Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Temperature Cable Component

Caricato da

Inayat HathiariCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Temperature Cable Component

Caricato da

Inayat HathiariCopyright:

Formati disponibili

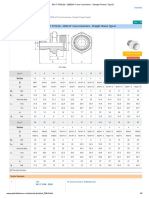

XLPE(Direct Burial)Page1

CALCULATION OF CONTINUOUS CURRENT CARRYING CAPACITY

1. Calculation Condition

1.1 General Condition

1) Standard

IEC 287(1993)

2) System Volatge

[kV]

132

3) Frequency

[Hz]

50

4) Maximum Operating Conductor Temperature

88.1

[mm2]

630

5) Nominal Cross Section Area

6) Material of Conductor

Copper

7) Sheath Bonding Method

Cross Bonding

1) Cable Laying Method

Direct Burial

2) Number of Circuit

1.2 Installation Condition

3) Axial Cable Distance of Phase

[mm]

4) Cable Arrangement

91

Trefoil Formation

5) Ambient Temperature

6) Depth of Cable Center

[mm]

35

900

7) Soil Thermal Resistivity

[K.m/W]

2.0

8) Axcial Distance between each Circuits

[mm]

600

8) Distance between centre cable of each circuit

[mm]

1200

2. Calculation Procedure

2.1 Conductor Resistance

1) D.C Resistance of Conductor at Maximum Temperature

Rx = Ro [ 1 +

Where,

(Tmax - 20)]

3.59E-05

Ro : DC resistance of Conductor at 20

: Temperature Coefficient

[/m]

Tmax : Maximum Conductor Temperature [

2) Skin Effect Factor

s =

Where,

Xs / ( 192 + 0.8Xs ) =

Xs = (8 f / Rx) x 10-7 * Ks =

0.061

3.500

[ /m]

2.83E-05

3.93E-03

88.1

XLPE(Direct Burial)Page2

f : System Frequency

50

Ks : Constant for Conductor

3) Proximity Effect Factor

p =

[ Xp4/(198+0.8Xp4) ] * (d1/S)2 * { 0.312*(d1/s)2 + 1.18 / [ Xp4/(192+0.8Xp4) + 0.27 ] }

=

Where,

0.024

Xp= (8 f / Rx) x 10-7 x Kp

3.5

d1 : Conductor Diameter (mm)

30.3

Kp : Constant

S : Axial Distance of Conductors (mm)

91

4) AC Resistance at Maximum Conductor Temperature

R = Rx (1 + s + p) =

3.89E-05

[ /m]

2.2 Metallic Layer Resistance

1) Metallic Shield (Copper Wires) Resistance at Operating Temperature

Rsc =

=

Where,

[/m]

[(1+Zk) * {1 + s (Tmax-20)}] / [{58*( /4) * {Cwd2 * Nw * s}]

1.39E-04

s : Temperature Coefficient

Tmax : Assumed Metallic Shield Temperature [

3.93E-03

85

Zk : Stranding effect factor

0.05

Cwd : Diameter of Metallic Shield [mm]

1.70

72

Nw : Number of Metallic Shield

s : Conductivity of metallic shield

2) Metallic Sheath (Lead Alloy) Resistance at Operating Temperature

RsL =

=

Where,

[40*s {1 + s (Tmax-20)}] / [ * {ds22-ds12}]*10-3

5.13E-04

s : Temperature Coefficient

Tmax : Assumed Metallic Shield Temperature [

[ /m]

0.004

85

ds2 : Outer diameter of the metallic sheath [mm]

78.20

ds1 : Outer diameter of the metallic sheath [mm]

73.80

21.4

s : Conductivity of metallic shield

XLPE(Direct Burial)Page3

3) Equivalent Resistance of Metallic Layer at Operating Temp.

/m]

1.09E-04

=

Where,

(Rsc * RsL) / (Rsc + RsL)

Rs =

Rsc : Resistance of metallic shield at Operating temp.

RsL : Resistance of metallic sheath at Operating temp.

1.39E-04

5.13E-04

2.3 Capacitance and Dielectric Loss

1) Capacitance

C = / {18 Ln (d2 / d3)} * 10-9

=

Where,

[F/m]

2.08E-10

: Relative Permittivity of Insulation

2.5

d2 : External Diameter of Insulation [mm]

65.6

d3 : Diameter of Conductor Screen

33.6

[mm]

2) Dielectric Loss per Unit Length in each phase

Wd =

* C * Uo * Tan

2

=

Where,

[W/m]

0.377

Uo : Phase-to-earth Voltage [V]

76000

Tan : Power Factor

0.001

f : System Frequency

50

2.4 Metallic Layer Loss Factor

s = +

1

0.173

: Loss Factor in Metallic Shield

: Loss Factor in Metallic Sheath

1

0.116

0.057

1) Loss Factor in Metallic Shield ( 1)

Circulating Current Loss Factor

11

0.03

Eddy Current Loss Factor

XLPE(Direct Burial)Page4

= ( Rsc/R ) * {gs* o*(1 +

12

+) + [(1 * ts) /(12*10

4

)]}

0.086

gs = 1 + (ts/Ds)1.74 * (

Where,

12

* Ds * 10

-3

[ (4* * )/ (107* s) ]1/2

1.012

- 1.6) =

=

135.05

s : Electric Resistivity of Metallic Shield at Operating Temperature

2.16E-08

Ds : External Diameter of Metallic Shield [mm]

72.6

ts : Thickness of Metallic Shield [mm]

1.70

Cables are installed in Trefoil Formation

o = 3 * [ m / (1 + m ) ] * ( ds / 2S )

2

0.022

(1.14m2.45 + 0.33) * ( ds / 2S )(0.92m+1.66) =

0.062

m = ( /Rsc)*10-7 =

0.226

Rsc : Resistance of Metallic Shield at Operating Temperature [ /m]

1.39E-04

ds : Mean Diameter of Metallic Shield [mm]

70.9

91

S : Distance between Conductor Axes [mm]

Loss Factor for Metallic Shield

= +

1

11

12

0.116

2) Loss Factor in Metallic Sheath ( 2)

Circulating Current Loss Factor

21

0.03

Eddy Current Loss Factor

22

= ( RsL/R ) * {gs* o*(1 +

=

Where,

+) + [(1 * ts) /(12*10

4

12

)]}

0.027

gs = 1 + (ts/Ds)1.74 * (

* Ds * 10

1

-3

- 1.6) =

1.003

XLPE(Direct Burial)Page5

[ (4* * )/ (107* s) ]1/2

38.26

s : Electric Resistivity of Metallic Sheath at Operating Temperature

2.70E-07

Ds : External Diameter of Metallic Sheath [mm]

78.2

ts : Thickness of Metallic Sheath [mm]

2.2

Cables are installed in Trefoil Formation

o = 3 * [ m / (1 + m ) ] * ( ds / 2S )

2

(1.14m2.45 + 0.33) * ( ds / 2S )(0.92m+1.66) =

0.002

0.074

m = ( /RsL)*10-7 =

0.061

RsL : Resistance of Metallic Sheath at Operating Temperature [ /m]

5.13E-04

ds : Mean Diameter of Metallic Sheath [mm]

76.0

91

S : Distance between Conductor Axes [mm]

Loss Factor for Metallic Sheath

= +

2

21

22

0.057

3) Loss Factor in Armouring

a =

Therefore, Total Metallic Layer Loss Factor

= s + a

0.173

2.5 Thermal Resistance

1) Thermal Resistance between Conductor and Metallic Shield [K.m/W]

T1 =

( t1 / 2 ) * Ln [ 1 + (2 t1 / dc ) ] =

: Thermal Resistivity of Insulation [K.m/W]

0.46

3.5

dc : Diameter of Conductor [mm]

30.3

t1 : Thickness of Insulation [mm]

19.5

XLPE(Direct Burial)Page6

2) Thermal Resistance of Outer Covering [K.m/W]

T3 = ( t3 / 2 ) * Ln [1 + 2*(ts/d3)] * 1.6 =

0.087

: Thermal Resistivity of Covering [K.m/W]

3.5

t3 : Thickness of Covering [mm]

4.0

d3 : Internal Diameter of Covering [mm]

78.2

3) External Thermal Resistance [K.m/W]

T41 =

(1.5/)* t*{LN(2U) - 0.630}

T42 =

( t/2* )*LN((2U)*[(d'p

(1cct)

/dp)(d'p/dp).....

(2cct's)

.... (d'pk/dpk).......(d'pq/dpq)]

=

Where,

2.861

( for 1 circuit )

3.620

( for 2 circuits )

2U = 2(2L/De) =

37.56

L : Buried Depth of Centre of Trefoil Group [mm]

855

De : External Diameter of One Cable [mm]

91

t : Thermal Resistivity of Soil [K.m/W]

2.00

dpk : Distance form Center of p-th Cable to Center of Cable k [mm]

d'pk : Distance form Center of p-th Cable to Center of Reflection

of Cable k in ground-air Surface [mm]

3. Current-carrying Capacity

I ={

- Wd [0.5 T + n (T + T + T )] } / { R [T + n (1 + ) T + n (1 + + ) (T + T )] }

P =

1cct

584

[A]

2cct

525

[A]

(3)1/2 * E * I *10-3

1cct

133.4

[MVA]

2cct

120.0

[MVA]

2cct

#REF!

[MVA]

0.5

XLPE(Direct Burial)Page7

Potrebbero piacerti anche

- Generator Basic SLDDocumento1 paginaGenerator Basic SLDInayat HathiariNessuna valutazione finora

- General Drawing ChecklistDocumento3 pagineGeneral Drawing ChecklistInayat HathiariNessuna valutazione finora

- WSU GENTheory 1PageperSlide 160114 PDFDocumento247 pagineWSU GENTheory 1PageperSlide 160114 PDFhermawanNessuna valutazione finora

- Engineering Drawing Checklist 01Documento3 pagineEngineering Drawing Checklist 01Inayat HathiariNessuna valutazione finora

- Generator Island and Interconnected PDFDocumento1 paginaGenerator Island and Interconnected PDFInayat HathiariNessuna valutazione finora

- Checklist For Single Line DiagramDocumento3 pagineChecklist For Single Line DiagramInayat HathiariNessuna valutazione finora

- Earthing ConceptsDocumento48 pagineEarthing Conceptsajaykcs9112Nessuna valutazione finora

- Theory and Technology of Instrument Transformers: Training Booklet: 2Documento48 pagineTheory and Technology of Instrument Transformers: Training Booklet: 2Xabi AlonsoNessuna valutazione finora

- Generator Field ConnectionDocumento1 paginaGenerator Field ConnectionInayat HathiariNessuna valutazione finora

- Digital SS PaperDocumento10 pagineDigital SS PaperInayat HathiariNessuna valutazione finora

- 317 ValverdeDocumento7 pagine317 ValverdeboopelectraNessuna valutazione finora

- Iso-648 Laboratory Glassware - Single-Volume PipettesDocumento18 pagineIso-648 Laboratory Glassware - Single-Volume PipettesDawn HaneyNessuna valutazione finora

- Generator Field Connection 02Documento1 paginaGenerator Field Connection 02Inayat HathiariNessuna valutazione finora

- Digital SS Solution 01Documento9 pagineDigital SS Solution 01Inayat HathiariNessuna valutazione finora

- Tutorial On Networking For Digital Substations: 2019 Texas A&M Protective Relaying ConferenceDocumento20 pagineTutorial On Networking For Digital Substations: 2019 Texas A&M Protective Relaying ConferenceInayat HathiariNessuna valutazione finora

- FOX515 OverviewDocumento2 pagineFOX515 OverviewInayat HathiariNessuna valutazione finora

- Digital Substation GuideDocumento3 pagineDigital Substation GuideInayat HathiariNessuna valutazione finora

- Caluse of IEC 61840 For Test On MV CableDocumento4 pagineCaluse of IEC 61840 For Test On MV CableInayat Hathiari0% (1)

- ME3011C EngDocumento16 pagineME3011C EngInayat HathiariNessuna valutazione finora

- Installation of Electrical Equipments PDFDocumento123 pagineInstallation of Electrical Equipments PDFInayat HathiariNessuna valutazione finora

- 2013-1 Thu Dufournet مهمDocumento186 pagine2013-1 Thu Dufournet مهمqais652002Nessuna valutazione finora

- Is 302 2 4 1993 PDFDocumento15 pagineIs 302 2 4 1993 PDFInayat HathiariNessuna valutazione finora

- HSR PhilosophyDocumento18 pagineHSR PhilosophyInayat HathiariNessuna valutazione finora

- Digital Substation Deployment AjarbaizanDocumento8 pagineDigital Substation Deployment AjarbaizanInayat HathiariNessuna valutazione finora

- Is 302 2 4 1993 PDFDocumento15 pagineIs 302 2 4 1993 PDFInayat HathiariNessuna valutazione finora

- Is 302 2 6 2009 PDFDocumento25 pagineIs 302 2 6 2009 PDFInayat HathiariNessuna valutazione finora

- Iso-648 Laboratory Glassware - Single-Volume PipettesDocumento18 pagineIso-648 Laboratory Glassware - Single-Volume PipettesDawn HaneyNessuna valutazione finora

- Is 302 2 8 1994 PDFDocumento14 pagineIs 302 2 8 1994 PDFInayat HathiariNessuna valutazione finora

- Is 302 2 6 2009 PDFDocumento25 pagineIs 302 2 6 2009 PDFInayat HathiariNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Presentation On LGDocumento27 paginePresentation On LGrohitsingh964Nessuna valutazione finora

- Transformer:-: Equipment Used To Raise or Lower The Potential Difference of An Alternating Current SupplyDocumento20 pagineTransformer:-: Equipment Used To Raise or Lower The Potential Difference of An Alternating Current SupplynazurahNessuna valutazione finora

- Arduino Basics NCDocumento13 pagineArduino Basics NCMansur CanNessuna valutazione finora

- RIPS C869 Manual Service PDFDocumento791 pagineRIPS C869 Manual Service PDFcatalinni50% (8)

- Casio EDIFICE EQW-T620DC - qw5423 PDFDocumento8 pagineCasio EDIFICE EQW-T620DC - qw5423 PDFAlexander TeplyakovNessuna valutazione finora

- ST Ep DR 86a 1Documento2 pagineST Ep DR 86a 1Sergio Trujillo CerroNessuna valutazione finora

- GX Work 2Documento9 pagineGX Work 2Hanafi HariyantoNessuna valutazione finora

- Innovative LED Streetlight Replacement PDFDocumento50 pagineInnovative LED Streetlight Replacement PDFLiu KennyNessuna valutazione finora

- @achyarnurandi - Simple Configuration TDM Emulation Service On Your Nokia 7705-SAR8 and 7705-SARFDocumento10 pagine@achyarnurandi - Simple Configuration TDM Emulation Service On Your Nokia 7705-SAR8 and 7705-SARFJesus Rosales100% (1)

- Whelen InstallGuide UPS690Documento4 pagineWhelen InstallGuide UPS690Anonymous S9LuwmNessuna valutazione finora

- ProMax 3D 3Ds 3DUserManualDocumento94 pagineProMax 3D 3Ds 3DUserManualNoctua IngenieriaNessuna valutazione finora

- PLC HoneyWellDocumento44 paginePLC HoneyWellJeremy100% (2)

- Sony Hdr-cx550 Xr550 Level-2 Ver-1.0 SMDocumento51 pagineSony Hdr-cx550 Xr550 Level-2 Ver-1.0 SMVoldemarNessuna valutazione finora

- Circuito Integrado TA8207KDocumento11 pagineCircuito Integrado TA8207KIberê CamposNessuna valutazione finora

- Quanta Complete Offer ABA-QME-101-14 REV PDFDocumento10 pagineQuanta Complete Offer ABA-QME-101-14 REV PDFGithu OommenNessuna valutazione finora

- Operating Instructions: KX-T7420 KX-T7425 KX-T7431 KX-T7433 KX-T7436Documento34 pagineOperating Instructions: KX-T7420 KX-T7425 KX-T7431 KX-T7433 KX-T7436Marina BoljanovicNessuna valutazione finora

- Sounder PDFDocumento2 pagineSounder PDFPercy GoitsemangNessuna valutazione finora

- 2000-05 The Computer Paper - Ontario EditionDocumento143 pagine2000-05 The Computer Paper - Ontario Editionthecomputerpaper0% (1)

- 74AC74 - 74ACT74 Dual D-Type Positive Edge-Triggered Flip-FlopDocumento10 pagine74AC74 - 74ACT74 Dual D-Type Positive Edge-Triggered Flip-FlopserviciobsasNessuna valutazione finora

- GV-N98TZL-512H GV-N98TZL-1GH: Sales KitDocumento8 pagineGV-N98TZL-512H GV-N98TZL-1GH: Sales Kitchristophe_GIGABYTENessuna valutazione finora

- Fifth Generation (5G) : by - Shaik Mohammed ShabazDocumento16 pagineFifth Generation (5G) : by - Shaik Mohammed Shabazshabaz AmanNessuna valutazione finora

- Circuit Diagram of Sample and Hold CircuitDocumento6 pagineCircuit Diagram of Sample and Hold Circuitalaa delewarNessuna valutazione finora

- AN1646Documento7 pagineAN1646Duc HuynhNessuna valutazione finora

- E8500 Manual PDFDocumento45 pagineE8500 Manual PDFAnggaraPerbawaPutraNessuna valutazione finora

- TLE-CHS-q3 - Mod7 - Basic-Concepts-of-Electricity - (Part-II) M4Documento16 pagineTLE-CHS-q3 - Mod7 - Basic-Concepts-of-Electricity - (Part-II) M4OmengMagcalas100% (2)

- 12 Ict-X PDFDocumento176 pagine12 Ict-X PDFAditya KumarNessuna valutazione finora

- TM4 MOTIVE Product Brochure WebDocumento4 pagineTM4 MOTIVE Product Brochure WebkasyapreddyNessuna valutazione finora

- GB - T 3733 (B) - 200824° Cone Connectors - Straight Thread, Type BDocumento3 pagineGB - T 3733 (B) - 200824° Cone Connectors - Straight Thread, Type BEr.Amritpal SinghNessuna valutazione finora

- Resistance Start Split Phase Induction MotorDocumento32 pagineResistance Start Split Phase Induction Motorrockingsandy100% (1)