Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Automated Bottle Cap Inspection Using Machine Vision System

Caricato da

Darksky PaulTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Automated Bottle Cap Inspection Using Machine Vision System

Caricato da

Darksky PaulCopyright:

Formati disponibili

July 2015 | IJIRT | Volume 2 Issue 2 | ISSN: 2349-6002

AUTOMATED BOTTLE CAP INSPECTION USING

MACHINE VISION SYSTEM

Pruthvi Kumar S1, Dr H.V Ramakrishna2

1

MTech in Industrial Automation and Robotics, Department of Mechanical Engineering

2

Professor, Department of Mechanical Engineering

Malnad College of Engineering, Hassan 573202, Karnataka

Abstract- The project work describes the design of

automated inspection of bottle cap using machine

vision system and sheds light on the working principle

and the hardware structure of the system. The

inspection of bottle cap is done by using machine

vision system via image processing by taking image of

the bottle cap in production line. The elements of the

system are inspection unit and rejection unit.

Microcontroller is used to control the system and it

drives the mechanical and electronic components.

MATLAB algorithm is used as a programming

language for image processing in inspection process.

IR module is used to sense the presence of bottles on

conveyor. Automatic rejection system is carried out

by an arm connected to the DC motor is incorporated

into the system. This system can replace the existing

conventional sensor based inspection and manual

inspection. The system has an extensive social

practical value thereby increasing the productivity,

improve the quality of inspection, product variety and

profitability.

I.INTRODUCTION

Machine vision system is generally referred to the

system which extracts desired features from digital

images. Captured input images are the main

objective of this system [1]. Application of the

vision system in industries in order to automate

manufacturing process is considered as Automated

visual inspection (AVI) when attempts are made to

inspect, control products and recognize the defects

by using only images of the products [3]. In fact,

human as inspectors are slower and their efficiency

is affected by their state of illness, exhaustion or

other human shortcomings. In some applications

they need sometimes special environments which

are dangerous and not conductive for human

operation [2]. On the other hand, especially in the

manufacturing environment, it is necessary to

improve quality control and productivity.

IJIRT 142462

Inspection is carried out by machine

vision system via image processing technique is

application in beverage and food industries, milk

industries, medicine industries and other chemical

product industries. In this area, accurate filling,

inspection of cap closure, sorting, recycling plastic

bottle, recognition between glass bottle and pet

bottles, inspection for over-fill or under-fill,

verification of label quality and detection of

defected products are inspected automatically.

Industrial vision system is not able to handle all

tasks in every field of application [2]. It means that

each system due to its specific requirements and its

limitations needs particular techniques that should

be taken into account.

The basic components for all bottle visual

inspection as for any other VIS is shown. The first

step in a visual inspection system is the image

acquisition, which is concerned about capturing a

good quality image through a camera. Camera

resolution, its position, colour of background and

speed of the conveyor belt and light has important

effect on image quality.

In this paper, we have shown basic

principle of bottle visual inspection by presenting

different methods and techniques for automation of

bottling and the most recent algorithms have been

stated. In this paper, we have concentrated on

developing a combine algorithm for four quality

inspection in bottle cap: Detection of tamper in side

view, Detection of tamper in top view, Detection of

without cap condition of bottle on conveyor and

different coloured cap of bottle on conveyor. So

developing such algorithm where four most

important parameters of automation of bottling are

combined we get an efficient bottling system.

Besides we have presented a detailed explanation

of image processing of bottle cap detection and

new algorithm combining the four parameters

INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY

131

July 2015 | IJIRT | Volume 2 Issue 2 | ISSN: 2349-6002

through list of figures. LabVIEW, MV Impact,

OpenCV, MATLAB, these softwares will provide

various digital image processing technique used for

obtaining required information from an acquired

image. Based on the extracted image the processor

will take decision i.e. acceptable or not acceptable.

Thus NOT acceptable component will be removed

from the production line using ejection mechanism

such as actuator or blower.

II. PROBLEM STATEMENT

Consider in any bottles seals and caps are used to

protect the product from leakage, spoilage and

tampering. Damaged seals or cap have a direct

impact on company profitability due to waste, it

makes customer rejection and potential liability.

The integrity of these seals and caps is also a signal

to the consumer about products safety and quality.

Producers must find reliable and cost effective

means of detecting these defects and weeding them

out before they get into the supply chain.

Conventional sensor based inspection methods

have proven to be expensive and difficult to setup

the system and change. In fact, human inspectors

are slower and their efficiency is affected by their

states of tiredness, illness or human short comings,

some cases they dont have proper skills and in

some toxic and hazardous cases human inspectors

are not sufficient. So therefore using of machine

vision system for inspection process is overcomes

this problem. In industrial inspection system to

reduce human efforts and for improves the quality

of inspection machine vision system is being

developed and automate the inspection process.

III.PROPOSED SYSTEM

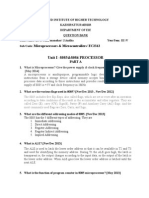

Fig1: BLOCK DIAGRAM OF THE SYSTEM

The bottles pass on one end to another end of

conveyor belt. When bottle comes under the

sensing range of IR sensor, bottles are sensed by

sensor. The camera then captures the image of the

IJIRT 142462

bottle cap continuously and sends them to

computer for processing. After image processing

the computer display the result of the cap image

weather the cap is original or defected. According

to the image processing result rejection system take

action on the defected bottle cap if there is defected

bottle cap present on conveyor it rejects from

conveyor. The inspection and rejection system are

controlled by microcontroller and motors are

interfaced with microcontroller through driver

circuit. IR sensor used to sense presence of bottle

on conveyor and send signal to microcontroller to

control the motors speed. The process is then

repeated again for every cycle.

A. Working Principle of the whole System

The system inspects different types of defected

bottle cap via image processing technique using

MATLAB algorithm. The defected cap of different

types of defection can be effectively detected by

image processing technique and rejection takes

place from rejection system. There are two units

are implemented for this system.

I.

Inspection unit

II.

Rejection unit

a) Inspection unit

In

inspection

unit

it

consists

of

microcontroller, IR module, Web cam, driver

circuit and conveyor. When bottles comes under

the sensing range IR module sense the presence of

bottles on conveyor and sends signal to the

microcontroller. Microcontroller actuates and sends

signal to the stepper motor via driver circuit and

controls the stepper motor speed finally conveyor

will stop. When conveyor stops web cam capture

the image of the bottle in required size and send it

to computer for processing. Image processing is

carried out in computer and computer display the

result of bottles. There are five different cases are

inspected in inspection unit

1. Original bottle image with no defect.

2. Bottle cap defected in side view.

3. Bottle cap defected in top view.

4. Bottle present but without cap condition.

5. Bottle present but with different color of

cap.

B) Rejection unit

An arm which is connected toDc motor and the DC

motor is directly interfaced with microcontroller

via driver circuit and this setup is used for rejection

system. If the defected bottles are comes on

conveyor the microcontroller sends signal to DC

motor, dc motor actuates and start rotating, the arm

INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY

132

July 2015 | IJIRT | Volume 2 Issue 2 | ISSN: 2349-6002

connected to the DC motor is hit the defected bottle

and kick it out from conveyor. This DC motor

operates between 12v DC power supply and which

is interfaced with microcontroller.

B. Flow Diagram of the System

Fig3: Matrix Value of the Captured

image shown in MATLAB

Edge detection

Edge detection is the fundamental step in

image processing, image analysis, and

image pattern recognition and computer

vision technique. There are many methods

of edge detection but most of them are

grouped into two categories search based

and zero crossing based. Edge detection

algorithm is applied for input image to

detect the edges of the bottle. This shows

the skeleton of the captured image hence

the defected portion can easily find in

edge detection. Here the using of K-means

algorithm to find the bottle cap from

original captured image to find weather

the cap is tampered or not.

Fig2: Diagram for detect the defected cap

IV SYSTEM SOFTWARE DESCRIPTION

We use MATLAB 14 for system software

development. Image acquisition toolbox is used to

capture the images from the webcam vision camera

interfaced [6, 7] with the PC. The image processing

toolbox is used to develop the algorithm to inspect

the bottle cap [1,2]. The instrumentation control i.e.

ATmega32 microcontroller is used to read the IR

sensor signals and controls all driver circuits. The

simple MATLAB algorithm is applied for image

processing of bottle cap and the image processing

steps are explained as follow. Steps involved in

image processing of bottle cap inspection:

Step 1: Processing on image:

Separating R,G,B matrix

Find the size of the matrix

Find the pixel of red color in each matrix

for tamper detection

IJIRT 142462

Fig4: Edge detection in sampling process

Step 2: Image clustering index takes place by

means of k-means algorithm.

Solidification: Clustering is a process of grouping

of similar data, objects and images in correct order.

In clustering the solidification process takes place

by means of only black and white color filled to the

image. White color is filled to the cap portion and

black color filled to background of image for

processing. In solidification filling of black and

white color shows defected portion clearly. This

image has binary numbers of zeros and ones are

clearly shows the defected portion easily. Zeros are

shows the defected portion and ones are show the

remaining cap portion.

INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY

133

July 2015 | IJIRT | Volume 2 Issue 2 | ISSN: 2349-6002

Step5: Display image information in final output of

image processing it display the image information

of the defected captured image by calculating the

area of the captured image and compare with the

original image area. If calculated area is less than

predefined value of the original image then the cap

is considered as defected. If the area of the captured

image is equal or greater than the predefined value

of original image then it will considered the

product is pass.

Fig5: Solidification in clustering index

Step3: After solidification it displays the segmented

caps in colors by overlapping the original color to

the particular cap portion of the clustered image.

The original color shows and compares the

defected region of captured image matrix values

and binary value. After the image is indexed, only

the indexed original image is displayed on screen.

In below picture shows the defected region clearly

by overlapping with original color of the image.

Fig8: Display output information with region

properties

V COMPARISON BETWEEN EXISTING WORK

& PROPOSED WORK

Existing work

My work

Title: PLC Based level

detection technique

Title: Micro controller based

bottle filling inspection System

Very high cost due to PLC

Less cost due to Controller

Complex algorithm

Easy idea(using RGB matrix)

Fig6: Overlapping with original color of bottle

cap

It supposed to check level of

bottle

It supposed to inspect the level

and if bottle is partial filled or

empty it will further go to refill.

Step4: In region properties detection it will

calculate the area of the defected cap and compares

with predefined value original cap length, width

and diameter. Finally the area and threshold value

of the detected cap is compared with region

properties of original cap.

It is not for Quality Control

It is inspection system for Quality

Control

Fig7: Image segmentation in processing

IJIRT 142462

VI COMPONENTS FOR MACHINE VISION

SYSTEM

A typical machine vision system will consists of

most of the following components

One or more digital or analogue cameras with

suitable optics for acquiring images, such as lenses

to focus the desired field of view onto the image

sensor and suitable, often very specialized, light

sources, Input/output hardware(e.g., digital I/O) or

communication links (e.g., Network connection or

RS-232) to report results. A synchronizing sensor

for product detection (often an optical or magnetic

sensor) for image acquisition and processing,

controlling devices like microcontrollers or PLC

INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY

134

July 2015 | IJIRT | Volume 2 Issue 2 | ISSN: 2349-6002

controller, motors for moving conveyor to

transports products from one end to another and

some form of actuators to sort, route or reject

defective part or products from production line, a

program to process images and detects relevant

features.

VII RESULTS

Fig13: Display the output of different colored

cap

VIII CONCLUSION

Fig9: Display of output with no defect

Fig10: Display of output with defected cap

The above work presents an automated

inspection of bottle cap using machine vision

system, which has the capability to inspect bottle

cap in different views and detect defects. This is

achieved by using image processing technique. The

present work provides a great deal of applications

in the field of low cost automation by using

microcontroller based vision system, especially in

inspection process where there is a need for

improve quality of inspection. The programming to

this system developed is flexible, quickly and easy

to understand. Even there is no need for the

operator to change the program even if different

types of defects, this reducing the time required to

change the program. This will increase the total

quality control and eliminate human inspector

effort. This concept can be used in food industries,

beverage industries, milk industries, medicine

industries, mineral water and chemical product

industries etc.

REFERENCES

Fig11: Display the output of Defected bottle

Fig12: Display the output of without cap bottle

IJIRT 142462

[1] Mario Campos, Manuel Ferreira, Teresa

Martins, Inspection of bottle crates in the Beer

Industry through Computer Vision, IEEE

International Journal, 2010.

[2] Domingo Mery and Olaya Medina, Automated

visual inspection of glass bottles using adapted

median filtering, IEEE International Journal,

2010.

[3] S. Sathiyamoothy, Industrial application of

machine vision, IJRET Volume-03, Eissn: 23191163, May, 2014.

[4] Golnabi H, Industrial machine vision system

and automated visual inspection in food, chemical

and bottling industries, Pg. 85-88, 2009.

[5] Juan Martnez Alajarin, Jose Luis-Delgado,

Luis M. Tom Balibrea, Automatic System for

Quality-Based Classication of Marble Textures,

INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY

135

July 2015 | IJIRT | Volume 2 Issue 2 | ISSN: 2349-6002

IEEE Transactions on Systems, Man, and

CyberneticsPart C: Applications and Reviews,

Vol. 35, No. 4, November 2010.

[6] Bolhouse V, Fundamentals of Machine

vision, version 3, May 2009.

[7] Elias Malamas, Euripides Petrakis, Michalis

Zervakis, A Survey on Industrial Vision Systems,

Applications and Tools, HIPER (BE97-5084)

under program Bright Euram of the European

Union (EU). 2009.

[8] Vinith Dave, S. K. Hadia, Automatic Bottle

Filling

Inspection

System

Using

Image

Processing, Vol. 4, Page 2319-7064, April-2013.

[9] Slim Abdelhedi, Khaled Taouil, Bassem

Hadjkacem, Design of Automatic Vision-based

Inspection System for Monitoring in an Olive Oil

Bottling Line, International Journal of Computer

Applications (0975 8887), Volume 51 No.21,

August 2012.

[10] Leila Yazdi, Anton Satria Prabuwono, Ehsan

Golkar, Feature Extraction for Fill Level and Cap

Inspection

in

Bottling

Machine,

IEEE

International Journal, International Conference on

Pattern Analysis and Intelligent Robotics, 2011.

[11] Miguel Carrasco, Luis Pizarro, Domingo

Mery, Visual inspection of glass bottlenecks by

multiple-view analysis, International Journal of

Computer Integrated Manufacturing, Vol. 23, No.

10, Pg. 925-941, oct-2010.

[12] Riza Sulaiman and Anton Prabuwono,

Intelligent Visual Inspection of Bottling

Production line Through Neural Network, Vol. 68,

No. 4, Feb-2008.

[13] Tadhg Brosnan, and Da-Wen Sun, Improving

Quality Inspection of Food products by Computer

Vision, Journal of food Engineering, Vol. 4, Pg.

61, May 2004.

[14] Dr. Vilas Sadegaonkar and Kiran Wagh,

Quality Inspection and Grading of mangoes by

Computer

Vision

and

image

Analysis,

International journal of Engineering Research and

Application, Vol. 5, ISSN: 2248-9622, Oct-2013.

[15] J Latha and N Devarajan, In-Process Vision

Inspection Systems for Sorting using Image

Processing Techniques , Journal of Computer

Science, No. 8, Pg. 528-532, 2012.

IJIRT 142462

INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY

136

Potrebbero piacerti anche

- Basic Electronic SurveillanceDocumento43 pagineBasic Electronic SurveillanceMike BaillieNessuna valutazione finora

- Design and Performance of Automatic Vending Machine Using VHDLDocumento9 pagineDesign and Performance of Automatic Vending Machine Using VHDLIJCERT PUBLICATIONSNessuna valutazione finora

- Face Recognisation TechnologyDocumento31 pagineFace Recognisation Technologysk100vermaNessuna valutazione finora

- Documentation-Fake News DetectionDocumento57 pagineDocumentation-Fake News Detection18IT030 Manoj GNessuna valutazione finora

- CS8091 Big Data Analytics MCQDocumento22 pagineCS8091 Big Data Analytics MCQSowmiya mohan100% (2)

- Clustering Methods For Big Data Analytics Techniques, Toolboxes and ApplicationsDocumento192 pagineClustering Methods For Big Data Analytics Techniques, Toolboxes and Applicationseda cevikNessuna valutazione finora

- Automated Bottle Cap Inspection Using MaDocumento6 pagineAutomated Bottle Cap Inspection Using MaThong NguyenNessuna valutazione finora

- Pyspark MaterialDocumento16 paginePyspark MaterialgokulNessuna valutazione finora

- Devikarani V S (4ub16ei016) SeminarDocumento30 pagineDevikarani V S (4ub16ei016) SeminarNagaveniNessuna valutazione finora

- E-Voting System Using Blockchain CorrctedDocumento33 pagineE-Voting System Using Blockchain CorrctedManu0% (1)

- Face Recognition Using PythonDocumento37 pagineFace Recognition Using Pythonrajat maheshwari100% (1)

- Fingerprint Verification System Seminar ReportDocumento32 pagineFingerprint Verification System Seminar ReportKedar Patil100% (1)

- Face Recognition and DetectionDocumento38 pagineFace Recognition and Detectionchaithra580Nessuna valutazione finora

- Pill Camera 17MCA56: AbstractDocumento31 paginePill Camera 17MCA56: AbstractTulsi KavyaNessuna valutazione finora

- Face Detection and Recognition in Indoor Environment Using Color Modeling, Haar Features and Local Binary PatternsDocumento59 pagineFace Detection and Recognition in Indoor Environment Using Color Modeling, Haar Features and Local Binary PatternsHan Hang Yong100% (3)

- Bronchoscopy Brochure 72dpiDocumento10 pagineBronchoscopy Brochure 72dpiKrista TranNessuna valutazione finora

- Hand Gesture Recognition For Sign Language Recognition: A ReviewDocumento6 pagineHand Gesture Recognition For Sign Language Recognition: A ReviewIJSTENessuna valutazione finora

- FRAS Final Report CSE 299Documento55 pagineFRAS Final Report CSE 299Suraj Kumar DasNessuna valutazione finora

- Biometrics Seminar ReportDocumento30 pagineBiometrics Seminar ReportAyushNessuna valutazione finora

- Photo Morphing Detection REPORTDocumento63 paginePhoto Morphing Detection REPORTPriyanka DargadNessuna valutazione finora

- Live Human Being Detection Using Robot Using DTMF TechnologyDocumento93 pagineLive Human Being Detection Using Robot Using DTMF TechnologySpandana Invincible100% (2)

- File 4Documento60 pagineFile 4AVADHESH CHAMOLANessuna valutazione finora

- Major Project ReportDocumento22 pagineMajor Project ReportRohini VhatkarNessuna valutazione finora

- IoT Based Biometric Voting SystemDocumento12 pagineIoT Based Biometric Voting SystemNgezeNessuna valutazione finora

- Realtime Visual Recognition in Deep Convolutional Neural NetworksDocumento13 pagineRealtime Visual Recognition in Deep Convolutional Neural NetworksICRDET 2019Nessuna valutazione finora

- Examination Staff Allotment SystemDocumento2 pagineExamination Staff Allotment SystemDHARUN SMARTNessuna valutazione finora

- Industrial Training On Iot Smart Parking SystemDocumento15 pagineIndustrial Training On Iot Smart Parking SystemAbhinav PanseNessuna valutazione finora

- Fingerprint Identification For Advanced Monitoring SystemDocumento13 pagineFingerprint Identification For Advanced Monitoring SystemAnupam KashyapNessuna valutazione finora

- PW4 Plant Leaf Disease DetectionDocumento27 paginePW4 Plant Leaf Disease DetectionTARA TARANNUMNessuna valutazione finora

- Facial Recognition and Face Mask Detection Using Machine LearningDocumento65 pagineFacial Recognition and Face Mask Detection Using Machine Learningqwerty123Nessuna valutazione finora

- Shortest Path Algorithm Seminar ReportDocumento23 pagineShortest Path Algorithm Seminar ReportVishakh ShewalkarNessuna valutazione finora

- Fruit OldDocumento37 pagineFruit OldAswin KrishnanNessuna valutazione finora

- Face Detection by Using OpenCVDocumento4 pagineFace Detection by Using OpenCVvickey rajputNessuna valutazione finora

- Animatronics SeminarDocumento32 pagineAnimatronics SeminarThockanattu Varkey Mathew86% (14)

- Electronic Voating MachineDocumento10 pagineElectronic Voating MachinerishabhNessuna valutazione finora

- 6 2D Platformer Report PDFDocumento68 pagine6 2D Platformer Report PDFassNessuna valutazione finora

- Traffic Signal Annunciator Alerts DriversDocumento32 pagineTraffic Signal Annunciator Alerts DriversJayesh KolheNessuna valutazione finora

- Automated Attendance System Using Face RecognitionDocumento33 pagineAutomated Attendance System Using Face RecognitionTejaswini ReddyNessuna valutazione finora

- Live Human Being Detection Wireless Remote Controlled RobotDocumento59 pagineLive Human Being Detection Wireless Remote Controlled RobotAnand Cool90% (10)

- Seminar ReportDocumento23 pagineSeminar ReportPrithviraj GhoseNessuna valutazione finora

- Sameer - Face Recognition Using PythonDocumento37 pagineSameer - Face Recognition Using Pythonrajat maheshwariNessuna valutazione finora

- Advanced Voting Machine Using Face RecognitionDocumento25 pagineAdvanced Voting Machine Using Face Recognitionritu OfficialNessuna valutazione finora

- Lung Cancer Detection Using Digital Image Processing On CT Scan ImagesDocumento7 pagineLung Cancer Detection Using Digital Image Processing On CT Scan ImagesShaka TechnologiesNessuna valutazione finora

- Machine Vision Overview and IntroductionDocumento48 pagineMachine Vision Overview and IntroductionburthoNessuna valutazione finora

- Wavelet Transform ASSIGNMENTDocumento2 pagineWavelet Transform ASSIGNMENTNaila NaseerNessuna valutazione finora

- 02111850087002-Master ThesisDocumento81 pagine02111850087002-Master ThesisSalman Khan LohaniNessuna valutazione finora

- Advancement in Patient Monitoring SystemDocumento23 pagineAdvancement in Patient Monitoring SystemNawaz Sherif NNessuna valutazione finora

- Biometric Voting Machine: Presented By:-Kalpit Vaya BRANCH:-E.C.EDocumento15 pagineBiometric Voting Machine: Presented By:-Kalpit Vaya BRANCH:-E.C.EKalpit VayaNessuna valutazione finora

- Face Recognition Using PCADocumento30 pagineFace Recognition Using PCAamit15094775100% (6)

- Votinng System Presented By:: Miss - Kamble Ankita LaxmanDocumento15 pagineVotinng System Presented By:: Miss - Kamble Ankita LaxmanAnkita KambleNessuna valutazione finora

- Face Recognition Based Attendance Management SystemDocumento5 pagineFace Recognition Based Attendance Management SystemIJRASETPublicationsNessuna valutazione finora

- Blue Brain Technology: Creating a Virtual Human BrainDocumento17 pagineBlue Brain Technology: Creating a Virtual Human BrainpoojavathiNessuna valutazione finora

- Fake Currency Tester and Counter Project ReportDocumento44 pagineFake Currency Tester and Counter Project ReportGagan Maggo100% (2)

- Raytracing ManualDocumento52 pagineRaytracing ManualBer Salazar JrNessuna valutazione finora

- Main Project (Batch - 9)Documento57 pagineMain Project (Batch - 9)RamNessuna valutazione finora

- Smart Irrigation System Using IoT Report 2016 PDFDocumento45 pagineSmart Irrigation System Using IoT Report 2016 PDFpavan puppalaNessuna valutazione finora

- NI Vision: NI 17xx Smart Camera User ManualDocumento90 pagineNI Vision: NI 17xx Smart Camera User ManualDushyant GuptaNessuna valutazione finora

- Project - Farmers BuddyDocumento34 pagineProject - Farmers BuddyGunjit MakhijaNessuna valutazione finora

- Final Year Project Phase 1 ReportDocumento25 pagineFinal Year Project Phase 1 ReportAman SharmaNessuna valutazione finora

- PCB Drilling MachineDocumento15 paginePCB Drilling MachinelalitlakshyNessuna valutazione finora

- Biometrics PPT FinalDocumento19 pagineBiometrics PPT FinalRama SudhaNessuna valutazione finora

- Automated Algorithmic Trading System Project ReportDocumento81 pagineAutomated Algorithmic Trading System Project ReportATHARVA KNessuna valutazione finora

- Project Report On "Android Sudoku Game": Gogte Institute of TechnologyDocumento28 pagineProject Report On "Android Sudoku Game": Gogte Institute of TechnologyRAVI KHOTNessuna valutazione finora

- The Detection System For Pharmaceutical Bottle-Packaging Constructed by Machine Vision TechnologyDocumento3 pagineThe Detection System For Pharmaceutical Bottle-Packaging Constructed by Machine Vision TechnologyMekaTronNessuna valutazione finora

- University College of Technology & Innovation: Ee001-3-1-Analysis of CircuitsDocumento3 pagineUniversity College of Technology & Innovation: Ee001-3-1-Analysis of CircuitsDarksky PaulNessuna valutazione finora

- Model Predictive Control of Vapor Compression Cycle For Large Transient Heat Flux CoolingDocumento6 pagineModel Predictive Control of Vapor Compression Cycle For Large Transient Heat Flux CoolingDarksky PaulNessuna valutazione finora

- EE00131ACLab 2Documento7 pagineEE00131ACLab 2Darksky PaulNessuna valutazione finora

- Iyengar 2010Documento11 pagineIyengar 2010Darksky PaulNessuna valutazione finora

- Automated Defect Detection of Steel Surface Using Neural Network Classifier With Co-Occurrence Features 2014Documento8 pagineAutomated Defect Detection of Steel Surface Using Neural Network Classifier With Co-Occurrence Features 2014Darksky PaulNessuna valutazione finora

- Microprocessor Question BankDocumento36 pagineMicroprocessor Question BankDarksky PaulNessuna valutazione finora

- UC1F1207ENGDocumento1 paginaUC1F1207ENGDarksky PaulNessuna valutazione finora

- Lab Report 2: Decoders and EncodersDocumento1 paginaLab Report 2: Decoders and EncodersDarksky PaulNessuna valutazione finora

- DFT, LTI Systems, FIR and IIR Filter DesignDocumento4 pagineDFT, LTI Systems, FIR and IIR Filter DesignDarksky PaulNessuna valutazione finora

- University College of Technology & Innovation: Ee001-3-1-Analysis of CircuitsDocumento6 pagineUniversity College of Technology & Innovation: Ee001-3-1-Analysis of CircuitsDarksky PaulNessuna valutazione finora

- Comparative Analysis of Vehicle Suspension System in Matlab-Simulink and Msc-Adams With The Help of Quarter Car ModelDocumento8 pagineComparative Analysis of Vehicle Suspension System in Matlab-Simulink and Msc-Adams With The Help of Quarter Car ModelHemanth KrishnaNessuna valutazione finora

- EE008 3.5 3 MSES (Digital Clock)Documento1 paginaEE008 3.5 3 MSES (Digital Clock)Darksky PaulNessuna valutazione finora

- Ijrras 5 1 02Documento11 pagineIjrras 5 1 02Darksky PaulNessuna valutazione finora

- Tutorial Motor Basics Lecture PDFDocumento23 pagineTutorial Motor Basics Lecture PDFBenjaminas OrlovasNessuna valutazione finora

- Assignment of MDDocumento35 pagineAssignment of MDDarksky Paul100% (1)

- AN698Documento10 pagineAN698Darksky PaulNessuna valutazione finora

- Tutorial Motor Basics Lecture PDFDocumento23 pagineTutorial Motor Basics Lecture PDFBenjaminas OrlovasNessuna valutazione finora

- Block1 ResultsDocumento12 pagineBlock1 ResultsDarksky PaulNessuna valutazione finora

- 6 Product Cycle2Documento16 pagine6 Product Cycle2Darksky PaulNessuna valutazione finora

- 14 Fea2Documento18 pagine14 Fea2Darksky PaulNessuna valutazione finora

- Fluid Mechanics Surface Flow IntroductionDocumento13 pagineFluid Mechanics Surface Flow IntroductionDarksky PaulNessuna valutazione finora

- Electrical Measurement - Signal Processing - and DisplaysDocumento11 pagineElectrical Measurement - Signal Processing - and DisplaysDarksky PaulNessuna valutazione finora

- 1 Overview2Documento13 pagine1 Overview2Darksky PaulNessuna valutazione finora

- Cylinder FinalDocumento2 pagineCylinder FinalDarksky PaulNessuna valutazione finora

- CGPADocumento1 paginaCGPADarksky PaulNessuna valutazione finora

- CylinderDocumento1 paginaCylinderDarksky PaulNessuna valutazione finora

- CNC IntroDocumento1 paginaCNC IntroDarksky PaulNessuna valutazione finora

- Assignment Question Paper (Cover)Documento1 paginaAssignment Question Paper (Cover)Darksky PaulNessuna valutazione finora

- Handwritten Character Recognition Based On Structural CharacteristicsDocumento4 pagineHandwritten Character Recognition Based On Structural CharacteristicsPradeepNessuna valutazione finora

- Clustering On Boston DatasetDocumento3 pagineClustering On Boston Datasetanubhav582Nessuna valutazione finora

- Development-of-a-machine-learning-model-for-knowledge-acquisition-relationship-extraction-and-discovery-in-domain-ontology-engineering-using-jaccord-relationship-extraction-and-neural-network2019International-Jour.pdfDocumento9 pagineDevelopment-of-a-machine-learning-model-for-knowledge-acquisition-relationship-extraction-and-discovery-in-domain-ontology-engineering-using-jaccord-relationship-extraction-and-neural-network2019International-Jour.pdfanon_576957892Nessuna valutazione finora

- Unsupervised Learning and ClusteringDocumento19 pagineUnsupervised Learning and ClusteringJeff PrattNessuna valutazione finora

- A Novel Approach To Credit Card Fraud Detection ModelDocumento3 pagineA Novel Approach To Credit Card Fraud Detection ModelJournal of ComputingNessuna valutazione finora

- Color Based SegmentationDocumento7 pagineColor Based SegmentationZaib Un Nisa HafeezNessuna valutazione finora

- ANL252 SU5 Jul2022Documento58 pagineANL252 SU5 Jul2022EbadNessuna valutazione finora

- Stock Market Prediction using Machine Learning and Deep LearningDocumento13 pagineStock Market Prediction using Machine Learning and Deep LearningappuNessuna valutazione finora

- Data Science Lab Master RecordDocumento59 pagineData Science Lab Master RecordpriyankaNessuna valutazione finora

- Assignment 5 - Ai MpecDocumento3 pagineAssignment 5 - Ai MpecAkarsh DubeyNessuna valutazione finora

- Assignment 5 1Documento13 pagineAssignment 5 1Unnati ThakkarNessuna valutazione finora

- CobWeb - A Toolbox For Automatic Tomographic Image PDFDocumento29 pagineCobWeb - A Toolbox For Automatic Tomographic Image PDFLea EleuteriNessuna valutazione finora

- Machine Learning: Algorithms TypesDocumento27 pagineMachine Learning: Algorithms TypesRaviprakash TripathyNessuna valutazione finora

- Data Analyst: Analyze Data and Model Phenomena With Realistic Business Cases. Start Your Career in Data Science Now!Documento14 pagineData Analyst: Analyze Data and Model Phenomena With Realistic Business Cases. Start Your Career in Data Science Now!ekkNessuna valutazione finora

- RBFNetworksDocumento32 pagineRBFNetworksFikri Ali NawawiNessuna valutazione finora

- FCM - The Fuzzy C-Means Clustering AlgorithmDocumento13 pagineFCM - The Fuzzy C-Means Clustering Algorithmsuchi87Nessuna valutazione finora

- Recent Advance in Content-Based Image Retrieval: A Literature SurveyDocumento22 pagineRecent Advance in Content-Based Image Retrieval: A Literature SurveyThanh LinhNessuna valutazione finora

- Oral Questions LP IIDocumento21 pagineOral Questions LP IIbigbangNessuna valutazione finora

- Computer Vision Based Turmeric Leaf Disease Detection and Classification A Step To Smart AgricultureDocumento5 pagineComputer Vision Based Turmeric Leaf Disease Detection and Classification A Step To Smart AgricultureAlexander Espinosa ValdezNessuna valutazione finora

- Weather Forecasting and Prediction Using Hybrid C5.0Documento14 pagineWeather Forecasting and Prediction Using Hybrid C5.0Logan Paul100% (1)

- Variable Representation and Cluster Analysis in Descriptive Data MiningDocumento6 pagineVariable Representation and Cluster Analysis in Descriptive Data MiningAngela PonceNessuna valutazione finora

- Machine Learning Fundamentals in 40 CharactersDocumento94 pagineMachine Learning Fundamentals in 40 CharactersKamal BoulefraNessuna valutazione finora

- C++ Armadillo SpecificationsDocumento15 pagineC++ Armadillo SpecificationstrisinoNessuna valutazione finora

- In-Class Short Exercises For Tutorial 7 - GroupingDocumento8 pagineIn-Class Short Exercises For Tutorial 7 - GroupingNancy MoNessuna valutazione finora

- Pa66 ML Exp6Documento9 paginePa66 ML Exp6Pratik ManeNessuna valutazione finora

- Data Mining PortfolioDocumento19 pagineData Mining PortfolioJohnMaynardNessuna valutazione finora