Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Alignment: Diagnosis, Service

Caricato da

2791957Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Alignment: Diagnosis, Service

Caricato da

2791957Copyright:

Formati disponibili

YVheel

Alignment Principlest

Diagnosis, and Service

ffi ALIGNMENT.RELATED

OBf ECTIVES: After studying Chapter 43, the reader

PROBLEMS

should be able to:

l.

Prepare for ASE Suspension and Steering (A4)

certification test content area "C" (Wheel Alignment

Diagnosis, Adiustment, and Repair).

2. Define camber, caster, toe, SAl, included angle, turning

3.

4.

5.

radius, thrust line, and set back.

Explain how camber, caster, and toe affect the

handling and tire wear of the vehicle.

List the many checks that should be performed

before aligning a vehicle.

Describe the proper alignment setup procedure.

*h""1 alignment

is the adjustment of the suspen-

sion and steering to ensure ProPer vehicle handling

with minimum tire wear. A change in alignment angles

may result from one or more of the following factors:

|

. Wear of the steering and the suspension

comPonents

2. Bent or damaged steering and suspension parts

3. Sagging springs,which can change the ride height

of the vehicle and therefore the alignment angles

By adlusting the suspension and steering comPonents,the proper alignment angles can be restored. An

alignment includes checking and adiusting, if necessary,

both front and rear wheels.

Most alignment diagnosis is symptom based. The following definitions of alignment symptom terms are

used in this book:

Fttll

A pull is generally defined as a definite"tug"

on the steering wheel toward the left or the right

while driving straight on a level road.

or $rift

A lead or drift is a mild pull that

does not cause a force on the steering wheel that the

driver must counteract. When the vehicle moves toward one side or the other, this is called a lead ot

drift. Alead or drift could be caused by the crown of

the road, as shown in Figure 43-1.

Lead

CAUTIONs When test driving a vehicle for a lead or a

drift, make sure that the road is free of traffic and that

your hands remain close to the steering wheel. Your

hands should simply be held away from the steering

wheel for just a second or two-just long enough to

check for a lead or

drift condition.

Wander A wander is a condition in which almost

constant steering wheel corrections by the driver are

necessary to maintain a straight-ahead direction on

a straight, level road.

Camber

Camber is the inward or outwctrd tilt of the wheels

from true uertical as uiewed from the front or rear of

the uehicle. See Figure 43-2.

CHAPTER 43

984

CROWN OF ROAD

Figure

needed

43-l

The crown of the road refers to the angle or slope of the roadway

to drain water offthe pavement. (Courtesy of Hunter Engineering Company)

POSITTVE

NEOATIVE

Figure 43-2 Positive and negative camber. (Courtesy of

Hunter Engineering Company)

1. If the top of the tire is tilted out, then camber is

positive (+).

2. If the top of the tire is tilted in, then camber is

negative (-).

3. Camber is zero (0') if the tilt of the wheel is truly

vertical, as shown in Figure 43-3.

4. Camber is measured in degrees or fractions of

degrees.

5. Camber can cause tire wear if ruot correct.

a. Excessive positive camber causes scuffing

and wear on the outside edge of the tire

b. Excessive negative camber causes scuffing

and wear on the inside edge of the tire

6. Camber can cause pull if it is unequal side to

side. The uehicle will pull toward the side with

the most positiae (or least negatiae) camber. A

difference of more than half a degree from one

side to the other will cause the vehicle to null.

See Figure 43-4.

Figure 43-3 Zero camber. (Courtesy of Hunter

Engineering Company)

7. Incorrect camber can cause excessive wear on

wheel bearings, as shown in Figure 43-5. Many

vehicle manufacturers specify positive camber so

that the vehicle's weight is applied to the larger

inner wheel bearing and spindle. As the vehicle

is loaded or when the springs sag, camber

usually decreases. If camber is kept positive,

then the running camber is kept rteay zero

degrees for best tire life.

Itwliddlifif-$fiSliilFrrll+i'ili6ild.ili:lridt['riut{ili{Uildlt]il$\illlilli!]Msl$6!16$ie}Jdlddd\1d*Mr1@ffiW}iM-1

{iqirl;1$.}iilil Many front-wheel-drive vehicles that use sealed

wheel bearings often are manufactured to have negative

camber.

8. Camber is ruol adjustable on many vehicles.

9. If camber is adjustable, the change is made by

moving the upper or the lower control arm or

Wheel Alignrnent Principles, Diagnosis, and Service

Figure 43-4 Camber tilts the tire and forms a cone shape that causes the wheel to roll

or pull outward toward the point of the cone. (Courtesy of Hunter Engineering

away

Company)

of the same tires, then the toe is called toe-in or positive (+) toe. See Figure 43-7.If the front of the tires

WEIGHT OF VEHICLE

INTERSECTS NEAR

OUTER WHEEL

BEARING

Figure 43-5 Negative camber applies the vehicle weight

to the smaller outer wheel bearing. Excessive negative

camber, therefore, may contribute to outer wheel bearing

failure. (Courtesy of Hunter Engineering Company)

are farther apart than the rear of the same tires,

then the wheels are toed-ouf or have negative (-)

toe. See Figure 43-8.

The purpose of the correct toe setting is to provide maximum stability with the minimum of tire

wear when the vehicle is being driven.

1. Toe is measured in fractions of degrees or in

fractions of an inch (usually sixteenths),

millimeters (mm), or decimals of an inch (such

as .06").

2. Incorrect toe is the major cause of excessiue tire

wear!

ffi4&Yffi: If the toe is improper by just U8" (3 mm) the resulting tire wear is equivalent to dragging a tire sideways 28 feet (8.5 meters) for everymile traveled (1.6 km).

strut assembly by means of one of the following

methods:

a. Shims

b. Eccentric

c. Slots

cams

10. Camber should be equal on both sides;however,

if camber cannot be adjusted exactly equal,

make certain that there is more camber on the

front of the left side to help compensate for the

road crown (half a degree maximum difference).

Toe

Toe is the dffirence in distance between the front and

rear of the tires. As viewed from the top of the vehicle (bird's-eye view), zero toe means that both wheels

on the same axle are parallel, as shown in Figure

43-6.If the front of the tires is closer than the rear

Toe causes camber-type wear on one side of

the tire if not correct, as shown in Figure 43-9

(p.987).

3. Incorrect

ftont

toe does

not cause a pull

condition. Incorrect toe on the front wheels is

split equally as the vehicle is driven because the

forces acting on the tires are exerted through the

tie rod and steering linkage to both wheels.

4. Incorrect (unequal) rear toe can cduse tire wean

See Figures 43-10 and 43-11 (p. 987). Ifthe toe

of the rear wheels is not equal, the steering

wheel will not be straight and will pull toward

the side with the most toe-in.

5. Front toe adjustment must be made by adjusting

the tie rod sleeves correctly. See Figure 43-12

(p.987).

CHAPTER 43

Figure 43-6 Zero toe. (Courtesy of Hunter Engineering Company)

t

I

Figure 43-7 Toe-in, also called positive (+) toe. (courtesy of Hunter Engineering

Company)

Figure 43-8 Toe-out, also called negative

Company)

(-)

toe. (courtesy of Hunter Engineering

Wheel Alignment Principles, Diagnosis, and Service

987

Figure 43-9 This tire is just one month old! lt was new

and installed on the front of a vehicle that had about l/4

inch (6 mm.) of toe out. By the time the customer

returned to the tire store for an alignment, the tire was

completely bald on the inside. Note the almost new tread

on the outside.

Figure 43-10 Rear toe-in (+). (Courtesy of Hunter

Engineering Company)

Figure 43-12 Toe on the front of most vehicles is

adjusted by turning the tire rod sleeve as shown.

(Courtesy of John Bean Company)

6. Most vehicle manufacturers specify a slight

amount of toe-in to compensate for the natural

tendency ofthe front wheels to spread apart

(become toed-out) due to the centrifugal force of

the rolling wheels acting on the steering linkage.

ft#4FYffi* Some manufacturers of front-wheel-drive vehicles specify a toe-out setting to compensate for the

toe-in forces created by the engine drive forces on the

front wheels.

7. Normal wear to the tie rod ends and other

steering linkage parts usually causes toe-out.

Caster

I Diagonal wear such as shown here is

usually caused by incorrect toe on the rear of a frontwheel-drive vehicle.

Figure 43-l

Ca.ster is the forward or rearward tilt of the steering

axis in reference to a uertical line as uiewed from the

side of the uehicle. The steering axis is defined as the

CHAPTER 43

line drawn through the upper and lower steering

Why Doesn't Unequal Front Toe on the

Front Wheels Cause the Vehicle to Pull?

Each wheel could have individual toe, but as the vehicle is

being driven, the forces on the tires tend to split the toe,

causing the steering wheel to cock at an angle as the front

wheels both track the same. lf the toe is different on the

rear of the vehicle, the rear will be "steered" similar to a

rudder on a boat because the rear wheels are not tied together as are the front wheels.

pivot points. On an SLA suspension system, the upper pivot is the upper ball joint and the lower pivot

is the lower ball joint. On a MacPherson strut system, the upper pivot is the center of the upper bearing mount and the lower pivot point is the lower ball

joint. "Zero center" means that the steering axis is

straight up and down, also called zero degrees or perfectly uerticol, as shown in Figure 43-t4.

1. Positive

(*)

caster is present when the upper

suspension pivot point is behind the lower pivot

point (ball joint) as viewed from the side. See

Figure 43-15.

2. Negative (*) caster is present when the upper

suspension pivot point is ahead of the lower

pivot point (ball joint) as viewed from the side.

3. Caster is measured in degrees or fractions of

degrees.

Smooth lnrToed-lnSmooth OutrToed-Out

Whenever the toe setting is not zero, a rubbing action on

the tire tread causes a feather-edge-type wear. See Figure

43-13. A quick-and-easy method to determine if incorrect toe could be the cause of excessive tire wear or

other problems is to simply rub your hand across the

tread of the tire. lf it feels smoother when you move your

hand toward the center of the vehicle than when you

move your hand toward the outside,then the cause is excessive toe-in. The opposite effect is caused by toe out.

This method may be used on all types of tires including

radial ply tires, where the wear may not appear as a

feather edge. Just remember this simple saying,"smooth

in,

4. Caster is not a tire wearing angle, but positive

caster does cause changes in camber during a

turn. See Figure 43-16. This condition is called

camber roll. (See the Tech Tip "Caster Angle

Tire Wear.")

5. Caster is a stability angle:

a. Ifcaster is excessively positive, vehicle

steering will be very stable (will tend to be

straight with Iittle steering wheel correction

needed) and help with steering wheel

returnability after a turn.

b. Ifthe caster is positive, the steering effort

will increase with increasing positive caster.

toed-in-smooth out. toed-out:'

0o

Feaffiered or $awtoottl

Tire wear pattern

* * * *

***

Shorp edges poini in the direction

of the toe problem

(lN - Toe In / OUT Toe Out)

Figure 43-13 Feather-edge-type tire wear is usually

caused by an incorrect toe setting. (Courtesy ofJohn Bean

Company)

FRONT

Figure 43-14 Zero caster. (Courtesy of Hunter

Engineering Company)

Wheel Alignment Principles, Diagnosis, and Service

989

FRONT

Figure 43-16 As the spindle rotates, it lifts the weight of

the vehicle due to the angle of the steering axis. (Courtesy

of Hunter Engineering Company)

Figure 43-15 Positive

(*)

caster. (Courtesy of Hunter

Engineering Company)

Greater road shocks will be felt by the driver

when driving over rough road surfaces.

Vehicles with as high as eleven degrees of

positive caster usually use a steering

dampener to control possible shimmy at

high speeds and to dampen the snap-back of

the spindle after a turn.

c. Ifcaster is negative, or excessively unequal,

the vehicle will not be as stable and will

tend to wander. If a vehicle is heavily loaded

in the rear, caster increases, as shown in

Figure 43-77.

6. Caster could cause pull if uneqral. The uehicle

will pull toward the side with the least positiue

caster.

7. Caster is ruol adjustable on many vehicles.

8. If caster is adjustable, the change is made by

moving either the lower or the upper pivot point

forward or backward by means of one of the

following methods:

a. Shims

b. Eccentric cams

c. Slots

d. Strut

rods

Figure 43-17 As the load increases in the rear of a vehicle, the top steering axis pivot

point moves rearward, increasing positive

Company)

(*)

caster. (Courtesy of Hunter Engineering

990

CHAPTER 43

$ ftd#:$'#;t Caster is only measured on the front turning

N wheels of the vehicle. Although some caster is built into

{ the rear suspension ofmany vehicles, rear caster is not

i

i

measured as part of a four-wheel alignment.

..

Steering Axis Inclination (SAl)

The steering axis is the angle formed between true

vertical and an imaginary line drawn between the

upper and lower pivot points of the spindle. See Figure 43-19. Steering q,xis inclincltion (SAI) is the inward tilt of the steering orls. SAI is also known as

kingpin incliruation (KPI) and is the imaginary line

drawn through the kingpin as viewed from the front.

$ss*ilEffded dhrag$*

Gaster Angle Tire Wear

The caster angle is generally considered to be a non-tirewearing angle. Even though this statement is true, excessive or unequal caster can indireAly cause tire wear. When

the front wheels on a vehicle with a lot of positive caster

are turned, they become angled, which is called camber

roll. (The caster angle is a measurement of the difference

in camber angle from when the wheel is turned inward

compared to when the wheel is turned outward.) Many

vehicle manufacturers design positive caster into the suspension system. This positive caster has increased the directional stability of these vehicles. However, if the vehicle is used exclusively in city-type driving, the positive

caster can cause tire wear to the outside shoulders of

both front tires, as seen in Figure 43-18.

The included angle is the SAI

added to the camber reading of the front wheels only.

The included arugle is determined by the design of the

steering knuclzle, or strut construction See Figure

43-20. Included angle is an important angle to

measure when diagnosing vehicle handling or tirewear problems.

Turning Radius

(Toe-Out on Turns)

Whenever a vehicle turns a corner, the inside wheel

has to turn at a sharper angle than the outside wheel

because the inside wheel has a shorter distance to

travel, as shown in Figure 43-2I. Turning radius is

also called

toe-out on turns, abbreviated*TOT" or,

more commonly, "TOOTr" and is determined bv the

OUTSIDETURN

SPINDLE MOVES DOWN

INSIDETURN

SPINDLE MOVES UP

Figure 43- | I As the front wheels on a vehicle with a lot of positive caster are turned,

the wheel tilts at an angle. This is called comber rol/ and can cause tire wear to both the

inside and outside edges of the tire.

Wheel Alignment Principles, Diagnosis, and

Service

991

angle of the steering knuckle arms. Turning radius

is a nonadjustable angle. The turning radius can and

should be measured as part of an alignment to check

if the steering arms are bent or damaged. Symptoms

STETfrIIIG AXIS

ll{cUiltTt0t{

{AilGLE)

of out-of-specification turning angle include tire

squeal noise during normal cornering even at low

speeds and/or scuffed tires.

This angle is also called the Ackerman Effect,

named for its promoter, the English publisher

Rudolph Ackerman, circa 1898.

sH0nt - [0[B.AR]| SusPEistot

8Tff8m0

Setback

Setbaclz is the angle formed by a line drawn perperldicular (90") to the front axles. See Figure 43-22. Setback is a nonadjustable measurement euen though it

may be corrected. Positive setback means the right

front wheel is set back farther than the left. Negative

setback means the left front wheel is set back farther

AXIS

ncUt{til0}l

than the right.

Thrust Angle

sTRltT

susPlilst0t

Figure 43-19 SAI is an imaginary line through the upper

and lower suspension pivot points.

s.A.l.

Thrust angle is the angle of the rear wheels as determined by the total rear toe.If both rear wheels have

zero toe, then the thrust angle is the same as the

geometric center line of the vehicle. The total of the

rear toe setting determines the thrust line, or the

direction the rear wheels are pointed. See Figure

43-23 (p. 993). On vehicles with an independent

rear suspension, if both wheels do not have equal

toe, the vehicle will pull in the direction of the side

with the most toe-in.

Tracking

CAMBER

S.A.l. + CAMBER

Tlaclzing is the term used to describe the fact that

the rear wheels should "track" directly behind the

front wheels. If the vehicle has been involved in an

accident, it is possible that the frame or rear axle

mounting could cause dog tracking.

INCLUOED ANGLE

ffi PREALIGNMENT CHECKS

Before checking or adjusting the front end alignment, the following items should be checked and corrected ifnecessary:

Figure 43-20 Included angle on a MacPherson strut-type

suspension. (Courtesy of Hunter Engineering Company)

1. Check all the tires for proper inflation

pressures and approximately the same size and

tread depth and that they are the

recommended size for the vehicle.

2. Check the front wheel bearings for proper

adjustment.

CHAPTER 43

| To provide handling, the inside wheel has to turn at a greater turning

radius than the outside wheel.

Figure 43-2

Figure 43-22 (a) Positive setback. (b) Negative setback. (Courtesy of Hunter

Engin'eering Company)

Wheel Alignment Principles, Diagnosis, and Service

Figure 43-23 (a) Zero thrust angle. (b) Thrust line to the right. (c) Thrust line to the

left. (Courtesy of Hunter Engineering Company)

3. Check for loose ball joints or torn ball joint boots.

See Figure 43-24.

4. Perform a dry park test to check the:

o Tie rod ends for damage or looseness

o Center link or rack bushings for play

5. Check the pitman arm for any movement.

6. Check for run-out of the wheels and the tires.

7. Check for vehicle ride height (should be level

front-to-back as well as side-to-side). Make sure

that the factory load leveling system is

functioning correctly, if so equipped. Check

height according to manufacturer's

specifications. See Figures 43-25 and 43-26.

$4#Tffix Manufacturers often have replacement springs

or spring spacers that can be installed between the coil

spring and the spring seat to restore proper ride level.

Ride (trim) is also called chassis heieht.

994

CHAPTER 43

Figure 43-24 The owner of this Honda thought that

all

an alignment. Obviously, something more

serious than an alignment caused this left rear wheel to

it needed was

angle inward at the top.

Figure 43-25 Measuring points for ride (trim)

height vary by manufacturer. (Courtesy of Hunter

Engineering Company)

8. Check for steering gear looseness at the frame.

9. Check for improperly operating shock absorbers.

10. Check for worn control arm bushings or ball

joints.

11. Check for loose or missing stabilizer bar

attachments.

t2. Check the trunk for excess loads.

13. Check for dragging brakes.

tr${hT-ffifl Checking for dragging brakes is usually performed when installing alignment heads to the wheels

prior to taking an alignment reading. A dragging brake

can cause the vehicle to pull or lead toward the side

with the dragging brake.

ffiffi

Figure 43-26 Measuring to be sure the left and right

sides of the vehicle are equal heights. lf this measurement

is not equal side-to-side by as little as llB" (3 mm), it can

affect the handling of the vehicle.

READING ATIGNMENT

SPECIFICATIONS

There are several methods used by vehicle manufacturers and alignment equipment manufacturers to

specify alignment angles.

Wheel Alignment Principles, Diagnosis, and

Plus

The Five-Wheel Alignment

The steering wheel should always be straight when driving on a straight, level road. lf the steering wheel is not

straight, the customer will often think that the wheel

alignment is not correct. One such customer complained

that the vehicle "pulled to the right" while driving on a

straight road. The service manager test drove the vehicle

and everything was perfect, except that the steering

wheel was not perfectly straight, even though the toe setting was correct. Whenever driving on a straight road,

the customer would "straighten the steering wheel" and,

of course, the vehicle went to one side. After "correctly"

adjusting toe with the steering wheel straight, the customer and the service manager were both satisfied. The

technician learned that regardless of how accurate the

alignment,the steering wheel must be straight because it

is this "fifth wheel" that the customer notices most.

995

or Minus Method

This method indicates the preferred setting with the

lowest and highest allowable value, indicated by a

negative (-) and positive (+) sign as in the specifications. For example, if a camber reading is specified as

+Yr" with a t and - value of rl"o, it could be written

as +7/r" *L/z'.TIte minimum value would be 0' (%'

0") and the maximum value would be *1'

- t/"" : tlr"

(+'/r" +

-- 1'). The range would be from 0o to 1o.

8ei$#T'ffi* The angle is assumed to be positive unless it is

labeled with a negative (*) sign in front of the number.

Specifrcations are often published in fractional

or decimal degrees or in degrees and minutes. There

are sixty minutes (written as 60') in one degree. See

the angle-unit conversion table below.

Angle-Unit Conversions

Units

fr$ffiT8t Many vehicle manufacturers now include the

maximum allowable steering wheel angle variation

from straight. This specification is commonly -+Jo

(plus or minus three degrees) or less.

Service

Fractional degrees

Conversions

tln"

Decimal degrees

0.25'

Degrees and minutes

0'15',

ffi

'/""

0.50'

0'30'

"/n"

0.75'

0"45'

ATIGNMENT SETUP

PROCEDURES

"Set Everything to Tero?tt

Afber confirming that the tires and all steering and

suspension components are serviceable, the vehicie

An apprentice service technician observed that the ex-

is ready for an alignment. The exact setup

perienced alignment technician seldom looked at the

specifications for the vehicle being aligned. When questioned, the technician said that for best tire life, the tires

should rotate perpendicular to the road. After studying

alignment specifications, the technician noticed that almost every camber and toe specification for both front

and rear included zero within the range of the specifications. Caster, of course, varies from one vehicle to an-

other and should be checked and adjusted to specifications. The beginning technician learned that zero camber

and zero toe will be acceptable and "within specifications" on almost all vehicles and is easy to remember!

Maximum/Mlnimum/

Preferred Method

This method indicates the preferred setting for each

alignment angle and the minimum and maximum

allowable value for each. The alignment technician

should always attempt to align the vehicle to the preferred setting. See Figure 43-27.

proce-

dures for the equipment being used must always be

followed. Typical alignment procedures include the

following steps:

#tep $. Drive onto the alignment rack straight and adjust the ramps and/or turn plates so that they are

centered under the tires of the vehicle. Use chocks

(blocks) for the wheels to prevent the vehicle from

accidentally rolling off the alignment rack.

Srer6* ?. Raise the vehicle off the alignment rack. See

Figure 43-28.

Stegr 3" Attach and calibrate the wheel sensors to

each wheel as specified by the alignment equipment manufacturer, as shown in Figure 43-29.

Step 4" Unlock all rack or turn plates.

$*ep 5. Lower the vehicle and "jounce" the vehicle by

pushing down on the center of the front and then

the rear bumper of the vehicle. This motion allows the suspension to become centered.

5*eg* *. Following the procedures for the alignment

equipment, determine all alignment angles.

CHAPTER 43

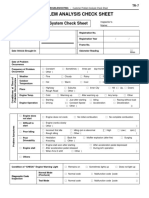

ALIGNTITENT SPECIFICATIONS

AT CUNB HE|/GHT

ACCEPIABTE ALIG]ITIIEI{I NAilGE

AT CURB HEIGIIT

;ROilT WHSE! ATIG]ITEIIT

-0.6'to

CAMBER. . AII.Side

To Side Differentiql .................

+0.6o

0.Zo or less

PNEFERRED

SET|II{G

+0.0o

0.0"

TOTAL TqE All Vehicles (See Nore)

Specified In Degrees

0.4"

CASTER-

To Side Coster

0.0'

0.2"

ln

REFERENCE ANGLE

AllModels

*Side

In to

+2.0o to +4.0o

+3.0"

Differentiol

'I

Not to Exceed

NEAR WHEET AIIGI{TENT

CAMBER. . AllModels

TOTAL TOE. All Vehicles (See Nore|

Specified In Degrees

.0" or less

0.0'

ACCEPTAITE AIIGilMEI|T NANGE

AT CURB HEIGHT

PREtrERRED

-0.6" to +0.4"

-0.1"

0.2" Out to 0.y'' ln

0.,l " ln

SETTING

-0.,|5" to +0.15"

THRUST ANGLE

.TOE

OUT When Bocked On Aliqnment

Rock ls TOE lN When Drivingl

NOTE: JotSl l* is the,orithmet[c sur;n of the left on{ ;ight wfree[ toe settings. Positive.is Toe-in, neqqtive is Toe-out.

lotol loe.must be,eguolll:pltl""Ylleoch fr6ntwheelto

it""ii;d;[$i:'i"iidii Fight

toe must be equol td withiri 0.02 degrees.

"nrr.JJ."-nt"r"-d

Figure 43'27 Typical alignment specifications for a vehicle at the proper curb height.

Curb height is ride height or trim height as measured at the curb weight. Curb weilht is

the weight of the vehicle with a full tank of fuel and all other flulds filled. (Courtesytf

Chrysler Corporation)

Figure 43-28 Using the alignment rack hydraulic

jacks,

raise the tires off the rack so that they can be rotated as

part ofthe compensating process.

Figure 43-29 This wheel sensor has a safety wheel that

screws to the valve stem to keep the sensor from falling

onto the ground if the clamps slip on the wheel lip.

Wheel Alignment Principles, Diagnosis, and

T'm*

Using a Two-Wheel Alignment

Rack lor a Four-Wheel Alignment

Alignment racks designed for total four-wheel alignment

are equipped with movable plates under the rear wheels.

Older racks used for front-end-only alignment do not

move and therefore will not allow the rear suspension to

become settled. This freedom of movement is necessary

to correctly perform a four-wheel alignment, especially

on a vehicle with independent rear suspension. One

commonly used "trick of the trade" is to place a two-layer

plastic garbage bag under each rear wheel before lowering the vehicle onto the rack. As the vehicle is lowered,

the rear wheels will easily slide over the plastic-on-plastic

surface. The rear wheels will resume the normal Position'

the same as if the vehicle were lowered onto movable

turn plates. Another method that is often used is to roll

the vehicle back about 4 feet ( 1.2 m) and then forward to

allow the rear independent suspension to settle.

F{#Yffie Some alignment machines do not have cables

long enough to allow this method to be used.

Toe

Service

997

is determined by measuring the angle of

both front and./or both rear wheels from the straight

ahead (0") position. Most alignment equipment reads

the toe angle for each wheel and tl:'e combined toe angle of both wheels on the same axle. This combined toe

is called total toe. Toe angle is more accurate than

the center-to-center distance, especially if oversize

tires are installed on the vehicle. See Figure 43-30.

Tffi#Y

turns (TOOT) is a diagnostic angle that is normally not measured as part of a regular alignment, but it is recommended that this measurement be made as a part of a total alignment

check. TOOT is measured by recording the angle of

the front wheels as indicated on the front turn

plates. See Figure 43-31. If, for example, the inside

wheel is turned 20', then the outside wheel should

Toe out on

STANPARD

NOTE

DIFFERNCE

OVERSIZE

STANOARD

TIRE

OVRSIZE

TIRF

Measuring Camberr Gasterr SAlt

Toe, and TOOT

Camber is measured with the wheels in

position on a level platform. Since

straight-ahead

the

anrhev

camber

is a vertical reference

Figure 43-30 lf toe for an oversize tire

is set by distance'

the toe angle will be too small. Toe angle is the same

regardless of tire size.

angle, alignment

equipment reads camber directly.

arter Caster is measured by moving the front

wheels through an arc both inward, then outward,

from straight ahead. This necessary movement of the

front wheels to measure caster is called caster

sweep. What the alignment measuring equipment is

actually doing is measuring the camber at one wheel

sweep and measuring the camber again at the other

extreme of the caster sweep. The caster angle itself is

the difference between the two camber readings.

SAa Steering axis inclination (SAI) is also measured by performing a caster sweep of the front

wheels. When measuring SAI separately, the usual

procedure involves raising the front wheels off the

ground and leveling and locking the wheel sensors

before performing a caster sweep. When the suspension is extended, the SAI is more accurately determined because the angle itself is expanded'

Figure 43-3 | The protractor scale on the front turn

plates allows the technician to test the turning radius by

turning one wheel to an angle specified by the manufacturer

and observing the angle of the other front wheel.

998

CHAPTER 43

indicate about 18'on the turn plate. The exact angles are usually specified by the vehicle manufacturer. The turning angle should only be checked after

the toe is correctly set. The turning angle for the

wheel on the outside of the turn should ruot uary more

than 11 l r' from specifications.

Ask Yourself These Three euestions

An older technician told a beginning technician that the

key to success in doing a proper alignment is to ask yourself three questions about the alignment angles:

Checking Frame Alignment

of Front-Wheel-Drive Vehicles

l.

"ls it within specificotions?,, For example, if

the specification reads lo -r I 12",any reading

Question

between

* l/2'and +l

Many front-wheel-drive vehicles mount the drive

train (engine and transaxle) and lower suspension

arms on a subframe or cradle. If the frame is shifted

either left or right, that can cause differences in SAI,

l12'is "within

specifications." All vehicles should be aligned to

within this range.

2. "ls itwithin l12' of the other side of the

vehicle?"Not only should the alignment be within

specifications, it should also be as equal as possible

from one side to the other. The difference between

the camber from one side to the other side is

called cross camber. Cross caster is the

difference between the caster angle from one side

Question

included angle, and camber. See Figures 48-38 and

43-34. Adjust the frame if SAI and camber angles

are different on the left and right, yet the included

angles are equal.

ffi#

to another.

Question 3. "lf

the camber ond coster connot be

front, is there more

camber on the Ieft ond more coster on the right to help

compensote for road "crown"T Seldom, if ever, are the

alignment angles perfectly equal. Sometimes, one

There are three types of alignment: geometric centerline, thrust line, and total four-wheel alignment.

exactly eguol side-to-side in the

#,ruwcdffir#&wftc #*ur*+*rf,frnm This type of alignment is

simply an alignment that uses the geometric centerline of the vehicle as the basis for all measurements

of toe (front or rear). See Figure 4B-Bb.This method

is now considered to be obsolete.

side of the vehicle is more difficult to adjust than

the other side. Regardless of the reasons, if there

hos to be a difference in front camber and/or cascer

angle, follow this advice to avoid a possible lead or

drift problem even if answers to the first two

questions are "yes." See Figure 43-32.

:

I

w

ef&

Left Front

j{

-:.-ry#

w

+

TYPES OF ALIGNMENTS

T"hrans$; ff*$ru,r* A thrust line alignment uses the

thrust angle of the rear wheels and sets the front

wheels parallel to the thrust line. See Fisure 48-86.

HINT: It has often been said that while the front

uffir

wheels steer the vehicle, the rear wheels determine the

direction the vehicle will travel. Just think of the rear

wheels as being like a rudder ofa boat. As the rudder

turns, the front ofthe boat turns.

@m

M,j,

ffili'I

Thrust line alignment is required for any vehicle with

a nonadjustable rear suspension. Ifa vehicle has an

adjustable rear suspension, then a total four-wheel

alignment is necessary to ensure proper tracking.

sdffi

W1

+

Camber

ffitLl

T{s

Figure 43-32 This computer alignment printout is very

useful for determining which angles are OK (in green) and

which angles need to be adjusted (in red).

-S]

+mEsfr ffi w*s tr*WF fti#e$ dhE

s?.d*trr* A total four-wheel

ffi

alignment is the most accurate method and is necessary to ensure maximum tire wear and vehicle han_

dling. The major difference between a thrust line

alignment and a total four-wheel alignment is that

the rear toe is adjusted to bring the thrust line to

zero.In other words, the rear toe on both rear wheels

is adjusted equally so that the actual direction the

rear wheels are pointed is the same as the geometric

centerline ofthe vehicle. See Figure 48-87.

*

fi,$

Wheel Alignment Principles, Diagnosis, and Service

ltFrsAt

RtcHTtAl-

16'

LIFT CAtttBgR

-3o

I'

RIGHTCAMBER

ll'lClu0El) AI{GLE = 13o

10910

5"

gt0

iil,r'rlu,f,,,rl

1,',,1,',,1,,1,1,,,,1,i,4,,,f0

vEHlc$ cEliTtRul,lt

I

I

I

f RAi,lE

CTITTIRLINT

In this example both SAI and camber are way offfrom being equal sideto-side. However, both sides have the same included angle, indicating that the frame may

be out of alignment. An attempt to align this vehicle by adlusting the camber on both

Figure 43-33

sides either with factory or aftermarket kits would result in a totally incorrect alignment.

(Courtesy of General Motors Corporation Service Technology Group)

sAl

- l2'

CIMBER

[{ctu0tD

1o

AIlIGLE

13"

100

\1,!rr

,l,,,io

V$lC|t

CENTEnLIIIE

FRAME CENTERTI}

OII BODY

Figure 43-34 This is the same vehicle as shown in Figure 43-33, excePt now the frame

(cradle) has been shifted over and correctly positioned. Notice how both the SAI and

camber become equal without any other adiustments necessary. (Courtesy of General

Motors Corporation Service Technology Group)

999

IOOO

CHAPTER 43

l1

THRUST LINE

GEOMETRIC

cENTERLTNE

.Figure 43-35 Geometric centerline alignment sets the front

toe readings based on the geometric centerline of the vehicle

and does not consider the thrust line ofthe rear wheel toe

angles. (Courtesy of Hunter Engineering Company)

.*

.{..

THRUST LINE

Figure 43-37 Four-wheel alignment corrects for any

rear-wheel toe to make the thrust line and the geometric

centerline of the vehicle the same. (Courtesy of Hunter

Engineering Company)

Four-Wheel Alignment procedure

The procedure for a total four-wheel alignment in_

cludes these steps:

1. Adjust the rear camber

<.THRUST LINE

(if applicable). See

Figure 43-38.

2. Adjust the rear toe (this should reduce the

thrust angle to near zero). See Fizure 4B_Bg.

3. Adjust the front caster and camber.

4. Adjust the front toe, making sure that the

steering wheel is in the straight-ahead position.

The Gritty Sotution

Many times it is difficult to loosen a TORX bolt, especially

those used to hold the backing plate onto the rear axle on

many GM vehicles. See Figure 4340. A technique that al_

ways seems to work is to place some valve grinding

Figure 43-36 Thrust line alignment sets the front toe

parallel with the rear wheel toe. (Courtesy of Hunter

Engineering Company)

compound on the fastener. The gritty compound keeps

the TORX socket from slipping up and our of the fasrener

and more force can be exerteJto break loose a tight bolt.

Valve grinding compound can also be used on phillips-head

screws as well as other types of bolts, nuts, and sockets.

Wheel Aiignment Principles, Diagnosis, and

Service

100

Locking Pliers to the Rescue

Figure 43-38 The rear camber is adjustable on this

vehicle by rotating the eccentric cam and watching the

alignment machine display.

Many vehicles use a iam nut on the tie rod end. This jam

nut must be loosened to adiust the toe. Because the end

of the tie rod is attached to a tie rod end that is movable,

loosening the nut is often difficult. Every time force is applied to the nut, the tie rod end socket moves and prevents the full force of the wrench from being applied to

the nut. To prevent this movement, simply attach locking

pliers (Vise Grips@) to hold the tie rod. Wedge the pliers

against the control arm to prevent any movement of the

tie rod. By preventing the tie rod from moving,full force

can be put on a wrench to loosen the .iam nut without doing any harm to the tie rod end.

&d$u*metmg Ftrefls #mam$*wrfffi;am*er Most SLAtype suspensions can be adjusted for caster and cam-

ber. Most manufacturers recommend adjusting

caster, then camber before adjusting the toe. As the

caster is changed, the camber and toe also change.

See Figure 43-47.If the camber is then adjusted, the

caster is unaffected. Many technicians adjust caster

and camber at the same time using shims, slots, or

eccentric cams.Always follow the manufacturer's recommended alignment procedure. Regardless of the

methods or procedures used, toe is always adjusted

after all the angles are set because caster and camber both affect the toe.

$*ft*rag Ym* Front toe is the last angle that should

be adjusted and is the most likely to need correction.

Most newer alignment equipment displays in degrees

oftoe instead ofinches oftoe. (See the toe unit conversion table on page 1003.)

Figure 43-39 The rear toe was easily set on this vehicle.

The adjusting nuts were easy to get to and turn. Rear toe

is not this easy on every vehicle.

* toe :

- toe :

toe-in

toe-out

Figure 43-40 Full contact plastic or

metal shims can be placed between the

axle housing and the brake backing

plate to change rear camber or toe or

both. (Courtesy of Northstar

Manufacturing Company, Inc.)

IOO2

CHAPTER 43

METHODS OF ADJUSTMENT

Tools and adjustment devices may be avairabre rrom aftermarket

suppliers to perform

adjustments in cases where manufacturers do not make such'rirovisions.

CASTER & CAMBER ADJUSTMENT

CASTER & CAMBER ADJUSTMENT

CASTER & CAMBER ADJUSTMENT

sLorrEDHoLEs

To increase caster, move shims from

rear to front. Camber: change shim

thickness equally.

CASTEB & CAMBER ADJU$TMENT

To increase caster, move shims from

To increase caster, move shims from

front to rear. Camber: change shim

thickness equally.

CASTER & CAMBER ADJUSTMENT

/ n

Slacken boits. move upper arm shaft

to obtain specified readings. Use

special tool.

CAMBER ADJUSTMENT

To adjust, rotate cam bolts. Sel camber first, check/adjust castel re-check

To adjust camber, loosen lwo nuts on

upper arm and move wheel in or out.

FRONT CASTER OR

REAR TOE ADJUSTMENT

CAMBER ADJUSTMENT

CAMBER ADJUSTMENT

To increase caster to positive, length-

to Increase or decrease camber set_

ting, rotate cam bolt.

Loosen nut on upper control arm and

rolate arm to set camber.

front to rear. Camber: change shim

thickness equaliy.

en strut. Increase or decrease toe-in

by lengthening or shortening rod.

Figure 43-4

Company)

camoer.

Typical methods of adjusting caster and camber. (Courtesy of

John Bean

Wheel Alignment Principles, Diagnosis, and

Conversions

Fractionai

*'

3tt16u

tln'

.t25"

.188"

.250"

t/

'lru"

inches

Decimal

.062"

inches

I

I

#gqg; To convert from degrees to decimal inches, simply divide by 2. For example, if the total toe is 0.25',

\_'-,._-- Toe

thetr one-half (divided by 2) is equal to 0.\25" (1/8"t.

is usually specifred in degrees because it more accuratelyreflects the toe angle regardless ofthe size ofthe

i wheels/tires.

t-_..*-

Millimeters

1.60 mm

3.18 mm

4.76mm 6.35 mm

Decimal

0.125"

0.25'

0.375'

0.5'

0'8'

0015'

0'23',

0'30'

degrees

Degrees

and

minutes

1t

.hraCtlOnal -|s-^

tln"

1003

ji:::i g:i:::i#.1#siJ!-:r::aa+:<fE@=

Toe Unit Conversions

Units

Service

" /ro

/ro

degrees

---.

-*-*--*-"

="-

FLAfS FOR

?toLsr(}

(nE noo EilD)

TURN DOWNWARDTO

DECREASE ROD LENGTH

steering. (Courtesy of Ford

Motor Company)

TX' XOT GRIP

THREAD AREA

TURN UPWARP

TO INCREASE

ROD LENGTH

LEFT.HAND SLEEVE

i

i

i

Toe is adjusted by turning the tie rod(s) or tie rod

end sleeve(s). See Figures 43-42 and 43-43'

To make sure the steering wheel is straight after

setting toe, the steering wheel must be locked in the

straight-ahead position while the toe is being adjusted. To lock the steering wheel, always use a steering wheel lock that presses against the seat and the

BALL SOCKET

XUT

Figure 43-42 Adlusting toe bY

rotating the tie rod on a vehicle

equipped with rack-and-pinion

JAI

TURN

DOWI{WARD

TO INCREASE

ROD LENGTH

TURN UPWARD TO

DECREASE ROD LENGTH

RIGHT.HAND SLEEVE

Figure 43-43 Toe is adjusted on a parallelogram-tyPe steering linlcage by turning

adjustable tie rod sleeves. Special tie rod sleeve adjusting tools should be used that griP

the slot in the sleeve and will not crush the sleeve while it is being rotated. (Courtesy of

Ford Motor Company)

IOO4

CHAPTER 43

outer rim of the steering wheel. Do not use the locking feature of the steering column to hold the steering wheel straight. Always "unlock" the steering column, straighten the steering wheel, and install the

steering wheel lock.

Si$i$rtqb!41Hi{'!$I\i4itr$l$iir}.1]4iisPl1l!

I

i

i

j steering wheel

tryittiii{ftfi!iiq}lirfit$S..:S}ti,!ii

If the vehicle is equipped with power steering,

the engine must be started and the steering wheel

straightened with the engine running to make sure the

t,'.'t,,'t'l'ltir

is straight. Lock the steering wheel

with

I the steering lock tool before stopping the engine. See

I Figure 43-44.

After straightening the steering wheel, turn the

tie rod adjustment until the toe for both wheels is

within specifications.

Many alignment machines include a screen that

shows straight-ahead steering. Simply adjust the tie

rod adjusters until the reading shows that the toe is

correct and t}l'e front wheels will result in a straight

steering wheel. This is often called centerline

steering and means that the steering wheel will be

centered when the vehicle is traveling a straight

course. Test drive the vehicle for proper handling

and centerline steering.

Left Thrust Line, But a puil to the Rightt

A new four-door sport sedan had been aligned several

times at the dealership in an attempt to solve a pull to the

right. The car had front-wheel-drive and had four-wheel

independent suspension. The dealer rotated the tires but

it made no difference. The alignment angles of all four

wheels were in the center of specifications. The dealer

even switched all four tires from another car in an at_

tempt to solve the problem.

ln frustration,the owner took the car to an alignment

shop. Almost immediately, the alignment technician dis-

covered the right rear wheel was slightly toed-in. Even

though the right rear being toed-in usually causes a thrust

line to the left, in this particular car, it caused a pull to the

right. See Figure 43-45. The alignment technician adjusted

the toe on the right rear wheel, which was adjustable, and

reset the fronr toe. The car drove beaurifully.

The owner was puzzled why the new car dealer was

unable to correct the problem. lt was later discovered

that the alignment machine at the dealership was out of

calibration by the exact amount that the right rear wheel

was out of specification. The car pulled to the right because the independent suspension created a rear steering force toward the left that caused the front to pull to

the right. Alignment equipment manufacturers recom-

mend that alignment equipment be calibrated regularly.

Figure 43-44 Many procedures for setting toe specify

that the steering wheel be held in the straight-ahead

position using a steering wheel lock, as shown. One

method recommended by Hunter Engineering sets toe

without using a steering wheel lock.

Figure 43-45 The toe-in on the right wheel creates

turning force toward the right.

Wheel Alignment Principles, Diagnosis, and

ffi

Service

1005

AFTERMARKET ALIGNMENT

METHODS

Accurate alignments are still possible on vehicles

without factory methods of adjustment by using

alignment kits or parts. Aftermarket alignment kits

are available for most vehicles. Even with factory

alignment methods, sometimes the range of adjustment is not enough to compensate for sagging frame

members or other normal or accident-related faults.

See Figures 43-46 and43-47.

Yry

(a)

(b)

Figure 43-46 (a) Aftermarket camber kit designed to provide some camber

adiustments for a vehicle that does not provide for any adiustment. (b) Installation of

this kit requires that the upper control arm shaft be removed. Note that the upper

control arm was simply rotated out over the wheel pivot on the upper ball ioint.

I006

CHAPTER 43

Figure 43'47 (a) The installation of some aftermarket alignment kits requires the use

of special tools such as this cutter which is being used to drill out spot welds on the

original alignment plate on a strut tower. (b) original plate being removed. (c) Note the

amount of movement the upper strut bearing mount has around the square openings in

the strut tower. An aftermarket plate can now be installed to allow both camber and

caster adiustment.

P37-l Begin the alignment procedure by first driving

the vehicle onto the alignment rack as straight as

possible.

P37-3 Check and adjust tire Pressures and perform

the other prealignment checks necessary to be assured

of a proper alignment.

P37-Z Position the front tires in the center of the turn

plates. These turn plates can be moved inward and

outward to match any width vehicle.

P37-4

Raise the vehicle and perform a dry park test

to

determine whether steering and/or suspension parts

may need replacement before continuing with the

alignment.

P37-5 Position both the front and rear

systems under the suspension system.

rack iacking

P37*6 Move the pads of the lifting unit under the

suspension so that the vehicle can be raised off of the

drive-on surface of the alignment rack.

|

007

P37-7 Lower the alignment rack floor supports before

lowering the alignment rack.

P37-8 When the alignment rack is lowered, the

support arms should contact the floor or the bottom of

the hoist in the case of this scissor-type alignment rack.

P37-9 With the alignment rack firmly supported

P37-l0 With the wheels off of the rack, install the

alignment heads. Position the alignment heads with the

valve core located in the I o'clock position so that the

safety cable can be installed to the valve core.

the support

by

the vehicle off the alignment rack

using the airihydraulic jacks previously placed under the

front and rear suspension.

legs, raise

P37-l I Remove the tire valve cap and either put it in

your pocket or place it in a location where it will not be

lost. Screw the safety cable for the alignment head to

the tire valve.

008

P37-l2

Connect all of the cables and lines necessary.

In this situation, the alignment heads are battery

powered and communicate to the alignment machine

via radio frequency signals. To power up this type of

alignment head, simply turn it on.

P37-13 The bubble leveland three lights in the circle

are used during the compensation process.

P37-14 Compensate all four alignment heads

according to the alignment machine specified

procedures. This compensation process allows for

correct alignment of the wheels even if the alignment

heads are not all installed to exactly the same depth or

if there is a bent wheel.

Lower the vehicle onto the turn plates.

P37-15 Remove the pins from the turn plates (both

front and rear).

F37-

P37-l ? Now is a good time to check for toe-out on

turns (TOOT). The front wheels are turned until the

turn plate under the outside wheel reads 20'.

P37-18 A check on the other side of the vehicle

indicates that the inside turn plate had rotated | 8',

which was within specifications for this vehicle. A bent

or damaged steering arm (knuckle) is the most likely

cause if the TOOT is not within specifications, and a

problem of tire squeal while turning a corner at low

speeds is the usual symptom.

009

P37-19 After lowering the vehicle and making sure the

wheels are turned in the straight-ahead position, jounce

(bounce) the vehicle at both front and rear to center

the suspension.

P37-21 To prevent the wheels from rotating during

the checking procedures, most alignment equipment

manufacturers specify that the brakes should be kept

applied. A brake pedal depressor tool connecrs

between rhe seat and the brake pedal.

P37-23 To measure caster, the front wheels must be

steered first in one direction, rhen the orher direction

as directed by on-screen directions. Most experts

recommend that the front wheels be turned using the

steering wheel because this creates the same forces on

the steering system as is normally exerted during

vehicle operation.

t0l0

P37-20 Some alignment machines such as this Hunter

I I have a built-in ride height gauge. The readout

P2

shows the actual measurement and the specifications so

the technician will know if replacement springs are

necessary before the alignment is begun.

P37-22 Whenever the brake pedal is depressed, the

brake lights will also be on with most vehicles. To

prevent the brake lights from draining the battery, the

brake light fuse could be removed or the connector to

the rear lights disconnected.

P37-24 After the casrer angle has been determined,

raise the front wheels off the rack and allow the wheels

to droop. This allows a more accurate measurement for

SAI than if the vehicle was kept on rhe rack.

{i:|.:::l:

ffii'**lC.t**

::

SM

!w.

**.srt.*.***

| 6*

*-*"

rs'

ra*"

I.F

*u

*t

t rg*t,

*'

1*'

4S'

t *i"

*lt*

qit$1*

qt.

54.t

hE;{

*hr

o &'

i.tu'

as'

kt

+*

'a*. ,i-

P37-25 The front wheels are again rotated to the

right and then to the left following the directions on the

alignment machine display to measure the steering axis

i r**

& ?t"

t8"

&!

Bt

rh-

G rr"

,h1

I i;_

*k

t.Jt'

i,:l'

*5r-

.g#-i

+.ls'

+*'

* *'

+-*"

"

.. -r.l

aL!

f,tl"

...-".,"..,

_1nll;,

P37-25 After all of the angles have been measured, the

alignment results can be printed out and compared to

specifications.

inclination (SAl).

'-'nnt-'-pF*

.*

:LT

.._

- ,-'

tfntre',-.1rt ,mmmf '

A$.rti.

.ri

W[h,1i-

*

**+BW++'-:@

'I

milmtlnm.

%ww

],ts

'

Pl7-27 This printout shows that most angles are out

of specification-not unusual for this training vehicle

that has been used by students Practicing replacing

suspension and steering components.

P37-28 Start correcting the alignment by adiusting

P37-79 After the rear camber has been adlusted,the

rear toe is then brought back into factory specifications

by rotating the rear tie-rod after loosening the iam nut.

Many vehicles require aftermarket shims to adiust the

rear toe and/or camber.

P37-30 After the rear camber and toe have been

adjusted,the front camber is now being adiusted by

loosening and moving the lower strut mount. The

caster on this vehicle was OK and did not require

adjustment. lf lt had required adjustment, the caster

should be adjusted before adjusting the camber.

rear camber. The rear camber is adiusted on this vehicle

by loosening the strut attachments bolts and moving the

bottom portion of the rear strut.

t0l

P37-3 | Before setting the front toe, start the engine if

the vehicle is equipped with power steering.

P37-32 Straighten the steering wheel and use a

steering wheel lock to hold the steering wheel in the

straight-ahead position as shown. Some methods of

adjusting front toe do not require that the steering

wheel be locked. Follow the recommended procedures

as specified by the alignment equipment manufacturer.

P37-33 After centering the steering wheel and locking

it in the srraight-ahead posltion,turn the engine and

?37-34 Loosen the jam nut to allow the tie-rod

lengthened or shortened to adjust the front toe.

ignition off

P37-35 Use a wrench or the flats of the tie-rod (if

to rotate the tie-rod to bring the toe into

equipped)

factory

l0 t2

specifi cations.

P37-35 After the roe

to

be

has been adjusted, hold the tierod with a wrench while tightening the lock (jam) nut to

prevent any change in the toe setting.

ffi.

ffi

P37-37 After the alignment

P37-38 After completing the alignment carefully

within factory

disconnect the alignment heads from the wheels.

Reinstall the valve caps and wheel covers if necessary.

is completed, print out the

results so the customer can see that all angles are

specifi cations.

P37-40 Install the pins in the turn plates before driving

P37-39 Lower the vehicle.

the vehicle off the alignment rack.

Remove any chocks (blocks) used

vehicle from moving on the rack.

P37-4

to keep the

P37-42 Carefully drive the vehicle off the alignment

rack. The vehicle should be driven to check for proper

vehicle handling and double-check that the steering

wheel is straight before returning the vehicle to the

customer.

t0 t3

IOI4

CHAPTER 43

H SUMMARY

1. Toe is the most important alignment angle because

toe is usually the first alignment angle needing correction and when incorrect causes severe tire wear.

2. Caster is the basic stability angle yet does not cause

tire wear (directly) ifnot correct or equal side-to-side.

3. Camber is both a pulling angle if not equal side-to-side

as well as a tire-wearing angle if not set to specifications.

4. SAI and included angle (SAI and camber added together) are important diagnostic measurements.

5. If the toe-out-on-turns (TOOT) reading is not within

specifications, a bent steering spindle (steering knuckle)

is the most likely cause.

6.

four-wheel alignment includes aligning

all

four

wheels of the vehicle, whereas a thrust line alignment

sets the front toe equal to the thrust line (total rear

toe) ofthe rear wheels.

7. Before attempting to align any vehicle, it must be

checked for proper ride height (trim height), tire conditions, and tire pressures as well as thoroughly inspected for the condition of all steering and suspension components.

8. The proper sequence for a complete four-wheel alignment is

a. Rear camber

b. Rear toe

c. Front caster and camber

d. Front toe

x REVTEYV

l.

2. Technician A says that a vehicle will pull (or lead) to the

side with the most camber (or least negative camber).

Technician B says that a vehicle will pull (or lead) to the

side with the most toe. Which technician is correct?

a. TechnicianAonly

b. Technician B only

c. Both Technicians A and B

d. Neither Technician A nor B

3. Technician A says that the vehicle will pull to the side

with the most toe in the rear. Technician B says that the

rear toe angle determines the thrust angle. Which technician is correct?

a. Technician A only

b. Technician B only

c. Both Technicians A and B

d. Neither Technician A nor B

4. Strut rods (ifadjustable) adjust:

a. Toe

b. Camber

c. Caster

d. Toe-out on turns

5. If metal shims are used for alignment adjustment in

the front, they adjust:

a. Camber

b. Caster

c. Toe

d. aandbonly

6. Technician A says that

as wear occurs, camber usually

becomes negative. Technician B says that as steering

linkage wear occurs, toe usually becomes toe-out ilom an

original toe-in specification. Which technician is correct?

a. TechnicianAonly

b. Technician B only

c. Both Technicians A and B

d. Neither Technician A nor B

QUESTIONS

Explain the three basic alignment angles of camber,

caster, and toe.

Use the Following Information to Answer

Question

2. Explain how knowing SAI, TOOT, and included angle

can help in the correct diagnosis of an aligrrment probIem.

Specifications: Minimum Preferred Maximum

3. List ten prealignment

Camber (degree)

1.0

7.4

.8

1.5

2.7

4. List the steps necessary to follow for a four-wheel aliqn-

Caster (degree)

Toe (inch)

-.10

.06

(degree) -.1

checks that should be performed

before the wheel alignment is checked and,/or adjusted.

.15

ment.

Results:

X ASE CERTTFICATION.TYPE

QUESTTONS

1. Technician A says that worn upper control arm bushings can cause play in the steering. Technician B says

that

defective universaljoint between the steering col-

umn and the steering gear box stub shaft can cause excessive steeringwheel play. Which technician is correct?

a. Technician A only

b. Technician B only

c. Both Technicians A and B

d. Neither Technician A nor B

Camber

Caster (degree)

Toe (inch)

1.8

1.6

7.12

+.12

7. The vehicle above will:

a. Pull toward the right and feather

b.

c.

d.

edge both

tires

Pull toward the left

Wear the outside of the left tire and the inside

of the right tire

None of the above

Wheel Alignment Principles, Diagnosis, and

Use the Following Information to Answer

Questions 8 and 9

Specifications: Minimum Preferred Maximum

Camber (degree)

Caster (degree)

Toe (inch)

/n

\J

t16

t/

ru

(degree) -0.3

-0.1

(degree) 3.6

Toe (inch)

-0.1,6

Caster

LA

+2

0

-

Lt

Tt2

'

Results:

Camber

-t

1.8

+0.32

31

t16

Service l0l5

8. The vehicle at the left will:

a. Pull toward the left

Pull toward the right

c. Wander

d. Lead to the left slightly

b.

9. The vehicle at the left will:

a. Wander

b. Wear tires, but not pull

c. Pull, but not wear tires

d. Pull toward the left and cause feather-edee

tire wear

10. Which alignment angle is most likely to need correction

and cause the most tire wear?

a. Toe

b.

c.

d.

Camber

Caster

SAYKPI

Potrebbero piacerti anche

- Silverado 2005 Wiring DiagramsDocumento149 pagineSilverado 2005 Wiring Diagramskurtleyba77% (26)

- 2012 Nissan Service Maintenance Guide PDFDocumento60 pagine2012 Nissan Service Maintenance Guide PDFsameermunshi007100% (1)

- Hunter Win Align ManualDocumento357 pagineHunter Win Align ManualdennisNessuna valutazione finora

- Pps 941803 3l Tdi Cata W Clean Diesel System Eng PDFDocumento103 paginePps 941803 3l Tdi Cata W Clean Diesel System Eng PDFmisternyckNessuna valutazione finora

- ARB 3438100 FittingDocumento7 pagineARB 3438100 FittingthailanNessuna valutazione finora

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDa EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualNessuna valutazione finora

- Eng Trouble Diag Aug 09Documento48 pagineEng Trouble Diag Aug 09279195750% (2)

- Capacities and SpecificationsDocumento26 pagineCapacities and SpecificationsWagner BernardinaNessuna valutazione finora

- Scania DC13 - Industrial Engine - PDF Installation ManualDocumento39 pagineScania DC13 - Industrial Engine - PDF Installation ManualGem RNessuna valutazione finora

- Wheel Alignment Theory OperationDocumento5 pagineWheel Alignment Theory OperationToua YajNessuna valutazione finora

- Suspension Front 4wdDocumento12 pagineSuspension Front 4wdAnimemanuel MuñozNessuna valutazione finora

- Toyota Tercel 4WD 1985Documento885 pagineToyota Tercel 4WD 1985Wilson JhNessuna valutazione finora

- Audi Workshop Manuals - A3 Mk1 Installing GearboxDocumento8 pagineAudi Workshop Manuals - A3 Mk1 Installing GearboxAlbertNessuna valutazione finora

- Front Wheel AlignmentDocumento19 pagineFront Wheel AlignmentFajar Setiawan J SNessuna valutazione finora

- Adjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersDocumento13 pagineAdjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersJ.d. LangleyNessuna valutazione finora

- Power: SolutionsDocumento12 paginePower: Solutionsmargarita margaNessuna valutazione finora

- Mode Generic Title Toyota/Lexus Title: Coolant TempDocumento6 pagineMode Generic Title Toyota/Lexus Title: Coolant TempMohamed Wahieb100% (1)

- Manual Transaxle Assy (E357) : To Model IndexDocumento1 paginaManual Transaxle Assy (E357) : To Model IndexHenrry MendezNessuna valutazione finora

- NLS 200 All Wheel Drive Crew Cab Australiano PDFDocumento4 pagineNLS 200 All Wheel Drive Crew Cab Australiano PDFdionymackNessuna valutazione finora

- B Series Engine Training Torque Pt.1Documento14 pagineB Series Engine Training Torque Pt.1Tri KinartoNessuna valutazione finora

- Musso GearboxmanualDocumento81 pagineMusso GearboxmanualembokoNessuna valutazione finora

- Automatic Gearbox 09KDocumento133 pagineAutomatic Gearbox 09KTintinPicasoNessuna valutazione finora

- Tightening Torques Items N.M KGF.M LB-FT: 4 Wheel Drive (4WD) SystemDocumento35 pagineTightening Torques Items N.M KGF.M LB-FT: 4 Wheel Drive (4WD) SystemZM OhnNessuna valutazione finora

- Valve Train Components and DesignDocumento44 pagineValve Train Components and Designsc100% (1)

- 1.6tdci Turbo Failure Caused by Injector Seal LealDocumento3 pagine1.6tdci Turbo Failure Caused by Injector Seal LealShane GreerNessuna valutazione finora

- Types of Axles Front Axle Rear Axle and Stub Axle PDFDocumento7 pagineTypes of Axles Front Axle Rear Axle and Stub Axle PDFraghavNessuna valutazione finora

- ARP - Bolt Catalogue (Bolting Information) - Cat03Documento82 pagineARP - Bolt Catalogue (Bolting Information) - Cat03petermorgan74931Nessuna valutazione finora

- Manual Transmission 5 SpeedDocumento12 pagineManual Transmission 5 Speedav1135100% (1)

- SuspensionDocumento45 pagineSuspensionGeorge JankoNessuna valutazione finora

- Manual Motor Hyundai Elantra - Unlocked PDFDocumento164 pagineManual Motor Hyundai Elantra - Unlocked PDFloky13100% (1)

- 2006.02 Motor Toyota EVAP-Non-Intrusive SystemDocumento3 pagine2006.02 Motor Toyota EVAP-Non-Intrusive SystemMNessuna valutazione finora

- Differential and Driveline96zjs - 3Documento34 pagineDifferential and Driveline96zjs - 3F-fatal FaxNessuna valutazione finora

- R35 Quick Start GuideDocumento12 pagineR35 Quick Start GuidemspetNessuna valutazione finora

- Headgasket Case History PDFDocumento3 pagineHeadgasket Case History PDFdromakiNessuna valutazione finora

- ST1832 G07 Complete VehicleDocumento52 pagineST1832 G07 Complete VehicleNguyễn Hoàng LongNessuna valutazione finora

- Common Rail Diagnostics With Frank MasseyDocumento1 paginaCommon Rail Diagnostics With Frank MasseyEdidjo DarwinNessuna valutazione finora

- V2 3 6 Final Gear and Differential GearDocumento44 pagineV2 3 6 Final Gear and Differential GearDwy Bagus NNessuna valutazione finora

- Swissauto 250Documento51 pagineSwissauto 250Mothi Ram100% (1)

- Ignition, Engine Control (b4204t2 CVVT 2000)Documento319 pagineIgnition, Engine Control (b4204t2 CVVT 2000)Jose PichinteNessuna valutazione finora

- ZD30 Engine Fault ListDocumento61 pagineZD30 Engine Fault Listlocario1Nessuna valutazione finora

- Timing Belt Mazda Millenia S 2002Documento5 pagineTiming Belt Mazda Millenia S 2002Carlos MendozaNessuna valutazione finora

- Report On I.C.E (Replica)Documento46 pagineReport On I.C.E (Replica)Ariel PortugalNessuna valutazione finora

- The Diagnostic Process VVDocumento29 pagineThe Diagnostic Process VVahmad razaNessuna valutazione finora

- Transmission TrainingDocumento22 pagineTransmission Trainingkeval patel100% (1)

- Ks Si 0014 en WebDocumento0 pagineKs Si 0014 en WebMoaed KanbarNessuna valutazione finora

- 14043.17D Passenger AWD PG R1.03 PDFDocumento79 pagine14043.17D Passenger AWD PG R1.03 PDFDavid LeeNessuna valutazione finora

- Manual Transfer CasesDocumento2 pagineManual Transfer CasesmechtronicNessuna valutazione finora

- 02 - Power BalancingDocumento8 pagine02 - Power Balancingveer sainNessuna valutazione finora

- Hunter Balancer TiresDocumento12 pagineHunter Balancer Tiresdionisio emilio reyes jimenezNessuna valutazione finora

- Scania 11 and 12 Litre Engines Workshop ManualDocumento142 pagineScania 11 and 12 Litre Engines Workshop ManualFogarasiIstvánNessuna valutazione finora

- Land Rover Defender CatalogueDocumento69 pagineLand Rover Defender CataloguepablogarciaclNessuna valutazione finora

- Lancia Scorpion Tecnhnical TipsDocumento11 pagineLancia Scorpion Tecnhnical Tipsphantom fiatNessuna valutazione finora

- Direct Injection Test (Voltage Vs Current) (Picoscope)Documento7 pagineDirect Injection Test (Voltage Vs Current) (Picoscope)Toni JuanNessuna valutazione finora

- BMW n54b30 2007 Engine ManagementDocumento51 pagineBMW n54b30 2007 Engine Managementeddix100% (1)

- Making Volleyball Statistics Simple PowerPointDocumento45 pagineMaking Volleyball Statistics Simple PowerPointShannon WilliamsNessuna valutazione finora

- Automotive Engine Rebuilding Guide Auto 250: Brigham Young University - IdahoDocumento25 pagineAutomotive Engine Rebuilding Guide Auto 250: Brigham Young University - Idaho2791957Nessuna valutazione finora

- Service Manual: 1XD-F8197-E0Documento0 pagineService Manual: 1XD-F8197-E0Julie LafranceNessuna valutazione finora

- Transporter With WBX Vag Self Study Programme PDFDocumento53 pagineTransporter With WBX Vag Self Study Programme PDFAllan CancinoNessuna valutazione finora

- Brake BoosterDocumento3 pagineBrake BoosterAgustín Arias PazNessuna valutazione finora

- Subject: Wheel Alignment Specifications, Requirements and Recommendations For GM VehiclesDocumento10 pagineSubject: Wheel Alignment Specifications, Requirements and Recommendations For GM VehiclesAnonymous 3aPuAai0% (1)

- Building a WWII Jeep: Finding, Restoring, & Rebuilding a Wartime LegendDa EverandBuilding a WWII Jeep: Finding, Restoring, & Rebuilding a Wartime LegendNessuna valutazione finora

- Automotive (Small Engine)Documento2 pagineAutomotive (Small Engine)2791957Nessuna valutazione finora

- ToolsCat 74Documento58 pagineToolsCat 742791957Nessuna valutazione finora

- CustomerDocumento1 paginaCustomer2791957Nessuna valutazione finora

- Swift - June 09 - 03 Instrument PanelDocumento56 pagineSwift - June 09 - 03 Instrument Panel2791957Nessuna valutazione finora

- Kelpro Engine MountsDocumento107 pagineKelpro Engine Mounts27919570% (1)

- Application Note AN05 - Bench Testing OBD Interfaces: Doubly Terminated!Documento3 pagineApplication Note AN05 - Bench Testing OBD Interfaces: Doubly Terminated!2791957Nessuna valutazione finora

- Battery Control System: DescriptionDocumento3 pagineBattery Control System: Description2791957100% (1)

- Q 117R2Documento2 pagineQ 117R22791957Nessuna valutazione finora

- Battery Test and Charging ProcduresDocumento6 pagineBattery Test and Charging Procdures2791957Nessuna valutazione finora

- A Smart Way To Drive Ecu ConsolidationDocumento4 pagineA Smart Way To Drive Ecu Consolidation2791957Nessuna valutazione finora

- Application Note AN06 - ELM327L and The PL-2303HX: Installing SoftwareDocumento2 pagineApplication Note AN06 - ELM327L and The PL-2303HX: Installing Software2791957Nessuna valutazione finora

- 05ivm EseriesDocumento56 pagine05ivm Eseries27919570% (1)

- 7 Steps Oxygen Sensor MTE THOMSON1Documento9 pagine7 Steps Oxygen Sensor MTE THOMSON12791957100% (1)

- 07 AutoDocumento6 pagine07 Auto2791957Nessuna valutazione finora

- Alto2011 CatalogDocumento538 pagineAlto2011 CatalogIsa Restrepo Fernandez0% (1)

- Emergency Response Guide-ToyotaDocumento143 pagineEmergency Response Guide-Toyota2791957100% (1)

- Ford Wiring Diagram 1994 9404Documento11 pagineFord Wiring Diagram 1994 94042791957Nessuna valutazione finora

- Franchise Agreements and Management ContractsDocumento24 pagineFranchise Agreements and Management Contracts2791957Nessuna valutazione finora

- BearingDocumento66 pagineBearing279195750% (2)

- Engine Fundamentals 1Documento55 pagineEngine Fundamentals 12791957Nessuna valutazione finora

- 1995 System Wiring DiagramsDocumento32 pagine1995 System Wiring Diagrams2791957Nessuna valutazione finora

- Engine Electrical System (D4FA - DSL1.5) : General Charging System Starting SystemDocumento28 pagineEngine Electrical System (D4FA - DSL1.5) : General Charging System Starting System2791957Nessuna valutazione finora

- 631D Trans Shift PointsDocumento20 pagine631D Trans Shift PointsDaveNessuna valutazione finora

- Benz Patent Motor Car - The First Automobile (1885-1886) - Daimler - Company - Tradition - Company HistoryDocumento4 pagineBenz Patent Motor Car - The First Automobile (1885-1886) - Daimler - Company - Tradition - Company HistoryRear BaueltazarNessuna valutazione finora

- Lambda Eng PDFDocumento5 pagineLambda Eng PDFivanmjwNessuna valutazione finora

- 320c & 320c L Excavators Amc00001-Up (Machine) Powered by 3066 Engine (... Page 1 of 2Documento2 pagine320c & 320c L Excavators Amc00001-Up (Machine) Powered by 3066 Engine (... Page 1 of 2soelist teo100% (1)

- Intervalo 1000 Horas - 938KDocumento3 pagineIntervalo 1000 Horas - 938KMatheus MongesNessuna valutazione finora

- Tire Size ComparisonDocumento1 paginaTire Size ComparisonBudi DarmawanNessuna valutazione finora

- (PDF) Siwes Technical ReportDocumento77 pagine(PDF) Siwes Technical ReportAgu Monfort0% (1)

- EN - 1994.K1100LT - Wiring.SLP - FinalDocumento15 pagineEN - 1994.K1100LT - Wiring.SLP - FinalaureliogutNessuna valutazione finora

- Warehouse Report JuliDocumento983 pagineWarehouse Report Julishubham sahuNessuna valutazione finora

- b737 Flight ControlsDocumento4 pagineb737 Flight ControlsPanagiotis SoutsasNessuna valutazione finora

- AJP MOTOS - PR3 Part List 125/200Documento52 pagineAJP MOTOS - PR3 Part List 125/200AJP MotosNessuna valutazione finora

- Caterpillar Engine Service Training Introduction To The 3176 EngineDocumento3 pagineCaterpillar Engine Service Training Introduction To The 3176 Enginefrancesca100% (44)