Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Volvo p1800s Stromberg 175 Instruction Book

Caricato da

vanapeer100%(2)Il 100% ha trovato utile questo documento (2 voti)

982 visualizzazioni8 paginevolvo p1800s strömberg 175 instruction book

Titolo originale

volvo p1800s stromberg 175 instruction book

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentovolvo p1800s strömberg 175 instruction book

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

100%(2)Il 100% ha trovato utile questo documento (2 voti)

982 visualizzazioni8 pagineVolvo p1800s Stromberg 175 Instruction Book

Caricato da

vanapeervolvo p1800s strömberg 175 instruction book

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 8

SUPPLEMENT TO INSTRUCTION BOOK

VOLVO 1800 S

To a great extent the instruction book for the Volvo 1800 $ (P)

applies also to the Volvo 1800 $ (S). This supplement deals only with

the important differences between the Volvo 1800 $ ($) and 1800

S (P) models

Type designation Engine Gearbox

18 — 3358S B20B M41

DESCRIPTION

Engine

The Volvo 1800 S is fitted with a new 2-litre, 4-cylinder engine with

type designation B 20 B. The engine is fitied with twin carburetors

The B 20 B engine has a higher torque than the previous B 1 B unit.

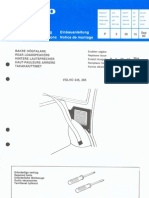

Exhaust emission control

The Volvo 1800 S is now fitted with exhaust emission control, that is,

system which as a result of better mixing and distributing of fuel

and air provides a more complete combustion and thereby cleaner

exhaust gases,

Exhaust emission control is provided partly through carburetors

specially designed for this purpose and partly by the engine having

a special induction manifold with throitles and preheating chamber,

see Fig. below. in

When driving at low speeds the throttles are closed so-that the

fuel-air mixture is forced to pass the preheating chamber.

When higher output is required, the throttles open so that the fuel-

air mixture flows directly to the cylinders,

1, Exhaust manifold 3. Intake manifold throttle 5. Carburetlor

2. Intake manifold 4, Carburettor throtiles 6. Preheating chamber

\ vy!

2 1

4

yowo

Nass

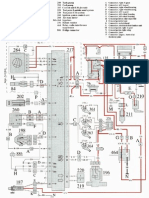

Electrical system

The electrical system is of the 12-Volt type and is equipped with a

voltage-regulated alternator. When replacing the battery or carrying

out any other work with the electrical system, the following should

be observed.

1. The battery connection to the wrong terminal will damage the

rectifiers. Before connecting up, check the polarity of the battery

with a voltmeter.

2. If extra batteries are used for starting, they must be properly

connected fo prevent the rectifiers from being damaged

The negative lead from the auxiliary battery for starting must

be connected to the negative terminal stud of the car battery and

the positive lead from the auxiliary battery for starting to the

positive terminal stud.

3. Ifa fast charger is used for charging the battery, the battery

leads should be disconnected.

The fasi charger must never be used as an auxiliary unit for

starting. If this is not observed, both the alternator and regulator

will be ruined.

4, Never disconnect the battery circuit (for example to change the

battery) while the engine is running, as this will ruin the alter-

nator immediately.

5. If any electrical welding work is to be carried out on the vehicle,

the welding unit must be connected as near as possible to the

welding point'and on the same main-component, for example

the:chassis or the body, etc. If such an arrangement is not possible,

disconnect both battery leads.

Power transmission

Clutch

The Volvo 1800 S has a mechanical clutch provided with a cable

control. The part of the text in the instruction book which covers the

clutch hydraulic system does not apply.

Overdrive

The Volvo 1800 S has been fitted with a new type of overdrive.

Besides being stronger, if has a smoother engagement and dis-

engagement than previously. The ratio for the new overdrive has

been altered fo 0.797:

Rear axle

The Volvo 1800 S is fitted with a rear axle with altered ratio 4.

Brakes

The brake system is a dual-circuit sysiem with disc brakes on the

front wheels and drum brakes on the rear wheels. The system is

provided with a tandem master cylinder and a direct operating

servo cylinder.

The principle for the dual-circuit system is that both front wheels

are connected to a rear wheel, that is, should one of the systems

cease to function, there is always brake power for both front wheels

and a rear wheel.

The delivery lines fo the rear wheels are fitted with relief valves

which prevent involuntary locking of the rear wheels.

The system also includes a warning lamp mounted io the left of the

revolution counter. This warning lamp lights if one of the circuits

does not function during braking. The lamp also indicaies when

the handbrake is applied

SERVICING

Maintenance system

With effect from the 1969 models, the maintenace system has been

modified. Servicing proceedure carried out at 5000 km (3000

miles) intervals are ot 1. Oil changing for the engine as well

as oil level checking for the gearbox, final drive, steering gear

and carburettor(s) should take place after every 10000 km (6000

miles), suitably in connection with the 10000 km (6000 miles)

inspection. However, as previously, during the running-in period

the engine oil should be changed after the first 2500 km (1500

miles) and the oil in the gearbox and final drive replaced after the

first 5000 km (3000 miles)

In addition to the above, the following should be checked when

filling with fuel:

the oil level in the engine

the coolant level

the brake fluid level

that the container for the windscreen washer fluid is full

about every 14 days the tyre pressure and the battery acid level.

Oil changing in engine

With a new or newly reconditioned engine the oi! should be changed

after the first 2500 km (1500 miles). Thereafter oil changing is

according to the intervals below.

The intervals for changing will depend to a great extent on the type

of oil used. For engine lubrication "For Service MS” should be used.

As far as viscosity is concerned a multigrade oil should primarily

be used. These oils are better suited for demanding operating con-

ditions, for instance, continuous driving in city traffic with incessant

stopping and starting and long periods idling.

For engine oil with viscosity SAE 10 W — 30 (multigrade),

10 W — 40 or 20 W — 50 the oil should be changed every

10000 km (6000 miles).

If an engine oil with viscosity SAE 10 W (singlegrade), 20/20 W

or 30 is used, the oil should be changed every 5000 km

(3000 miles), or at least twice a year.

At very low temperatures (—20° C = 4° F) multigrade oil SAE 5 W

— 20 is recommended. However, this oil should not be used when

the temperature constantly exceeds 0° C (32° F).

Viscosity Temperature | Oil changing | Oil capacity

Oil quality range intervals*)

SAE 10 W —30

10 W — 40 | all the year | 10000 km

20 W — 50 | round (6000 miles) | Exel oil 7

"For Service MS” 3.25 litres

| (5.72 Imp.

pints = 6.86

SAE 10 W below —10° C US pints)

(14 F)

20/20 W | between —10° | 5000 km Incl. oil filter

| Cand +30°C| (3000 miles) | 3.75 litres

| (14° Fand (at least (6.60 Imp.

90° F) twice @ year) | pints = 7.91

30 above +30°C US pints)

(90° F)

"For Service MS”

*) During running-in the oil should be changed after the first 2500

km (1500 miles).

Positive crankcase ventilation

The 1800 S is provided with positive crankcase ventilation which

has been given a different design in relation to previous models.

The positive crankcase ventilation prevents crankcase gases from

being released into the atmosphere. Instead they are sucked into

the engine through the intake manifold and participate in the com-

bustion after which they are blown out through the exhaust pipe

together with the other combustion gases.

Every 40000 km (25000 miles) the components for the positive

crankcese ventilation should be cleaned and this operation ought to

be done in a Volvo workshop.

Air cleaner

The engine has a new type of air cleaner, a so-called rod-lype

cleaner which is the same for both the carburetors.

The air cleaner consists of a plastic casing with replaceable

paper cleaner insert.

The insert should be replaced after every 40000 km (25000 miles)

If the car is run mainly on roads which are very dusty, the cleaner,

however, should be replaced more often,

To change the cleaner, slacken the clamps retaining the upper part

of the air cleaner so that the upper part can be taken off. The insert

is now available for replacement.

Draining the coolant

The coolant should be changed every other year. To drain the

coolant, open a cock on the right-hand side of the engine and

release the hose connected to the lower part of the radiator. There

is no drain plug on the radiator,

Carburettors

The carburettors on the Volvo 1800 S models are set and tested with

@ CO-gauge at the factory. Any subsequent checking or adjustment

of the carbureitor’s selling need not be done other than when

carrying out repairs to or replacement of the carburetors.

The only measure required to be carried out at regular intervals is

a check on the oil level in the damping cylinders, this being carried

out every 10000 km (6000 miles).

Replacing the servo cylinder air cleaner

Normally, the servo cylinder air cleaner should be replaced every

40000 km (25000 miles). When driving mainly on dusty roads re-

placement should take place more often. The servo cylinder air

cleaner should be replaced at a Volvo workshop having ihe proper

equipment for this purpose.

Brake fluid

The brake system is fitted with twin brake fluid containers, one for

each circuit. The brake fluid level can suitably be checked when

filling fuel in connection with the oil level check for the engine.

The fluid should be between the Max. and Min. marks.

As far as the hydraulic brake system is concerned, only brake

fluids meeting the requirements according to SAE 70 R 3

may be used. N. B. Do not use brake fluids with designation

SAE 70 R 1, HD or similar. From a traffic safety point of

view, it is very important that brake fluid of inferior value

is not used. A first-class brake fluid must, namely, fulfil the

heavy demands made by temperature variations and in

addition must not have a damaging effect on the rubber

components in the brake system.

SPECIFICATIONS

Engine

Type designation . Volvo B 20 B

Ouiput (DIN) at r.p.m. . 105 h.p./5500

Oviput (SAE) at r.p.m. 118 h.p./5800

16.5 kpm/3500 (119 Ib.fi.)

17 kpmn/3500 (123 Ib.ft.)

88.9 mm (3.5")

80 mm (3.15”)

Max. torque (DIN) af r.p.m

Max, torque (SAE) at r.p.m.

Bore ..

Stroke .

Displacement. . 1.99 litres

Compression ratio . 9.531

Velyeclearanca, warmurd cle,

nla ee sete 50—.55 mm (.020—.022”)

Valve clearances, warm and cold,

exhaust 50—.55 mm (.020—.022”)

Idling speed, warm engine. 800 r.p.m

Fuel system

Carburetors, type ............. Horizontal

designation Zenith-Stromberg 175 CD 2 SE

Fuel, octane rating, min......... 100

Cooling system

Thermostat begins opening at... approx. 82° C (179° F)

fully open at . . approx. 95° C (204° F)

Ignition system

Ignition setting, stroboscope setting s

(vacuum governor disconnected). 10° 8.1.D.C. at 600—800 r.p.m.

Spark plug, normal driving Bosch W 200 T 35%)

hard driving Bosch W 225 T 35%)

electrode gap . .7—.8 mm (.028—.032")

fightening torque... 3.5—4.0 kgm (25—29 Ib. ft.)

Ponrs. dSmw- ( oie" )

Electrical system

Baitery, electrolyte specific gravity 1.28

recharged at... 1.21

Alternator, current rating mex. . 35 A

output max. . 450 W.

Gearbox

Type designation ....... M4t

Ratio, 1st speed . ones)

2nd speed 1.99:1

3rd speed 1.36:1

4th speed : da

4th speed with overdrive.. .797:1

reverse 2.5... 3.25:1

rinal drive 7 aud

Ratio:

with gearbox M41 oe ..ce.ee eee 43:1

*) Or corresponding

AB VOLVO GOTEBORG SWEDEN

TP 620/f, (Ence!

2). 4000, 10,68. neevore.cde cess

Potrebbero piacerti anche

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesDa EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesValutazione: 5 su 5 stelle5/5 (1)

- Construction and Manufacture of AutomobilesDa EverandConstruction and Manufacture of AutomobilesValutazione: 5 su 5 stelle5/5 (1)

- Ford Manual for Owners and Operators of Ford Cars and Trucks (1919)Da EverandFord Manual for Owners and Operators of Ford Cars and Trucks (1919)Nessuna valutazione finora

- Carbtune PDFDocumento22 pagineCarbtune PDFndmvillocilloNessuna valutazione finora

- Carburetor Assembly Yamaha 1200 XLTDocumento18 pagineCarburetor Assembly Yamaha 1200 XLTduduleNessuna valutazione finora

- Volkswagen - 003 2 Band Type Rear Transaxle: Rebuilder KitsDocumento1 paginaVolkswagen - 003 2 Band Type Rear Transaxle: Rebuilder Kitstitanes76Nessuna valutazione finora

- Subaru Mod. 501 Brake Systems PDFDocumento56 pagineSubaru Mod. 501 Brake Systems PDFDavid VelazquezNessuna valutazione finora

- Kawasaki Teikei TK-22 Carburetor InformationDocumento6 pagineKawasaki Teikei TK-22 Carburetor Informationcaotonic1150100% (1)

- Tuning SU CarburettorDocumento25 pagineTuning SU Carburettorcrkg100% (1)

- Adjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersDocumento13 pagineAdjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersJ.d. LangleyNessuna valutazione finora

- 2000-01-3090 - Design of A Restricted Induction System For A High Speed Four Cylinder EngineDocumento8 pagine2000-01-3090 - Design of A Restricted Induction System For A High Speed Four Cylinder EngineCaio PaimNessuna valutazione finora

- Carb Turbo Kit InstructionsDocumento11 pagineCarb Turbo Kit InstructionsKevin ShankleNessuna valutazione finora

- 199R9934 3rev2 PDFDocumento16 pagine199R9934 3rev2 PDFbatman2054Nessuna valutazione finora

- Catalogue Janspeed Feb 81Documento22 pagineCatalogue Janspeed Feb 81Paul Bottomley100% (1)

- Aj6 Engineering IgnitionDocumento9 pagineAj6 Engineering IgnitionBo BoboNessuna valutazione finora

- Repairing Jaeger & Smiths SpeedometersDocumento25 pagineRepairing Jaeger & Smiths SpeedometersMichael Carnell100% (2)

- KZ Slide Carb Tuning-1Documento6 pagineKZ Slide Carb Tuning-1pertonpcNessuna valutazione finora

- 914Documento221 pagine914leo2396Nessuna valutazione finora

- Solex Tuning CarburetorDocumento47 pagineSolex Tuning CarburetorCiner FarukNessuna valutazione finora

- Cylinder Head InstallDocumento2 pagineCylinder Head InstallMiguel Moreno FernándezNessuna valutazione finora

- VBL Mitsubishi F4A F5ADocumento1 paginaVBL Mitsubishi F4A F5APedroMecanico100% (1)

- Body Dimension DiagramDocumento10 pagineBody Dimension DiagramDwi Rizky Febriyanto IpepNessuna valutazione finora

- Volkswagen Jetta, Golf, GTI 1999, 2000 2.8 Liter VR6 2V Engine Mechanical, Engine Code(s) : AFPDocumento33 pagineVolkswagen Jetta, Golf, GTI 1999, 2000 2.8 Liter VR6 2V Engine Mechanical, Engine Code(s) : AFPBoris StoyanovNessuna valutazione finora

- Holley 1909 Carb ManualDocumento9 pagineHolley 1909 Carb ManualALMOST610Nessuna valutazione finora

- Volkswagen Beetle: General HistoryDocumento6 pagineVolkswagen Beetle: General HistoryIsanahsadNessuna valutazione finora

- Index For Holden H-G Series Bulletins Issued Durinf The Years 1949 and 1950Documento2 pagineIndex For Holden H-G Series Bulletins Issued Durinf The Years 1949 and 1950Grant Millar100% (2)

- 2 DescriptionDocumento24 pagine2 Descriptionvanapeer100% (3)

- AxlesDocumento44 pagineAxlesJuan Cruz FonsecaNessuna valutazione finora

- Lancia Scorpion Tecnhnical TipsDocumento11 pagineLancia Scorpion Tecnhnical Tipsphantom fiatNessuna valutazione finora

- Smith Speed Ore PairDocumento27 pagineSmith Speed Ore PairiansoadyNessuna valutazione finora

- Autoweek February 6, 1989Documento4 pagineAutoweek February 6, 1989bzrongNessuna valutazione finora

- WisecochartDocumento15 pagineWisecochartVitNessuna valutazione finora

- Lunati CatalogDocumento302 pagineLunati Catalogbmzero100% (5)

- Find Your Car's Date of Manufacture (VIN)Documento15 pagineFind Your Car's Date of Manufacture (VIN)Rohit SaxenaNessuna valutazione finora

- Suzuki DT15 (1986-1988)Documento39 pagineSuzuki DT15 (1986-1988)Suministros Lasser100% (1)

- Vincent TechnicalDocumento58 pagineVincent TechnicalCiprian MaiorNessuna valutazione finora

- Sequential Shifter Fitting Instructions v2 A4Documento17 pagineSequential Shifter Fitting Instructions v2 A4Ufix FabricationNessuna valutazione finora

- LH2.2 & EZ-F User Manual Issue 2bDocumento73 pagineLH2.2 & EZ-F User Manual Issue 2bphilro52Nessuna valutazione finora

- 750cc Ural ManualDocumento128 pagine750cc Ural ManualCammac69Nessuna valutazione finora

- Weber Carb Buyers GuideDocumento2 pagineWeber Carb Buyers Guideclaudio_sorianoNessuna valutazione finora

- Zenith Stromberg Tech TipsDocumento5 pagineZenith Stromberg Tech TipsMarcopolohuesos PerezNessuna valutazione finora

- Zenith PDFDocumento9 pagineZenith PDFhansolosnahNessuna valutazione finora

- Overdrive Repairs and Maintenance 1976Documento44 pagineOverdrive Repairs and Maintenance 1976vanapeer100% (6)

- Borgeson Steering JointsDocumento29 pagineBorgeson Steering JointsKerry Murray100% (1)

- Go Kart WikipediaDocumento11 pagineGo Kart WikipediaPreet NagpalNessuna valutazione finora

- Brake Shoes Removal and Installation PDFDocumento6 pagineBrake Shoes Removal and Installation PDFMichael HernandezNessuna valutazione finora

- Fox Shocks Float and Float 2 RebuildDocumento22 pagineFox Shocks Float and Float 2 RebuildJules De MontignyNessuna valutazione finora

- Carb Owners ManualDocumento26 pagineCarb Owners ManualTroy Bauer100% (14)

- Tuning SU CarburetorsDocumento50 pagineTuning SU CarburetorsDaniel Southam100% (1)

- Carburetor Overhaul, GL1100: by RoadyDocumento14 pagineCarburetor Overhaul, GL1100: by RoadyAndy StowellNessuna valutazione finora

- Nissan Frontier Service Manual ClutchDocumento15 pagineNissan Frontier Service Manual ClutchDaniel AguirreNessuna valutazione finora

- Application: 1990 Ford Bronco 1990 Ford BroncoDocumento43 pagineApplication: 1990 Ford Bronco 1990 Ford BroncoWin CardonaNessuna valutazione finora

- 199R7948 5rev5 PDFDocumento16 pagine199R7948 5rev5 PDFbatman2054Nessuna valutazione finora

- Echlin Part No RefDocumento85 pagineEchlin Part No Refpilveni100% (1)

- Desmo Drom IDocumento5 pagineDesmo Drom IWilliamNessuna valutazione finora

- TREMEC TR-6070 Transmission: 7-Speed RWD Manual TransmissionDocumento2 pagineTREMEC TR-6070 Transmission: 7-Speed RWD Manual TransmissionAngelNessuna valutazione finora

- Dragon Days: The story of Miss Bardahl and the 1960s kids who loved hydros (2020 edition)Da EverandDragon Days: The story of Miss Bardahl and the 1960s kids who loved hydros (2020 edition)Nessuna valutazione finora

- Volvo 850 EngineDocumento15 pagineVolvo 850 Enginevanapeer100% (3)

- TP2103201Documento68 pagineTP2103201vanapeer83% (6)

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Volvo 240 1979Documento28 pagineVolvo 240 1979vanapeerNessuna valutazione finora

- Mitsubishi TD04 Melett PartlistDocumento11 pagineMitsubishi TD04 Melett Partlistvanapeer100% (3)

- Melett Price List 2Documento49 pagineMelett Price List 2vanapeer100% (1)

- Melett Price ListDocumento30 pagineMelett Price ListvanapeerNessuna valutazione finora

- B21etl-Grpa Installation Instructions For B21ETLDocumento32 pagineB21etl-Grpa Installation Instructions For B21ETLvanapeer100% (1)

- Superpro Volvo 240 Bushings Complete ListingDocumento9 pagineSuperpro Volvo 240 Bushings Complete ListingvanapeerNessuna valutazione finora

- Volvo Ecu and Amm ApplicationDocumento1 paginaVolvo Ecu and Amm ApplicationvanapeerNessuna valutazione finora

- Intake Protection 1973-1985Documento1 paginaIntake Protection 1973-1985vanapeerNessuna valutazione finora

- TP31201-1 700 Multi-Link Rear SuspensionDocumento42 pagineTP31201-1 700 Multi-Link Rear Suspensionvanapeer100% (1)

- TP11740-2 Carburetted Fuel SystemsDocumento116 pagineTP11740-2 Carburetted Fuel Systemsvanapeer100% (5)

- (Aug 81) Map Reading LampDocumento1 pagina(Aug 81) Map Reading LampvanapeerNessuna valutazione finora

- 3-38-27 (Apr 93) Digital Outer - Inner Temperature 1981Documento16 pagine3-38-27 (Apr 93) Digital Outer - Inner Temperature 1981vanapeer100% (1)

- 3-39-15 (Sep 80) Rear Speaker 245 - 265Documento6 pagine3-39-15 (Sep 80) Rear Speaker 245 - 265vanapeerNessuna valutazione finora

- CB RadioDocumento4 pagineCB RadiovanapeerNessuna valutazione finora

- 283782-Manual CB Radio - Owner's ManualDocumento8 pagine283782-Manual CB Radio - Owner's Manualvanapeer100% (1)

- Volvo TP 31397-1 IgnitionDocumento108 pagineVolvo TP 31397-1 Ignitionvanapeer100% (7)

- Injector Heptan FlowsDocumento38 pagineInjector Heptan FlowsvanapeerNessuna valutazione finora

- LH-Jetronic 2.2 B230FTDocumento11 pagineLH-Jetronic 2.2 B230FTvanapeer100% (4)

- tp3908202 940 1995 Wiring Diagrams Section 3 39Documento215 paginetp3908202 940 1995 Wiring Diagrams Section 3 39vanapeer83% (6)

- LH-Jetronic 2.2 B230FTDocumento11 pagineLH-Jetronic 2.2 B230FTvanapeer100% (4)