Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Swiss International LLC

Caricato da

Burning TrainTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Swiss International LLC

Caricato da

Burning TrainCopyright:

Formati disponibili

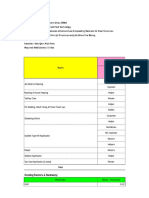

SWISS INTERNATIONAL LLC

P.O. Box: 1840, PC:133

Al Khuwair, Sultanate of Oman

Swiss Doc No.:

SI/ITP/EP/02/15

GHATHERING STATION - ON PLOT, GHABA NORTH

SITE QUALITY CONTROL PLAN FOR EPOXY INTUMESCENT FIREPROOFING FOR

EQUIPMENTS' SADDLES

Phase

Activity Description

Type of Test

Controlling Document

Acceptance Criteria

Responsible

Frequency of

Person at

Inspection

Location

1.0

MS & ITP Approvals and Applicator's Qualification

1.1

MS & ITP Approvals

Contract Document,

DEP34.19.20.11

Approved Drawings, SPGen

1246, DEP34.19.20.11

SP-1246 Part 1 to 5

Gen

1.2

Applicator's Qualification

Verification of

applicators'

certificates

- DEP34.19.20.11 Gen

SP-1246 Part 1 to 5

- Chartek 1709

Application manual

2.0

MATERIALS INSPECTION

2.1

PFP - Chartek 1709

Visual Inspection

-DEP34.19.20.11 Gen

-Technical Data Sheet

-Materials Inspection

Report

Visual Inspection

- DEP34.19.20.11 Gen

-Technical Data Sheet

- Materials Inspection

Report

- Glass/Carbon hybrid Fibre Mesh

manufactured by International Paints

- Unopened & undamaged pack

- Matching batch number, Expiry Date

Verification

100%

Visual Inspection

- DEP34.19.20.11 Gen

-Technical Data Sheet

- Materials Inspection

Report

- Zinc phosphate baseed primer

manufactured by International Paints

- Unopened & undamaged pack

- Matching batch number, Shelf life

Verification

100%

Visual Inspection

- DEP34.19.20.11 Gen

-Technical Data Sheet

- Materials Inspection

Report

- RAL 9010

- Acrylic polyurethane based top coat

manufactured by International Paints

- Unopened & undamaged pack

- Matching batch number, Shelf life

Verification

100%

Visual Inspection

- DEP34.19.20.11 Gen

-Technical Data Sheet

-Swiss MS:SI-MS-EP01

- Materials Inspection

Report

-GTA123 thinner manufactured by

International Paints

- Unopened & undamaged pack

- Shelf life

Verification

100%

2.2

2.3

2.4

2.5

HK-1 Mesh

Primer - Intergard 251

Top Coat - Interthane 990

Thinner - GTA123

Rev.01

Company Doc No.:

Records

SWISS

AHEC

PDO

Ensure that MS and ITP are approved by

PDO. Coating system specified in the

contract document/approved drawings

shall be followed.

Verification

100%

QCE

Approved ITP and MS

R/A

R/A

Applicator should be trained & certified

by Chartek 1709 manufacturer

Verification

100%

QCE

Applicator Certificates

R/A

R/A

Verification

100%

QCE/QCI

Batch Certificates, Delivery Note,

Materials Inspection Report,

Form No. SI/QCP/EP/020, Check

List for Fireproofing. Form No.

SI/QCP/EP/026, Data Sheet

QCE/QCI

Batch Certificates, Delivery Note,

Materials Inspection Report,

Form No. SI/QCP/EP/020, Check

List for Fireproofing. Form No.

SI/QCP/EP/026, Data Sheet

QCE/QCI

Batch Certificates, Delivery Note,

Materials Inspection Report,

Form No. SI/QCP/EP/020, Check

List for Fireproofing. Form No.

SI/QCP/EP/026, Data Sheet

QCE/QCI

Batch Certificates, Delivery Note,

Materials Inspection Report,

Form No. SI/QCP/EP/020, Check

List for Fireproofing. Form No.

SI/QCP/EP/026, Data Sheet

QCE/QCI

Batch Certificates, Delivery Note,

Materials Inspection Report,

Form No. SI/QCP/EP/020, Check

List for Fireproofing. Form No.

SI/QCP/EP/026, Data Sheet

- Epoxy Intumescent PFP Materials

manufactured by International Paint

- Unopened & undamaged pack

- Matching batch number, Shelf life

1 of 4

SWISS INTERNATIONAL LLC

P.O. Box: 1840, PC:133

Al Khuwair, Sultanate of Oman

Swiss Doc No.:

SI/ITP/EP/02/15

GHATHERING STATION - ON PLOT, GHABA NORTH

SITE QUALITY CONTROL PLAN FOR EPOXY INTUMESCENT FIREPROOFING FOR

EQUIPMENTS' SADDLES

Phase

Activity Description

Type of Test

Controlling Document

Acceptance Criteria

Responsible

Frequency of

Person at

Inspection

Location

Rev.01

Company Doc No.:

Records

SWISS

AHEC

PDO

QCE/QCI

Check List for Fireproofing. Form

No. SI/QCP/EP/026, Blasting &

Painting Report,

Form No. SI/QCP/EP/021

3.0

INPROCESS INSPECTION - PRIMER (INTERGARD 251) APPLICATION

3.1

Paint Mixing & Application

Verification

Swiss MS: SI-MS-EP-01

- Mixing ratio: 4 Part A:1 Part B (by Vol)

as per data sheet.

- Cl-3.1 has to be followed before/during

primer application.

3.2

Dry/Wet Film Thickness

Verification

Swiss MS: SI-MS-EP-01

- WFT :80 - 119microns

- DFT:50 - 75 microns

Verification

100%

QCE/QCI

Check List for Fireproofing. Form

No. SI/QCP/EP/026, Blasting &

Painting Report,

Form No. SI/QCP/EP/021

4.0

INPROCESS INSPECTION - PFP (CHARTEK 1709) APPLICATION

4.1

Surface Preparation

Inspection

Swiss MS: SI-MS-EP-01

-Free from oil, grease, rust, dirt, loose

dust etc.

-Min. 16 hours overcoating interval

- No chalking

Verification

100%

QCE/QCI

Check List for Fireproofing. Form

No. SI/QCP/EP/026

4.2

Application of Chartek 1709 - First

Coat

Inspection

Swiss MS: SI-MS-EP-01

- Hand Application

- approx 5.6mm of first coat

Random

Verification

QCE/QCI

Check List for Fireproofing. Form

No. SI/QCP/EP/026

WFT Report Form No.

SI/QCP/EP/022

4.3

Installation of HK-1 Mesh

Verification

Swiss MS: SI-MS-EP-01

- HK-1 at approx mid of total DFT

-Min.150mm of mesh overlap

Random

Verification

QCE/QCI

4.4

Re-application of Chartek 1709 Final Coat

Inspection

Swiss MS: SI-MS-EP-01

- Mesh can be visible,.

- No major undulation in surface finish

- Approx DFT 10.57mm

Random

Verification

QCE/QCI

2 of 4

Random

Verification

Check List for Fireproofing. Form

No. SI/QCP/EP/026

Check List for Fireproofing. Form

No. SI/QCP/EP/026

WFT Report Form No.

SI/QCP/EP/023

SWISS INTERNATIONAL LLC

P.O. Box: 1840, PC:133

Al Khuwair, Sultanate of Oman

Swiss Doc No.:

SI/ITP/EP/02/15

GHATHERING STATION - ON PLOT, GHABA NORTH

SITE QUALITY CONTROL PLAN FOR EPOXY INTUMESCENT FIREPROOFING FOR

EQUIPMENTS' SADDLES

Phase

4.5

Activity Description

Dry Film Thickness (DFT)

Type of Test

Inspection

Controlling Document

Swiss MS: SI-MS-EP-01

Acceptance Criteria

- Aveg. Thickness shall be as per

Appendix A attached to MS

-Individual DFT not less than 85% of

prescribed DFT

Responsible

Frequency of

Person at

Inspection

Location

Random

Verification

QCE/QCI

Rev.01

Company Doc No.:

Records

SWISS

AHEC

PDO

Check List for Fireproofing. Form

No. SI/QCP/EP/026

WFT Report Form No.

SI/QCP/EP/024

R/W

INPROCESS INSPECTION - TOP COAT (INTERTHANE 990, RAL 9010) APPLICATION

5.1

Surface Preparation

Inspection

Swiss MS: SI-MS-EP-01

5.2

Paint Mixing & Application

Inspection

Swiss MS: SI-MS-EP-01

5.3

Wet Film Thickness

Inspection

Swiss MS: SI-MS-EP-01

5.4

Final Dry Film Thickness

6.0

FINAL INSPECTION

6.1

Visual Inspection

6.2

Final Documentation Signed Of

DFT measurement

Review

- No oil, grease, rust, dirt, loose dust

etc.

- RAL Number/Color

Verification

100%

QCE/QCI

Check List for Fireproofing. Form

No. SI/QCP/EP/026

Random

Verification

QCE/QCI

Check List for Fireproofing. Form

No. SI/QCP/EP/026

Random

Verification

QCE/QCI

Check List for Fireproofing. Form

No. SI/QCP/EP/026

WFT Report Form No.

SI/QCP/EP/024

- Aveg. Thickness shall be as per

Appendix A attached to MS

-Individual DFT not less than 85% of

prescribed DFT

Random

Verification

QCE/QCI

Check List for Fireproofing. Form

No. SI/QCP/EP/026

WFT Report Form No.

SI/QCP/EP/024

Approved QCP

Check List

Inspection

Completion.

100%

QCE/QCI

Check List for Fireproofing. Form

No. SI/QCP/EP/026

Approved QCP

Inspection reports shall be signed by all

three parties.

Inspection

Completion.

100%

QCE/QCI

Check List for Fireproofing. Form

No. SI/QCP/EP/026

Swiss MS: SI-MS-EP-01

Mixing ratio: 6 Part A:1 Part B (by Vol)

as per data sheet.

WFT : Min. 100microns

3 of 4

SWISS INTERNATIONAL LLC

P.O. Box: 1840, PC:133

Al Khuwair, Sultanate of Oman

GHATHERING STATION - ON PLOT, GHABA NORTH

SITE QUALITY CONTROL PLAN FOR EPOXY INTUMESCENT FIREPROOFING FOR

EQUIPMENTS' SADDLES

Phase

Activity Description

Type of Test

Controlling Document

Acceptance Criteria

Responsible

Frequency of

Person at

Inspection

Location

Swiss Doc No.:

SI/ITP/EP/02/15

Rev.01

Company Doc No.:

Records

SWISS

AHEC

PDO

H =Hold-Need approval to proceed activity; W= Witness- Company to be notified prior to starting the activity,if company do not attend, activity can proceed; S= survey the works; R= Review- A stage during construction activity

where only review of record will be done; M= Monitor - A stage during construction activity shall be monitored, QCE= Quality Control Engineer, QCI= Quality Control Inspector.

4 of 4

Potrebbero piacerti anche

- ITP For CW and ACW Piping WorkDocumento8 pagineITP For CW and ACW Piping WorkPhong DoNessuna valutazione finora

- Blasting Painting Procedure For Structural Steel Rev 00Documento17 pagineBlasting Painting Procedure For Structural Steel Rev 00Praful N KNessuna valutazione finora

- Surface Preparation and PaintingDocumento4 pagineSurface Preparation and PaintingSimbu ArasanNessuna valutazione finora

- Itp - 002 - Duct Installation - IfrDocumento3 pagineItp - 002 - Duct Installation - IfrMari BelajarNessuna valutazione finora

- Method Statement For Civil Works For Control BuildingDocumento26 pagineMethod Statement For Civil Works For Control BuildingUtku Can KılıçNessuna valutazione finora

- A2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5Documento5 pagineA2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5ochableNessuna valutazione finora

- Inspection Test Plan Rev 1Documento2 pagineInspection Test Plan Rev 1Mohd KhairiNessuna valutazione finora

- General Format For Girder Fabrication Check ListDocumento4 pagineGeneral Format For Girder Fabrication Check ListBhanu Pratap ChoudhuryNessuna valutazione finora

- Field ITP Civil Rev-8after Lump-Sump.Documento17 pagineField ITP Civil Rev-8after Lump-Sump.Echik Kici100% (3)

- ITP C 005 (Structural Concrete)Documento4 pagineITP C 005 (Structural Concrete)segun ajibolaNessuna valutazione finora

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesDocumento2 pagineDuqm Refinery Project EPC Package 2 - Utilities and OffsitesDadaso Baburao JamdarNessuna valutazione finora

- Saudi Technical LTD: Qa / QC Department Organization ChartDocumento1 paginaSaudi Technical LTD: Qa / QC Department Organization Chartzahid_497Nessuna valutazione finora

- Method of Statement For GroutingDocumento7 pagineMethod of Statement For Groutingmohammad.a.d94Nessuna valutazione finora

- Wps Mig PDF FreeDocumento3 pagineWps Mig PDF Freehanz bermejoNessuna valutazione finora

- 1.5 Guidelines For Preparing Inspections & Test Plans (Itp) Agrarian Reform Communities ProjectDocumento5 pagine1.5 Guidelines For Preparing Inspections & Test Plans (Itp) Agrarian Reform Communities ProjectJason Angel BuñagNessuna valutazione finora

- Checklist1101 - Structural Steelwork - Fabrication - UnlockedDocumento2 pagineChecklist1101 - Structural Steelwork - Fabrication - UnlockedsouravrobinNessuna valutazione finora

- ITP Inspection and Test Plan 6MODocumento2 pagineITP Inspection and Test Plan 6MOAS DevNessuna valutazione finora

- Approved Itp-Dss - 28 Sep 2016Documento4 pagineApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianNessuna valutazione finora

- Inar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaDocumento14 pagineInar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaSreedhar Patnaik.MNessuna valutazione finora

- ITP For Steel Structure1Documento3 pagineITP For Steel Structure1吴兴泊Nessuna valutazione finora

- PP WP28Documento15 paginePP WP28mohd as shahiddin jafriNessuna valutazione finora

- Sample # 1Documento3 pagineSample # 1Clarence Ferro100% (1)

- TP-01Hydrostatic Test Cover SheetDocumento4 pagineTP-01Hydrostatic Test Cover SheetAnonymous GaMb5H52100% (1)

- Daily Painting Report System P 01ndDocumento49 pagineDaily Painting Report System P 01ndArung IdNessuna valutazione finora

- ITP (Test Procedure) PDFDocumento2 pagineITP (Test Procedure) PDFkrishnit100% (1)

- Itp StructureDocumento47 pagineItp StructureMohammed Ady Ganjar100% (4)

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDocumento3 pagineBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNessuna valutazione finora

- ITP Installation of Boiler - R1Documento14 pagineITP Installation of Boiler - R1crys100% (4)

- Blasting Coating ProcedureDocumento61 pagineBlasting Coating ProcedureZohair Aftab100% (1)

- 00-V016 Quality EHS Record Control Procedure Rev 180311Documento5 pagine00-V016 Quality EHS Record Control Procedure Rev 180311Tuong NguyenNessuna valutazione finora

- Tank Erection Procedure: Note: This Is The Sample Document For The Related Job OnlyDocumento5 pagineTank Erection Procedure: Note: This Is The Sample Document For The Related Job Onlygeorge israelNessuna valutazione finora

- ITP AllDocumento1 paginaITP AllMuhammadIqbalMughalNessuna valutazione finora

- Attachment 5 - Painting and Coating System Including Colour CodeDocumento54 pagineAttachment 5 - Painting and Coating System Including Colour CodeVan Anh0% (1)

- Method Statement Installation Os Static Equipment and InternalsDocumento24 pagineMethod Statement Installation Os Static Equipment and InternalsAjin SNessuna valutazione finora

- 4.-QA-QC-Plan-job Desc Field PDFDocumento12 pagine4.-QA-QC-Plan-job Desc Field PDFAli HajirassoulihaNessuna valutazione finora

- KSPC Packing Marking Shipping InstructionDocumento9 pagineKSPC Packing Marking Shipping InstructionMohammed Ahmed NasherNessuna valutazione finora

- Ms For Repair and Welding Jointscoating and PaintingDocumento9 pagineMs For Repair and Welding Jointscoating and Paintingmansih457100% (1)

- Painting Maual For Power Sector ErectionDocumento32 paginePainting Maual For Power Sector Erectionnagarathinam82Nessuna valutazione finora

- Dinesh Qa-Qc EngineerDocumento6 pagineDinesh Qa-Qc EngineerDinesh SomwanshiNessuna valutazione finora

- P1066-CTD-QAC-ITP-004-Rev-A-Inspection & Test Plan For Surface Preparation, Painting & Coating Works-Approved Code-BDocumento16 pagineP1066-CTD-QAC-ITP-004-Rev-A-Inspection & Test Plan For Surface Preparation, Painting & Coating Works-Approved Code-BEILA545 QAQCNessuna valutazione finora

- Blasting & Coating Procedure For Fabricated Steel StructureDocumento8 pagineBlasting & Coating Procedure For Fabricated Steel Structurejasmineamma100% (1)

- 36 - Painting Procedure - Rev0Documento21 pagine36 - Painting Procedure - Rev0Duc ThinNessuna valutazione finora

- Storage Tank Foundation Settlement Quality Control and Inspection Report FormDocumento1 paginaStorage Tank Foundation Settlement Quality Control and Inspection Report FormKhepa BabaNessuna valutazione finora

- Painting Work Method StatementDocumento5 paginePainting Work Method StatementMusthafa ShaikNessuna valutazione finora

- Request For Inspection of MaterialDocumento3 pagineRequest For Inspection of MaterialSopi Labu100% (1)

- Inspection and Test Plan: Enclosed Ground Flare (EGF)Documento17 pagineInspection and Test Plan: Enclosed Ground Flare (EGF)vincent100% (1)

- ItpDocumento7 pagineItpJose Sherin100% (1)

- Obite TC & Ogbogu Cluster - Ultrasonic Examination Procedure For Steel StructureDocumento22 pagineObite TC & Ogbogu Cluster - Ultrasonic Examination Procedure For Steel StructureeetuaNessuna valutazione finora

- FM-16 Material Verification RecordDocumento1 paginaFM-16 Material Verification RecordBleep NewsNessuna valutazione finora

- Traffic Signage - Installation - ItpDocumento1 paginaTraffic Signage - Installation - Itpmoytabura96Nessuna valutazione finora

- Welder and Welder Operator Qualification Record FormDocumento1 paginaWelder and Welder Operator Qualification Record FormNanaba Nanayaw DwomohNessuna valutazione finora

- Itp For Fabrication Steel Structure of Warehouse and WorkshopDocumento6 pagineItp For Fabrication Steel Structure of Warehouse and WorkshopPhong Do100% (1)

- (Painting Works) : Inspection and Test PlanDocumento2 pagine(Painting Works) : Inspection and Test Planrize1159Nessuna valutazione finora

- 001 Itp For Painting Rev 0Documento7 pagine001 Itp For Painting Rev 0Alif Rahmat FebriantoNessuna valutazione finora

- Inspection Test Plan (Itp) : Mobile Fire ExtinguisherDocumento4 pagineInspection Test Plan (Itp) : Mobile Fire Extinguisher87482127Nessuna valutazione finora

- 21Documento6 pagine21Dannis AnantoNessuna valutazione finora

- Ped Certification ProcedureDocumento7 paginePed Certification Procedureabhinandan100% (1)

- QCP - PP Insulation Using Wire MeshDocumento5 pagineQCP - PP Insulation Using Wire MeshBurning TrainNessuna valutazione finora

- ITP-001 Steelwork Fabrication Rev ADocumento5 pagineITP-001 Steelwork Fabrication Rev AMarcus Cox100% (2)

- Test Certificate 01Documento1 paginaTest Certificate 01Anoop RaghuNessuna valutazione finora

- SP-1246 Part 1 Technical RequirementsDocumento27 pagineSP-1246 Part 1 Technical RequirementsBurning TrainNessuna valutazione finora

- RFQ 9019-14 (2 Hrs Fire Rating)Documento1 paginaRFQ 9019-14 (2 Hrs Fire Rating)Burning TrainNessuna valutazione finora

- Oman PTA PJT Piping BOM Rev.a 2015.09.10 (Painting)Documento14 pagineOman PTA PJT Piping BOM Rev.a 2015.09.10 (Painting)Burning Train100% (1)

- PCS 1Documento4 paginePCS 1Burning TrainNessuna valutazione finora

- PCS 3Documento3 paginePCS 3Burning TrainNessuna valutazione finora

- PCS 6Documento3 paginePCS 6Burning TrainNessuna valutazione finora

- SNCP QTNDocumento4 pagineSNCP QTNBurning TrainNessuna valutazione finora

- So QTN 64 16Documento3 pagineSo QTN 64 16Burning TrainNessuna valutazione finora

- Typhoon BOQDocumento3 pagineTyphoon BOQBurning TrainNessuna valutazione finora

- SNCP QTNDocumento5 pagineSNCP QTNBurning TrainNessuna valutazione finora

- Costing For - IsOLATEKDocumento2 pagineCosting For - IsOLATEKBurning TrainNessuna valutazione finora

- Costing For - IsOLATEKDocumento2 pagineCosting For - IsOLATEKBurning TrainNessuna valutazione finora

- CostingDocumento1 paginaCostingBurning TrainNessuna valutazione finora

- Measureemnts - 1Documento1 paginaMeasureemnts - 1Burning TrainNessuna valutazione finora

- SRIP FP QTNDocumento5 pagineSRIP FP QTNBurning TrainNessuna valutazione finora

- Swiss Offer-WB3 Supply and ApplyDocumento2 pagineSwiss Offer-WB3 Supply and ApplyBurning TrainNessuna valutazione finora

- So QTN 64 16Documento3 pagineSo QTN 64 16Burning TrainNessuna valutazione finora

- Anchor Bolt Column Layout Plan: Mezzanine Floor AboveDocumento13 pagineAnchor Bolt Column Layout Plan: Mezzanine Floor AboveBurning TrainNessuna valutazione finora

- Intumescent EveDocumento20 pagineIntumescent EveBurning Train100% (1)

- Project: Zauliyah Gas Plant Project Client: Petroleum Development Oman Maint Contractor: Al Hassan Engineering Co. SAOGDocumento5 pagineProject: Zauliyah Gas Plant Project Client: Petroleum Development Oman Maint Contractor: Al Hassan Engineering Co. SAOGBurning TrainNessuna valutazione finora

- Swiss Offer For Intumescent CoatingDocumento3 pagineSwiss Offer For Intumescent CoatingBurning TrainNessuna valutazione finora

- Fire Paint Area - QuantityDocumento19 pagineFire Paint Area - QuantityBurning TrainNessuna valutazione finora

- Petroleum Development Oman Gathering Station - On Plot (No. 47), Ghaba North Pdo Contract No .Documento10 paginePetroleum Development Oman Gathering Station - On Plot (No. 47), Ghaba North Pdo Contract No .Burning TrainNessuna valutazione finora

- AnnexDocumento1 paginaAnnexBurning TrainNessuna valutazione finora

- Sis Docu. Title Sis Docu. Ref. No. Date Project Client ScopeDocumento2 pagineSis Docu. Title Sis Docu. Ref. No. Date Project Client ScopeBurning TrainNessuna valutazione finora

- Petroleum Development Oman Gathering Station - On Plot (No. 47), Ghaba North Pdo Contract No .Documento10 paginePetroleum Development Oman Gathering Station - On Plot (No. 47), Ghaba North Pdo Contract No .Burning TrainNessuna valutazione finora

- Job Acceptance Report No. Oman Date: 0 8 0 2 1 6: Swiss International LLCDocumento2 pagineJob Acceptance Report No. Oman Date: 0 8 0 2 1 6: Swiss International LLCBurning TrainNessuna valutazione finora

- CostingDocumento2 pagineCostingBurning TrainNessuna valutazione finora

- Costing KDC 2Documento22 pagineCosting KDC 2Burning TrainNessuna valutazione finora

- Contemporary Philippine Arts From The Regions 12Documento3 pagineContemporary Philippine Arts From The Regions 12Julienne Mae N. MahometanoNessuna valutazione finora

- Business Freedom: An Animated Powerpoint TemplateDocumento19 pagineBusiness Freedom: An Animated Powerpoint TemplateKevin LpsNessuna valutazione finora

- A-B-C Socks: SuppliesDocumento6 pagineA-B-C Socks: Supplieslloollo0Nessuna valutazione finora

- Construction Painting NC IIDocumento62 pagineConstruction Painting NC IIStephanie NicholsNessuna valutazione finora

- University of Jodhpur CampusDocumento4 pagineUniversity of Jodhpur CampusnidhiNessuna valutazione finora

- Tletvl Technical Drafting Specialization Las Week3 & 4Documento10 pagineTletvl Technical Drafting Specialization Las Week3 & 4Nixon AtienzaNessuna valutazione finora

- WBS of REsidentaial BuildingDocumento2 pagineWBS of REsidentaial BuildingJitesh Aneja100% (1)

- Hardam Furigay Colleges Foundation, IncDocumento2 pagineHardam Furigay Colleges Foundation, IncZerhan LaarinNessuna valutazione finora

- Vill477-Dig-A0-17-Existing Site PlanDocumento1 paginaVill477-Dig-A0-17-Existing Site PlanDivya SajivNessuna valutazione finora

- Representation of Nature in ArtDocumento35 pagineRepresentation of Nature in ArtSofia Vindas100% (1)

- AM1100 Property From The Estate of Queen Juliana 14-17 March 2011Documento1 paginaAM1100 Property From The Estate of Queen Juliana 14-17 March 2011GavelNessuna valutazione finora

- Create This Book Pages To Print - Google Search 2Documento1 paginaCreate This Book Pages To Print - Google Search 2karenhanysalipNessuna valutazione finora

- Takamatsu Ninjutsu Hiketsu Bun Essence of NinjutsuDocumento2 pagineTakamatsu Ninjutsu Hiketsu Bun Essence of NinjutsumvonicNessuna valutazione finora

- Pune 2024Documento3 paginePune 2024designerNessuna valutazione finora

- Visual Reasoning - Practice SheetDocumento21 pagineVisual Reasoning - Practice SheetSahilNessuna valutazione finora

- HaridwarDocumento29 pagineHaridwarMahendra Singh NegiNessuna valutazione finora

- Bloom ExcerptDocumento50 pagineBloom ExcerptYesica DiazNessuna valutazione finora

- Wheatcroft - The Enemy at The Gate (Review)Documento2 pagineWheatcroft - The Enemy at The Gate (Review)MegadethNessuna valutazione finora

- Wall Tile Collection: Digital 30x60cmDocumento68 pagineWall Tile Collection: Digital 30x60cmAdvait WayangankarNessuna valutazione finora

- Rossow Wedding Ceremony, Dinner, Reception PlaylistDocumento3 pagineRossow Wedding Ceremony, Dinner, Reception PlaylistDJ Nick SalNessuna valutazione finora

- Laminated Paper Airplane Seaboat InstructionsDocumento3 pagineLaminated Paper Airplane Seaboat InstructionsMugenNessuna valutazione finora

- Avillion Farms Commercial E-BrochureDocumento36 pagineAvillion Farms Commercial E-BrochureBhagyaNessuna valutazione finora

- Raymond Pettibon Exhibition PosterDocumento2 pagineRaymond Pettibon Exhibition PosterThe Renaissance SocietyNessuna valutazione finora

- Hear Thou The Song of My Heart SatbDocumento6 pagineHear Thou The Song of My Heart SatbjesaxNessuna valutazione finora

- Tasić, N. Eneolitske Kulture Središnjeg I Zapadnog BalkanaDocumento243 pagineTasić, N. Eneolitske Kulture Središnjeg I Zapadnog BalkanaGlembay280100% (5)

- Nowhere Boy (2009) : Case StudyDocumento12 pagineNowhere Boy (2009) : Case Studytremckenzie12asmediaNessuna valutazione finora

- Trono Branco - 11Documento28 pagineTrono Branco - 11Janis OliveiraNessuna valutazione finora

- Name: .: Week 16: Unit 1Documento4 pagineName: .: Week 16: Unit 1elenaNessuna valutazione finora

- Karaoke ListDocumento30 pagineKaraoke Listinef111Nessuna valutazione finora

- Gost 3916-96Documento7 pagineGost 3916-96Jing VeeNessuna valutazione finora