Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SPFA List

Caricato da

carlosTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SPFA List

Caricato da

carlosCopyright:

Formati disponibili

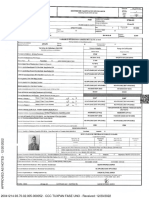

SPFA Certification Assessment Check List

*Denotes 2nd/3rd year audit check points

Major Minor Complie

s

Management Responsibility

Is there a written statement afirming

that the company policy is to direct

1. Policy

all activities in such a manner that

Statements

the fabricated product meets the

quality requirements specified in the

contract documents?

Is there a written statement afirming

that the company will provide shop

detail drawings and instructions which

adequately interpret the owners

designs and specifications and which

are approved by the owner?

Is there a written statement afirming

company policy to manufacture from

approved shop detail drawings and

procedures and ship a finished

product in accordance with contract

documents and specifications?

Is there a written statement afirming

that the company policy is to provide

the inspection and control procedures

to assure that the fabricated product

is in conformance with the contract

documents and specifications?

Does the organization identify all

2. Organization

personnel required to support the

& Personnel Quality Control System?

Observation, Objective

Evidence, or

Comment

The quality policy is

distributed in specific areas

of the plant and all

employees have a badge

with the written policy.

It stipulated in the quality

manual of North American

Pipe Fabricators.

It stipulated in the quality

manual of North American

Pipe Fabricators.

It stipulated in the quality

manual of North American

Pipe Fabricators.

It stipulated in organization

They are described in the

job description

you have trained personnel.

Do job descriptions for management

personnel adequately define their

responsibilities in support of the

Quality Control System?

Are management personnel with

responsibilities afecting Quality,

qualified to discharge the duties of

their position?

Are Supervisors qualified by

experience and/or education?

you have trained personnel.

They are described in the

job description

Do job descriptions for operations

and procurement personnel

adequately define their

responsibilities in support of the

Quality Control System?

Are employees familiar with

their job responsibilities?

It is carried out talks with all

the staf hacerca their

responsibilities.

format

(Specification Check

Is shop supervision conversant with

current workmanship provisions,

including AWS, ASME, AWWA and

customer requirements?

Page

1

List) where requirements

and client code are

described delivered.

June

2012

*Denotes 2nd/3rd year audit check points

Major Minor Complie

s

Does

the

Fabricator

maintain

suficient

data

relating

to

shop

3. Corrective

nonconformances

and

field

Action Process *

problems, to allow management to

evaluate the efectiveness of the

(No Conformance Report)

Is there evidence that management

reviews

data

related

to

shop

nonconformances and field problems

for the purpose of evaluating and

possibly revising the Quality System?

Is there a system used to

identify nonconforming

work

in aprogress?

Is there

written procedure for

controlling further processing and

correcting nonconforming material or

work in process rejected by the quality

control personnel?

Does this system assure that the

level of authority of the individual

dispositioning the nonconforming

condition is commensurate with the

magnitude of the problem?

Does this system manifest the use of

a corrective action approach, to

preclude the future recurrence of

repetitive, nonconforming conditions?

4. Quality

Manual &

Procedures *

Does plant management review

assigned work to determine quality

requirements?

Is there a written procedure for

distribution of special quality

requirements to plant departments?

Does fabricator follow its written

procedure?

Is there a written procedure for

distributing drawings, procedures and

special requirements to the shop

force?

Are distribution procedures followed?

Observation, Objective

Evidence, or

Comment

are performed

NCR Format

of has records.

is performed by system

identification (Tags)

It is being made General

Procedure to cover this

point

It will be established in

nonconforming product

procedure.

it is carried out but will be

written in the procedure.

Internal audits for review

will be established in all

areas

It is performed through the

format (Engineering

Transmital Letter)

*

*

Engineering & Drafting

For the in-house design Engineering

Department, the following questions

1. Design

are to be evaluated.

Are there personnel available, with

knowledge of applicable codes and

specifications, to provide technical

answers to other departments?

Does the fabricator have access,

internally or externally, to a water

pipe design engineer, or engineers,

qualified by experience, licensing, or

registration?

If the procedures are

followed.

the distribution is made

right through the process

(Engineering Transmital

Letter))

---------------------------------------

the company has staf with

the knowledge and training

needed to design pressure

vessels.

yes

*Denotes 2nd/3rd year audit check points

2. Drafting

If there is an organized in-house

Drafting Department, the following

questions are to be evaluated.

Is there an in-house drafting

capability with adequate

supervisory experience and/or

training

in water pipe

Do job descriptions

fordetailing?

drafting/engineering department

personnel define their

responsibilities in support of the

Quality Control System?

Are employees familiar with

their job responsibilities?

Is there adequate drafting personnel

including an experienced Foreman?

*

*

*

Major Minor Complie

s

Observation, Objective

Evidence, or

Comment

the company has staf with

the knowledge and training

needed to water pipe

detailing.

They are defined in the job

description by area

*

staf familiar with the

performance of their

staf

familiar withand

the work.

responsibilities

performance of their

responsibilities

and work.

Not Applicable

If detail drawings are sublet, the

following questions are to be

evaluated.

Are shop details sublet to a qualified

piping- drafting firm, with adequate

experience and/or training specifically in

water

pipe

detailing?

Does the

fabricator

employ a person

Not Applicable

Not Applicable

capable of supervising/evaluating and

coordinating

outside shop detail drawings?

Does this person furnish adequate

instructions to the sublet detailer, which

will assure adequate compliance with the

customers design requirements?

Not Applicable

Does this person have adequate

experience to evaluate the correctness

and completeness of the sublet drawings,

materials and technical information?

Not Applicable

Does the drafting department maintain

a current document control log of

customer- supplied specifications and

design drawings, indicating their

revision status?

Are detail drawings (including revisions)

checked and reviewed by qualified

persons, other than the one responsible

for the drawing activity?

Does the engineering/drafting

department maintain a current log of

shop detail drawings listing the latest and

all previous approval and revision dates?

Not Applicable

Is there a written procedure for

3. Project

receipt, distribution and control of

Management & design drawings, detail drawings,

Procedures

special requirements or

procedures, and revisions thereto?

Not Applicable

Not Applicable

adapt document control

procedure for all types of

products.

Is there a written procedure to assure that

the shop force and quality control have

access to the latest job specification

requirements, including provisions for

control of addendum and revisions?

Is there a written procedure to assure

that all pressure-retaining materials

within a component maintain traceability

to manufacturers test reports, including

components supplied by sub

contractors?

Are there provisions to assure that

4. Library *

Major Minor Complie

s

procedure for all types of

products.

obsolete drawings and documents are

destroyed or isolated from use

throughout the plant? (May be assured

by other departments.)

adapt document control

procedure for all types of

products.

adapt document control

procedure for all types of

products.

Are legible copies of approved drawings, and

procedures for processes such as welding,

testing, examination and inspection, furnished

to quality control and production supervisors?

latest

You do not have hard copy or

specifications subcripcion for

latest

You do edition.

not have hard copy or

specifications subcripcion for

You do not have hard copy or

latest

specifications subcripcion for

3 - AWS

latest

You do not have hard copy or

4 - SSPC

specifications subcripcion for

latest

it has what it takes for pressure

vessels.

5 - ASME

You do not have hard copy or

specifications subcripcion for

6 - NACE

latest

Materials Management

Is all information required by the

customers specification adequately

1. Purchasing * conveyed to a Bill of Materials or

Material Requisition, for use by

Purchasing?

Are Purchasing Documents for material

and services reviewed for conformance

to design drawings and specifications,

and approved before issuing purchase

order?

Are there procedures to assure all phases

of subcontract services are ordered and

furnished to contract requirements?

If an order is accepted on the basis of

requiring SPFA Certification, is subcontract

activity awarded to and accomplished by

an SPFA certified subcontractor?

--------------------------

You do not have hard copy or

specifications subcripcion for

Current reference library, including

addenda and errata, as applicable,

of the following codes and

standards organizations:

1 - AWWA

2 - ASTM

Observation, Objective

Evidence, or

Comment

adapt document

control

the information reaches the

department purchases through recap

which is reviewed by engineering and

where annotation requirements are

made, the requisition and purchase

order is filled with the information

contained in the recap.

They are reviewed by

engineering

adapt procurement process.

make list of certified

suppliers SPFA

Are customer requirements outside of

the governing AWWA standards

communicated to the subcontractor?

Are procurement sources adequately

evaluated or otherwise qualified to

insure their capability of supply?

2. Material

Receipt and

Storage*

*

*

*

*

*

*

Major Minor Complie

s

requisition and purchase

order.

adapt procurement process.

Are all purchased materials and

subcontract service items inspected,

before being placed in stock or

incorporated into the work, to confirm

compliance with the Purchasing

Do material suppliers provide

certificates of conformance to confirm

that the items supplied conform to

the Purchasing Document

requirements?

Are mill test reports or certificates

of compliance reviewed to confirm

compliance with material

specifications?

Raw material blocked off ground and

handled to prevent permanent

distortion?

Is material type, grade and

thickness verified prior to

fabrication?

They are inspected in

accordance with purchase

order and material

specifications.

Yes.

They are reviewed by the

quality control department in

accordance with applicable

stock

determines

specifications

. the type of

Is there adequate and proper storage

for lining materials?

*

*

Are controls set up to ensure

adequate identification on incoming

purchased items?

Are mill test reports or

certificates of compliance kept

on file when material

traceability is required?

Provisions for suitable loading,

blocking, and bracing for shipment?

Are records maintained and procedures

functioning to ensure traceability of grade,

and where required, heat numbers, and

material test reports for special

requirements?

*

4. Shipping*

blocked of ground can be verified

in warehouse area

They are reviewed by the

quality control department in

accordance with applicable

specifications and purchase

order.

area delimited in stock

area delimited in stock

Is there adequate storage for

coating materials?

3. ID &

Traceability

Observation, Objective

Evidence, or

Comment

They specified

in the

A travs de las etiquetas se

identifican con la anotacin de las

especificaciones de materiales.

se mantiene la trazabilidad en

cada corte de material slo para

hacer trmico inicial anotacin.

the certificate with the

annotated heat in the

piece is sought.

They are reviewed before

departure of the load.

Pipe Fabrication

1. Facilities &

Equipment

Does management have a current

inventory of fabrication equipment in

the plant?

Does the fabricator have adequate

rolls?

Does the fabricator have adequate

shears?

Does the fabricator have adequate

brakes?

*

*

*

*

controlled by the

maintenance department.

*Denotes 2nd/3rd year audit check points

2. Welding

*

*

*

*

*

Major Minor Complie

s

If fabricator manufactures straight

run pipe sections, is hydrostatic

equipment available and in use?

Does the fabricator have

adequate end- forming

equipment?

Does the fabricator have a competent

welding technician or supervisor in

house, or outside expert available on

call?

Does this person have the authority

hydrostatic testing area

*

*

to control welding procedures in the

shop?

Are welders certified per AWS, ASME

and/or customer requirements?

*

*

Does the fabricator have written

welding procedures specification

(WPS)?

Are WPS supported by a Procedure

Qualification Record (PQR) ? (not

applicable to WPS' defined as

prequalified by a governing welding

code or standard)

Does the fabricator have written

welding procedures for each

process in use (i.e., SMAW, SAW,

GMAW, manual or

semiautomatic, and automatic)

Are WPS specifications followed in

production and within the designed

parameters (i.e., voltage, amps,

travel speed and filler materials)?

Is a welder identification process

followed in the shop?

Does the fabricator have

automatic or semiautomatic

equipment

for

making

continuous welds?

Is manual welding equipment in

use, in acceptable operating

condition?

Does fabricator have burning

equipment?

Are welding consumables

purchased, stored, and used in

conformance with AWS

requirements?

Is there a maintenance schedule

established for equipment and tools,

3. Maintenance* and a maintenance log kept

showing compliance with the

schedule?

Are welding machines checked at

least annually or when problems

*

occur, to ensure correct amperage

and voltage reading?

Observation, Objective

Evidence, or

Commentand

it has equipment

it has CWI certificate No.

11121581

-------------------------------------there are records for

qualification of welders.

shown in manufacturing

area.

shown in file.

shown in manufacturing

area.

shown in manufacturing

area.

Weld map shown 525

project

Process SAW.

*

*

------------------------------------------------------------------

It is met with proper

storage for each welding

specification.

you have to test and

measurement equipment.

check sheet parameters

voltage and amperage held

every 6 months or when

required shown.

*Denotes 2nd/3rd year audit check points

4. Housekeeping*

Major Minor Complie

s

Is housekeeping adequate?

verified.

Coating & Lining

1. Clean and

Is there pre-blasting or postPaint - In-House

blasting equipment?

Applications

Are there provisions for control of

surface preparation in accordance

*

with applicable standards?

*

*

2. Cement

Coating and

Lining

Observation, Objective

Evidence, or

order andComment

cleaning plant is

--------------------------------------

anchor and cleaning

records are shown.

Is surface preparation checked prior to

lining and coating, when required, and

are records of these checks

maintained?

Are there provisions for agitation,

temperature control and methods of

lining or coating application?

anchor and cleaning

records are shown.

Are there provisions for wet and dry

film paint/epoxy measurements, and

are the results of such checks

recorded?

Are there provisions for

determining if atmospheric

conditions are suitable for

blasting and application of

coatings per manufacturers

Are atmospheric conditions at the

time of blasting/coating recorded

and maintained?

Is the lining/coating checked after

application?

it has equipment to check

environmental conditions

and agitation paint.

it has equipment to verify

dry to wet thickness and

thickness gauge.

it is show technicians sheet

by specified by the

manufacturer and customer

requirements.

records and witness anchor

thicknesses shown.

------------------------------------

records are displayed.

Is there testing equipment in use

(either by the fabricator or his

subcontractor) to test cement mortar

coatings and linings per AWWA C205?

Is there a written procedure being

utilized for cement mortar testing

outlining the necessary steps, duration

of curing, and break procedures as

prescribed by AWWA C205?

Are accurate records of these

tests being maintained?

Subcontracted Coatings and Linings

If the fabricator utilizes the services

of a subcontractor, is the

subcontractor familiar with AWWA

C205?

Does the subcontractor make and

maintain records of testing per the

above requirements for In-House

Coating/Lining operations?

adjust the procedure and

make changes to North

American pipe fabricators.

*

records are displayed.

Not Applicable

Not Applicable

Not Applicable

*Denotes 2nd/3rd year audit check points

Does the fabricator receive and

maintain records of the work

Quality subcontracted?

Control

1. QC

Inspections*

Are Quality Control hold points

established, and is workmanship

checked for conformance, before

further processing of the product

occurs?

Is there a system used to

indicate nonconforming

work

in progress?

Is there

a program for training shop

Major Minor Complie

s

Observation, Objective

Evidence, or

Comment

Not Applicable.

established through the

traveling sheet.

They are established through tags

and NON-Conformance

Format.

---------------------------------

------------------------------------

inspectors, including written minimum

qualification requirements?

*

*

*

Does the organization include a

qualified

Quality Control Supervisor?

Are there qualified shop inspectors?

Only PT and MT

Does the organization include at

least one qualified in-house Mag

Particle, Liquid Dye, Radiographic,

and Ultrasonic Inspection

Technician?

Is a qualified testing service available

and used if required?

Only PT and MT

Is there in-house physical testing

equipment and personnel?

Are contract specifications and

special provisions on file?

Is there an adequate in-process

inspection procedure, including

records of all inspections?

subcontract

Only PT

-----------------------------It is done Through formats.

Does Quality Control have authority

to stop, and responsibility to inform,

operating supervision of

nonconforming work?

Is the nonconformance control

system used in support of quality and

procedural improvement?

It has sufficient authority

and adequate

communication lines.

----------------------------

--------------------------

Does Quality Control monitor

welding in the shop to assure

proper procedures are followed?

Are final checks performed prior to

shipment to insure that all operations

were satisfactorily completed?

They are recorded in the

format of final inspection

*Denotes 2nd/3rd year audit check points

2. Facilities &

Equipment

*

*

*

Do the inspectors have the

following equipment

available?

Tape (all tapes required to do the

inspection)?

Wet and dry film liquid coating

gauges

Tag System to tag nonconforming

Is work

equipment available, when

required, for the following NDT

procedures?

Liquid Penetrant Dye

Magnetic Particle

Ultrasonic

Radiographic

3. Calibration

*

*

Major Minor Complie

s

Is there a procedure for calibration

of quality critical equipment?

Is calibrated equipment

marked with identification &

calibration

Are recordsdate?

of calibration maintained?

Does the verification process include

tapes, squares, levels, and welding

gauges to ensure that they are in

good condition?

Observation, Objective

Evidence, or

Comment

------------------------------

*

*

-------------------------------------------------------------

*

*

*

*

*

*

*

You do not have equipment.

You do not have equipment.

You do not have equipment.

It sets out in the quality

manual ASME.

exhibit 13 and 14 the

quality control manual

ASME

-------------------------------------are verified tapes, levels

and welding gauges house

Potrebbero piacerti anche

- PWHT EC SH 034 - EncryptedDocumento7 paginePWHT EC SH 034 - EncryptedcarlosNessuna valutazione finora

- QEP-SOP-2267 Rev 1 - PMDocumento12 pagineQEP-SOP-2267 Rev 1 - PMcarlosNessuna valutazione finora

- 20041214-93 70 02 005-000052 02 VDR 02 01Documento3 pagine20041214-93 70 02 005-000052 02 VDR 02 01carlosNessuna valutazione finora

- PWHT EC SH 032 - EncryptedDocumento3 paginePWHT EC SH 032 - EncryptedcarlosNessuna valutazione finora

- Boehler Welding QLine OverviewDocumento4 pagineBoehler Welding QLine OverviewcarlosNessuna valutazione finora

- Ingles Clase 2Documento48 pagineIngles Clase 2carlos100% (1)

- Yes/No QS:: What's My Job?Documento4 pagineYes/No QS:: What's My Job?carlosNessuna valutazione finora

- Supplemental Requirements For Applicators of Complex Coatings Endorsement (CCE)Documento3 pagineSupplemental Requirements For Applicators of Complex Coatings Endorsement (CCE)carlosNessuna valutazione finora

- Trabajo Final Ingles V.Documento135 pagineTrabajo Final Ingles V.carlosNessuna valutazione finora

- Ingles 5Documento134 pagineIngles 5carlosNessuna valutazione finora

- Astm A6Documento62 pagineAstm A6carlos100% (1)

- Bu-Sp-207-20-R1-Audit-Guide-Building-Fabricator-With-Coatings-Endorsement EspañolDocumento20 pagineBu-Sp-207-20-R1-Audit-Guide-Building-Fabricator-With-Coatings-Endorsement EspañolcarlosNessuna valutazione finora

- Aisc 207-20 Audit Guide All Fabricator, Manufacturer and Erector Programs and EndorsementsDocumento18 pagineAisc 207-20 Audit Guide All Fabricator, Manufacturer and Erector Programs and EndorsementscarlosNessuna valutazione finora

- Sample Management Review Form ErectorsDocumento15 pagineSample Management Review Form ErectorscarlosNessuna valutazione finora

- Supplemental Requirements For Building Fabricators (BU) : Section 1 Before Your AuditDocumento2 pagineSupplemental Requirements For Building Fabricators (BU) : Section 1 Before Your AuditcarlosNessuna valutazione finora

- Application Document Submittal - Fab and Manuf Rev. 5 14 21Documento7 pagineApplication Document Submittal - Fab and Manuf Rev. 5 14 21carlosNessuna valutazione finora

- Mock Exercise Instructions For Fabricators of Simple BridgesDocumento7 pagineMock Exercise Instructions For Fabricators of Simple BridgescarlosNessuna valutazione finora

- Mock Exercise Instructions For Fabricators of Steel BuildingsDocumento8 pagineMock Exercise Instructions For Fabricators of Steel BuildingscarlosNessuna valutazione finora

- Coded Marking Log - PipeDocumento1 paginaCoded Marking Log - PipecarlosNessuna valutazione finora

- 207-20 CambiosDocumento74 pagine207-20 CambioscarlosNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- WPS Asme IxDocumento4 pagineWPS Asme Ixjcarlosherrerac7100% (1)

- Fabrication and Testing of Structures: Ships / High Speed, Light Craft and Naval Surface CraftDocumento30 pagineFabrication and Testing of Structures: Ships / High Speed, Light Craft and Naval Surface CraftaseNessuna valutazione finora

- Inspection and Test Plan (Itp) For Staircase Handrail 1 & 2Documento3 pagineInspection and Test Plan (Itp) For Staircase Handrail 1 & 2Environ Support100% (1)

- Inspection and Test Plan: Technip France Abu Dhabi ASME B31.3 Ed 2008 Abbreviations UsedDocumento4 pagineInspection and Test Plan: Technip France Abu Dhabi ASME B31.3 Ed 2008 Abbreviations UsedattaullaNessuna valutazione finora

- PDF Iso 3834 Checklist 1 CompressDocumento12 paginePDF Iso 3834 Checklist 1 CompressViệt VũNessuna valutazione finora

- Butt JointsDocumento21 pagineButt JointsRaj1-23Nessuna valutazione finora

- ES-14-602-01 Site Fab and Ist PipingDocumento26 pagineES-14-602-01 Site Fab and Ist PipingKhas BaniNessuna valutazione finora

- Cover MDRDocumento21 pagineCover MDRerlima pengasinanNessuna valutazione finora

- Guide To Writing A Welding Procedure Specification - December 2015Documento23 pagineGuide To Writing A Welding Procedure Specification - December 2015arnoldbatista55100% (3)

- S 705v2020 06 Supplementary Specification To API Recommended Practice 582 For Welding of Pressure Containing Equipment and PipingDocumento58 pagineS 705v2020 06 Supplementary Specification To API Recommended Practice 582 For Welding of Pressure Containing Equipment and PipingandyNessuna valutazione finora

- Material Requisition - ValvesDocumento10 pagineMaterial Requisition - Valvesashish.mathur1Nessuna valutazione finora

- Welding Manual: Cheema Boilers LimitedDocumento19 pagineWelding Manual: Cheema Boilers LimitedRajesh ThakurNessuna valutazione finora

- Essentials of WeldingDocumento13 pagineEssentials of WeldingRonald AlconisNessuna valutazione finora

- Abddou Med Amine cv-2-3Documento5 pagineAbddou Med Amine cv-2-3امينNessuna valutazione finora

- DRTF PLEM Fabrication & Construction PDFDocumento17 pagineDRTF PLEM Fabrication & Construction PDFMohd Fadli Mohd NoorNessuna valutazione finora

- Steps of Making WPSDocumento51 pagineSteps of Making WPSDavid Macatangay100% (7)

- SFLC STD Spec 0740 - Welding and Allied ProcessesDocumento37 pagineSFLC STD Spec 0740 - Welding and Allied ProcessesRobert Delafosse100% (1)

- Pressure Vessel Quality Manual 2Documento51 paginePressure Vessel Quality Manual 2Nguyen Duc Dung75% (4)

- BS EN - Qualification CodesDocumento4 pagineBS EN - Qualification CodesBalkishan DyavanapellyNessuna valutazione finora

- Agirm Agn 4500210653 Itp 001 02 Kas3 Iso Seawater Strainer Forward Sea ChestDocumento6 pagineAgirm Agn 4500210653 Itp 001 02 Kas3 Iso Seawater Strainer Forward Sea ChestRJS TUTORIALNessuna valutazione finora

- Welding Procedure SpecificationDocumento3 pagineWelding Procedure SpecificationCarlos Bustamante100% (1)

- Comparison of EN ISO 15614-1 - 2012 Vs 2017Documento6 pagineComparison of EN ISO 15614-1 - 2012 Vs 2017Swiss CIS AGNessuna valutazione finora

- AWS C7.3-2016 - Process Specification For Electron Beam WeldingDocumento36 pagineAWS C7.3-2016 - Process Specification For Electron Beam Weldingarnoldbatista55100% (1)

- Article Iii Welding Performance Qualifications: QW-300 GeneralDocumento9 pagineArticle Iii Welding Performance Qualifications: QW-300 GeneralArifin Fauzi LubisNessuna valutazione finora

- Dokumen - Tips - A Comparison of Iso 15614 Part 1 and Asme IxDocumento2 pagineDokumen - Tips - A Comparison of Iso 15614 Part 1 and Asme Ixjuan carlos beltranNessuna valutazione finora

- Iso 3834-5 - 2021Documento10 pagineIso 3834-5 - 2021Tran VoNessuna valutazione finora

- Casti Asme Section Ix 2013 PDFDocumento530 pagineCasti Asme Section Ix 2013 PDFKumararaja Konikki100% (14)

- Nioec SP 90 02Documento77 pagineNioec SP 90 02aminNessuna valutazione finora

- D.VASANTHAN, B.E (Mechanical) Senior Engineer - Quality Total Experience - 7 YearsDocumento3 pagineD.VASANTHAN, B.E (Mechanical) Senior Engineer - Quality Total Experience - 7 YearsKolusu SivakumarNessuna valutazione finora

- Fabrication Sequence PDFDocumento38 pagineFabrication Sequence PDFharry_1981100% (7)