVELOPMENT OF EMBEDDED

CONTROLLER USING MPLAB

The embedded programming for protection system is done using

Microchip product MPLAB IDE. The MPLAB IDE is a software program

that runs on personal computer to provide development environment for

embedded microcontroller design. The design cycle for developing an

embedded controller application (PIC 16F877) is as follows:

Step 1: High level design

Decide which PIC microcontroller is needed for the protection

system

Step 2: Software coding

Write software coding for the application either using assembly

language or C language.

Step 3: Execute

Compile or assemble the software coding. Find whether there is any

error and warning message.

Step 4: Test

Remove the bugs in executed coding using testing tool of MPLAB

Step 5: Burn into the device

Finally tested coding is burned into target embedded PIC

controller device.

237

7.10

SOFTWARE ALGORITHM

The algorithm used for developing embedded programming is

given below:

i)

Implement the complete microcontroller based integrated

protection system.

ii)

The tolerable value obtained from simulation results are

entered as reference values to the microcontroller unit.

iii)

Start the machine at rated condition.

iv)

Monitor and read supply voltages (Va, Vb, Vc) and line

currents (Ia, Ib, Ic) through potential transformer (PT) and

current transformer (CT).

v)

Measured voltages and currents are digitally passed to

microcontroller unit via voltage and current sensing circuits.

vi)

Comparisons are made between measured values and the

reference values (Tolerable Value).

vii) If (A ~ B =240) then stop the motor and display message

as Phase reversing (PR). Otherwise,

viii) If (Va | Vb | Vc =0) then generate trip signal to stop the motor

and display message as Single Phasing (SP). Otherwise,

ix)

If (% of Voltage Unbalance > 5%) then stop the motor and

display message as Voltage unbalance condition (UB) Else,

x)

If (% of Current Unbalance > 40%) then stop the motor and

display message as Current unbalance condition (CU) Else,

xi)

If the mean value of VSa, VSb and VSc is less than 0.8 times

of rated voltage (set value), than trip the motor after a

238

specified time delay and display message as Under Voltages

(UV).Otherwise,

xii) If the mean value of VSa, VSb, VSc is more than 1.1 times of

set value, then trip the motor after a time delay and display

message as Over Voltage (OV) otherwise

xiii) If the amplitude of IR, IY, IB is 9 times of set value for time

T, then trip the motor and display ever message as

Instantaneous current (IC). Otherwise,

xiv) If amplitude of Ia, Ib, Ic 7 times of set value for time T, then

trip the motor after a specified time delay and display the error

message as Locked rotor (LR). Otherwise,

xv)

If amplitude of Ia, Ib, Ic 2.5 times of set value for time T,

then trip the motor after specified time delay and display error

message as Stalling (ST). Otherwise,

xvi) If amplitude of Ia, Ib, Ic 1.5 times of set value for time T,

then trip the motor after specified time delay and display error

message as over current (OC).Otherwise,

xvii) If the phasor sum of Ia, Ib, Ic > 1A, then trip the motor after a

specified time delay and display error message as Ground

Fault (GF). Otherwise,

xviii) Goto step iv.

239

7.11

HARDWARE TEST RESULTS

A prototype model is developed and tested on a 3 ph, 450V, 50Hz,

2.2 kW, 4.6A induction motor. The microcontroller based multifunction

motor protection system responded to all types of faults perfectly by tripping

the motor after the specified time delay and displayed the corresponding error

message in the LED seven segment display unit. Every fault was executed

more than 10 times in different environment conditions. The waveforms for

various fault conditions are observed using Digital Storage Oscilloscope and

presented in Figure 7.9 Figure 7.17. The photograph of hardware testing

setup and protection system of induction machine are shown in

Figure 7.18 (a - b).

Figure 7.9 Output signals from the motor

protection

system

during

normal operating condition

Figure 7.10 Output

signals

from

the

motor

protection

system

during

single

phasing

condition

240

Figure 7.11 Output

signals

from

the Figure 7.12 Output signals from the

motor

protection

system

motor

during

under

voltage

during unbalanced voltage

condition

system

condition

Figure 7.13 Output signals from the

motor

protection

protection

system

during overload condition

Figure 7.14 Output signals from the

motor

protection

during

condition

phase

system

reversing

241

Figure 7.15 Output

motor

signals

protection

during

locked

condition

Figure 7.17

from

the Figure 7.16 Output signals from the zero

system

rotor

crossing detectors (IDR, IDY)

during

normal

operating

condition

Output signals from the zero crossing detectors (IDR, IDY) during

phase reversal

242

(a) Hardware test setup

(b) Protection system of induction motor

Figure 7.18 Hardware test setup and developed embedded motor

protection relay

243

7.12

CONCLUSION

The developed microcontroller (MC) based relay features and

specifications are given below in Tables 7.3 and 7.4. The developed model is

commissioned at M/s. Harshini Textiles, Anamalai, Coimbatore, India for the

main motor drive in LR-6 Ring Frame machine and working satisfactorily.

Table 7.3 Microcontroller based relay features

Protected Item

Time Characteristic

Over Current (OC)

Two Step Definite Time

Over Voltage Under voltage (Under current )

Within 5 Sec.

Phase Loss (PL)

Within 3 Sec.

Ground Fault

Within 1 Sec.

Unbalance (UB)

Within 8 Sec.

Locked Rotor (LR)

Immediately.

Instantaneous Current

Within 5 Sec.

Over Voltage

Within 5 Sec.

Phase reversal

Within 1 Sec.

Stall

Within 3 Sec.

Table 7.4 Microcontroller based relay specifications

Protected Item

Current Sett. (IOC)

Delay Time (D-Time)

Over-current Trip Time (O-Time)

Under voltage Trip Time (U-time)

Phase Loss

Ground Fault

Unbalance

Locked Rotor

Alert

Time Characteristic

0.5-5A, Wide Range

(6-3000 A) With external CT

1-25 sec (Definite time) / OFF

0.5 / 1.30 sec & 0.5/1-10 sec

(2 step Definite Time)

0.5/1-30 Sec (Definite Time)

On / Off

0.02 3 A (Definite time type) /OFF

5-50% OFF (Disable)

(2-5) * (Ioc)

50-100% OFF of Ioc

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Indigenously designed servo voltage stabilizer controllerDocumento39 pagineIndigenously designed servo voltage stabilizer controllershalu29Nessuna valutazione finora

- Sinewave Inverter DC Capacitor Ripple CurrentDocumento6 pagineSinewave Inverter DC Capacitor Ripple Currentshalu29Nessuna valutazione finora

- Future Value TablesDocumento123 pagineFuture Value TablesShankar ReddyNessuna valutazione finora

- Laboratory Tests Predict Retention and Drainage Aid PerformanceDocumento14 pagineLaboratory Tests Predict Retention and Drainage Aid Performanceshalu29Nessuna valutazione finora

- SWG & MM ConversionDocumento70 pagineSWG & MM Conversionshalu2980% (10)

- Chemical Details For Paper IndustriesDocumento2 pagineChemical Details For Paper Industriesshalu29Nessuna valutazione finora

- Details of Chemical VendorsDocumento3 pagineDetails of Chemical Vendorsshalu29Nessuna valutazione finora

- UChip PIC16F72 Based Relay TIMER Board CircuitDocumento1 paginaUChip PIC16F72 Based Relay TIMER Board Circuitshalu29Nessuna valutazione finora

- UChip PIC16F72 Based Relay TIMER Board CircuitDocumento1 paginaUChip PIC16F72 Based Relay TIMER Board Circuitshalu29Nessuna valutazione finora

- Household Power & Energy Consumption CalculationDocumento2 pagineHousehold Power & Energy Consumption Calculationshalu29Nessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Microprocessor Systems & Interfacing EEE-342: Comsats UniversityDocumento7 pagineMicroprocessor Systems & Interfacing EEE-342: Comsats UniversityBilal HabibNessuna valutazione finora

- Frequency Converter Type Vacon NX For Alimak's Hoists and Lifts User's ManualDocumento27 pagineFrequency Converter Type Vacon NX For Alimak's Hoists and Lifts User's Manualsulthan1975Nessuna valutazione finora

- ADOH NanoBoard3000 RS 232SerialInterface 120312 1844 45872Documento2 pagineADOH NanoBoard3000 RS 232SerialInterface 120312 1844 45872Bones BrennanNessuna valutazione finora

- Compact Rectifier Module for Telecom and Network ApplicationsDocumento2 pagineCompact Rectifier Module for Telecom and Network ApplicationsleonardomarinNessuna valutazione finora

- BRC7E83 Operation Manual DaikinDocumento12 pagineBRC7E83 Operation Manual Daikinkalai arasanNessuna valutazione finora

- Mobile Robot Chapter 7: The Motors of The Robot (V.4a)Documento18 pagineMobile Robot Chapter 7: The Motors of The Robot (V.4a)Carlos RamirezNessuna valutazione finora

- Nova Ii & Nova Iv ReceiversDocumento4 pagineNova Ii & Nova Iv ReceiversTlacat V LaolliNessuna valutazione finora

- 31010NSM-UPS2000-G - (3 kVA C10 kVA) - V2 V100R001C11 User Manual Draft BDocumento86 pagine31010NSM-UPS2000-G - (3 kVA C10 kVA) - V2 V100R001C11 User Manual Draft BNCT Net Company TelecomNessuna valutazione finora

- Internship Report Pakistan Telecommunication Company Limited, BahawalpurDocumento30 pagineInternship Report Pakistan Telecommunication Company Limited, BahawalpurTooba AliNessuna valutazione finora

- FINAL Harmonic Study Report - HJI - First PhaseDocumento37 pagineFINAL Harmonic Study Report - HJI - First Phasemanu100% (1)

- Minor Project SynopsisDocumento3 pagineMinor Project SynopsisHappy RajputNessuna valutazione finora

- Synchronization For QDPSK - Costas Loop and Gardner Algorithm Using FpgasDocumento5 pagineSynchronization For QDPSK - Costas Loop and Gardner Algorithm Using FpgasSatya NagendraNessuna valutazione finora

- Blind Navigation Using RFID For Indoor EnvironmentDocumento15 pagineBlind Navigation Using RFID For Indoor EnvironmentTruptiiiiNessuna valutazione finora

- Comparison of Outer Rotor Radial Flux and Axial Flux PM Motors For CMG ApplicationDocumento6 pagineComparison of Outer Rotor Radial Flux and Axial Flux PM Motors For CMG ApplicationsosiNessuna valutazione finora

- Frequency Response Part1Documento10 pagineFrequency Response Part1Mira BunsuNessuna valutazione finora

- MiCOM P44XDocumento8 pagineMiCOM P44XMahesh YadaNessuna valutazione finora

- CompalDocumento71 pagineCompalPaulo RochaNessuna valutazione finora

- Lesson 6 PID Control of Heat Exchanger Temp PDFDocumento2 pagineLesson 6 PID Control of Heat Exchanger Temp PDFJenny GoNessuna valutazione finora

- Thyristors & Triacs - Ten Golden RulesDocumento11 pagineThyristors & Triacs - Ten Golden RulesVlad ThalheimerNessuna valutazione finora

- Sharp Lc-37d42u Lc-37d43u Lc-C3742u Supp1Documento6 pagineSharp Lc-37d42u Lc-37d43u Lc-C3742u Supp1Carlos MoratoNessuna valutazione finora

- Manual Do Operador IL NT 12-2008Documento9 pagineManual Do Operador IL NT 12-2008albertooliveira100% (1)

- Dell Inspiron 1440 Wistron Alba UMA 08243 91.4BK01.001 Rev 1 SchematicsDocumento61 pagineDell Inspiron 1440 Wistron Alba UMA 08243 91.4BK01.001 Rev 1 SchematicsBablu SharmaNessuna valutazione finora

- Formula Notes Network AnalysisDocumento9 pagineFormula Notes Network AnalysisSubramanyam Kamatham100% (1)

- PID Speed ControlDocumento9 paginePID Speed ControlMilinda Seneviratne100% (1)

- Patient Monitor Maintenance CheckDocumento2 paginePatient Monitor Maintenance CheckDickyNessuna valutazione finora

- TRSS Overview Presentation - SCHNEIDERDocumento99 pagineTRSS Overview Presentation - SCHNEIDERDante FalconNessuna valutazione finora

- Led TV : Owner'S ManualDocumento24 pagineLed TV : Owner'S Manualhadi yanNessuna valutazione finora

- Littelfuse ProtectionRelays SE 601 DatasheetDocumento1 paginaLittelfuse ProtectionRelays SE 601 DatasheettrueavatharNessuna valutazione finora

- Inovance Md310 VFD Quick Guide English 20-4-20Documento64 pagineInovance Md310 VFD Quick Guide English 20-4-20phu chuNessuna valutazione finora

- 6-Pin Wire Harness Assembly Installation GuideDocumento2 pagine6-Pin Wire Harness Assembly Installation Guidelucian stoianofNessuna valutazione finora