Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Equivalent Head-down Load vs. Movement Relationships Evaluated from Bi-directional Pile Load Tests

Caricato da

Shahab KhaledDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Equivalent Head-down Load vs. Movement Relationships Evaluated from Bi-directional Pile Load Tests

Caricato da

Shahab KhaledCopyright:

Formati disponibili

KSCE Journal of Civil Engineering (2012) 16(7):1170-1177

DOI 10.1007/s12205-012-1700-8

Geotechnical Engineering

www.springer.com/12205

Equivalent Head-down Load vs. Movement Relationships Evaluated from

Bi-directional Pile Load Tests

Sung-Ryul Kim* and Sung-Gyo Chung**

Received September 14, 2011/Accepted February 19, 2012

Abstract

The increasing use of bi-directional (Osterberg cell) load tests in piles necessitates a reliable evaluation of the load-movement

relationship equivalent to the head-down load test. In this study, the existing evaluation methods were reviewed, and a new method

for evaluating the equivalent head-down curve was proposed. This method considers possible situations, such as non-measured axial

load distribution along the pile and the existence of residual load distribution. Three cases, in which bi-directional and head-down

load tests were performed at the same site, were analyzed in order to validate the proposed method. The results of the case studies

showed that the equivalent load-movement curves obtained either without assuming unit shaft resistance distribution or by

considering the effect of residual load agreed well with the measured curves obtained from the head-down test. Therefore, the

proposed method is recommended for practical use.

Keywords: deep foundation, foundation engineering, load test, pile, residual stress

1. Introduction

With the increase in the design load of piled foundations in

recent years, a common head-down load test is sometimes

insufficient to evaluate the bearing capacity of piles. Thus, the bidirectional (Osterberg cell) load test has been increasingly

applied in practice. In this test, a loading device, also known as

the O-cell, is installed at the pile toe. The toe resistance

provides the reaction force to mobilize the shaft resistance and

vice versa. The toe and shaft resistances can then be evaluated

separately, even without strain gauge measurements. The O-cell

test separates the toe and shaft resistances mobilizing them in

opposite directions, whereas the head-down test combines them

in the same direction. Piles for axial load are designed to function

similarly to a head-down test, and the design load is determined

after combining shaft and toe resistances, thus, a method to construct an equivalent head-down load-movement curve is needed.

Osterberg (1998) proposed a method of constructing the equivalent curve, based on an assumption of the pile being a rigid

body. An improved method was proposed by Loadtest (2001),

Kwon et al. (2005) and Lee and Park (2008), who all considered

a pile elastic compression. Unlike such simple approaches, Kim

and Mission (2011) and Xi et al. (2010) performed analysis using

load transfer function for shaft and toe resistances. However,

because their methods were developed based on an assumed unit

shaft resistance, or ignoring the effect of residual load, the appli-

cations may be limited in practice.

The purpose of this study, therefore, is to propose a method to

enable a more practical construction of the equivalent curve. To

achieve this, the existing methods are reviewed, and a new

method is proposed to construct the reliable equivalent curve for

piles under the following conditions: (1) non-measured axial

load distribution along the pile, and (2) the existence of residual

load. In addition, three case studies are analyzed to validate the

proposed method, including two cases involving long drilled

shafts and one case, in which a long concrete pile was driven into

a thick deltaic deposit. The equivalent curves obtained from the

proposed method are compared with those of existing methods

and with the measured load-movement curve from a head-down

test.

2. Existing Methods of Constructing Equivalent

Head-down Load-movement Curve

The following simple methods for constructing the equivalent

curves were reviewed: Osterberg (1998), Loadtest (2001), Kwon

et al. (2005), and Lee and Park (2008).

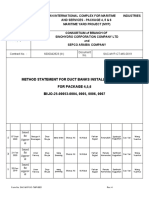

During the O-cell test, three kinds of load-movement curves

are generally obtained as shown in Fig. 1; (1) (toe resistance, Qd)

vs. (downward pile toe movement, D1), (2) (shaft resistance, Qu)

vs. (upward pile toe movement, D2), and (3) (shaft resistance, Qu)

vs. (upward pile head movement, D3).

*Member, Associate Professor, Dept. of Civil Engineering, Dong-A University, Busan 604-714, Korea (Corresponding Author, E-mail: sungryul@dau.

ac.kr)

**Member, Professor, Dept. of Civil Engineering, Dong-A University, Busan 604-714, Korea (E-mail: sgchung@dau.ac.kr)

1170

Equivalent Head-down Load vs. Movement Relationships Evaluated from Bi-directional Pile Load Tests

Loadtest (2001) considered the additional pile compression

induced by the head-down load. Because D2 in the Original

method includes the pile compression by the O-cell load at toe,

toe, the additional pile compression by the different loading

direction between the O-cell and head-down tests should be

expressed as:

= d + head toe

where,

Fig. 1. Load-movement Curves Obtained from the O-cell Tests

Osterberg (1998) proposed a construction method for the

equivalent curve based on the assumption that the pile is a rigid

body. This method is denoted as Original method in this paper.

If the pile is assumed to be rigid, the top and bottom have the

same deflection but different loads. An arbitrary movement is

selected, after which the toe and shaft resistances are determined

as the loads corresponding to the arbitrary movement at (Qd, D1)

and (Qu, D2) curves, respectively. (The sum of the shaft and the

toe resistances) vs. (the arbitrary movement) becomes a single

point at the equivalent load-movement curve. The equivalent head

down curve is obtained by repeating this process at different

movement points. This method, however, does not satisfy the

real condition because the toe movement D2 includes the pile

compression by the O-cell load.

In general, the head-down load at the pile head induces larger

pile compression compared with the equivalent upward load at

the pile toe. For example, Fig. 2 shows the load distributions obtained from the head-down and O-cell tests. The pile compression is proportional to the area of the load distribution curves,

that is, area ABCE for the head-down test and area FGH for the

O-cell test. Therefore, at the head-down test, the pile compression consists of d and head induced by Qd and Qu, respectively

(Fig. 2a), whereas it consists only of toe induced by the Qu at the

O-cell test (Fig. 2b).

d: Pile compression induced by equivalent head-down

load of Qd

head: Pile compression induced by equivalent head-down

load of Qu

toe: Pile compression induced by upward toe load of Qu

The equivalent curve was obtained by adding to the corresponding movements in the curve obtained from Original method.

In this method, the magnitudes of head, toe, and d were calculated using Eqs. (2), (3), and (4), respectively. Various shapes

of the unit shaft resistance can be taken into account with the

centroid factor C.

QuL

head = ( 1 C ) -------EA

(2)

Qu L

toe = C --------EA

(3)

Qd L

d = --------EA

(4)

where, C: Centroid factor = (the distance to the centroid from the

bottom of the unit shaft resistance)/(overall length

of unit shaft resistance): C=1/3 for a linear distribution of unit shaft resistance; C=1/2 for a constant

distribution

E: Youngs modulus of pile

A: Sectional area of pile

L: Pile penetration length

Kwon et al. (2005) and Lee and Park (2008) modified the

Original method to obtain the equivalent curve of a true rigid

pile. They evaluated the equivalent head-down load Qu using

(Qu, D3) curve instead of the (Qu, D2) curve in Fig. 1 because D3

does not include the pile compression. The pile compression of

(head+d) was then added to the corresponding movements in

the curve of the true rigid pile. The head was calculated using

either Eq. (5) based on measured pile compressions (Kwon et al.,

2005) or Eq. (2) based on theoretical pile compressions (Lee and

Park, 2008). Eqs. (2) and (5) use an assumed unit shaft resistance

distribution, theoretically producing the same results.

head = ( D2 D3 )

Fig. 2. Load Distributions and Pile Compressions Developed from

the Head-down and O-cell Tests: (a) Head-down Test, (b)

O-cell Test

Vol. 16, No. 7 / November 2012

(1)

(5)

where, =1: For a constant unit shaft resistance with depth

=2: For a linear increase of unit shaft resistance with

depth

1171

Sung-Ryul Kim and Sung-Gyo Chung

3. Development of a Construction Method

The previous construction methods were only based on an assumed distribution of unit shaft resistance, or possibly, on a measured distribution using strain gauge instrumentation.

By improving the existing methods, a new construction method

is proposed, which determines a pile compression without assuming the unit shaft resistance distribution. In addition, the residual

load, which may exist in piles because of the rearrangement or

consolidation in the surrounding soil prior to the pile load test, is

considered in the proposed method for the evaluation of the pile

compression. Basically, the proposed method constructs the equivalent curve by applying the same procedure in Kwons method

(2005). However, the proposed method accurately evaluates head

in two possible cases: (1) when residual load can be ignored and

(2) when residual load is significant. The practical evaluations of

these two cases are presented below.

3.1 When Residual Load is Non-significant

3.1.1 When Axial Load Distribution is Unknown

Although an axial load distribution along a pile is unknown,

the pile compression head can be evaluated using the measured

pile compression during O-cell tests.

Theoretically, the sum of toe and head should be (QuL)/(EA)

under the following conditions: (1) the residual load can be ignored

along the pile, (2) the side shear is identical regardless of the

loading direction (i.e., bottom-up or head-down loads), and (3)

the EA is constant along the pile length from pile top to bottom.

Because toe is equal to the measured pile compression at an

O-cell test of (D2 D3), head is thus evaluated using Eq. (6). If

the measured pile compression is accurate, Eq. (6) theoretically

gives an accurate head value without the measurement of pile

compression.

head

Qu L

QuL

= -------- toe = -------- ( D2 D3 )

EA

EA

(Gregersen et al., 1973; Altae et al., 1993), and for bored piles in

sand (Baker et al., 1993). Likewise, Fellenius (2004) argued that

the residual load can be mobilized irrespective of the types of

piles and soils. Therefore, if the residual load is not considered,

the estimated resistance distribution may be different from the

actual (true) distribution. Although this error does not affect the

measured pile capacity, it may affect the designers interpretation

and subsequent use of the shaft resistance distribution.

The effect of the residual load on pile compression is shown in

Fig. 4. It is assumed that the residual load indicated by area EFG

in Fig. 4(a) exists in the pile prior to a load test. The area EFH in

Fig. 4(b) indicates the test resistance, which is mobilized by the

O-cell load, assuming zero pile strain. The true shaft resistance is

the sum of the residual load and the test resistance (Fig. 4c).

Because the pile compression that results from the residual

load has an identical effect on both the O-cell and the head-down

load test, head decreases and is then calculated using Eq. (8).

Qu L area EHI area EFG

-------------------------------------------------head = --------

EA

area EFHI

(6)

(8)

where the notations E, F, G, H, and I are shown in Fig. 4(c).

3.1.2 When Axial Load Distribution is Known

If the axial load distribution is measured during a load test, the

pile compression head can be calculated directly from the load

distribution curve shown in Fig. 3 using Eq. (7). Calculating loaddistributed areas based on the maximum applied load at the final

loading step is convenient. This procedure should provide a more

accurate estimate of the pile compression based on a measured

load distribution.

Qu L area ACD

---------------------------head = --------EA area ABCD

Fig. 3. Combined Shaft Load Distribution of the O-cell and Headdown Tests

If the false load distribution in Fig. 4(b) is used without the

residual load, head is proportional to the area EHI in Fig. 4(b)

(7)

where the notations A, B, C and D are shown in Fig. 3.

3.2 When Residual Load is Significant

In general, large residual load develops due to the negative

skin friction in soft ground. Several researchers have observed

that the residual load may also develop for driven piles in sand

Fig. 4. True Resistance by the Inclusion of the Residual Loads: (a)

Residual Load, (b) False Resistance, (c) True Resistance

1172

KSCE Journal of Civil Engineering

Equivalent Head-down Load vs. Movement Relationships Evaluated from Bi-directional Pile Load Tests

rather than to the [(area EHI) - (area EFG)] in Fig. 4(c). This

may lead to a significant overestimation of the pile compression.

4. Case Studies

Three cases were analyzed, namely, two drilled shafts and a

driven concrete pile to verify the proposed construction method

of an equivalent curve. The third case involved the monitoring of

the residual load. In these cases, the equivalent curve using the

proposed method was compared with the measured curve

obtained from the head-down load tests, which were performed

at the same site.

4.1 Case 1: Drilled Shaft in Busan, Korea

The O-cell and head-down load tests were performed separately for two drilled shafts on the same site as shown in Fig. 5.

The pile diameter was 1.5 m, the penetration depth was 33.5 m,

and the pile toe was embedded about 5 m into the weathered

rock. The axial load distribution was measured using strain

gauge pairs at 12 levels. The load test was performed one month

after the concrete placement, the period of which would be

insufficient to mobilize the residual load. The detailed results are

described in the paper of Kwon et al. (2005).

Fig. 6 shows the load movement curve of the O-cell test. The

maximum applied load was about 19 MN, which induced a large

downward toe movement of 214 mm.

Pile compressions have a large influence on an equivalent

curve. Thus, the pile compression toe was evaluated using three

methods, after which the results were compared in Fig. 7. The

methods were as follows: (1) the conversion of strain into pile

compression using 12 levels of strain gauge measurements; (2)

LVDT measurement using the telltale reading; and, (3) theoretical

calculation assuming linear unit shaft resistance distribution. The

Strain gauge measurement curve increased proportionally with

the increase in applied load, whereas the LVDT measurement

curve increased rapidly about 3.6 mm at about 16 MN. This abrupt

Fig. 5. Schematic Drawing of the Test Piles and Definition of

Movement and Pile Compression

Vol. 16, No. 7 / November 2012

Fig. 6. Load-movement Curve in the O-cell Test (The buoyant

weight of pile was 1.36 MN)

Fig. 7. Comparison of Pile Compressions, toe

increase in toe movement may have occurred due to measurement error, because pile damages were not detected from strain

gauge results. Therefore, the strain gauge measurement gave a

more reliable estimation of pile compression. In addition, the pile

compression of strain gauge measurement became identical with

that of the theoretical calculation at the final loading step. Thus,

the assumption of the linear increase of unit shaft resistance is

reasonable.

The equivalent load-movement curves obtained using the proposed method were compared with that of the head-down load

test (Fig. 8).

The curve, denoted as Unknown distribution, was obtained

assuming that the axial load distribution was unknown, and by

inputting the measured movements of D2 and D3 into Eq. (6) in

the evaluation of the pile compression head. The curve, denoted

as Known distribution, was obtained by applying the area ratio

of (area ACD)/(area ABCD) as 2/3 in Eq. (7), based on the linear

increase of unit shaft resistance confirmed in Fig. 7. Given with

C=1/3 in Eq. (2), the predicted curve from the Loadtest method

(2001) becomes identical with the Known distribution curve of

the proposed method.

In Fig. 8, the movements of the proposed method are a little

1173

Sung-Ryul Kim and Sung-Gyo Chung

Fig. 8. Comparison of Equivalent Load-movement Curves

larger than that of the measured curve. The larger movement of

the equivalent curve can be attributed to the large toe downward

movement D1 at the O-cell test because of the poor filling of

concrete near the pile toe as reported by Kwon et al. (2005).

The comparison showed that the equivalent curve by the proposed method predicted a similar trend with the measured curve,

and the method can be applied successfully to the case with an

unknown axial load distribution.

4.2 Case 2: Multiple O-cell Test for a Drilled Shaft in the

Singapore MRT Project

The head-down and the O-cell pile load tests were performed

separately for two drilled shafts at Singapore MRT (Mass Rapid

Transit) project. The soil layer, as shown in Fig. 9, consisted of a

silty clay layer, a clayey silt layer, and a very stiff silty clay layer

below 37 m, which comprised the bearing stratum of the test

piles. The diameter of the test piles was 1.2 m, and the multi-level

O-cells were installed at depths of 26.9 m and 36.9 m, respec-

Fig. 9. Schematic Drawing of Test Piles and Definition of Movement and Pile Compression

tively. The load test was performed 20 days after the concrete

placement, thus the effect of the residual load was insignificant.

The detailed description about the test is reported in the paper of

Lee and Park (2008).

The O-cell test was performed in two stages. In the first

stage, the bottom O-cell (36.9 m deep) was expanded, and the

toe resistance Qd was measured. In the second stage, the middle

O-cell (26.9 m deep) was expanded to measure the Lower Side

Shear (LSS) and the Upper Side Shear (USS) under zero toe

resistance by the toe opening of the bottom O-cell. Therefore,

the total resistance can be represented by the sum [Qd+LSS

+USS].

If the equivalent load of [Qd+LSS+USS] is applied on the pile

head, the following pile compressions would occur along the pile

(Fig. 9); (1) d-EB = the pile compression by Qd, (2) head-LSS = the

pile compression along lower side by LSS, (3) d-LSS = the pile

compression along the upper side by the reaction of LSS, and (4)

head-USS = the pile compression along the upper side by USS.

Each pile compression was evaluated by adopting Eqs. (4) and

(6) as follows:

Qd L

d EB = -------EA

(9)

( LSS )L

d LSS = -------------------1

EA

(10)

head-LSS = pile compression along lower side during 2nd step (11)

= (D4 D1)

( USS )L

head USS = --------------------1 ( D5 D3 )

EA

(12)

where the notations D1, D3, D4, and D5 are defined in Fig. 9

L1: Pile length of upper side

LSS: Shaft resistance along lower side at (LSS, D1) curve

of second step

Qd: Toe resistance at (Qd, D1) curve of the first step

USS: Shaft resistance along upper side at (USS, D3) curve

of second step

Figure 10 shows the measured load-movement curves of the

O-cell test. At the first stage, the maximum downward toe movement occurred at about 60 mm, which was enough to mobilize

the toe resistance. At the second stage, the middle O-cell expansion induced the upward movement of about 80 mm and the

downward movement of 10 mm. The LSS at the 10 mm movement did not reach the maximum value. The LSS was assumed

to be constant after the maximum test load.

Figure 11 shows the comparison between the equivalent curve

using the proposed method and the measured curve using the

head-down load test. The comparison showed that the equivalent

curve using the proposed method showed good agreement with

the measured curve.

This case study shows that the proposed method can properly

evaluate the equivalent head-down curve without assuming unit

shaft resistance distribution. Moreover, the proposed method can

1174

KSCE Journal of Civil Engineering

Equivalent Head-down Load vs. Movement Relationships Evaluated from Bi-directional Pile Load Tests

Fig. 12. Soil Profile and the Strain-gage Instrumented Pile

Fig. 10. Multi-level O-cell Test Results: (a) Stage 1, (b) Stage 2 (Data

courtesy of Hyundai Engineering & Construction company)

Fig. 11. Comparison of Equivalent Load-movement Curves

especially be applied to the multi-level O-cell tests.

4.3 Case 3: Combined Load Tests for the Driven PHC Pile

in Busan, Korea

A long PHC pile, with a 600 mm diameter, was driven 56 m

deep into the deltaic area (Fig. 12). The soil profile consisted of a

fill layer, sand, and clay layers. The fill of 5 m thickness was placed

on the original ground surface in the mid-1990s. The piezometer

Vol. 16, No. 7 / November 2012

measurements indicated that excess pore pressure of about

20~30 kPa existed in the middle of soft clay layer at the time of

the pile installation. Therefore, residual load by the negative skin

friction was expected to develop along the pile during the dissipation of the excess pore pressure.

The test pile was a hollow cylindrical precast concrete pile,

known as a PHC pile, with a 600 mm outer diameter and an 85

mm thickness. The pile was instrumented with pairs of vibrating

wire strain gauges placed diametrically opposite at twelve levels.

The strain gauges were attached to a rebar cage, which was

inserted into the void of the pile after the driving. The bottom end

of the cage was connected to an O-cell with a 400 mm diameter.

Finally, the central void was filled with cement grout over its full

length above the O-cell.

The mobilization of the residual load was monitored for seven

months after the pile installation. A combination of the head-down

and O-cell tests was chosen because the soil resistance of the test

pile was estimated to exceed the compressive strength of the pile

concrete.

As a first step, the O-cell test was performed until the downward

movement of the pile toe reached 90 mm (Fig. 13b). However,

no head upward movement D3 occurred during the O-cell test,

because the O-cell load was not enough to fully mobilize the

shaft resistance. The head down test followed, and the ultimate

shaft resistance under the zero toe resistance, which resulted

from the toe opening, was confirmed (Fig. 14). The detailed test

results and the methods of converting strains to loads are also

given by Fellenius et al. (2009) and Kim et al. (2011).

In Fig. 13, two cyclic load-movement curves at the pile toe

obtained from the O-cell test are shown. The first cyclic loading

was applied to separate the O-cell from the pile toe, while the

second one was for the main analysis. Fig. 14 shows the curves

of (the head down load) vs. (the pile toe and head movements).

The pile toe movement was insignificant until the 4,200 kN, i.e.,

the pile compression occurred without the pile penetration.

Figure 15 shows the measured residual load and the load-dis-

1175

Sung-Ryul Kim and Sung-Gyo Chung

Fig. 15. Residual Load and Load Distribution at the Maximum Ocell Load

Fig. 13. Load-movement Curves Obtained from the O-cell Test

(The buoyancy weight of the pile was 230 kN): (a) Upward

Movement, (b) Downward Movement

Fig. 16. Comparison of the Equivalent and Measured Curves

the residual load before the head-down test (area EFJ) was used

for this analysis.

Figure 16 shows the comparison between the equivalent curve

and the directly measured curve from the head-down test. The

equivalent curve, which considered the residual load, agreed

well with the measured curve, whereas the equivalent curve that

ignored the residual load significantly overestimated the pile

movement.

5. Conclusions

Fig. 14. Load-movement Curves Obtained from the Head-down

Test

tribution of the maximum applied load in the O-cell test. The

shape of unit shaft resistance was not obtained by the O-cell test.

Thus, an attempt was made with the assumption that the unit

shaft resistance increased linearly with depth. That is, Eq. (8)

with the ratio (area EHI)/(area EFHI) equal to 2/3, was applied,

which is also proved with the area ratio of 0.65 calculated using

the load distribution measured by the head-down test. In addition,

A new method was proposed to construct the equivalent headdown load movement curve on the bi-directional load tests. The

proposed method was verified by comparing the equivalent

curve from the bi-directional load tests and the measured curve

from the head-down load tests. The following conclusions are

drawn from the study.

1. The proposed construction method evaluates the pile compression of the equivalent curves in two ways: (1) using the measured pile compression at a bi-directional load test without

1176

KSCE Journal of Civil Engineering

Equivalent Head-down Load vs. Movement Relationships Evaluated from Bi-directional Pile Load Tests

assuming the unit shaft resistance distribution, and (2) by considering the effect of residual load.

2. The residual load was negligible in the first and second case

studies, in which the load tests were performed within a month

after pile installation. A comparison between the equivalent

curve obtained using the proposed method and the measured

curve obtained from the head-down load tests showed that the

proposed method properly constructed the equivalent curve

using the measured compression in the O-cell tests, and that it

can be successfully applied to a multi level O-cell test.

3. In the case of a long PHC pile driven into the thick deposit, in

which a long term measurement of pile strains was performed,

the estimated equivalent load-movement curve obtained considering the effect of residual load agreed well with the measured curve from the head-down test.

Notations

The following symbols were used in this paper:

A: Sectional area of the pile

C: (distance to the centroid from the bottom of the unit

shaft resistance)/(overall length of unit shaft resistance)

D1: Downward pile toe movement at the O-cell tests

D2: Upward pile toe movement at the O-cell tests

D3: Upward pile head movement at the O-cell tests

E: Youngs modulus of pile

L: Pile penetration length

L1: Pile length of upper side

LSS: Shaft resistance along lower side below the O-cell

Qd: Downward load at pile toe which initiates toe resistance

Qu: Upward net load at pile toe which arouses shaft resistance

USS: Shaft resistance along upper side above the O-cell

: Coefficient, which was used to evaluate the pile compression by the Qu at the pile head in Kwon et al.s

method

: Additional pile compression by the different loading

direction between the O-cell and head-down tests

d: Pile compression induced by equivalent head-down

load of Qd

d-EB: Pile compression induced by Qd at the multi-level Ocell tests

d-LSS: Pile compression along upper side by the reaction of

LSS at the multi-level O-cell tests

head: Pile compression induced by equivalent head-down

load of Qu

head-LSS: Pile compression along lower side by LSS at the multilevel O-cell tests

head-USS: Pile compression along upper side by USS at the

Vol. 16, No. 7 / November 2012

multi-level O-cell tests

toe: Pile compression induced by upward toe load of Qu

Acknowledgements

This work was supported by the Korea Science and Engineering Foundation (KOSEF) NRL Program grant funded by the

Korea government (MEST) (No. R0A-2008-000-20076-0), and by

Basic Science Research Program through the National Research

Foundation of Korea (NRF) funded by the Ministry of Education,

Science and Technology (No. 2009-0067319).

References

Altaee, A., Evgin, E., and Fellenius, B. H. (1993). Load transfer for

piles in sand and the critical depth. Can. Geotech. J., Vol. 30, No. 3,

pp. 455-463.

Baker, C. N., Park, G., Braid, J. L., Drumright, E. E., and Mensah, F.

(1993). Drilled shafts for bridge foundations, Rep. No. FHWA RD

92 004, FHWA, Wa.

Fellenius, B. H. (2004). Unified design of piled foundations with

emphasis on settlement analysis. Proc., ASCE Geotechnical

Special Publication No. 125, Current Practices and Future Trends

in Deep Foundations, ASCE, Va., pp. 253-275.

Fellenius, B. H., Kim, S. R., and Chung, S. G. (2009). Long-term

monitoring of strain in instrumented piles. Journal of Geotechnical

and Geoenviromental Engineering, Vol. 135, No. 11, pp. 1583-1595.

Gregersen, O. S., Aas, G., and DiBiagio, E. (1973). Load tests on

friction piles in loose sand. Proc. 8th Int. Conf. Soil Mech. and

Found. Engrg, ICSMFE, pp. 109-117.

Kim, S. R., Chung, S. G., and Fellenius, B. H. (2011). Distribution of

residual load and true shaft resistance for a driven instrumented test

pile. Can. Geotech. J., Vol. 48, No. 4, pp. 583-598.

Kim, H. J. and Mission, J. L. (2011). Improved evaluation of equivalent top-down load-displacement curve from a bottom-up pile load

test. Journal of Geotechnical and Geoenviromental Engineering, Vol. 137, No. 6, pp. 568-578.

Kwon, O. S., Choi, Y. K., Kwon, O. K., and Kim, M. M. (2005).

Comparison of the bidirectional load test with the top-down load

test. Transportation Research Record. 1936, Transportation

Research Board, Washington, D.C., pp. 108-116.

Lee, J. S. and Park, Y. H. (2008). Equivalent pile load-head settlement

curve using a bi-directional pile load test. Computers and Geotechnics, Vol. 35, No. 2, pp. 124-133.

Loadtest (2001). Construction of the equivalent top-loaded loadsettlement curve from the results of an O-cell test, Loadtest

Appendix to Reports.

Osterberg, J. O. (1998). The Osterberg load test method for drilled

shafts and driven piles-The First ten years. Proceedings 7th

International Conference on Deep Foundations, Vienna, Austria,

June 15-17, Deep Foundation Institute, Englewood Cliffs, N.J.

Xi, X., Chen, L., and Liu, W. (2010). An analytical solution to

transform O-cell pile test data into conventional load-settlement

curve. GeoShanghai 2010 International Conference, Geotechnical

Special Publication No. 205, pp. 192-199.

1177

Potrebbero piacerti anche

- Finite Element Modeling of Mat FoundationsDocumento7 pagineFinite Element Modeling of Mat FoundationsAhmed Al-Amri100% (1)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDa EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNessuna valutazione finora

- 10.1049 - Ip-C - 19820046 Foundation Uplift ResistanceDocumento11 pagine10.1049 - Ip-C - 19820046 Foundation Uplift ResistanceJitendraNessuna valutazione finora

- 2-Days Course Santa Cruz Per PDFDocumento440 pagine2-Days Course Santa Cruz Per PDFAmilcar Reynaldo Vargas RamosNessuna valutazione finora

- 180 Toe Resistance From CPT AnalysisDocumento8 pagine180 Toe Resistance From CPT AnalysisRifky NetriadyNessuna valutazione finora

- Mayne Et Al - CPT 95 US ReportDocumento16 pagineMayne Et Al - CPT 95 US ReportgalermmNessuna valutazione finora

- Subsurface Flow To Drains H.P Ritzama PDFDocumento20 pagineSubsurface Flow To Drains H.P Ritzama PDFLeonardo Faúndez GNessuna valutazione finora

- 4) Webinar Content - DR - KMK-03.05.2020Documento90 pagine4) Webinar Content - DR - KMK-03.05.2020Amith Unnimadhavan UNessuna valutazione finora

- Foundation Design and Construction in Hong KongDocumento20 pagineFoundation Design and Construction in Hong KongXet Fat100% (1)

- Topic 4 Prof. Hadi KhabbazDocumento54 pagineTopic 4 Prof. Hadi KhabbazCEG BangladeshNessuna valutazione finora

- YJACK - MS 20170211 - BD For BP600mm WL2827kN TL5654kN (Yjackpiletest@Gmail - Com)Documento55 pagineYJACK - MS 20170211 - BD For BP600mm WL2827kN TL5654kN (Yjackpiletest@Gmail - Com)KS Lee100% (1)

- Dr. Anil Joseph PDFDocumento104 pagineDr. Anil Joseph PDFmaran2326Nessuna valutazione finora

- Under Reamed Piles ComparisonDocumento15 pagineUnder Reamed Piles ComparisonMaheswara VarmaNessuna valutazione finora

- CE3115 Slope Part 1 Jan 2018Documento106 pagineCE3115 Slope Part 1 Jan 2018jess100% (1)

- Special Considerations and Challenges in Seismic Design of Tall BuildingsDocumento55 pagineSpecial Considerations and Challenges in Seismic Design of Tall Buildingsf430_boyNessuna valutazione finora

- Permanent Seismically Induced Displacement of Rock-Founded Structures Computed by The Newmark ProgramDocumento204 paginePermanent Seismically Induced Displacement of Rock-Founded Structures Computed by The Newmark Programnenad lazicNessuna valutazione finora

- Laboratory & Field Techniques: CPT TestingDocumento19 pagineLaboratory & Field Techniques: CPT TestingBobNessuna valutazione finora

- Osterberg Test As An Alternative Pile Testing MethodDocumento6 pagineOsterberg Test As An Alternative Pile Testing MethodBinSayeedNessuna valutazione finora

- A Correlation For Permanent Earthquake-Induced DeformationDocumento12 pagineA Correlation For Permanent Earthquake-Induced DeformationhnavastNessuna valutazione finora

- Bauer - MS For PDA at Commercial Tower On Plot W-8 C37-1, AUH - Rev 1 - 01-08-2017 PDFDocumento11 pagineBauer - MS For PDA at Commercial Tower On Plot W-8 C37-1, AUH - Rev 1 - 01-08-2017 PDFJack DoverNessuna valutazione finora

- Slope Stability Analysis Report PDFDocumento7 pagineSlope Stability Analysis Report PDFPrakash Singh RawalNessuna valutazione finora

- Development of A New Family of Normalized Modulus Reduction and Materials Dumping Curves Darendeli PhD-2008)Documento25 pagineDevelopment of A New Family of Normalized Modulus Reduction and Materials Dumping Curves Darendeli PhD-2008)omar45Nessuna valutazione finora

- Plaxis Simulation of Static Pile Tests and Determination of Reaction Piles InfluenceDocumento7 paginePlaxis Simulation of Static Pile Tests and Determination of Reaction Piles InfluenceAnonymous 5exSerNessuna valutazione finora

- Behaviour of Single Pile in Sloping Ground Under Static Lateral LoadDocumento4 pagineBehaviour of Single Pile in Sloping Ground Under Static Lateral LoadpkNessuna valutazione finora

- Stone Pitching Underwater Bed ProfileDocumento6 pagineStone Pitching Underwater Bed ProfileMonu Kumar100% (1)

- Topic 8 Dr. KamruzzamanDocumento14 pagineTopic 8 Dr. KamruzzamanCEG BangladeshNessuna valutazione finora

- Ratio of Undrained Shear Stress To Vertical Effective StressDocumento5 pagineRatio of Undrained Shear Stress To Vertical Effective StressCarlos AcostaNessuna valutazione finora

- A Case Study On Underpinning of Pile FoundationDocumento15 pagineA Case Study On Underpinning of Pile Foundationmaran2326Nessuna valutazione finora

- Design Considerations For Offshore Piles PDFDocumento1 paginaDesign Considerations For Offshore Piles PDFarkadjyothiprakashNessuna valutazione finora

- G&P Digest Issue 6Documento8 pagineG&P Digest Issue 6Chua Chim HueeNessuna valutazione finora

- Geotechnical Challenges On Soft GroundDocumento80 pagineGeotechnical Challenges On Soft GroundWan NasrulNessuna valutazione finora

- CIVE1129 - Lecture Notes - Bearing Capacity PDFDocumento14 pagineCIVE1129 - Lecture Notes - Bearing Capacity PDFLee Tin YanNessuna valutazione finora

- Numerical Modelling of Deep Mixed Columns PDFDocumento27 pagineNumerical Modelling of Deep Mixed Columns PDFvickneshj9406Nessuna valutazione finora

- Prediction of The Axial Bearing Capactity of Piles by Five-Cone Penetration Test Based Design MethodsDocumento9 paginePrediction of The Axial Bearing Capactity of Piles by Five-Cone Penetration Test Based Design MethodsFernando SmithNessuna valutazione finora

- CPRF Analysis PDFDocumento8 pagineCPRF Analysis PDFMohd FirojNessuna valutazione finora

- Topic 3 Dr. KamruzzamanDocumento45 pagineTopic 3 Dr. KamruzzamanCEG BangladeshNessuna valutazione finora

- Foundations For Dynamic and Sensitive Equipment: University of Minnesota - Structures Seminar October 30, 2015Documento40 pagineFoundations For Dynamic and Sensitive Equipment: University of Minnesota - Structures Seminar October 30, 2015Dimas RussyNessuna valutazione finora

- EC7-1 Ch. 8 Anchors Amendment 2012 NOM PDFDocumento36 pagineEC7-1 Ch. 8 Anchors Amendment 2012 NOM PDFAnNessuna valutazione finora

- Prof. Wei Ming Gong - Load Cell Test20171108Documento67 pagineProf. Wei Ming Gong - Load Cell Test20171108Rajinda BintangNessuna valutazione finora

- PLAXIS 2023.1 Barcelona Basic ModelDocumento54 paginePLAXIS 2023.1 Barcelona Basic ModelHuy Hiep NguyenNessuna valutazione finora

- Modelling NATM tunnels with PLAXIS 3D Tunnel programDocumento20 pagineModelling NATM tunnels with PLAXIS 3D Tunnel programGEOMAHESHNessuna valutazione finora

- Designing compression piles according to Eurocode 7Documento12 pagineDesigning compression piles according to Eurocode 7Aniket DNessuna valutazione finora

- Cyntech Helical Piles BrochureDocumento4 pagineCyntech Helical Piles Brochurerahmat ilhamNessuna valutazione finora

- Innovation in instrumented test piles using global strain extensometersDocumento6 pagineInnovation in instrumented test piles using global strain extensometersG-SamNessuna valutazione finora

- Pais & Kausel 1988, Approx Stiff SDE (Corrected)Documento15 paginePais & Kausel 1988, Approx Stiff SDE (Corrected)Androutsopoulou MariannaNessuna valutazione finora

- Inclinometer observation sheetDocumento50 pagineInclinometer observation sheetAnshuman SinghNessuna valutazione finora

- Foundation On LayeredDocumento14 pagineFoundation On LayeredPanxo OrdenesNessuna valutazione finora

- Pile Dynamic Test PDFDocumento69 paginePile Dynamic Test PDFYosafat JuwonoNessuna valutazione finora

- Site Response AnalysisDocumento263 pagineSite Response Analysismark_torreonNessuna valutazione finora

- Case Studies in Geotechnical Engineering: Problems and SolutionsDocumento52 pagineCase Studies in Geotechnical Engineering: Problems and Solutionsmaran2326Nessuna valutazione finora

- Modelling Excavations in PLAXISDocumento28 pagineModelling Excavations in PLAXISMong100% (1)

- Draft Guidelines On Geo-Synthetics For Coastal Protection and Port WorksDocumento51 pagineDraft Guidelines On Geo-Synthetics For Coastal Protection and Port WorksGautham GautiNessuna valutazione finora

- Load TestDocumento16 pagineLoad TestMI ChoudharyNessuna valutazione finora

- N66067216 Final Project Plaxis 2DDocumento11 pagineN66067216 Final Project Plaxis 2DBagas AryasetaNessuna valutazione finora

- Evaluation of Shear Resistance of High Strength Concrete Beams Without Web Reinforcement Using AnsysDocumento7 pagineEvaluation of Shear Resistance of High Strength Concrete Beams Without Web Reinforcement Using AnsysHuda JawadNessuna valutazione finora

- Product Handbook Structureal Steel PDFDocumento175 pagineProduct Handbook Structureal Steel PDFRanu JanuarNessuna valutazione finora

- FHWA HI 97 021 Subsurface InvestigationDocumento314 pagineFHWA HI 97 021 Subsurface InvestigationShahab KhaledNessuna valutazione finora

- Pressed PDFDocumento38 paginePressed PDFShahab KhaledNessuna valutazione finora

- Post Tension Ing Manual Index 6thedDocumento8 paginePost Tension Ing Manual Index 6thedGuzalgNessuna valutazione finora

- Benoit Latapie - Foundations For Infrastructure Projects in MENA PDFDocumento29 pagineBenoit Latapie - Foundations For Infrastructure Projects in MENA PDFShahab KhaledNessuna valutazione finora

- Geo 5 User Guide enDocumento1.431 pagineGeo 5 User Guide enShahab KhaledNessuna valutazione finora

- 2D Numerical Simulations of Soil Nail WallsDocumento12 pagine2D Numerical Simulations of Soil Nail WallsShahab KhaledNessuna valutazione finora

- Cold Formed Sheet Piles 2013 PDFDocumento24 pagineCold Formed Sheet Piles 2013 PDFShahab KhaledNessuna valutazione finora

- Trench Stability in Cohesive SoilDocumento6 pagineTrench Stability in Cohesive SoilShahab KhaledNessuna valutazione finora

- Application of bidirectional static loading tests to evaluate deep foundationsDocumento7 pagineApplication of bidirectional static loading tests to evaluate deep foundationshugojameswoodNessuna valutazione finora

- Deep Excavation ExampleDocumento7 pagineDeep Excavation ExampleShahab KhaledNessuna valutazione finora

- P MultipilersDocumento6 pagineP MultipilersShahab KhaledNessuna valutazione finora

- NTU Seminar Actions Wanted Deador Live Euro CodeDocumento48 pagineNTU Seminar Actions Wanted Deador Live Euro CodeShahab KhaledNessuna valutazione finora

- Code of Practice For Railway ProtectionDocumento101 pagineCode of Practice For Railway ProtectionWilliam100% (1)

- Retaining Walls and Geotechnical Design To Eurocode 7Documento92 pagineRetaining Walls and Geotechnical Design To Eurocode 7josif100% (5)

- Seismic Zoning of Eastern ArabiaDocumento9 pagineSeismic Zoning of Eastern Arabiabennorth84Nessuna valutazione finora

- Vertica Loaded Single PileDocumento10 pagineVertica Loaded Single PilebekmenNessuna valutazione finora

- Barrettes Construction in Soft ClayDocumento6 pagineBarrettes Construction in Soft ClayShahab KhaledNessuna valutazione finora

- Bare Conductors PDFDocumento40 pagineBare Conductors PDFGerardo MorenoNessuna valutazione finora

- Top-Down Synthesis of Nanostructured Materials: Mechanical and Thermal Processing MethodsDocumento9 pagineTop-Down Synthesis of Nanostructured Materials: Mechanical and Thermal Processing MethodsGloria HendersonNessuna valutazione finora

- Mechanical Behavior and Elasticity TheoryDocumento25 pagineMechanical Behavior and Elasticity TheoryRosni hasanNessuna valutazione finora

- Hmma 865-03Documento24 pagineHmma 865-03eugenio.gutenbertNessuna valutazione finora

- Grouting MaterialDocumento2 pagineGrouting MaterialAjinkya Uprikar100% (1)

- 3D Printing in Construction ChallengesDocumento7 pagine3D Printing in Construction Challengesابو النمرNessuna valutazione finora

- CIPP DesignDocumento6 pagineCIPP DesignkwesiwellsNessuna valutazione finora

- Thousand Tower & Sendai MTDocumento7 pagineThousand Tower & Sendai MTAnastasia YesicaNessuna valutazione finora

- Alpha Rma 7 Flux GelDocumento2 pagineAlpha Rma 7 Flux GelAdrian NoslacanNessuna valutazione finora

- Practice Set - 2 (B) Young's Modulus: ElasticityDocumento7 paginePractice Set - 2 (B) Young's Modulus: ElasticityWillis ChekovNessuna valutazione finora

- Gi Duct Works WMSDocumento8 pagineGi Duct Works WMSpuwe qiheNessuna valutazione finora

- Coralina Natural: Medición Carga (N) Esfuerzo de Flexión (Mpa)Documento1 paginaCoralina Natural: Medición Carga (N) Esfuerzo de Flexión (Mpa)ENessuna valutazione finora

- Orifice Plate Calculator Pressure Drop CalculationsDocumento4 pagineOrifice Plate Calculator Pressure Drop CalculationsAnderson Pioner100% (1)

- Hyperdesmo - ADY-E: One-Component, Semi-Glossy, Aliphatic, Elastic Polyurethane Top CoatDocumento3 pagineHyperdesmo - ADY-E: One-Component, Semi-Glossy, Aliphatic, Elastic Polyurethane Top Coatmeena nachiyarNessuna valutazione finora

- Manual of Steel Construction Load & Resistance Factor DesignDocumento14 pagineManual of Steel Construction Load & Resistance Factor DesignJose Luis VazquezNessuna valutazione finora

- Method StatementDocumento31 pagineMethod StatementMuneeb KhanNessuna valutazione finora

- Molykote High Temperature GreasesDocumento1 paginaMolykote High Temperature GreasesProject Sales Corp100% (1)

- Roof Layout: General Notes For BuildersDocumento4 pagineRoof Layout: General Notes For Buildersivanstankovic4Nessuna valutazione finora

- UWP 25418 001 Elevated Water Tank 5000L CR02 PDFDocumento1 paginaUWP 25418 001 Elevated Water Tank 5000L CR02 PDFer.praveenraj30Nessuna valutazione finora

- BARRIERTA GTE 403 EN enDocumento2 pagineBARRIERTA GTE 403 EN enSiska JozefNessuna valutazione finora

- Herramientas KenalmetalDocumento10 pagineHerramientas KenalmetalGeovanny SanjuanNessuna valutazione finora

- HOSHIZAKI KM1200 SWE All Models PDFDocumento141 pagineHOSHIZAKI KM1200 SWE All Models PDFjorge castilloNessuna valutazione finora

- Solute Transport and Heat Transfer in Single-Phase Flow in Porous Medium With Generative/Destructive Chemical Reaction and Variable Viscosity ImpactsDocumento10 pagineSolute Transport and Heat Transfer in Single-Phase Flow in Porous Medium With Generative/Destructive Chemical Reaction and Variable Viscosity ImpactsAnonymous 5sBa2pNessuna valutazione finora

- Field Leak Testing of Polyethylene (PE) and Crosslinked Polyethylene (PEX) Pressure Piping Systems Using Hydrostatic PressureDocumento5 pagineField Leak Testing of Polyethylene (PE) and Crosslinked Polyethylene (PEX) Pressure Piping Systems Using Hydrostatic Pressureabdelkader benabdallah100% (1)

- 3-0515.090 Rev 27 (515-2536) English Rotor-X Flow Sensor ManualDocumento12 pagine3-0515.090 Rev 27 (515-2536) English Rotor-X Flow Sensor Manualabbas dehghanNessuna valutazione finora

- 2007 Russian Aluminum Alloys For Ultra Deep Water EngDocumento8 pagine2007 Russian Aluminum Alloys For Ultra Deep Water EngHossam Ali RaghebNessuna valutazione finora

- Compact Refrigerator ManualDocumento16 pagineCompact Refrigerator Manualvictor nuñezNessuna valutazione finora

- Analysis of The Filament-Wound Glass Reinforced Rectangular Cross Section Composite Pipes in AnsysDocumento1 paginaAnalysis of The Filament-Wound Glass Reinforced Rectangular Cross Section Composite Pipes in AnsysIJIERT-International Journal of Innovations in Engineering Research and TechnologyNessuna valutazione finora

- Burj Al Arab: Cofferdam & RiggingDocumento12 pagineBurj Al Arab: Cofferdam & RiggingazharahmadnazriNessuna valutazione finora

- Fire and Smoke Fire - and - Smoke - Tight - Sliding - Doorstight Sliding Doors Mutli Purpose Doors 86038 enDocumento32 pagineFire and Smoke Fire - and - Smoke - Tight - Sliding - Doorstight Sliding Doors Mutli Purpose Doors 86038 enAna GainaNessuna valutazione finora

- Can't Hurt Me by David Goggins - Book Summary: Master Your Mind and Defy the OddsDa EverandCan't Hurt Me by David Goggins - Book Summary: Master Your Mind and Defy the OddsValutazione: 4.5 su 5 stelle4.5/5 (381)

- Summary of Bad Therapy by Abigail Shrier: Why the Kids Aren't Growing UpDa EverandSummary of Bad Therapy by Abigail Shrier: Why the Kids Aren't Growing UpValutazione: 5 su 5 stelle5/5 (1)

- Summary: Atomic Habits by James Clear: An Easy & Proven Way to Build Good Habits & Break Bad OnesDa EverandSummary: Atomic Habits by James Clear: An Easy & Proven Way to Build Good Habits & Break Bad OnesValutazione: 5 su 5 stelle5/5 (1631)

- Summary of Atomic Habits by James ClearDa EverandSummary of Atomic Habits by James ClearValutazione: 5 su 5 stelle5/5 (168)

- Summary of Slow Productivity by Cal Newport: The Lost Art of Accomplishment Without BurnoutDa EverandSummary of Slow Productivity by Cal Newport: The Lost Art of Accomplishment Without BurnoutValutazione: 1 su 5 stelle1/5 (1)

- Summary of The Anxious Generation by Jonathan Haidt: How the Great Rewiring of Childhood Is Causing an Epidemic of Mental IllnessDa EverandSummary of The Anxious Generation by Jonathan Haidt: How the Great Rewiring of Childhood Is Causing an Epidemic of Mental IllnessNessuna valutazione finora

- The One Thing: The Surprisingly Simple Truth Behind Extraordinary ResultsDa EverandThe One Thing: The Surprisingly Simple Truth Behind Extraordinary ResultsValutazione: 4.5 su 5 stelle4.5/5 (708)

- The War of Art by Steven Pressfield - Book Summary: Break Through The Blocks And Win Your Inner Creative BattlesDa EverandThe War of Art by Steven Pressfield - Book Summary: Break Through The Blocks And Win Your Inner Creative BattlesValutazione: 4.5 su 5 stelle4.5/5 (273)

- The Body Keeps the Score by Bessel Van der Kolk, M.D. - Book Summary: Brain, Mind, and Body in the Healing of TraumaDa EverandThe Body Keeps the Score by Bessel Van der Kolk, M.D. - Book Summary: Brain, Mind, and Body in the Healing of TraumaValutazione: 4.5 su 5 stelle4.5/5 (266)

- How To Win Friends and Influence People by Dale Carnegie - Book SummaryDa EverandHow To Win Friends and Influence People by Dale Carnegie - Book SummaryValutazione: 5 su 5 stelle5/5 (555)

- The Compound Effect by Darren Hardy - Book Summary: Jumpstart Your Income, Your Life, Your SuccessDa EverandThe Compound Effect by Darren Hardy - Book Summary: Jumpstart Your Income, Your Life, Your SuccessValutazione: 5 su 5 stelle5/5 (456)

- Summary of 12 Rules for Life: An Antidote to ChaosDa EverandSummary of 12 Rules for Life: An Antidote to ChaosValutazione: 4.5 su 5 stelle4.5/5 (294)

- Mindset by Carol S. Dweck - Book Summary: The New Psychology of SuccessDa EverandMindset by Carol S. Dweck - Book Summary: The New Psychology of SuccessValutazione: 4.5 su 5 stelle4.5/5 (327)

- Essentialism by Greg McKeown - Book Summary: The Disciplined Pursuit of LessDa EverandEssentialism by Greg McKeown - Book Summary: The Disciplined Pursuit of LessValutazione: 4.5 su 5 stelle4.5/5 (187)

- Summary of Supercommunicators by Charles Duhigg: How to Unlock the Secret Language of ConnectionDa EverandSummary of Supercommunicators by Charles Duhigg: How to Unlock the Secret Language of ConnectionNessuna valutazione finora

- Make It Stick by Peter C. Brown, Henry L. Roediger III, Mark A. McDaniel - Book Summary: The Science of Successful LearningDa EverandMake It Stick by Peter C. Brown, Henry L. Roediger III, Mark A. McDaniel - Book Summary: The Science of Successful LearningValutazione: 4.5 su 5 stelle4.5/5 (55)

- The Whole-Brain Child by Daniel J. Siegel, M.D., and Tina Payne Bryson, PhD. - Book Summary: 12 Revolutionary Strategies to Nurture Your Child’s Developing MindDa EverandThe Whole-Brain Child by Daniel J. Siegel, M.D., and Tina Payne Bryson, PhD. - Book Summary: 12 Revolutionary Strategies to Nurture Your Child’s Developing MindValutazione: 4.5 su 5 stelle4.5/5 (57)

- Book Summary of The Subtle Art of Not Giving a F*ck by Mark MansonDa EverandBook Summary of The Subtle Art of Not Giving a F*ck by Mark MansonValutazione: 4.5 su 5 stelle4.5/5 (577)

- Designing Your Life by Bill Burnett, Dave Evans - Book Summary: How to Build a Well-Lived, Joyful LifeDa EverandDesigning Your Life by Bill Burnett, Dave Evans - Book Summary: How to Build a Well-Lived, Joyful LifeValutazione: 4.5 su 5 stelle4.5/5 (61)

- Summary of The Galveston Diet by Mary Claire Haver MD: The Doctor-Developed, Patient-Proven Plan to Burn Fat and Tame Your Hormonal SymptomsDa EverandSummary of The Galveston Diet by Mary Claire Haver MD: The Doctor-Developed, Patient-Proven Plan to Burn Fat and Tame Your Hormonal SymptomsNessuna valutazione finora

- SUMMARY: So Good They Can't Ignore You (UNOFFICIAL SUMMARY: Lesson from Cal Newport)Da EverandSUMMARY: So Good They Can't Ignore You (UNOFFICIAL SUMMARY: Lesson from Cal Newport)Valutazione: 4.5 su 5 stelle4.5/5 (14)

- The 5 Second Rule by Mel Robbins - Book Summary: Transform Your Life, Work, and Confidence with Everyday CourageDa EverandThe 5 Second Rule by Mel Robbins - Book Summary: Transform Your Life, Work, and Confidence with Everyday CourageValutazione: 4.5 su 5 stelle4.5/5 (328)

- Summary, Analysis, and Review of Cal Newport's Deep WorkDa EverandSummary, Analysis, and Review of Cal Newport's Deep WorkValutazione: 3.5 su 5 stelle3.5/5 (18)

- Steal Like an Artist by Austin Kleon - Book Summary: 10 Things Nobody Told You About Being CreativeDa EverandSteal Like an Artist by Austin Kleon - Book Summary: 10 Things Nobody Told You About Being CreativeValutazione: 4.5 su 5 stelle4.5/5 (128)

- We Were the Lucky Ones: by Georgia Hunter | Conversation StartersDa EverandWe Were the Lucky Ones: by Georgia Hunter | Conversation StartersNessuna valutazione finora

- Summary of The Hunger Habit by Judson Brewer: Why We Eat When We're Not Hungry and How to StopDa EverandSummary of The Hunger Habit by Judson Brewer: Why We Eat When We're Not Hungry and How to StopNessuna valutazione finora

- Summary, Analysis, and Review of Daniel Kahneman's Thinking, Fast and SlowDa EverandSummary, Analysis, and Review of Daniel Kahneman's Thinking, Fast and SlowValutazione: 3.5 su 5 stelle3.5/5 (2)

- One Hundred Years of Solitude: A Novel by Gabriel Garcia Márquez | Conversation StartersDa EverandOne Hundred Years of Solitude: A Novel by Gabriel Garcia Márquez | Conversation StartersValutazione: 3.5 su 5 stelle3.5/5 (10)