Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cao Lanh Hcb50 Instruction

Caricato da

Nam NamCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cao Lanh Hcb50 Instruction

Caricato da

Nam NamCopyright:

Formati disponibili

Installation and operation instruction of HCB50

Brief introduction

The power of the HCB-50 climbing formwork system is the hydraulic system,which

includes the oil cylinder and inverting box.The inverting box can control the climbing of the

steel rail or the bracket.The steel rail and the bracket can inter-climbing,so the whole

system will climb up steadily.Cranes are not needed during the construction.Its easy to

operate,highly active and safe. Its the best choice for the construction of high buildings

and towers.There are mainly four parts in the whole system:formwork system,anchor

system,bracket system and hydraulic system.

Page 1 of 11

Installation and operation instruction of HCB50

General assembly drawing 1

Page 2 of 11

Installation and operation instruction of HCB50

1.1

1.1Formwork system

To first choice formwork system of timber beam and plywood because of the work

high above the ground which use light weight and high-strength formwork system,:

flange clamp

1.2 Anchor system

There are four parts in this system,they are anchor plate, high-strength bolt, Tensile

bolt and V-climbing cone.

Anchor system

anchor plate

Tensile bolt

high-strength bolt

V-climbing cone

1.3 Bracket system

Bracket system is the important support part of the whole system. The primary

parts are:upper platform,vertical waling,climbing bracketretrusive set,wall-attached

support,anchor shoes,steel rail, suspended platform.

Page 3 of 11

Installation and operation instruction of HCB50

1.3.1 Upper platform

Put the board on the adjustable-pitch

handrail will from the upper platform.The

adjustable-pitch handrail is fixed on the

beam,Its angle can be adjusted to make sure

its horizontal when the formwork system is

adjustable-pitch handrail

climbing,which will be convenient for workers

to work.

1.3.2 Vertical waling and pull-push prop

Name and No.

Vertical waling

Sketch

Name and No.

Pull-push prop for

vertical waling

Page 4 of 11

Sketch

Installation and operation instruction of HCB50

1.3.3 Climbing bracket

Climbing bracket assembly

Name and Article

No.

Beam

For

climbing

bracket

Sketch

Upright

for platform

Its the most important

support part in the whole

system.Compared with the

formwork HCB-50,the brace

for climbing bracket

is

replaced by pull-push prop,

the length of the pull-push

prop can be adjusted, which

is the structure base of the

HCB-50 system can climb

slantways.

Upright

for

climbing

bracket

Pull-push

prop for climbing

bracket

1.3.4Retrusive set

Retrusive set is fixed on the top of the

beam for climbing bracket.The gear in the

retrusive set is joggle with the gear rack

Retrusive set assembly

on the beam for climbing bracket.So the

set can move along the beam.

Page 5 of 11

Installation and operation instruction of HCB50

1.3.5 Wall-attached support

One side is fixed on the end of the upriht for the

climbing bracket,the other side props tightly on the

wall.Its function is support and fixation the system.

Wall-attached support

1.3.6 Anchor shoe

Anchor shoe is the most important bearing parts in the whole formwork system.One

side is fixed with the anchor system,the other side is fixed with clymbing bracket.There

are two kinds of anchor shoes,they are single anchor shoe and double anchor

shoe.Thereinto,the double anchor shoe can bear more pressure,so we can make choice

according to the demand.

Double anchor shoe

Name and

No.

Double

anchor

shoe

01090203A

Sketch

Name and No.

Sketch

Bearing pin

Safe pin20

L=530

1.3.7 Main beam head

One side is hung on the anchor

system,the other side is fixed with the

climbing bracket. Its function is connecting

the anchor system and the clymbing

bracket.

Page 6 of 11

Installation and operation instruction of HCB50

Main beam head assembly

1.3.8 Steel rail

Steel rail

Steel rail is the orbit of the formwork

systems climbing.The climbing direction is

changed by the inverting box which is the

important carry-over force parts between

the bracket and steel rail.It can control the

climbing of the steel rail or the bracket.The

steel rail and the bracket can interclimbing.

1.3.9 Suspended platform

Suspended platform assembly

Suspended platform is fixed under the whole

formwork system.Its convenient for workers

to backout the anchors and do clearing work.

1.4 Hydraulic system

It includes the console of hydraulic power unit, oil cylinder, synchronous valve,hose,

hydraulic valve and power distrabution device.

2.Assembly process of the system

Page 7 of 11

Installation and operation instruction of HCB50

1. Assemble the climbing bracket.

3. The hoisting of the climbing bracket.

2. Fix the platform board.

4. Consolidate the girder and fix

all the platforms.

5. The hoisting of the formwork and the

girder.

3. Climbing process

Page 8 of 11

Installation and operation instruction of HCB50

Finish pouring the concreteremove the formworkfix the wall-attached setclimb

up the steel railclimb up the bracketcolligate the reinforcing steel barclean the

templates and brush release agentfix the anchors on the templatesmove the

formwork system to its placepour the concrete.The sketches are shown below:

The 1st step

finish assembling the

system

pour the concrete

colligate the reinforcing

The 2nd step

remove the formwork

insert the steel rail

climb up

The 3rd step

climb up to the riht place

install the suspened plaform

move the formwork to its

place

steel bar on the platforms

The 4th step

(1)make sure the

formwork is on its place

pour the concrete

climb up

The 5th step

finish pouring the

concrete

(2)remove the formwork

The 6th step

come into the standard

climbing stage

(2)pour the concrete again

4The safe operation of management

4.1 It must wear a seatbelt and the necessary protective equipmentto install anchor and

bracket. high-strength bolt and v-climbing cone connection must be tightened, to brush

the antisticking agent on v-climbing cone so as to easyly removal.

4.2 Concrete strength must be above 10MPa so that it can climb.

Page 9 of 11

Installation and operation instruction of HCB50

4.3 The climbing operation can not do if the night light no good enough.

4.4 The climbing operation can not do when in thunderstorms, strong winds (more than

8), fog, snow and other adverse weather conditions.

4.5 Pump Station should be operated by specially-assigned person and other people

can not operate, the pressure of hydraulic pump must be less than 16MPa when

hydraulic pump is working.

4.6 When climbing formwork all the personnel must leave the mold except the operator,,

when climb up in place other work can do.

4.7 It must set the warning limit about three meters distance around the climb formwork

when climbing and all the people can not enter.

4.8 Before Climb up the steel rail and the bracketsthe operator must check whether

the machine is running normally and the normal can be climbing, ready all the tools and

put less thing on the bracket before to climb.

4.9 The operator has to train strictly they can operate independently after the Project

Department approved.

4.10 when climbing up, the bracket may not put heavy things.

5. Matched moulds

5.1 To clean up the formwork, brush the antisticking agent, install the anchor system

before matched moulds.

5.2 To measure the location of the formwork tie rod hole, it cant conflict with steel bar.

5.3 To remove the formwork and close to the surface of concrete.

5.4 To adjust the formwork verticality with line or equipment .

5.5 To plug into chamfering hob.

5.6 Put the bushing and the tie rod together and tighten each bolt .

5.7 To check theformwork verticality and fasten each sway brace.

5.8 Pouring the concrete.

6Removal of formwork

6.1 To remove the shuttering when the strength of concrete reach the requirements.

6.2 To remove all of the through walls high-strengh bolts and exposed corners, taking

the tie rod (including the bevel tie rod, etc.).

6.3 To pull out the chamfering hob pin.

6.4 To remove the formwork backwards (the formwork can be moved(600mm-700mm),

and then plug into the chamfering hob pin.

7. Removal of hydraulic climbing frame

7.1 To remove the formwork with tower crane.

7.2 To remove the formwork above the main platform truss system with tower crane.

7.3 To take out steel rail with tower crane.

7.4 To remove the hydraulic unit and the distribution unit

7.5 To remove the hydraulic console desk of the main platform bridge, lifting the

hydraulic control station suspended and some hydraulic unit.

Page 10 of 11

Installation and operation instruction of HCB50

7.6 The operators should stand at the platform and remove equipment for wall-attached

and the v-climbing cone .

7.7 Lifting the climbing bracket and the suspended platform with tower crane and stop

when reach the appropriate height, remove the highest equipment for wall-attached and

the v-climbing cone and repair the holes from v-climbing cone.

7.8 Finally, to remove bracket which connected with the ladder or lift , the operator set

down hook and remove equipment for wall-attached and the v-climbing cone, the

operator should leave from the elevator or the ladder and then lift the last bracket .

Page 11 of 11

Potrebbero piacerti anche

- Chevy Differentials: How to Rebuild the 10- and 12-BoltDa EverandChevy Differentials: How to Rebuild the 10- and 12-BoltValutazione: 5 su 5 stelle5/5 (8)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDa EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideValutazione: 4.5 su 5 stelle4.5/5 (8)

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionDa EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionValutazione: 4 su 5 stelle4/5 (1)

- Master Specifications Vehicle LiftsDocumento14 pagineMaster Specifications Vehicle LiftskarliftsolutionNessuna valutazione finora

- PCI 6th Edition Flexural Component DesignDocumento127 paginePCI 6th Edition Flexural Component DesignEnger AlingasaNessuna valutazione finora

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideDa EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideValutazione: 4 su 5 stelle4/5 (8)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheDa EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheValutazione: 4.5 su 5 stelle4.5/5 (2)

- Composting Toilet Construction ManualDocumento23 pagineComposting Toilet Construction ManualalinupNessuna valutazione finora

- Tribological Processes in the Valve Train Systems with Lightweight Valves: New Research and ModellingDa EverandTribological Processes in the Valve Train Systems with Lightweight Valves: New Research and ModellingValutazione: 1.5 su 5 stelle1.5/5 (2)

- Rotary Drilling Rig ComponentsDocumento130 pagineRotary Drilling Rig Componentsgarry_dirak100% (21)

- Sany Piling RigDocumento66 pagineSany Piling RigRajan Mullappilly100% (2)

- 01 Introduction To Directional DrillingDocumento36 pagine01 Introduction To Directional DrillingKhanh Pham MinhNessuna valutazione finora

- Lift ShaftDocumento21 pagineLift Shaftvijking100% (2)

- 7000 Series Field Operations Manual PDFDocumento45 pagine7000 Series Field Operations Manual PDFmanzanaNessuna valutazione finora

- Rig Operations Components GuideDocumento130 pagineRig Operations Components GuideOmar Santamaría Castillo100% (1)

- SATIP-A-114-01 Earthworks: Site Preparation, Excavation and Backfilling During ConstructionDocumento2 pagineSATIP-A-114-01 Earthworks: Site Preparation, Excavation and Backfilling During ConstructionNino Celso AstilleroNessuna valutazione finora

- Cameron U Ram BopDocumento29 pagineCameron U Ram BopAnaruzzaman SheikhNessuna valutazione finora

- Korean Language Guide (2013) PDFDocumento205 pagineKorean Language Guide (2013) PDFAnna Chen100% (1)

- An Investigation of The Fatigue and Fretting PerformanceDocumento19 pagineAn Investigation of The Fatigue and Fretting PerformanceKrishna PrasadNessuna valutazione finora

- Liner Hanger & Setting ToolDocumento58 pagineLiner Hanger & Setting ToolRobert Koch100% (1)

- Fampc4000 05Documento94 pagineFampc4000 05Lucio Valderrama PeredaNessuna valutazione finora

- Hoisting System (Sistema de Elevacion)Documento8 pagineHoisting System (Sistema de Elevacion)Ferna DiazNessuna valutazione finora

- SPANCO FR WSB Instmaint Manual 103 0011 Rev06 11Documento24 pagineSPANCO FR WSB Instmaint Manual 103 0011 Rev06 11Eduardo OchaitaNessuna valutazione finora

- 11# EOT Crane Operation ManualDocumento82 pagine11# EOT Crane Operation Manualibnmessaoud10100% (5)

- Topographic Map Symbols GuideDocumento1 paginaTopographic Map Symbols GuideRonaldo Jr. DIAZ100% (1)

- Boiler Erection PDFDocumento44 pagineBoiler Erection PDFShankar Jha100% (1)

- Problem 826 - Continuous Beam by Three-Moment Equation - Strength of Materials ReviewDocumento4 pagineProblem 826 - Continuous Beam by Three-Moment Equation - Strength of Materials ReviewJhundel Factor PajarillagaNessuna valutazione finora

- Load Chart CK 2500Documento28 pagineLoad Chart CK 2500ArisNessuna valutazione finora

- Es Iso - 1452-3 - 2015 (E)Documento41 pagineEs Iso - 1452-3 - 2015 (E)Chalew GebruNessuna valutazione finora

- CAH Small Frame Air Hoist Manual 11720901Documento30 pagineCAH Small Frame Air Hoist Manual 11720901cj7man80Nessuna valutazione finora

- Erection of Boiler ColumnsDocumento44 pagineErection of Boiler ColumnsS.KAMBAN100% (1)

- CEP Design Features And Parameters ComparisonDocumento35 pagineCEP Design Features And Parameters ComparisonGaurav100% (1)

- Single Girder Overheade Crane Operation ManualDocumento51 pagineSingle Girder Overheade Crane Operation ManualHamdy Ahmed HassanNessuna valutazione finora

- Erection & Installation ProcedureDocumento3 pagineErection & Installation ProcedureForos IscNessuna valutazione finora

- Rotary Drilling Rig ComponentDocumento130 pagineRotary Drilling Rig ComponentRamez Rimez0% (1)

- Installation of Monorail CraneDocumento28 pagineInstallation of Monorail CraneVijay Bhushan EkkaNessuna valutazione finora

- COMPONENTE Rotary Drilling RigDocumento65 pagineCOMPONENTE Rotary Drilling RigsteauafaranumeNessuna valutazione finora

- L&T Formwork Systems GuideDocumento23 pagineL&T Formwork Systems Guidevijking100% (1)

- Operating Instruction of PE Series Jaw CrusherDocumento22 pagineOperating Instruction of PE Series Jaw CrusherEnso E Rosales FNessuna valutazione finora

- VOLVO PF4410 TRACKED PAVER Service Repair Manual PDFDocumento15 pagineVOLVO PF4410 TRACKED PAVER Service Repair Manual PDFfjjsjekdmme0% (1)

- Boiler Ash Handling Operation & Maintenance PDFDocumento64 pagineBoiler Ash Handling Operation & Maintenance PDFdreamboy87Nessuna valutazione finora

- Cordwood Construction PDFDocumento8 pagineCordwood Construction PDFamondaca100% (1)

- Catalogue Bridges and Bridge TechnologiesDocumento58 pagineCatalogue Bridges and Bridge TechnologiesNam NamNessuna valutazione finora

- Septic Tank Design ConceptDocumento20 pagineSeptic Tank Design Conceptsatya prakash goudaNessuna valutazione finora

- DY 50/4防喷器吊移装置说明书 (英)Documento10 pagineDY 50/4防喷器吊移装置说明书 (英)Nader abobakrNessuna valutazione finora

- Operating ManualDocumento34 pagineOperating ManualLauraNessuna valutazione finora

- BOP Handling System Operation ManualDocumento10 pagineBOP Handling System Operation ManualJosé ManuelNessuna valutazione finora

- QJY Car Lift 6328693Documento12 pagineQJY Car Lift 6328693Ildikó BodnárNessuna valutazione finora

- Chapter 1 Survey of Tower Crane Technical Specs and Safety RulesDocumento50 pagineChapter 1 Survey of Tower Crane Technical Specs and Safety RuleskrmchariNessuna valutazione finora

- User Manual: International Industry of Metallic Formwork SystemsDocumento9 pagineUser Manual: International Industry of Metallic Formwork Systemsjachoijachoi100% (1)

- H-Beam Assembly and Straightening MachinesDocumento5 pagineH-Beam Assembly and Straightening MachinesHo NgocNessuna valutazione finora

- Method Statement Pipe JackingDocumento1 paginaMethod Statement Pipe JackingNur NeynaNessuna valutazione finora

- B1000×3000 板式喂料机 B1000×3000 Apron FeederDocumento10 pagineB1000×3000 板式喂料机 B1000×3000 Apron FeederRahmat YusufNessuna valutazione finora

- Bucket ElevatorDocumento7 pagineBucket ElevatorlateraNessuna valutazione finora

- Automatic Side Stand With Breaking Locking SystemDocumento44 pagineAutomatic Side Stand With Breaking Locking SystemSaravanan Viswakarma100% (2)

- Construction of Surge Shaft Using Slip Form TechniqueDocumento4 pagineConstruction of Surge Shaft Using Slip Form TechniqueCharumitra Singh YadavNessuna valutazione finora

- Perf MGMT BSC TrainingDocumento12 paginePerf MGMT BSC Trainingchibssa alemayehuNessuna valutazione finora

- Cyclone Operating SystemDocumento7 pagineCyclone Operating SystemShuriqqNessuna valutazione finora

- Internship ProjectDocumento17 pagineInternship Projectinteraman123Nessuna valutazione finora

- Strela Putzmeister BP 2059 GBDocumento7 pagineStrela Putzmeister BP 2059 GBunwesentlich100% (1)

- Step Pulley Term Project ReportDocumento15 pagineStep Pulley Term Project ReportAnis Badshah75% (4)

- Illumena Mavig Susp Install-EDocumento16 pagineIllumena Mavig Susp Install-Ejoam36Nessuna valutazione finora

- VP1 Service ParkerDocumento16 pagineVP1 Service ParkerAdrian Alonso Bustos GonzalezNessuna valutazione finora

- SOP Terminal Tractor01Documento11 pagineSOP Terminal Tractor01vozefjadavNessuna valutazione finora

- Installation Instructions For Vilter 25972Documento8 pagineInstallation Instructions For Vilter 25972jorge castilloNessuna valutazione finora

- Jacking SystemsDocumento19 pagineJacking SystemsAbabNessuna valutazione finora

- Manual - 9 HAKI Block Bracket - INTDocumento12 pagineManual - 9 HAKI Block Bracket - INTwilliamsaminNessuna valutazione finora

- Ae 1013 Helicopter Maintenance NewDocumento16 pagineAe 1013 Helicopter Maintenance NewAeronaughtycs Hamdan100% (1)

- H-6745_00_MEF_00_081_DCDocumento33 pagineH-6745_00_MEF_00_081_DCfuad aliNessuna valutazione finora

- Manual Hidraulico Montacargas Yale Gp060rcDocumento52 pagineManual Hidraulico Montacargas Yale Gp060rcPepe AlNessuna valutazione finora

- 708 Floor Scale Installation and Maintenance Manual: Emery Winslow Scale CompanyDocumento34 pagine708 Floor Scale Installation and Maintenance Manual: Emery Winslow Scale CompanyImran MohiuddinNessuna valutazione finora

- OSHA 1910.66 App A - Guidelines (Advisory)Documento4 pagineOSHA 1910.66 App A - Guidelines (Advisory)Gunnie PandherNessuna valutazione finora

- SPSP2011 BookDocumento162 pagineSPSP2011 BookNam NamNessuna valutazione finora

- FHWA Guidance on Transportation Enhancement ActivitiesDocumento56 pagineFHWA Guidance on Transportation Enhancement ActivitiesNam NamNessuna valutazione finora

- Calculation of Auto-Climbingsystem For Cao Lanh BridgeDocumento10 pagineCalculation of Auto-Climbingsystem For Cao Lanh BridgeNam NamNessuna valutazione finora

- Tlsbondvaluesconcreteandpiles 1Documento4 pagineTlsbondvaluesconcreteandpiles 1Nam NamNessuna valutazione finora

- Topic1 3 Foundations Footings 13Documento19 pagineTopic1 3 Foundations Footings 13Hussein JaberNessuna valutazione finora

- RF Buildings SOR 2013-14-CIVILDocumento110 pagineRF Buildings SOR 2013-14-CIVILMadhu KrishnaNessuna valutazione finora

- Chapter 3Documento34 pagineChapter 3Jeric EliveraNessuna valutazione finora

- Effective use of bone ash in constructionDocumento3 pagineEffective use of bone ash in constructionManuNessuna valutazione finora

- 612c (Uas 2019)Documento37 pagine612c (Uas 2019)jawarta simamoraNessuna valutazione finora

- 2-CE 305 MOD 2 Singly RCFDocumento10 pagine2-CE 305 MOD 2 Singly RCFLester Khiets RoaNessuna valutazione finora

- Proposed Pangsapuri 5 Tingkat: Verification Esteem DataDocumento33 pagineProposed Pangsapuri 5 Tingkat: Verification Esteem DataMohamad Fazwan Bin Mohd NasirNessuna valutazione finora

- Presentation Gene TGDocumento40 paginePresentation Gene TGsuvraNessuna valutazione finora

- Is 883 1994 PDFDocumento21 pagineIs 883 1994 PDFkrishnanunniNessuna valutazione finora

- Din 16963-06Documento4 pagineDin 16963-06MaurícioAndradeNessuna valutazione finora

- Accepted Manuscript: 10.1016/j.polymertesting.2015.01.020Documento32 pagineAccepted Manuscript: 10.1016/j.polymertesting.2015.01.020Dharun TNessuna valutazione finora

- Nishihara PDFDocumento15 pagineNishihara PDFBill BatNessuna valutazione finora

- PD MeterDocumento3 paginePD Meterreach_arindomNessuna valutazione finora

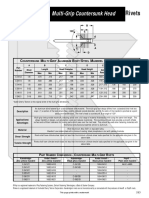

- Rivets Multi Grip CountersunkDocumento1 paginaRivets Multi Grip CountersunkIsrael OluwagbemiNessuna valutazione finora

- The Concrete Centre: Spreadsheets To BS 8110 EtcDocumento1 paginaThe Concrete Centre: Spreadsheets To BS 8110 EtcmayphyoNessuna valutazione finora

- Orthographic Projection ExplainedDocumento23 pagineOrthographic Projection ExplainedErdem ImrakNessuna valutazione finora

- Carbon Fiber Prepreg PDSDocumento1 paginaCarbon Fiber Prepreg PDSMauro RosarioNessuna valutazione finora

- Week 1 Lecture MaterialDocumento95 pagineWeek 1 Lecture MaterialSeema Gawali SonwaneNessuna valutazione finora

- List of Office DocumentsDocumento16 pagineList of Office DocumentsMay Ann DuronNessuna valutazione finora

- Design Standards Volume 3 02 DrainageDocumento90 pagineDesign Standards Volume 3 02 DrainageLeonardo TejedorNessuna valutazione finora