Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Soap Line No. - 3 - IQ-OQ

Caricato da

Affrianaa SiagianCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Soap Line No. - 3 - IQ-OQ

Caricato da

Affrianaa SiagianCopyright:

Formati disponibili

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 1 of 38

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

Soap Line No. - 3

Prepared by:

Signature

Date

Signature

Date

Signature

Date

QA Department

Reviewed by:

Production Executive

Approved by:

Manager Engineering

Production Manager

Quality Assurance manager

Site Head

DOCUMENT HISTORY

Revision

Date

Reason for Changing

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 2 of 38

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

EQUIPMENT

Bottle Air Rinser

EQUIPMENT: QUALIFICATION

PROTOCOL

PROTOCOL NO. : Utt 1/EQP/Soap Line No. - 3 - 003

EQUIPMENT

: Soap Line No. - 3

LOCATION

: Soap Section, Unit - 1

DEPARTMENT

: Production

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 3 of 38

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

OBJECTIVE :

To qualify the installation, operation, instrumentation, and

control system of the equipment. This qualification will also

define and document the evidence needed to verify that the

equipment is installed according to design specification and

complies with standard operating procedures and cGMP

requirements.

PROCEDURE :

Qualification to be carried out in the following sequential

order.

A. Installation qualification

B. Safety qualification

C. Operational qualification

D. Performance qualification & Conclusion

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 4 of 38

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

INDEX

P A G E N O.

1.0

INSTALLATION

QUALIFICATION

5 - 15

2.0

SAFETY & ENVIRONMENTAL

QUALIFICATION

16 - 17

3.0

OPERATIONAL QUALIFICATION

18 - 19

4.0

PERFORMANCE QUALIFICATION

& CONCLUSION

20 40

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 5 of 38

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

INSTALLATION QUALIFICATION

1.1 Objective

To Installed the soap line no. - 3 for

producing finish goods as per the specified

requirement.

1.3 Equipments P.O.

CAP/UTT1/SCE/11/03

CAP/UTT1/SCE/11/04

MIL India

Ltd.

Mazzoni

LB S.P.A.

DESIGN, MANUFACTURING &

SUPPLY OF TOILET SOAP

FINISHING LINE WITH METAL

DETECTOR (BEFORE CAKE

STAMPING) & FIRST FILLS OF OIL

FOR ALL EQUIPMENT:

CAPACITY :3 TON PER HOUR

DESIGN, MANUFACTURING,

SUPPLY, TESTING &

COMMISSIONING OF SOAP

STAMPING MACHINE ALONG WITH

OTHER ACCESSORIES.

(FOB NORTHERN ITALIAN PORT,

PACKED CONDITION)

CAP/UTT1/SCE/11/011

CAP/UTT1/SCE/11/074

CAP/UTT1/SCE/11/061

1.4 Supplier

1.5 Approved Installation

Drg

( Attach a copy of drg,

if any)

1.6 Procedure

Deep

electrical

Dhanvan

thri

Engineer

s Pvt.

Ltd.

Khosla

Machines

Pvt. Ltd.

Laying and fixing of Electrical

fittings

SOAP CONVEYING SYSTEM AS PER

DETAILS OUTLINED IN ANNEXURE2 ENCLOSED HEREWITH.

MIL INDIA

MAZZONI LB

DHANVANTHRI

KHOSLA

------

Toilet Soap wrapping Machine

[Model: WRAPPER - 4000T (3rd

Generation)] as per details

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 6 of 38

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

1.6.1 Installation

Qualification

Checklist

1.6.2 Auxiliary

Equipment Features

1.6.3 List of Spare

Parts

1.6.4 Utility and

Services Required

1.6.5 Non-compliance

and thereafter

Compliance Reports

Details below..

1.6.1

INSTALLATION QUALIFICATION CHECK LIST

1.6.1.1

Equipment Details of Soap Line No. - 3

Equipment

Make

MODEL

YEAR

BATCH WEIGHING

SYSTEM

MIL INDIA

Double sigma mixture

MIL INDIA

simplex plodder

MIL INDIA

triple roll mill

MIL INDIA

HRM-3000

11-Nov

duplex plodder

MIL INDIA

B-350

11-Nov

metal detector

TECHNOFOUR

ELECTRONICS

PVT.LTD.

METALTRAP 03

SEP. 2011

DSM-SMIX-750

SEP. 2011

11-Oct

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 7 of 38

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

stumper

MAZZONI LB

STUR-10/T16

2011

wrapping Machine

KHOSLA

W1- 874, W2874, W3-899,W4

-900

2011

TAPPING MACHINE

ITW

5 FAM

METLER TOLEDO

IND 560

auto weigh check

weigher

1.6.1.2

1.6.1.3

b.

Model / Make

: See in above table

c.

MFG.YEAR

: See in above table

e.

Capacity

f.

Location

: Soap Section, Production

g.

Purpose

: Soap Production

Operating manual Copy:

Available

Location

Purchase order (If available

: Yes

: FINANCE

Material in Product / Commodity contact (Parts Material)

Part

a)

3000 KGS/HRS

: Yes

: MAINT. OFFICER

Available

Location

1.6.1.4

2010

DSM

Specified

MS

Actual

MS

7

Remarks

OK

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 8 of 38

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

b)

c)

d)

SRP

TRM

DFP

MS

MS

MS

MS

MS

MS

1.6.1.5 Gear Box Oil:

DSM- SERVO MESH SP-220

SRP SERVO MESH SP-320

TRM SERVO SYSTEM -68, HYDRAULIC OIL GRADE -68

DFP - SERVO MESH SP-320

1.6.1.7 Motor & Gear Box Details:

DOUBLE SIGMA MIXER

MOTOR 1

Make

HP

RPM

:

:

:

NORD

30

19

:

:

:

NORD

40

26

:

:

:

NORD

75:69

PARALLEL GEARED MOTOR

MOTOR 2

Make

HP

RPM

MOTOR 1

Make

Ratio

Size & Type

OK

OK

OK

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 9 of 38

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

MOTOR 2

Make

Ratio

Size & Type

:

:

:

NORD

57:43

PARALLEL GEARED MOTOR

Make

HP

RPM

:

:

:

ABB

40

1500

Make

Ratio

Size & Type

:

:

:

ABB

50:1

HELICAL GEAR BOX

Make

HP

RPM

:

:

:

ABB

45KW

1470

Make

Ratio

Size & Type

:

:

:

ABB

5:1

RI 140

Make

HP

RPM

:

:

:

ABB

50

1500

Make

Ratio

Size & Type

:

:

:

MIL INDIA

50:1

HELICAL GEAR BOX

SRP

TRM

DFP PRELIMINARY

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 10 of 38

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

DFP FINAL

Make

HP

RPM

:

:

:

ABB

60

1500

Make

Ratio

Size & Type

:

:

:

MIL INDIA

50:1

HELICAL GEAR BOX

Make

HP

MAZZONI LB

:

:

BONFIGLIOLI RIOOTTORI

.18 KW

Make

HP

RPM

:

:

:

AB (SERVO)

6.79 KW

3000

METAL DETECTOR

Dhanvanthri Conveyers: ALL MOTORS

Make

HP

RPM

:

:

:

SIEMENS

.37 KW

1380

WRAPPING M/C: ALL WRAPPING

Make

HP

RPM

:

:

:

SIEMENS

1.5KW

1400

10

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 11 of 38

Equipment: Soap Line No. - 3

Revision :

1.6.3

Date: April. 2012

LIST OF SPARE PARTS :

DSM

02. CO3

02. CO4

KEYLESS COUPLING

-2

PRECISION LOCK NUT

-2

02. CO7

OIL SEAL

-3

03. CO1

RINGFEDER LOCKING ELEMENT

-2

03. CO2

BEARING

-2

03. CO3

OIL SEAL

-3

03. CO4

LOCK NUT

-2

03. CO5

LOCK WASHER

-2

03. CO6

O-RING

-2

05. CO6

FRL UNIT FRC

-1

05. CO7

DOUBLE SOLENOID VALVE

05. CO8

SOLENOID VALVE COIL

-2

05. CO9

SILENCER

-2

-1

SRP

250-13-00

BALL BEARING FOR INPUT SHAFT

-1

250-14-00

TAPER ROLL BEARING FOR INPUT SHAFT

-2

250-15-00

Taper roll bearing for 1st intermediate shaft

-2

250-16-00

Taper roll bearing for 1st intermediate shaft

-2

11

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 12 of 38

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

250-17-00

Spherical roller bearing for output shaft

-2

250-18-00

Oil seal for input shaft

-1

250-19-00

Oil seal for input shaft

-2

250-20-00

input pinion shaft

-1

250-21-00

input gear

-1

250-22-00

1st intermediate pinion shaft

-1

250-23-00

intermediate gear

-1

250-24-00

2nd intermediate pinion shaft

-1

250-25-00

output gear

-1

250-26-00

out put hollow shaft

-1

TRM

S. NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

EQUIPMENT

PRECISION LOCK NUT

BEARING

TIMING BELT

ROTARY V-SEAL

O RING

BEARING

BEARING

NILOS RING

RADIAL SHAFT SEAL

ROTARY UNION-RH

ROTARY UNION- LH

CIRCLIP

NYLON CHEEK LH

NYLON CHEEK RH

SCRAPPER BLADE

12

PART NO.

01.C1

02.02C1

02.C4

03.01.C7

03.01.C8

03.02.C1

03.02.C2

03.02.C3

03.03.C7

03.07.C1

03.07.C2

03.07.C3

05.02.00

05.03.00

06.06.00

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

16

17

18

19

20

21

22

23

24

Date: April. 2012

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 13 of 38

SOLENOID VALVE

SOLENOID COIL

FRL UNIT

SILENCER

CONVEYOR BELT

BEARING

BUSH

RTD SENSOR

HYLUM FOR BELT SCRAPPER

06.C02

06.C03

06.C06

06.C07

07.00.C2

07.00.C1

09.05.03

07.07.01

SPARES FOR HYDRAULIC SYSTEM

1

2

3

4

5

6

SUCTION STRAINER

FILTER ELEMENT

SPARE SOLENOID COIL FOR DIRECTION VALVE

PRESSURE TRANSDUCER

SPARE DIAPHRAM FOR ACCUMULATOR

SEAL KIT FOR HYDRAULIC CYLINDER

DFP

S. NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

EQUIPMENT

V BELT

V BELT

MAIN SGAFT

COUNTER SHAFT

OIL SEAL

BEARING

O RING

O RING

BEARING

OIL SEAL

OIL SEAL

U CUP OIL SEAL

O RING

O RING

BEARING

PART NO.

2.C4

2.C5

4.3

4.6

4.C1

4.C6

4.C7

4.C8

4.C9

4.C10

4.C12

4.C13

4.C16

4.C17

4.C21

13

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

1.6.4

Sr.

No.

a.

b.

f.

Date: April. 2012

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 14 of 38

LOCK WASHER

LOCK NUT

LOCK WASHER

LOCK NUT

WORM RH

WORM LH

WORM SUPPORTING PIN

SPACER FOR WS PIN

BUSH FOR WS PLATE

SPACER FOR WS PLATE

EYE BOLT

NUT FOR EYE BOLT

WASHER

BUSH

SPACER

SHREDDER DRIVING SHAFT

SHREDDER (RH)

SHREDDER (LH)

O RING

O RING

O RING

4.C22

4.C23

4.C33

4.C34

7.1

7.2

9.1

9.3

9.4

9.5

9.8

9.9

9.1

9.18

9.19B

9.2

9.23B

9.24B

9.C4

10.2.C1

10.3.C1

UTILITIES AND SERVICES REQUIRED

Requirements

Compressed air

Electrical network

Steam

Specification

Verification

6 kg

As per drawing

NA

ok

ok

NA

(Verification to be authorized by the respective Manager)

14

Checked

by

Varun

Varun

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

1.6.3

Date: April. 2012

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 15 of 38

NON COMPLIANCE CONFORMANCE REPORT

Description of Non Compliance

- NA

Activities carried out to conform to the requirements ( Use

separate sheet, if required)

- NA

Result of rechecking

- NA

1.7 CONCLUSION : Since the IQ. Is satisfactory, the machine is qualified for

doing the operational qualification trials.

15

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 16 of 38

SAFETY & ENVIROMENTAL QUALIFICATION

2.1

2.2

2.3

New Equipment Checklist

Machine Guarding Checklist

Management of Change

2.1 NEW EQUIPMENT CHECKLIST

1

2

3

Name of Equipment

Location of Equipment

Function of Equipment

4

5

Photograph of equipment

Short Description of modification,

in case of modification

Purpose of Modification

Have interlocks been interlocks on

1. All Guards are hinged and

are removable

2. Guards protect the point of

operation and doors to

hazardous transmission

drive

All interlocks drives in proper

working order on machine? Test

done to Verify?

Is Electrical wiring properly done

with proper electrical grounding? (

To be certified by Electrical

Manager)

Has an Electrical or Mechanical

lock-out capability been provided?

(Zero mechanical state)

Is the equipment safe in flammable

liquid process area?

6

7

8

9

10

11

DSM, TRM, Cutter, Stamper, Conveyor

Soap section Unit 1

Crushing, Refining, extruding, stamping cakes and

packing

NA

NA

Yes

Except the stumper M /c where the die fall when the power

supply goes off. Braking system is not functional

Earthing wire to be provided to inclined conveyor motors

Yes

Yes

16

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

Date: April. 2012

Is air line (if used) proper-specific

air pressure required for Operation

& Isolation capability?

If maintenance work is to be

carried out, can it be done with

Ease & Safely?

Is there enough room around the

machine for all free movement

whilst operating machine?

(Specific clear area measurement)

If a pressure vessel has pressure

test done & approved by

competent person?

Are all caution & special

instruction notices posted on

machine?

Are operating instruction

available?

Has a SOP been developed?

Have machine operators received

training

Has personal protective equipment

been identified obtained

& supplied?

Is operating height suitable so as

not to cause operational hazard?

Does the equipment have any fire

hazard?

If yes , is adequate precaution

taken ? (To be certified by Safety

Head)

Are there normal fire fighting

equipment provided?

Have all necessary material

handling problems been looked

Into & resolved?

Asbestos containing material used

in any part of the machine?

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 17 of 38

Yes, Pressure vessel tested

Except the stumper machine

No, any work at height job, telescopic ladder cannot be

provided at the area

Pressure vessel test due on 27.06.2012

Yes

Yes

In Process.

Yes

Yes

Yes

No

Yes

Yes, fire extinguishers are placed near to the equipments

FG outer movement from the lollipop are to FG area is

difficult

No.

17

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 18 of 38

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

OPERATIONAL QUALIFICATIO

1

CHECK LIST FOR OPERATIONAL QUALIFICATION

3.1.1. SOP SOP to be made.

3.1.2. CALIBRATION - NA

1.4.3.

NO LOAD TRIAL & LOAD TRIAL

MACHINE

DSM1

CURRENT

amp

NO LOAD

18

LOAD

27

DSM2

amp

12

18

SRP

amp

21

39.2

TRM

amp

23

34

DFP1

amp

18.28

49.05

DFP2

amp

23.5

47.7

1.73

1.72

1.74

BELT CONVEYOR 2

1.75

1.74

1.74

LUBRICATION PUMP

1.01

1.02

HYDRAULIC PUMP

0.72

0.73

0.73

DISCHARGE CONVEYOR

0.74

0.74

0.73

VACUUM PUMP

2.49

2.48

2.49

BELT CONVEYOR 1

Parameters to be studied

OBSERVATIONS: ok

18

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 19 of 38

3.1.5 EQUIPMENT NON CONFORMANCE REPORT

Description of non- conformance

Sr. No.

Probable reasons for non

conformance

NA

Observation

NA

Correction of non- conformance

Sr. No.

Correction Done

NA

Done by

NA

Checked by

NA

Checked by

NA

REMARKS

NA

COMPLIANCE REPORT

Sr. No.

TRIAL TAKEN

NA

CONCLUSION :

Since the OQ. Is satisfactory, the machine is qualified for

doing the performance qualification trials.

19

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 20 of 38

Performance Qualification

SUBJECT: Process Validation of Soap Manufacturing and packing process of Soap to be

manufactured using new Soap Line no 3 at Unit 1 Reckitt Benckiser India Limited,

Sitarganj.

PROTOCOL NUMBER

REVISION: 0

DATE: 19.04.12

SITE: Reckitt Benckiser India Limited , Unit 1

B 96 ELDECO , SIDCUL

Industrial Park , Sitarganj

EQUIPMENTS:

1. Sigma Mixer

2. Simplex Plodder

3. Triple Roll Mill

4. Duplex Plodder

5. Metal detector

6. Stamper

7. Wrapping Machines

8. Auto checkweigher Machine

9. IJP Outer coding Machine

OBJECTIVE:

To provide documented evidence that Soap when manufactured using Soap Line no 3 to meet the

desired quality standards.

Since the new soap line is being used for Manufacturing, Wrapping & packing, validation is required.

PREPARED BY:

Parveen Guleria / Girish Singh

Officer - QA

REVIEWED BY:

P. Ramudu

Manager - QA

SIGNATURE

Kuldip singh

Manager Production

T. Jayachandran

Manager - Maintenance

APPROVED BY:

20

DATE

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 21 of 38

K.N. Jha

FM

Nitin Shetty

Head of QA South East Asia

Document History

Revision

Date

Reason of Changing

Original Issue

Table of Contents

Page No.

1.0 General Introduction

1.1 Background

1.2 Scope

1.3 Validation Team

3

3

3

2.0 Responsibilities

2.1 Technical Assurance

2.2 Site Manufacturing

2.3 Quality Assurance

3

3

3

3.0 Pre PQ Checklist

4

5

4.0 Performance Qualification (PQ) Trials

4.1 Lot Size

4.2 Equipment

4.3 Process Parameter Matrix

4.4 Critical Process Parameters

6

6

6

6

5.0 Acceptance Criteria

6.0 Failure Investigation

7.0 Conditional Acceptance

8.0 Disposition of Product

Attachment I Packaging Materials Confirmation Checklist

21

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 22 of 38

Attachment II Test Instrument Calibration Checklist

Attachment III- Sigma Mixer Data

Attachment IV Simplex Plodder Data

Attachment V Simplex Plodder, TRM and Metal detector Check list

Attachment VI Data Collection form

10-11

Attachment VII - Packing Operation

12-13

Attachment VIII - Chemical Analysis Report

1.0

GENERAL INTRODUCTION

1.1

1.2

1.3

Background:

In the View of Substantial Expansion Capacity, this Soap mfg & packing Line has been

commissioned in Unit 1

This Soap line no 3 will be used for Manufacturing, wrapping & packing of al variants &

SKUs of Soap.

Scope:

This is a prospective validation will involve Manufacturing, Wrapping and packing of 3

consecutive days of production to confirm the process consistency and reproducibility.

Validation Team:

RBIL QA

RBIL Production

RBIL Maintenance

2.0

14-15-16

: Girish Singh ,Parveen Guleria ,P Ramudu,

: Kuldip Singh ,Sanjay Tripathy

: T.Jayachandran, Varun, T Jeewahn, Dharampal

RESPONSIBILITY:

2.1

2.2

Technical Assurance

2.1.1

Approved Process, Product Specification

2.1.2

Approved RM/PM Specification.

2.1.3

Approved test methods

Site Manufacturing

22

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

2.2.1

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 23 of 38

Documentation of all process settings, conditions & adjustments during

validation in BMR

2.3

2.2.2

Staff/crew for process operation

2.2.3

Assist QA in completion of pre-PQ Checklist.

Quality Assurance:

2.3.1

PQ Protocol and approval prior to the process qualification runs

2.3.2

Testing and release of all raw materials.

2.3.3

Assist collection of the process qualification run samples and testing

2.3.4

Completion of validation run and report.

4.0 Pre-PQ checklist:

All relevant reference documents are listed below.

Check points

Product manufacturing license no. & issuance date.

Material Specifications

RM

PM

Process Specification

23

Number/Date

No change

Verified by

PG

No change in

formulation and

PMS

PG

No change in Batch

Manufacturing.

PG

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 24 of 38

Check points

Product manufacturing license no. & issuance date.

Product Specification

Approved Art work copies

Approved Shade Cards (Light Standard Dark)

Approved Packaging Reference Materials

Product attributes & variables criteria

(Attachment IV)

Approved Standard Test Methods

Raw Materials

Packaging Materials

In-process Bulk

Finished Product

Testing Capability

Availability of Equipment & Accessories

Trained & Qualified Analyst

Released Materials

RM

PM

Instrument Calibration Records

Manufacturing

Stamping

Packing

Testing

Pre-Validation Equipment Cleaning & Sanitizing

Manufacturing

Process Validation Protocol

Number/Date

No change

Verified by

PG

No change in FG

specification

No change in AW of

Wrapper.

Existing shade

cards of Wrapper

are applicable

Same as existing

Existing AQL of

Soap are

applicable.

No change

PG

Available

PG

RM/PM Released

as per existing

protocols

Manufacturing ,

Stamping

Packaging,& testing

validation data is

attached

Packing

configuration is

same as existing.

PG

New Line

PG

PG

PG

PG

PG

PG

PG

PG

24

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

5.0

Date: April. 2012

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 25 of 38

PERFORMANCE QUALIFICATION (PQ) TRIALS:

Validation is demonstrated by establishing documented evidence from 5 validation batches,

which provide a high degree of assurance that a specific process will consistently produce a

product meeting its pre-determined specifications and quality attributes. Entire product

manufactured during the validation run must comply with the requirements set out in this

protocol.

5.1

Equipment:

Equipment

ID No.

Make

Sr. No.

MIL INDIA

PROJECT NO 455-02

TAG NO TSF- 2

MIL INDIA

PROJECT NO 455-04

TAG NO TSF- 3

MIL INDIA

PROJECT NO 455-07

TAG NO TSF- 5

MIL INDIA

PROJECT NO 455-10

TAG NO TSF- 7

DOUBLE SIGMA

MIXTURE

SIMPLEX PLODDER

TRIPLE ROLL MILL

DUPLEX PLODDER

METAL DETECTER

TECHNOFOUR

ELECTRONICS PVT.LTD.

STAMPER

MAZZONI LB

186/2011

WRAPPING MACHINE

KHOSLA

WTT/LIQ/FLG/LI

Z/WS-01

METLER TOLEDO

W1-875

W2-874

W3-899

W4-900

-

AUTO WEIGH

CHECKWEIGHER

Critical Process Parameters

Operation

5.2.1 Mfg : Soap Mixer

Critical steps & sampling

plan

Criteria for Acceptance

Observation

Collect samples from two

different places of sigma

mixer for each batch for 5

consecutive batches from the

TCC content and color in all

the 5 Batches checked must

be complying with FPS.

Annexure III

25

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 26 of 38

Double Sigma mixer for TCC

content & colour.

5.2.2 Simplex Plodder

Check the Cleaning and pore

size of Mess of Plodder on

shift basis for three days.

It should be neat and clean,

bulk should come out

smoothly.

Annexure IV

5.2.3 TRM

Check the feeding and

discharging roller mill gap in

every shift for 3 days.

Annexure V

5.2.4 Duplex Plodder

Check the Vaccum and

temperature of chiller.

Check the metal detector with

three standard once in every

shift for three days.

This must be :

Feeding Roller Gap :0.3mm

Discharging Roller Gap :

0.15mm

It should be approperiate

Metal detector functioning

should be ok

Annexure V

Should be complies with

RBIL Quality Standards

Annexure VI

Should be complies with

RBIL Quality Standards

Annexure VII

Should complies the

Standard

Annexure II

Should be accurate, proper

visible and readable.

Annexure VII

Criteria for Acceptance

Observation

5.2.5 Metal detector

5.2.6 Stamper

5.2.7 Wrapping

Machines

5.2.8 Auto

checkwiegher

5.2.9 IJP Outer coding

Check the soaps of Both dye

hourly basis for Weight, cake

finishing , Logo Apearance

etc.

Check the soaps of all

wrapping machines at hourly

basis for coding , wrapping

Quality.

Check the functioning,

calibration and tolerance of

machine shift basis for three

days.

Check outer coding on hourly

basis for three days.

Annexure

5.3 Critical FG Parameters

Parameters

Critical steps & sampling

plan

26

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 27 of 38

5.3.1 Physical

Check every pallet as per

root +1 scheme for all FG KPI

parameters.

Should comply as per RBIL

AQL.

Annexure VII

5.3.2 Chemical

Collect the sample randomly

and check for all chemical

parameters on shift basis.

Should comply to Existing

Soap Analysis protocol.

Annexure VIII

6.0

ACCEPTANCE CRITERIA:

Validation will be deemed successful upon, product compliance for all Critical Product and

Process Parameters in accordance with the requirements set out in this protocol.

7.0

DEVIATION/FAILURE INVESTIGATION:

Any & all deviations with respect to meeting the requirements are to be investigated by the

validation team and documented as a failure investigation summary section in the validation

report. Failure investigation summary must include the following components

7.1

Description of the nature of the failure and its implications for product performance & consumer

acceptance.

7.2

Assessment of the cause of failure.

7.3

Corrective action plan.

7.4

Timeframe for completion of corrective action plan.

The failure investigation will remain open until the corrective action is complete. At the

completion of corrective actions, a failure investigation closure report will be written and

approved.

8.0

CONDITIONAL ACCEPTANCE:

The validation may be accepted by the validation committee, if one or more of the acceptance criteria

are not met, with the following conditions

27

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 28 of 38

8.1

The justification for conditional acceptance shall be documented in the PQ report

8.2

Consideration of potential impact on product function and consumer acceptance.

8.3

Review of potential causes and corrective actions.

Corrective action plan shall be defined and shall come with designees and a schedule. Outputs of the

conditional acceptance are documented in a Validation Report, reviewed and approved by validation

committee.

9.0

DISPOSITION OF PRODUCT:

All products produced during PQ runs will be held, until completion of the validation program.

Following successful completion of the validation program products produced during PQ and

meeting requirements can be considered for release.

ANNEXURE I

Packaging Materials Confirmation Checklist

Packaging Material

Stiffener

Wrapper

Outer

Self Adhesive BOPP Tape

TDS No.

A.R. No.

0267111

D0267101

D0271408

PU12D/1459

PU12B/919

PU12D/1669

PU12D/0794

ANNEXURE II

Test Instrument Calibration Records

28

Verified by /

Date

19.04.12/GS

19.04.12/GS

19.04.12/GS

19.04.12/GS

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

Instrument

Instrument

Identification

Production

Balance

Capacity : 6kg

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 29 of 38

Last

Calibration

Date

Next

Calibration

Date

Verified by /

Date

GS

RU/WB/SOAP/09

Auto checkweigher

Calibration

18/04/12

18/07/12

WTT/LIQ/FLG/LIZ/WS09/09/11

01

08/09/12

GS

ANNEXURE III

Sigma Mixer Data

Parameter

Batch No.1

Batch No.2

Batch No.3

Batch No.4

Batch No.5

TCC content

Color

Checked By

0.66 & 0.67

OK

Firoz

0.66 & 0.68

OK

Firoz

PG/ GS

OK

Firoz

PG/ GS

0.67 & 0.66

OK

Firoz

PG/ GS

0.67 & 0.68

OK

Firoz

PG/ GS

Checked By

Verified by

0.68 & 0.68

Verified by

PG/ GS

ANNEXURE IV

Simplex Plodder Data

Parameter

19.04.12 G Shift

20.04.12 G Shift

21.04.12 G Shift

Cleaning

OK

Mess pore size

OK

OK

OK

OK

OK

29

Pankaj

Pankaj

Firoz

PG

PG

PG

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

ANNEXURE V

Simplex Plodder, TRM and Metal detector Check list

Parameter

19.04.12 G Shift

20.04.12 G Shift

21.04.12 G Shift

Cleaning

of SP

Mess pore

size of SP

Gap of

feeding

roller

Gap of

Discharging

roller

Functioning

of Metal

Detector

OK

OK

OK

OK

Clean

Verified

by

PG

Clean

OK

OK

OK

OK

PG

Clean

OK

OK

OK

OK

PG

Annexure VI

Data Collection Form

Fill weight check: Recommended Tablet Weight

70gm :

68.6 gm to 71.4gm (Average weight should not be less than 70gm

120gm :

Soap - 70g Weight - Line NO. 3 at Unit - 1

ate : 19/04/12

ange in gm 70g 2%

Cavity

No./ Time

9:45

Date: April. 2012

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 30 of 38

Shift - General

( 68.6 to 71.4 )

Upper Dye

Cavity 1

70.83

Cavity 2 Cavity 3

70.16

70.96

Cavity

4

71.11

Lower Dye

Cavity

5

70.99

Cavity

6

70.90

30

Cavity

1

70.77

Cavity Cavity

2

3

70.83 71.33

Cavity

4

71.1

Cavity 5

71.02

Cavity

6

71.09

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

10:40

11:30

12:40

1:40

2:30

3:40

4:40

5:40

Average

aximum

Minimum

Date: April. 2012

70.24

71.06

70.13

71.11

71.1

71.31

70.36

71.25

71.29

71.04

71.36

70.67

71.22

71.01

70.34

71

71.36

70.24

71.41

70.97

71.27

70.95

70.68

71

71.41

70.13

71.37

71.03

71.09

71.26

70.91

71

71.37

70.91

71.15

70.76

71.53

71.21

70.97

71

71.53

70.36

71.44

70.86

71.05

70.94

70.76

71

71.44

70.76

Shift - General

( 68.6 to 71.4 )

70.16

70.96

70.13

71.1

71.11

70.36

71.99

71.29

ate : 20/04/12

ange in gm 70g 2%

9:45

70.83

10:40

70.24

11:30

12:40

71.06

71.11

71.31

71.25

71.09

1:40

14:45

15:55

17:15

17:50

19:00

20:00

20:45

21:45

Average

aximum

Minimum

71.36

71.17

70.93

70.33

70.27

71.41

71.22

70.83

70.2

70.36

71.34

71.12

71.1

70.25

70.64

71.15

70.5

70.4

70.27

70.35

71.44

71.27

71.15

70.39

70.74

70.37

70.4

71

71.36

70.24

71.05

70.47

71

71.41

70.13

71.4

71.1

71

71.4

70.25

70.68

70.44

71

71.25

70.27

70.27

70.76

71

71.99

70.27

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 31 of 38

71.28

Bypass

STOP

Bypass

Bypass

Bypass

Bypass

Bypass

71

71.28

70.9

71.11

71.17

71.27

71.32

71.64

71.16

71.23

71.25

70.09

71.42

71.23

71.12

71.17

71.22

71.63

71.54

71.06

71

71.63

70.77

71.31

71.01

70.95

71.63

70.54

71

71.63

70.54

71.37

70.99

70.91

71.09

71.12

71

71.64

70.91

71.27

71.17

70.95

71.05

71.06

71

71.27

70.95

71.29

71.18

71.24

70.97

71.08

71

71.42

70.09

71.39

71.11

71.26

70.99

71.08

71

71.39

70.99

70.90

71.28

By

Pass

Stop

By

Pass

71.3

71.25

70.33

70.22

Stop

Stop

70.64

70.65

71

71.3

70.22

70.77

71.11

70.88

71.27

71.33

71.64

71.1

71.23

9:45

10:40

70.83

70.24

71.17

71.32

71.16

71.25

11:30

71.06

71.17

70.17

71.05

70.33

70.34

71.31

71.12

71.08

70.36

70.25

71.37

70.8

70.6

70.29

70.36

71.27

71.12

70.8

70.37

70.64

1:40

14:45

15:55

17:15

17:50

71.36

71.17

70.93

70.33

70.27

70.32

70.68

71

71.17

70.17

70.65

70.35

71

71.32

70.25

70.7

70.27

71

71.64

70.27

70.25

70.34

71

71.27

70.25

20:45

21:45

Average

Maximum

Minimum

70.37

70.4

71

71.36

70.24

Soap - 70g Weight - Line NO. 3 at Unit - 1

31

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 32 of 38

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

Date :21/04/12

Range in gm

Shift - A+B

70g

2%

( 68.6 to 71.4 )

Upper Dye

Cavity No./ Time Cavity 1

7:10

70.51

8:15

9:20

70.52

10:32

11:30

69.97

12:35

70.1

1:45

70.16

2:50

69.92

3:50

70.16

5:10

69.78

6:15

70.17

7:10

70.16

8:00

70.12

9:00

10:00

Average

70

Maximum

70.52

Minimum

69.78

Lower Dye

Cavity

2

70.48

Cavity

3

70.76

Cavity

4

70.5

Cavity

5

70.4

70.6

70.49

70.4

70.62

70.1

70.25

70.19

69.68

70.22

70.32

70.19

70.06

70

70.08

69.96

70.03

69.78

69.9

69.96

70.16

70

69.92

70.16

70.19

69.91

70.16

69.92

69.97

69.96

70.1

69.84

69.97

70.12

69.96

69.8

69.94

70.1

69.94

69.92

69.99

70

70.6

69.68

70

70.76

69.78

70

70.5

69.84

70

70.62

69.8

Cavity Cavity Cavity Cavity Cavity Cavity Cavit

6

1

2

3

4

5

6

70.71

70.2 70.62 70.81 70.54 70.59 70.7

STOP

70.81 70.76 70.21 70.41 70.61 70.29 70.6

STOP

70.3

69.98 69.91 70.08 69.72 70.1 69.9

69.96

69.9 69.91 70.14 70.06

70

69.9

69.94 70.16 69.96 70.22 70.1

69.9

69.9

70.13 69.72 69.92 69.72 70.01 70.03 69.8

70.2

70.16 70.19 69.9 69.92 69.83 69.7

69.81 69.68 69.85 69.88 70.1 69.68 70.0

69.61 69.95 70.06 70.22 69.9

70.1 70.1

70.01 70.03 69.96 69.99 69.99 69.86 70.2

70.1

70.02 69.92 69.91 70.04 70.05 70.1

STOP

STOP

70

70

70

70

70

70

70

70.81 70.76 70.62 70.81 70.61 70.59 70.7

69.61 69.68 69.85 69.72 69.72 69.68 69.7

Annexure VII

DATA COLLECTION FORM

32

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 33 of 38

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

DATE: 19.04.12, SHIFT G

Packing Operation

Parameter LOGO

Wrapping

Quality

9:45

10:40

11:30

12:40

1:40

2:30

3:40

4:40

5:40

Coding on

Wrapper

Coding on

Outer

Outer

Taping

Quality

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

Check

weigher

Performan

ce

OK

OK

OK

OK

OK

OK

OK

OK

OK

Verified by

PG

PG

PG

PG

PG

PG

PG

PG

PG

DATE: 20.04.12, SHIFT G

Packing Operation

Parameter

LOGO

9:45

10:40

11:30

12:40

1:40

14:45

15:55

17:15

17:50

Wrapping

Quality

Coding on

Wrapper

Coding on

Outer

Outer Taping

Quality

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

Verified

by /

Date

PG

PG

OK

OK

OK

OK

OK

PG

OK

OK

OK

OK

OK

PG

OK

OK

OK

OK

OK

PG

OK

OK

OK

OK

OK

PG

OK

OK

OK

OK

OK

PG

OK

OK

OK

OK

OK

PG

OK

OK

OK

OK

OK

PG

DATE: 21.04.12, SHIFT G

Packing Operation

33

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 34 of 38

Equipment: Soap Line No. - 3

Revision :

Parameter

7:10

8:15

9:15

10:30

11:30

12:30

13:30

14:50

15:50

17:10

18:15

19:10

20:00

21:00

10:00

Date: April. 2012

LOGO

Wrapping

Quality

Coding on

Wrapper

Coding on

Outer

OK

OK

Outer

Taping

Quality

OK

OK

Verified

by /

Date

GS

GS

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

GS

OK

OK

OK

OK

OK

GS

OK

OK

OK

OK

OK

GS

OK

OK

OK

OK

OK

GS

OK

OK

OK

OK

OK

OK

GS

OK

OK

OK

OK

GS

OK

OK

OK

OK

OK

GS

OK

OK

OK

OK

OK

GS

OK

OK

OK

OK

OK

GS

OK

OK

OK

OK

OK

GS

OK

OK

OK

OK

OK

OK

GS

OK

OK

OK

OK

GS

OK

OK

OK

OK

OK

GS

Annexure VIII

Chemical Analysis Report (Reference: FPS: 104197, Issue No. 02, Date: 01 April 12.)

Date: 19.04.12, Shift:

G

34

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 35 of 38

Parameter

Specification

Findings

Verified by

Appearance

Essentially free from abrasion marks, pitting, sharp

surface marking and surface dirt. Color should be uniform

with no patchy appearance

Strong orange colored soap cake, comparable with

Standard Shade Range

As per approved art work from RBIL, QA.

Characteristic pineceous and phenolic odour, Comparable

to standard.

The word "Dettol (R)" with a sword logo is embossed on

one face. Letter size for the word "Dettol" and regd. trade

mark (R) and size of sword logo should be as per the

approved art work.

When packed should be within +/- 2 % of the filled weight

claimed.

14 % w/w maximum.

71% w/w minimum

0.8% w/w maximum

Complies

PG

Complies

PG

Complies

PG

Complies

PG

Not less than 250 ml.

309.83

0.05% w/w maximum.

0.035

0.665% - 0.77%, w/w.

0.693

10 ppm maximum.

0.47-0.58% w/w.

6.45 g/50 cm2 maximum

0.565

5.73

Should be grade 7 or better

Should be grade 4 or better

Should be grade 4 or better

Appearance, colour and odour should be comparable to

the standard.

4

4

Coulor

Shape of cake

Odour

Surface marking

Tablet weight

Loss on drying

Total Fatty Matter

Chloride as Nacl

Lather (5 % Aq.

Soln.)

Free caustic alkali

as NaoH

TCC Content

Chloroaniline

content

Total Phenolic

Mush

Bar feel Wash

down

Dry Crack Test

Wet Crack Test

Accelerated aging

test

Rosin acid % by

Mass of TFM

Matter insoluble

in alcohol

Free Carbonated

PG

Complies

70.16

13.18

71.35

0.523

Complies

3 % w/w maximum.

10 % w/w maximum.

7.19

1 % w/w maximum.

35

PG

PG

PG

PG

PG

PG

PG

PG

PG

PG

PG

PG

PG

PG

PG

PG

PG

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 36 of 38

alkali

Annexure VIII

Chemical Analysis Report (Reference: FPS: 104197, Issue No. 02, Date: 01April, 2012

Date: 20.04.12, Shift:

G

Parameter

Specification

Findings

Verified by

Appearance

Essentially free from abrasion marks, pitting, sharp

surface marking and surface dirt. Color should be

uniform with no patchy appearance

Strong orange colored soap cake, comparable with

Standard Shade Range

Complies

GS

Complies

GS

Shape of cake

As per approved art work from RBIL, QA.

Complies

GS

Odour

Characteristic pineceous and phenolic odour,

Comparable to standard.

The word "Dettol (R)" with a sword logo is embossed on

one face. Letter size for the word "Dettol" and regd.

trade mark (R) and size of sword logo should be as per

the approved art work.

When packed should be within +/- 2 % of the filled weight

claimed.

14 % w/w maximum.

71% w/w minimum

0.8% w/w maximum

Complies

GS

Not less than 250 ml.

309.83

0.05% w/w maximum.

0.044

0.665% - 0.77%, w/w.

0.691

10 ppm maximum.

0.47-0.58% w/w.

6.45 g/50 cm2 maximum

0.565

5.55

Should be grade 7 or better

Should be grade 4 or better

Should be grade 4 or better

Appearance, colour and odour should be comparable to

the standard.

4

4

Coulor

Surface marking

Tablet weight

Loss on drying

Total Fatty Matter

Chloride as Nacl

Lather (5 % Aq.

Soln.)

Free caustic alkali

as NaoH

TCC Content

Chloroaniline

content

Total Phenolic

Mush

Bar feel Wash

down

Dry Crack Test

Wet Crack Test

Accelerated aging

test

36

GS

Complies

70.24

13.15

71.77

0.525

Complies

GS

GS

GS

GS

GS

GS

GS

GS

GS

GS

GS

GS

GS

GS

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 37 of 38

Equipment: Soap Line No. - 3

Revision :

Rosin acid % by

Mass of TFM

Matter insoluble

in alcohol

Free Carbonated

alkali

Date: April. 2012

3 % w/w maximum.

10 % w/w maximum.

7.05

1 % w/w maximum.

GS

GS

GS

Annexure VIII

Chemical Analysis Report (Reference: FPS: 104197, Issue No. 02, Date: 01April, 2012

Date: 21.04.12, Shift:

G

Parameter

Specification

Findings Verified by /

Date

Complies

Appearance

Essentially free from abrasion marks, pitting, sharp

PG

surface marking and surface dirt. Color should be uniform

with no patchy appearance

Complies

PG

Color

Strong orange colored soap cake, comparable with

Standard Shade Range

Complies

PG

Shape of cake

As per approved art work from RBIL, QA.

Odour

Surface marking

Tablet weight

Loss on drying

Total Fatty Matter

Chloride as Nacl

Lather (5 % Aq.

Soln.)

Free caustic alkali

as NaOH

TCC Content

Chloroaniline

content

Total Phenolic

Characteristic pineceous and phenolic odour,

Comparable to standard.

The word "Dettol (R)" with a sword logo is embossed on

one face. Letter size for the word "Dettol" and regd.

trade mark (R) and size of sword logo should be as per

the approved art work.

When packed should be within +/- 2 % of the filled weight

claimed.

14 % w/w maximum.

71% w/w minimum

0.8% w/w maximum

Complies

Not less than 250 ml.

303.79

0.05% w/w maximum.

0.034

0.665% - 0.77%, w/w.

0.691

10 ppm maximum.

0.47-0.58% w/w.

0.538

37

PG

PG

Complies

70.19

13.09

71.72

0.524

PG

PG

PG

PG

PG

PG

PG

PG

PG

RECKITT BENCKISER (INDIA) LTD.

SITARGANJ

EQUIPMENT QUALIFICATION PROTOCOL

Equipment: Soap Line No. - 3

Revision :

Date: April. 2012

Protocol No.: UTT 1/EQP/Soap Line 03 003

Page 38 of 38

PG

Mush

Bar feel Wash

down

Dry Crack Test

6.45 g/50 cm2 maximum

5.94

Should be grade 7 or better

Should be grade 4 or better

PG

Wet Crack Test

Should be grade 4 or better

PG

Accelerated aging

test

Rosin acid % by

Mass of TFM

Matter insoluble

in alcohol

Free Carbonated

alkali

Appearance, color and odour should be comparable to

the standard.

Complies

3 % w/w maximum.

10 % w/w maximum.

7.46

1 % w/w maximum.

38

PG

PG

PG

PG

PG

Potrebbero piacerti anche

- Handling of Sieves and ScreensDocumento4 pagineHandling of Sieves and Screensreflectprakash3610Nessuna valutazione finora

- SOP For Cleaning of Sticker Labeling MachineDocumento2 pagineSOP For Cleaning of Sticker Labeling MachineYousifNessuna valutazione finora

- PV 01Documento20 paginePV 01Logan KandanNessuna valutazione finora

- IVT - Validation Final ReportDocumento5 pagineIVT - Validation Final ReportDoan Chi ThienNessuna valutazione finora

- F Ex of e Nadine Hydrochloride Master Batch RecordDocumento18 pagineF Ex of e Nadine Hydrochloride Master Batch RecordKrisnanti Angela SariNessuna valutazione finora

- Level Based Training OutlineDocumento11 pagineLevel Based Training OutlinesureshchitraNessuna valutazione finora

- Validation of Coating Equipment Ketik UlangDocumento6 pagineValidation of Coating Equipment Ketik UlangSatish Hiremath100% (2)

- SOP For Reprocessing and Reworking - PharmaguidelineDocumento2 pagineSOP For Reprocessing and Reworking - PharmaguidelineTuriyo AnthonyNessuna valutazione finora

- Solitaire Pharmacia Pvt. LTD.: Restricted Circulation Authorised Persons OnlyDocumento8 pagineSolitaire Pharmacia Pvt. LTD.: Restricted Circulation Authorised Persons OnlyNgoc Sang HuynhNessuna valutazione finora

- Tablet Section Cost DR SabDocumento6 pagineTablet Section Cost DR SabAbdul SamadNessuna valutazione finora

- Performance QUALIFICATION OF RLAFDocumento22 paginePerformance QUALIFICATION OF RLAFBRIJENDRA KUMAR SINGHNessuna valutazione finora

- QASpecialist I 2011 4Documento2 pagineQASpecialist I 2011 4Bryan NicollNessuna valutazione finora

- Basic Aspects of Process Validation of Solid Oral Dosage FormsDocumento15 pagineBasic Aspects of Process Validation of Solid Oral Dosage FormsAbeer TamimiNessuna valutazione finora

- Eskag Pharma Pvt. LTD., Haridwar, Unit-I Department: Quality Assurance Product MatrixDocumento20 pagineEskag Pharma Pvt. LTD., Haridwar, Unit-I Department: Quality Assurance Product MatrixMohit ChauhanNessuna valutazione finora

- Aries Drugs Private Limited: Site Master FileDocumento23 pagineAries Drugs Private Limited: Site Master FiletesteNessuna valutazione finora

- 3-Test Report of Amlodipine Besilate 3Documento1 pagina3-Test Report of Amlodipine Besilate 3ShagorShagorNessuna valutazione finora

- 13 SOP Cleaning For Dispensing AreaDocumento3 pagine13 SOP Cleaning For Dispensing Areaanoushia alviNessuna valutazione finora

- Validate Furosemide Tablet ProcessDocumento26 pagineValidate Furosemide Tablet ProcessPatricia Joyce Malabanan SunglaoNessuna valutazione finora

- Standard Operating Procedure Department: ProductionDocumento2 pagineStandard Operating Procedure Department: Productionasit_mNessuna valutazione finora

- Urs PLMDocumento17 pagineUrs PLMMohammadIsmailNessuna valutazione finora

- Inspection of Quality Control Laboratories PDFDocumento18 pagineInspection of Quality Control Laboratories PDFHamid HamidNessuna valutazione finora

- SOP For Operation of Carton Coding MachineDocumento3 pagineSOP For Operation of Carton Coding MachineJayant Kumar JhaNessuna valutazione finora

- Resume of Quality Assurance ProfessionalDocumento4 pagineResume of Quality Assurance ProfessionalK.m. Ehsan Morshed RanaNessuna valutazione finora

- Annual Product Quality Review (APQR) SOP - PharmaBDocumento14 pagineAnnual Product Quality Review (APQR) SOP - PharmaBrehmat ali100% (1)

- Finalized Draft of Intas Audit Compliance Report 05-12-20Documento14 pagineFinalized Draft of Intas Audit Compliance Report 05-12-20DeepakNessuna valutazione finora

- Hold Time Study Ensures Clean Equipment QualityDocumento11 pagineHold Time Study Ensures Clean Equipment QualityMarwa AhmedNessuna valutazione finora

- 10 - Design and Performance QualificationDocumento8 pagine10 - Design and Performance Qualificationsainzb83Nessuna valutazione finora

- 01 - Assay Procedure Development Protocol (APDP) of Celozin TabletDocumento5 pagine01 - Assay Procedure Development Protocol (APDP) of Celozin TabletShagorShagorNessuna valutazione finora

- Template Data PQR SANTA E 100Documento124 pagineTemplate Data PQR SANTA E 100Dina FadillaNessuna valutazione finora

- Testing Procedure of Caps: Ferozsons Laboratories Limited Work InstructionsDocumento8 pagineTesting Procedure of Caps: Ferozsons Laboratories Limited Work InstructionsaKureishiNessuna valutazione finora

- Zest Pharma Internship ReportDocumento23 pagineZest Pharma Internship ReportAnvi JainNessuna valutazione finora

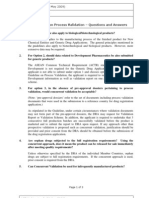

- ASEAN Guideline On Process Validation - Q& ADocumento3 pagineASEAN Guideline On Process Validation - Q& AMuqeet KazmiNessuna valutazione finora

- SOP of Sanitation of PW SystemDocumento6 pagineSOP of Sanitation of PW Systemanon_350461302100% (1)

- Cleaning Guidelines for 30” Vibratory SifterDocumento1 paginaCleaning Guidelines for 30” Vibratory SifterananthNessuna valutazione finora

- Regulation of Cosmetics in Japan PDFDocumento32 pagineRegulation of Cosmetics in Japan PDFMucharla Praveen KumarNessuna valutazione finora

- 63 Leak TesterDocumento6 pagine63 Leak Testersystacare remediesNessuna valutazione finora

- Standard plant entry procedureDocumento2 pagineStandard plant entry procedureBejoy KarimNessuna valutazione finora

- Oil-Free Compressed Air SystemDocumento5 pagineOil-Free Compressed Air SystemRonaldo JanglinNessuna valutazione finora

- 2 Process Validation QandA Version 4 (June 2011) - Adopted 18th PPWG Meeting PDFDocumento4 pagine2 Process Validation QandA Version 4 (June 2011) - Adopted 18th PPWG Meeting PDFVishal SomaniNessuna valutazione finora

- Sop For Good Manufacturing Practices: Written by Verified by Function Name Signature DateDocumento17 pagineSop For Good Manufacturing Practices: Written by Verified by Function Name Signature DateSreelakshmi RakeshNessuna valutazione finora

- Amit ResumeDocumento5 pagineAmit ResumeASHOK KUMAR LENKANessuna valutazione finora

- Operation & Cleaning Procedure for Octagonal BlenderDocumento7 pagineOperation & Cleaning Procedure for Octagonal BlenderNgoc Sang HuynhNessuna valutazione finora

- SOP for GLP Compliance in Quality Control LabsDocumento2 pagineSOP for GLP Compliance in Quality Control LabsPrince MoniNessuna valutazione finora

- Validation Protocol for Duke Process FRM3Documento10 pagineValidation Protocol for Duke Process FRM3Prashansa ShresthaNessuna valutazione finora

- GS Coating Equipment enDocumento8 pagineGS Coating Equipment enAkber LakhaniNessuna valutazione finora

- Multimill ManualDocumento3 pagineMultimill ManualVikas SehgalNessuna valutazione finora

- 2 CVPDocumento5 pagine2 CVPQANessuna valutazione finora

- Labaid Pharmaceuticals Limited: Standard Operating ProcedureDocumento8 pagineLabaid Pharmaceuticals Limited: Standard Operating ProceduremasumNessuna valutazione finora

- Sample FAT ProtocolDocumento6 pagineSample FAT ProtocolMatej Petric0% (1)

- Example RA For Transport To Regulated MarketsDocumento7 pagineExample RA For Transport To Regulated MarketsDoan Chi ThienNessuna valutazione finora

- GMP Trends-1Documento177 pagineGMP Trends-1skvemulaNessuna valutazione finora

- 2-O&c of Paam Af 90 TDocumento6 pagine2-O&c of Paam Af 90 Tananth100% (1)

- Change Control Matrix For Facility ChangeDocumento2 pagineChange Control Matrix For Facility ChangePrem Goel100% (1)

- Compression BasicDocumento24 pagineCompression BasicEKA NURUL FALAH 02511740000082Nessuna valutazione finora

- Tablet Technology EditedDocumento42 pagineTablet Technology EditedPramod Kc100% (1)

- Xoxiban 10mg Tab VPDocumento13 pagineXoxiban 10mg Tab VPziauddin bukhariNessuna valutazione finora

- Invitation To One Day Work Shop - Revised Schedule MDocumento3 pagineInvitation To One Day Work Shop - Revised Schedule MSohinyNessuna valutazione finora

- Q-11650, Cage Blender-600 LTRSDocumento7 pagineQ-11650, Cage Blender-600 LTRSanita shindeNessuna valutazione finora

- Oil Flushing Method StatementDocumento22 pagineOil Flushing Method StatementAnh Dũng NguyễnNessuna valutazione finora

- Design Basis for LPG & Propylene Storage FacilitiesDocumento12 pagineDesign Basis for LPG & Propylene Storage Facilitiessatnam1979100% (1)

- Summarise The Information by Selecting and Reporting The Main FeaturesDocumento3 pagineSummarise The Information by Selecting and Reporting The Main FeaturesAffrianaa SiagianNessuna valutazione finora

- Afriana Siagian Maintenance Planning: Progress ReportDocumento3 pagineAfriana Siagian Maintenance Planning: Progress ReportAffrianaa SiagianNessuna valutazione finora

- Travel: A Girls' Guide byDocumento13 pagineTravel: A Girls' Guide bysdas123Nessuna valutazione finora

- Cordell Place SF 3-00Documento31 pagineCordell Place SF 3-00Affrianaa SiagianNessuna valutazione finora

- 3 Deec 521255 C 47 Bfe 3Documento20 pagine3 Deec 521255 C 47 Bfe 3Affrianaa SiagianNessuna valutazione finora

- Johnson Paper 06Documento17 pagineJohnson Paper 06Affrianaa SiagianNessuna valutazione finora

- 13th ITCC2015 Application Form - 2Documento3 pagine13th ITCC2015 Application Form - 2Affrianaa SiagianNessuna valutazione finora

- Inventory and production requests across locationsDocumento1 paginaInventory and production requests across locationsAffrianaa SiagianNessuna valutazione finora

- Entrepreneurship: - PTLP - PTI - PSK/ Apk - Ergonomi - Gamtek - SCMDocumento1 paginaEntrepreneurship: - PTLP - PTI - PSK/ Apk - Ergonomi - Gamtek - SCMAffrianaa SiagianNessuna valutazione finora

- 3x2x2x2 Factorial Experiment ResultsDocumento4 pagine3x2x2x2 Factorial Experiment ResultsAffrianaa SiagianNessuna valutazione finora

- Sign TableDocumento1 paginaSign TableAffrianaa SiagianNessuna valutazione finora

- Wilcoxon Rank Sum TableDocumento4 pagineWilcoxon Rank Sum TableputraickoNessuna valutazione finora

- Ftu R-200 PDFDocumento111 pagineFtu R-200 PDFdumaibangetNessuna valutazione finora

- SCADA Security: What Is An Industrial Control System?Scada - PCS, Dcs SecurityDocumento3 pagineSCADA Security: What Is An Industrial Control System?Scada - PCS, Dcs SecurityDeeee357100% (1)

- OPNET IT Guru Analysis of MPLS Implementation Benefits in WSN Over IP For 6LoWPAN Network Nodes.Documento33 pagineOPNET IT Guru Analysis of MPLS Implementation Benefits in WSN Over IP For 6LoWPAN Network Nodes.Wao Eric WamolaNessuna valutazione finora

- TechTarget IT AcronymsDocumento91 pagineTechTarget IT AcronymsTaha ShahzadNessuna valutazione finora

- Chapter 5Documento111 pagineChapter 5Kaustubh ParthasarathyNessuna valutazione finora

- REF542plus IEC61850 ConfStatement 756361 ENd Rel3.0SP1Documento74 pagineREF542plus IEC61850 ConfStatement 756361 ENd Rel3.0SP1josleinyNessuna valutazione finora

- Network Security and Firewall - ClearOSDocumento41 pagineNetwork Security and Firewall - ClearOSHuynh KhoaNessuna valutazione finora

- The Nature and Aesthetics ofDocumento28 pagineThe Nature and Aesthetics ofJaime Rodriguez UrbinaNessuna valutazione finora

- Frame RelayDocumento44 pagineFrame RelayNitin ChauhanNessuna valutazione finora

- Understanding Computer NetworksDocumento94 pagineUnderstanding Computer NetworksawanishNessuna valutazione finora

- Comunicación Modbus RTUDocumento34 pagineComunicación Modbus RTUJuan Felipe HernandezNessuna valutazione finora

- DNP3 Security Framework Provides Confidentiality, Integrity and AuthenticityDocumento32 pagineDNP3 Security Framework Provides Confidentiality, Integrity and AuthenticityAlfredo RisueñoNessuna valutazione finora

- Contain Slides by Leon-Garcia and WidjajaDocumento56 pagineContain Slides by Leon-Garcia and WidjajaAnonymous 6iFFjEpzYjNessuna valutazione finora

- Linux - VPN - A Technical Guide To IPSec Virtual Private NetworksDocumento348 pagineLinux - VPN - A Technical Guide To IPSec Virtual Private Networksallado123Nessuna valutazione finora

- Link LayerDocumento58 pagineLink LayerrajindermmathNessuna valutazione finora

- RET541 543ParlistENaDocumento145 pagineRET541 543ParlistENaMatthew Mason100% (1)

- CBSN4103 AnswerDocumento9 pagineCBSN4103 AnswerKreatif TuisyenNessuna valutazione finora

- Efficient Broadcasting With GuaranteedDocumento12 pagineEfficient Broadcasting With GuaranteedKarthick LakshminarayananNessuna valutazione finora

- Mef 10.3Documento20 pagineMef 10.3Suma RaoNessuna valutazione finora

- Network Secured Authentication With Client System Monitor ControlDocumento5 pagineNetwork Secured Authentication With Client System Monitor ControlmaheshboobalanNessuna valutazione finora

- IEEE 1278 DIS StandardDocumento61 pagineIEEE 1278 DIS Standardforumid2697Nessuna valutazione finora

- MC UbtDocumento131 pagineMC UbtgazmendisufiNessuna valutazione finora

- Corrector FMGDocumento5 pagineCorrector FMGFabricio Mayta BenitezNessuna valutazione finora

- Wireless Protocol Gateway ARP600: Product GuideDocumento20 pagineWireless Protocol Gateway ARP600: Product GuideparadiseparasNessuna valutazione finora

- DNP3.0 Technical Manual PDFDocumento97 pagineDNP3.0 Technical Manual PDFRoh OJNessuna valutazione finora

- Pondicherry University SyllabusDocumento39 paginePondicherry University Syllabussat007is4uNessuna valutazione finora

- Embedded Systems Course Details PDFDocumento10 pagineEmbedded Systems Course Details PDFraghuramNessuna valutazione finora

- Business Data Communications and Networking: Jerry Fitzgerald and Alan DennisDocumento40 pagineBusiness Data Communications and Networking: Jerry Fitzgerald and Alan DennisAlejandra OrtizNessuna valutazione finora

- Interfacing DC Motor Using PIC MicrocontrollerDocumento9 pagineInterfacing DC Motor Using PIC MicrocontrollerkevgnpNessuna valutazione finora

- Parallel Computers (2) - Introduction to Distributed Memory Systems and Communication Networks (40Documento20 pagineParallel Computers (2) - Introduction to Distributed Memory Systems and Communication Networks (40Varun NagpalNessuna valutazione finora