Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Panel LG Display Lp156wh4-Tln1 2

Caricato da

Aldemir Fernando BattagliaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Panel LG Display Lp156wh4-Tln1 2

Caricato da

Aldemir Fernando BattagliaCopyright:

Formati disponibili

www.panelook.

com

Global LCD Panel Exchange Center

LP156WH4

Liquid Crystal Display

Product Specification

SPECIFICATION

FOR

APPROVAL

) Preliminary Specification

( ) Final Specification

Title

Customer

15.6 HD TFT LCD

SUPPLIER

General

*MODEL

MODEL

Suffix

LG Display Co., Ltd.

LP156WH4

TLN1

*When you obtain standard approval,

please use the above model name without suffix

APPROVED BY

APPROVED BY

SIGNATURE

SIGNATURE

C. I. Kim / S.Manager

/

REVIEWED BY

B. T. Jang / Manager

B. D. Jun / Manager

/

PREPARED BY

C. H. Yun / Engineer

C.K.D / Engineer

Products Engineering Dept.

LG Display Co., Ltd

Please return 1 copy for your confirmation with

your signature and comments.

Ver. 1.0

Feb. 28, 2012

1 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

LP156WH4

Liquid Crystal Display

Product Specification

Contents

No

ITEM

Page

COVER

CONTENTS

RECORD OF REVISIONS

GENERAL DESCRIPTION

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL SPECIFICATIONS

3-1

ELECTRICAL CHARACTREISTICS

3-2

INTERFACE CONNECTIONS

3-3

LVDS SIGNAL TIMING SPECIFICATION

3-3

SIGNAL TIMING SPECIFICATIONS

11

3-4

SIGNAL TIMING WAVEFORMS

11

3-5

COLOR INPUT DATA REFERNECE

12

3-6

POWER SEQUENCE

13

6-7

8

9-10

OPTICAL SFECIFICATIONS

14-16

MECHANICAL CHARACTERISTICS

17-20

APPENDIX. LPL PROPOSAL FOR SYSTEM COVER DESIGN

21-23

A

6

RELIABLITY

INTERNATIONAL STANDARDS

24

7-1

SAFETY

25

7-2

EMC

25

7-3

ENVIRONMENT

25

PACKING

8-1

DESIGNATION OF LOT MARK

26

8-2

PACKING FORM

26

8-3

LABEL DESCRIPTION

27

9

A

Ver. 1.0

PRECAUTIONS

28-29

APPENDIX. Enhanced Extended Display Identification Data

30-32

Feb. 28, 2012

2 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

Global LCD Panel Exchange Center

www.panelook.com

LP156WH4

Liquid Crystal Display

Product Specification

RECORD OF REVISIONS

Revision No Revision Date

Page

0.0

Jul. 21, 2011

0.1

Aus. 31. 2011

30-32

0.2

Oct. 12. 2011

Jan. 05. 2012

0.0

EDID Update

0.0

14

Update Color coordinates

0.0

15

Update scale

18-19

Update LCM Drawing

27

Update Label drawing

EDID Update

15

30-32

-

1.0

Ver. 1.0

Feb. 28, 2012

EDID

ver

First Draft (Preliminary Specification)

30-32

1.0

Description

14

Update Gray scale

1.0

EDID Update

Final Draft

Optical Characteristics

Feb. 28, 2012

1.0

3 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

LP156WH4

Liquid Crystal Display

Product Specification

1. General Description

The LP156WH4 is a Color Active Matrix Liquid Crystal Display with an integral LED backlight system. The

matrix employs a-Si Thin Film Transistor as the active element. It is a transmissive type display operating in

the normally white mode. This TFT-LCD has 15.6 inches diagonally measured active display area with HD

resolution (1366 horizontal by 768 vertical pixel array). Each pixel is divided into Red, Green and Blue subpixels or dots which are arranged in vertical stripes. Gray scale or the brightness of the sub-pixel color is

determined with a 6-bit gray scale signal for each dot, thus, presenting a palette of more than 262,144

colors. The LP156WH4 has been designed to apply the interface method that enables low power, high

speed, low EMI. The LP156WH4 is intended to support applications where thin thickness, low power are

critical factors and graphic displays are important. In combination with the vertical arrangement of the subpixels, the LP156WH4 characteristics provide an excellent flat display for office automation products such

as Notebook PC.

1

EEPROM Block

for EDID

User connector

40

1366

TFT-LCD Panel

LVDS

1port

Timing Control

Block

DVCC

Pin

VCC

(HD, GIP, TN)

768

CLKs

Power

Block

AVCC, AVDD

VGH, VGL, GMA

Source Driver

(Bottom Bent)

GIP CLKs, DSC

VLED

LED_EN

PWM

LED Driver

Block

VOUT_LED

FB1~4

Control & Data

LED Backlight Assy

Power

EDID signal & Power

General Features

Active Screen Size

15.6 inches diagonal

Outline Dimension

359.3(H, typ) 209.5(V, typ) 5.5(D,max) [mm]

Pixel Pitch

0.252mm 0.252 mm

Pixel Format

1366 horiz. By 768 vert. Pixels RGB strip arrangement

Color Depth

6-bit, 262,144 colors

Luminance, White

220 cd/m2(Typ.5 point @ PWM Duty = 100%)

Power Consumption

Total 4.3 W(Typ.) Logic : 0.7W (Typ.@ Mosaic), B/L : 3.6W (Typ.@ VLED 12V )

Weight

420g (Max.)

Display Operating Mode

Transmissive mode, normally white

Surface Treatment

Glare treatment of the front polarizer

RoHS Comply

Yes

BFR / PVC / As Free

Yes for all

Ver. 1.0

Feb. 28, 2012

4 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

LP156WH4

Liquid Crystal Display

Product Specification

2. Absolute Maximum Ratings

The following are maximum values which, if exceeded, may cause faulty operation or damage to the unit.

Table 1. ABSOLUTE MAXIMUM RATINGS

Values

Parameter

Symbol

Min

Max

Units

Notes

Power Input Voltage

VCC

-0.3

4.0

Vdc

at 25 r 5qC

Operating Temperature

TOP

50

qC

Storage Temperature

HST

-20

60

qC

Operating Ambient Humidity

HOP

10

90

%RH

Storage Humidity

HST

10

90

%RH

Note : 1. Temperature and relative humidity range are shown in the figure below.

Wet bulb temperature should be 39qC Max, and no condensation of water.

90% 80%

60%

60

50

40%

40

30

20

20%

10

Humidity[(%)RH]

Wet Bulb

Temperature []

Storage

Operation

0

10%

-20

10

20

30

40

50

60

70

80

Dry Bulb Temperature []

Ver. 1.0

Feb. 28, 2012

5 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

Global LCD Panel Exchange Center

www.panelook.com

LP156WH4

Liquid Crystal Display

Product Specification

3. Electrical Specifications

3-1. Electrical Characteristics

The LP156WH4 requires two power inputs. The first logic is employed to power the LCD electronics and to

drive the TFT array and liquid crystal. The second backlight is the input about LED BL.with LED Driver.

Table 2. ELECTRICAL CHARACTERISTICS

Values

Parameter

Symbol

Unit

Notes

3.6

220

255

mA

0.7

0.8

ICC_P

1500

mA

ZLVDS

90

100

110

LED Power Input Voltage

VLED

7.0

12.0

21.0

LED Power Input Current

ILED

300

325

mA

LED Power Consumption

PLED

3.6

3.9

LED Power Inrush Current

ILED_P

1500

mA

100

0.2

PWM Impedance

ZPWM

20

40

60

PWM Frequency

FPWM

150

1000

Hz

PWM High Level Voltage

VPWM_H

2.2

5.3

PWM Low Level Voltage

VPWM_L

0.3

ZPWM

20

40

60

LED_EN High Voltage

VLED_EN_H

2.2

5.3

LED_EN Low Voltage

VLED_EN_L

0.3

12,000

Hrs

Min

Typ

Max

VCC

3.0

3.3

ICC

Power Consumption

PCC

Power Supply Inrush Current

LVDS Impedance

LOGIC :

Power Supply Input Voltage

Power Supply Input Current

Mosaic

BACKLIGHT : ( with LED Driver)

PWM Duty Ratio

PWM Jitter

LED_EN Impedance

Life Time

Ver. 1.0

Feb. 28, 2012

10

11

6 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

LP156WH4

Liquid Crystal Display

Product Specification

Note)

1. The measuring position is the connector of LCM and the test conditions are under 25, fv = 60Hz,

Black pattern.

2. The specified Icc current and power consumption are under

the Vcc = 3.3V , 25, fv = 60Hz condition and Mosaic pattern.

3. This Spec. is the max load condition for the cable impedance designing.

The below figures are the measuring Vcc condition and the Vcc control block LGD used.

The Vcc condition is same as the minimum of T1 at Power on sequence.

Rising time

Vcc

0V

3.3V

90%

10%

0.5ms

4. This impedance value is needed for proper display and measured form LVDS Tx to the mating connector.

5. The measuring position is the connector of LCM and the test conditions are under 25.

6. The current and power consumption with LED Driver are under the Vled = 12.0V , 25, Dimming of

Max luminance and White pattern with the normal frame frequency operated(60Hz).

7. The below figures are the measuring Vled condition

12.0V

and the Vled control block LGD used.

Rising time 90%

VLED control block is same with Vcc control block.

VLED

0V

10%

0.5ms

8. The operation of LED Driver below minimum dimming ratio may cause flickering or reliability issue.

9. If Jitter of PWM is bigger than maximum, it may induce flickering.

10. This Spec. is not effective at 100% dimming ratio as an exception because it has DC level equivalent

to 0Hz. In spite of acceptable range as defined, the PWM Frequency should be fixed and stable for

more consistent brightness control at any specific level desired.

11. The life time is determined as the time at which brightness of LCD is 50% compare to that of minimum

value specified in table 7. under general user conditionU

Ver. 1.0

Feb. 28, 2012

7 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

Global LCD Panel Exchange Center

www.panelook.com

LP156WH4

Liquid Crystal Display

Product Specification

3-2. Interface Connections

This LCD employs two interface connections, a 40 pin connector used for the module electronics interface and

the other connector used for the integral backlight system.

Table 3. MODULE CONNECTOR PIN CONFIGURATION (CN1)

Pin

Symbol

NC

VCC

VCC

V EEDID

Description

No Connection.

LCD Logic and driver power (3.3V Typ.)

LCD Logic and driver power (3.3V Typ.)

DDC Power (3.3V)

NC

Clk EEDID

DDC Clock

DATA EEDID

DDC Data

ORX0-

Negative LVDS differential data input

ORX0+

Positive LVDS differential data input

10

GND

11

ORX1-

12

ORX1+

13

GND

14

ORX2-

15

ORX2+

16

GND

17

ORXC-

18

ORXC+

19

GND

20

NC

No Connection.

LCM Ground

Negative LVDS differential data input

Positive LVDS differential data input

LCM Ground

[Interface Chip]

1. LCD :

SiW, SW0645(LCD Controller)

Including LVDS Receiver.

2. System : SiW LVDSRx or equivalent

* Pin to Pin compatible with LVDS

[Connector]

LSMtron GT05Q-40S-H10-MN

[Mating Connector]

20453-040T-0# series or equivalent

[Connector pin arrangement]

Negative LVDS differential data input

Positive LVDS differential data input

X

[W

LCM Ground

Negative LVDS differential clock input

Positive LVDS differential clock input

LCM Ground

[LCD Module Rear View]

No Connection

21

NC

22

GND

23

NC

No Connection

24

NC

No Connection

25

GND

26

NC

No Connection

27

NC

No Connection

28

GND

29

NC

30

31

NC

GND

No Connection

LCM Ground (LED Backlight Ground)

32

GND

LCM Ground (LED Backlight Ground)

33

GND

LCM Ground (LED Backlight Ground)

No Connection

LCM Ground

LCM Ground

LCM Ground

No Connection

34

NC

35

PWM

36

LED_EN

37

38

NC

VLED

LED Backlight On/Off

No Connection

LED Backlight Power (7V-21V)

39

VLED

LED Backlight Power (7V-21V)

40

VLED

LED Backlight Power (7V-21V)

Ver. 1.0

Notes

No Connection.

System PWM Signal input for dimming

Feb. 28, 2012

8 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

LP156WH4

Liquid Crystal Display

Product Specification

3-3. LVDS Signal Timing Specifications

3-3-1. DC Specification

LVDS |VID|

LVDS +

VIN_MAX VIN_MIN

VCM

# |VID| = |(LVDS+) (LVDS-)|

# VCM = {(LVDS+) + (LVDS-)}/2

0V

Symb

ol

Min

Max

Unit

Notes

LVDS Differential Voltage

|VID|

100

600

mV

LVDS Common mode Voltage

VCM

0.6

1.8

LVDS Input Voltage Range

VIN

0.3

2.1

Description

3-3-2. AC Specification

Tclk

LVDS Clock

LVDS Data

tSKEW

Description

tSKEW (Fclk = 1/Tclk)

1) 85MHz > Fclk 65MHz : -400 ~ +400

2) 65MHz > Fclk 25MHz : -600 ~ +600

Symbol

Min

Max

Unit

Notes

tSKEW

- 400

+ 400

ps

85MHz > Fclk

65MHz

tSKEW

- 600

+ 600

ps

65MHz > Fclk

25MHz

tSKEW_EO

- 1/7

+ 1/7

Tclk

Maximum deviation

of input clock frequency during SSC

FDEV

Maximum modulation frequency

of input clock during SSC

FMOD

200

KHz

LVDS Clock to Data Skew Margin

LVDS Clock to Clock Skew Margin (Even

to Odd)

Ver. 1.0

Feb. 28, 2012

9 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

LP156WH4

Liquid Crystal Display

Product Specification

tSKEW_EO

LVDS Odd Clock

Tclk

LVDS Even Clock

Tclk

LVDS Even Data

< Clock skew margin between channel >

Freq.

Fmax

m QGmkl}

Fcenter

Fmin

X

mtvk

Time

< Spread Spectrum >

3-3-3. Data Format

1) LVDS 1 Port

RCLK+

RA+/-

R3

R2

R1

R0

G0

R5

R4

R3

R2

R1

R0

G0

R5

R4

RB+/-

G4

G3

G2

G1

B1

B0

G5

G4

G3

G2

G1

B1

B0

G5

RC+/-

B5

B4

B3

B2

DE

B5

B4

B3

B2

DE

RD+/-

G7

G6

R7

R6

G7

G6

R7

R6

Previous (N-1)th Cycle

VSYNC HSYNC

B7

B6

Current (Nth ) Cycle

VSYNC HSYNC

B7

B6

Next (N+1)th Cycle

< LVDS Data Format >

Ver. 1.0

Feb. 28, 2012

10 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

Global LCD Panel Exchange Center

www.panelook.com

LP156WH4

Liquid Crystal Display

Product Specification

3-4. Signal Timing Specifications

This is the signal timing required at the input of the User connector. All of the interface signal timing should be

satisfied with the following specifications and specifications of LVDS Tx/Rx for its proper operation.

Table 4. TIMING TABLE

ITEM

Symbol

Min

Typ

Max

Unit

fCLK

70.0

MHz

Period

tHP

1464

1492

1528

Width

tWH

32

48

62

Width-Active

tWHA

1366

1366

1366

Period

tVP

776

782

792

Width

tWV

Width-Active

tWVA

768

768

768

Horizontal back porch

tHBP

34

42

60

Horizontal front porch

tHFP

32

36

40

Vertical back porch

tVBP

12

Vertical front porch

tVFP

DCLK

Frequency

Hsync

Vsync

Data

Enable

Note

tCLK

tHP

tCLK

tHP

Appendix) all reliabilities are specified for timing specification based on refresh rate of 60Hz.

However, LP156WH4 has a good actual performance even at lower refresh rate (e.g. 40Hz or 50Hz)

for power saving mode, whereas LP156WH4 is secured only for function under lower refresh rate.

60Hz at Normal mode, 50Hz, 40Hz at Power save mode. Dont care Flicker level (power save mode).

3-5. Signal Timing Waveforms

Condition : VCC =3.3V

High: 0.7VCC

Data Enable, Hsync, Vsync

Low: 0.3VCC

tCLK

DCLK

Hsync

0.5 Vcc

tHP

tWH

tHBP

tWHA

tHFP

tWVA

tVFP

Data Enable

tVP

tWV

Vsync

tVBP

Data Enable

Ver. 1.0

Feb. 28, 2012

11 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

LP156WH4

Liquid Crystal Display

Product Specification

3-6. Color Input Data Reference

The brightness of each primary color (red,green and blue) is based on the 6-bit gray scale data input for the

color ; the higher the binary input, the brighter the color. The table below provides a reference for color

versus data input.

Table 5. COLOR DATA REFERENCE

Input Color Data

RED

Color

Basic

Color

RED

GREEN

BLUE

Ver. 1.0

GREEN

MSB

BLUE

LSB MSB

R5

R4 R3 R2 R1

Black

Red

Green

Blue

Cyan

Magenta

LSB

G4 G3 G2 G1 G0 B5

B4

0 0

0 0

1 0

0 1

0 0

0 1

1 0

Yellow

White

RED (00)

RED (01)

R0 G5

LSB MSB

B3

B2

B1

B0

0 0

1 0

0 1

1 1

0 1

1 1

1 0

1 1

1 1

0 0

0 0

1 0

0 0

RED (62)

0 0

0 0

RED (63)

1 0

0 0

GREEN (00)

0 0

0 0

GREEN (01)

0 0

1 0

...

GREEN (62)

0 1

0 0

GREEN (63)

0 1

1 0

BLUE (00)

0 0

0 0

BLUE (01)

0 0

0 0

BLUE (62)

0 0

0 1

BLUE (63)

0 0

0 1

Feb. 28, 2012

12 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

LP156WH4

Liquid Crystal Display

Product Specification

3-7. Power Sequence

90%

90%

Power Supply Input

VCC

0V 10%

10%

T1

Interface Signal, Vi

LVDS

T2

T4

T3 T7

Valid Data

0V

T5

LED BL

On/Off Control Signal

LED_EN

3.0V

3.0V

T6

0V (Off)

T10

T9

Valid Data

LED BL

Dimming Control Signal

PWM

0V (Low)

T8

T11

90%

LED Driver Input Voltage

VLED

0V

10%

90%

T13

T12

10%

Table 6. POWER SEQUENCE TABLE

Value

Logic

Parameter

Min.

Typ.

Max.

T1

0.5

T2

T3

Value

Units

LED

Parameter

Min.

Typ.

Max.

10

ms

T8

ms

50

ms

T9

ms

ms

T10

ms

T4

150

ms

T11

ms

T5

200

ms

T12

0.5

ms

T6

ms

T13

ms

T7

10

ms

Units

Note)

1. Do not insert the mating cable when system turn on.

2. Valid Data have to meet 3-3. LVDS Signal Timing Specifications

3. LVDS, LED_EN and PWM need to be on pull-down condition on invalid status.

4. LGD recommend the rising sequence of VLED after the Vcc and valid status of LVDS turn on.

Ver. 1.0

Feb. 28, 2012

13 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

LP156WH4

Liquid Crystal Display

Product Specification

4. Optical Specification

Optical characteristics are determined after the unit has been ON and stable for approximately 30 minutes in

a dark environment at 25qC. The values specified are at an approximate distance 50cm from the LCD surface

at a viewing angle of ) and 4 equal to 0q.

FIG. 1 presents additional information concerning the measurement equipment and method.

FIG. 1 Optical Characteristic Measurement Equipment and Method

Optical Stage(x,y)

LCD Module

Pritchard 880 or

equivalent

50cm

Table 9. OPTICAL CHARACTERISTICS

Table 7. OPTICAL CHARACTERISTICS

Parameter

Symbol

Ta=25qC, Vcc=3.3V, fV=60Hz, fCLK= 70.0MHz

Values

Min

Typ

Max

Units

Contrast Ratio

CR

400

500

Surface Luminance, white

LWH

185

220

cd/m2

G WHITE_5P

80

G WHITE_13P

60

70

TrR+ TrD

16

ms

RX

0.588

0.618

0.648

RY

0.339

0.369

0.399

GX

0.325

0.355

0.385

GY

0.573

0.603

0.633

BX

0.121

0.151

0.181

BY

0.073

0.103

0.133

WX

0.283

0.313

0.343

WY

0.299

0.329

0.359

Luminance Variation

Response Time

Notes

1

2

3

4

Color Coordinates

RED

GREEN

BLUE

WHITE

Viewing Angle

x axis, right()=0q)

4r

40

45

degree

x axis, left ()=180q)

4l

40

45

degree

y axis, up ()=90q)

4u

10

15

degree

y axis, down ()=270q)

4d

30

35

degree

Gray Scale

Ver. 1.0

6

Feb. 28, 2012

14 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

LP156WH4

Liquid Crystal Display

Product Specification

Note)

1. Contrast Ratio(CR) is defined mathematically as

Surface Luminance with all white pixels

Contrast Ratio =

Surface Luminance with all black pixels

2. Surface luminance is the average of 5 point across the LCD surface 50cm from the surface with

all pixels displaying white. For more information see FIG 1.

LWH = Average(L1,L2, L5)

3. The variation in surface luminance , The panel total variation (G WHITE) is determined by measuring LN

at each test position 1 through 13 and then defined as followed numerical formula.

For more information see FIG 2.

G WHITE =

Maximum(L1,L2, L13)

Minimum(L1,L2, L13)

4. Response time is the time required for the display to transition from white to black (rise time, Tr R) and

from black to white(Decay Time, TrD). For additional information see FIG 3.

5. Viewing angle is the angle at which the contrast ratio is greater than 10. The angles are determined

for the horizontal or x axis and the vertical or y axis with respect to the z axis which is normal to the

LCD surface. For more information see FIG 4.

* fV = 60Hz

6. Gray scale specification

Ver. 1.0

Gray Level

Luminance [%] (Typ)

L0

0.16

L7

1.48

L15

5.57

L23

12

L31

20.8

L39

35.3

L47

55.5

L55

79.1

L63

100

Feb. 28, 2012

15 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

LP156WH4

Liquid Crystal Display

Product Specification

FIG. 2 Luminance

<Measuring point for Average Luminance & measuring point for Luminance variation>

H

A

10mm

6

8

3

B

V

11

H,V : ACTIVE AREA

A : H/4 mm

B : V/4 mm

10

1

4

10mm

POINTS: 13 POINTS

5 13

12

FIG. 3 Response Time

Active Area

The response time is defined as the following figure and shall be measured by switching the input signal

for black and white.

TrD

TrR

%

100

90

Optical

Response

10

0

white

white

black

FIG. 4 Viewing angle

Normal

Eye

<Dimension of viewing angle range>

I = 180q

,

Left

I = 90q , Up

T

I

I = 0q

I = 270q

Ver. 1.0

,

Right

,

Down

Feb. 28, 2012

16 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

Global LCD Panel Exchange Center

www.panelook.com

LP156WH4

Liquid Crystal Display

Product Specification

5. Mechanical Characteristics

The contents provide general mechanical characteristics for the model LP156WH4. In addition the figures

in the next page are detailed mechanical drawing of the LCD.

Outline Dimension

Horizontal

359.3 r 0.5mm

Vertical

209.5 r 0.5mm

Thickness

5.5mm (max)

Horizontal

350.0 r 0.5mm

Vertical

197.1 r 0.5mm

Horizontal

344.232 mm

Vertical

193.536 mm

Bezel Area

Active Display Area

Weight

Surface Treatment

Ver. 1.0

420g (Max.)

Glare treatment of the front polarizer

Feb. 28, 2012

17 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

Global LCD Panel Exchange Center

www.panelook.com

LP156WH4

Liquid Crystal Display

Product Specification

Note) Unit:[mm], General tolerance: r 0.5mm

<FRONT VIEW>

Ver. 1.0

Feb. 28, 2012

18 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

Global LCD Panel Exchange Center

www.panelook.com

LP156WH4

Liquid Crystal Display

Product Specification

Note) Unit:[mm], General tolerance: r 0.5mm

<REAR VIEW>

Ver. 1.0

Feb. 28, 2012

19 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

Global LCD Panel Exchange Center

www.panelook.com

LP156WH4

Liquid Crystal Display

Product Specification

[ DETAIL DESCRIPTION OF SIDE MOUNTING SCREW ]

* Mounting Screw Length (A)

= 2.0(Min) / 2.5(Max)

* Mounting Screw Hole Depth (B)

= 2.5(Min)

* Mounting hole location : 3.1(Typ)

* Torque : 2.5 kgf.cm(Max) / 2.3kgf.cm(Min)

(Measurement gauge : torque meter)

Notes : 1. Screw plated through the method of non-electrolytic nickel plating is preferred

to reduce possibility that results in vertical and/or horizontal line defect due to

the conductive particles from screw surface.

Ver. 1.0

Feb. 28, 2012

20 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

LP156WH4

Liquid Crystal Display

Product Specification

LGD Proposal for system cover design.(Appendix)

1

Gap check for securing the enough gap between LCM

and System cover.

Max Thickness

Sponge

LCM Reflector Side

System Cover

A Boundary Line

1.Rear

side of LCM is sensitive against external stress,and previous check

about interference is highly needed.

Define

2.In case there is something from system cover comes into the boundary

above,mechanical interference may cause the FOS defects.

(Eg: Ripple, White spot..)

Check if antenna cable is sufficiently apart from T-CON of LCD Module.

Define

{Tjvu

{Tjvu

GOOD

NO GOOD

1.If system antenna is overlapped with T-CON,it might be cause the noise.

Ver. 1.0

Feb. 28, 2012

21 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

Global LCD Panel Exchange Center

www.panelook.com

LP156WH4

Liquid Crystal Display

Product Specification

LGD Proposal for system cover design.

3

Gap check for securing the enough gap between LCM

and System hinge.

COF

(D-IC)

Hinge

Side Mount Screw Hole (4ea)

GAP:Min2.0mm

(L TYPE)

(I TYPE)

1.At

Define

least 2.0mm of gap needs to be secured to prevent the shock

related defects.

2.L type of hinge is recommended than I type under shock test.

4

Checking the path of the System wire.

#3

#2

Bad

#1

Ok

Good

1.COF area needs to be handled with care.

Define

Ver. 1.0

2.GOOD Wire path design to system side.

OK Wire path is located between COFs.

BADWire path overlapped with COF area.

Feb. 28, 2012

22 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

LP156WH4

Liquid Crystal Display

Product Specification

LGD Proposal for system cover design.

5

Using a bracket on the top of LCM is not recommended.

bracket

Define

1.Condition without bracket is good for mechanical noise,and can minimize

the light leakage from deformation of bracket.

2.The results shows that there is no difference between the condition

with or without bracket.

Securing additional gap on CNT area..

System cover inner side.

A-1

User connector

area.

User connector

Cable pathway.

A~A-1

cut

FPC:Flexible Printed Circuit.

Define

Ver. 1.0

1.CNT area is specially sensitive against external stress,and additional

gap by cutting on system cover will be helpful on removing the Ripple.

2.Using a thinner CNT will be better. (eg: FPC type)

Feb. 28, 2012

23 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

Global LCD Panel Exchange Center

www.panelook.com

LP156WH4

Liquid Crystal Display

Product Specification

6. Reliability

Environment test condition

No.

Test Item

Conditions

High temperature storage test

Ta= 60qC, 240h

Low temperature storage test

Ta= -20qC, 240h

High temperature operation test

Ta= 50qC, 50%RH, 240h

Low temperature operation test

Ta= 0qC, 240h

Vibration test (non-operating)

Sine wave, 10 ~ 500 ~ 10Hz, 1.5G, 0.37oct/min

3 axis, 1hour/axis

Shock test (non-operating)

Half sine wave, 180G, 2ms

one shock of each six faces(I.e. run 180G 2ms

for all six faces)

Altitude

0 ~ 10,000 feet (3,048m) 24Hr

0 ~ 40,000 feet (12,192m) 24Hr

operating

storage / shipment

{ Result Evaluation Criteria }

There should be no change which might affect the practical display function when the display quality

test is conducted under normal operating condition.

Ver. 1.0

Feb. 28, 2012

24 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

Global LCD Panel Exchange Center

www.panelook.com

LP156WH4

Liquid Crystal Display

Product Specification

7. International Standards

7-1. Safety

a) UL 60950-1, Second Edition, Underwriters Laboratories Inc.

Information Technology Equipment - Safety - Part 1 : General Requirements.

b) CAN/CSA C22.2 No.60950-1-07, Second Edition, Canadian Standards Association.

Information Technology Equipment - Safety - Part 1 : General Requirements.

c) EN 60950-1:2006 + A11:2009, European Committee for Electrotechnical Standardization (CENELEC).

Information Technology Equipment - Safety - Part 1 : General Requirements.

d) IEC 60950-1:2005, Second Edition, The International Electrotechnical Commission (IEC).

Information Technology Equipment - Safety - Part 1 : General Requirements.

7-2. EMC

a) ANSI C63.4 American National Standard for Methods of Measurement of Radio-Noise

Emissions from Low-Voltage Electrical and Electronic Equipment in the Range of 9 kHz to 40 GHz.

American National Standards Institute (ANSI), 2003.

b) CISPR 22 Information technology equipment Radio disturbance characteristics Limit and

methods of measurement." International Special Committee on Radio Interference

(CISPR), 2005.

c) CISPR 13 Sound and television broadcast receivers and associated equipment Radio disturbance

characteristics Limits and method of measurement." International Special Committee on Radio

Interference (CISPR), 2006.

7-3. Environment

a) RoHS, Directive 2002/95/EC of the European Parliament and of the council of 27 January 2003

Ver. 1.0

Feb. 28, 2012

25 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

LP156WH4

Liquid Crystal Display

Product Specification

8. Packing

8-1. Designation of Lot Mark

a) Lot Mark

A

A,B,C : SIZE(INCH)

E : MONTH

D : YEAR

F ~ M : SERIAL NO.

Note

1. YEAR

Year

2011

2012

2013

2014

2015

2016

2017

2018

2019

2020

Mark

Month

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

Mark

2. MONTH

b) Location of Lot Mark

Serial No. is printed on the label. The label is attached to the backside of the LCD module.

This is subject to change without prior notice.

8-2. Packing Form

a) Package quantity in one box : 22 pcs

b) Box Size : 468x355x270mm

Ver. 1.0

Feb. 28, 2012

26 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

Global LCD Panel Exchange Center

www.panelook.com

LP156WH4

Liquid Crystal Display

Product Specification

8-3. Label Description

Model Name

Lenovo CODE

LGD CODE

Lot Mark

LGD Code

(1) Model Name : L P 1 5 6 W H 4 -

T L N 1

Revision Code

Product Type

Display Mode

Basic Model Serial No.

Resolution : HD

Size (inch) : 15.6

Application : NBPC

LGD Brand Initial: L

(2) Lot Mark

: 1 5 6 A

7 C 0 0 0 0 0 0 1

SERIAL NO.

MONTH

YEAR

SIZE

Lenovo Code

1)Lenovo P/N : 0A66660

2)FRU P/N : 04W3340

Ver. 1.0

Feb. 28, 2012

27 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

Global LCD Panel Exchange Center

www.panelook.com

LP156WH4

Liquid Crystal Display

Product Specification

9. PRECAUTIONS

Please pay attention to the followings when you use this TFT LCD module.

9-1. MOUNTING PRECAUTIONS

(1) You must mount a module using holes arranged in four corners or four sides.

(2) You should consider the mounting structure so that uneven force (ex. Twisted stress) is not applied to

t

h

e

module. And the case on which a module is mounted should have sufficient strength so that external

force is not transmitted directly to the module.

(3) Please attach the surface transparent protective plate to the surface in order to protect the polarizer.

Transparent protective plate should have sufficient strength in order to the resist external force.

(4) You should adopt radiation structure to satisfy the temperature specification.

(5) Acetic acid type and chlorine type materials for the cover case are not desirable because the former

generates corrosive gas of attacking the polarizer at high temperature and the latter causes circuit break

by electro-chemical reaction.

(6) Do not touch, push or rub the exposed polarizers with glass, tweezers or anything harder than HB

pencil lead. And please do not rub with dust clothes with chemical treatment.

Do not touch the surface of polarizer for bare hand or greasy cloth.(Some cosmetics are detrimental

to the polarizer.)

(7) When the surface becomes dusty, please wipe gently with absorbent cotton or other soft materials like

chamois soaks with petroleum benzene. Normal-hexane is recommended for cleaning the adhesives

used to attach front / rear polarizers. Do not use acetone, toluene and alcohol because they cause

chemical damage to the polarizer.

(8) Wipe off saliva or water drops as soon as possible. Their long time contact with polarizer causes

deformations and color fading.

(9) Do not open the case because inside circuits do not have sufficient strength.

9-2. OPERATING PRECAUTIONS

(1) The spike noise causes the mis-operation of circuits. It should be lower than following voltage :

V= 200mV(Over and under shoot voltage)

(2) Response time depends on the temperature.(In lower temperature, it becomes longer.)

(3) Brightness depends on the temperature. (In lower temperature, it becomes lower.)

And in lower temperature, response time(required time that brightness is stable after turned on) becomes

longer.

(4) Be careful for condensation at sudden temperature change. Condensation makes damage to polarizer or

electrical contacted parts. And after fading condensation, smear or spot will occur.

(5) When fixed patterns are displayed for a long time, remnant image is likely to occur.

(6) Module has high frequency circuits. Sufficient suppression to the electromagnetic interference shall be

done by system manufacturers. Grounding and shielding methods may be important to minimized the

interference.

Ver. 1.0

Feb. 28, 2012

28 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

Global LCD Panel Exchange Center

www.panelook.com

LP156WH4

Liquid Crystal Display

Product Specification

9-3. ELECTROSTATIC DISCHARGE CONTROL

Since a module is composed of electronic circuits, it is not strong to electrostatic discharge. Make certain that

treatment persons are connected to ground through wrist band etc. And dont touch interface pin directly.

9-4. PRECAUTIONS FOR STRONG LIGHT EXPOSURE

Strong light exposure causes degradation of polarizer and color filter.

9-5. STORAGE

When storing modules as spares for a long time, the following precautions are necessary.

(1) Store them in a dark place. Do not expose the module to sunlight or fluorescent light. Keep the

temperature between 5qC and 35qC at normal humidity.

(2) The polarizer surface should not come in contact with any other object.

It is recommended that they be stored in the container in which they were shipped.

9-6. HANDLING PRECAUTIONS FOR PROTECTION FILM

(1) When the protection film is peeled off, static electricity is generated between the film and polarizer.

This should be peeled off slowly and carefully by people who are electrically grounded and with well

ion-blown equipment or in such a condition, etc.

(2) The protection film is attached to the polarizer with a small amount of glue. If some stress is applied

to rub the protection film against the polarizer during the time you peel off the film, the glue is apt to

remain on the polarizer.

Please carefully peel off the protection film without rubbing it against the polarizer.

(3) When the module with protection film attached is stored for a long time, sometimes there remains a

very small amount of glue still on the polarizer after the protection film is peeled off.

(4) You can remove the glue easily. When the glue remains on the polarizer surface or its vestige is

recognized, please wipe them off with absorbent cotton waste or other soft material like chamois

soaked with normal-hexane.

Ver. 1.0

Feb. 28, 2012

29 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

LP156WH4

Liquid Crystal Display

Product Specification

Byte

(Hex)

00

01

02

03

04

05

06

07

08

09

0A

0B

0C

0D

0E

0F

10

11

18

12

EDID structure version # = 1

19

13

EDID revision # = 3

20

14

Video input Definition = Digital signal

21

15

Max H image size (Rounded cm) = 34 cm

22

16

Max V image size (Rounded cm) = 19 cm

23

17

24

18

25

26

19

1A

Display gamma = (gamma*100)-100 = Example:(2.2*100)-100=120 = 2.2 Gamma

Feature Support (no_DPMS, no_Active Off/Very Low Power, RGB color display, Timing BLK

1,no_ GTF)

Red/Green Low Bits (RxRy/GxGy)

Blue/White Low Bits (BxBy/WxWy)

27

1B

Red X

Rx = 0.618

28

1C

Red Y

Ry = 0.369

29

1D

Green X

Gx = 0.355

30

1E

Green Y

Gy = 0.603

31

1F

Blue X

Bx = 0.151

32

20

Blue Y

By = 0.103

33

21

White X

Wx = 0.313

34

22

White Y

Wy = 0.329

35

23

Established timing 1 (00h if not used)

00

00000000

36

24

Established timing 2 (00h if not used)

00

00000000

37

25

Manufacturer's timings (00h if not used)

00

00000000

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

26

27

28

29

2A

2B

2C

2D

2E

2F

30

31

32

33

34

35

Standard timing ID1 (01h if not used)

Standard timing ID1 (01h if not used)

Standard timing ID2 (01h if not used)

Standard timing ID2 (01h if not used)

Standard timing ID3 (01h if not used)

Standard timing ID3 (01h if not used)

Standard timing ID4 (01h if not used)

Standard timing ID4 (01h if not used)

Standard timing ID5 (01h if not used)

Standard timing ID5 (01h if not used)

Standard timing ID6 (01h if not used)

Standard timing ID6 (01h if not used)

Standard timing ID7 (01h if not used)

Standard timing ID7 (01h if not used)

Standard timing ID8 (01h if not used)

Standard timing ID8 (01h if not used)

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

00000001

00000001

Established

Panel Color Coordinates

Timings

Standard Timing ID

Ver. 1.0

Value

(Hex)

1/3

Byte

(Dec)

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Display

Parameters

Vendor / Product

EDID Version

Header

APPENDIX A. Enhanced Extended Display Identification Data (EEDIDTM)

Field Name and Comments

Header

Header

Header

Header

Header

Header

Header

Header

EISA manufacture code ( 3 Character ID )

EISA manufacture code (Compressed ASC)

Panel Supplier Reserved - Product Code

( Hex. LSB first )

LCD Module Serial No - Preferred but Optional ("0"

LCD Module Serial No - Preferred but Optional ("0"

LCD Module Serial No - Preferred but Optional ("0"

LCD Module Serial No - Preferred but Optional ("0"

Week of Manufacture

Year of Manufacture

Feb. 28, 2012

LGD

033Ah

If not used)

If not used)

If not used)

If not used)

00 weeks

2011 years

00

FF

FF

FF

FF

FF

FF

00

30

E4

3A

03

00

00

00

00

00

15

01

03

80

22

13

78

Value

(Bin)

00000000

11111111

11111111

11111111

11111111

11111111

11111111

00000000

00110000

11100100

00111010

00000011

00000000

00000000

00000000

00000000

00000000

00010101

00000001

00000011

10000000

00100010

00010011

01111000

0A

00001010

61

D5

9E

5E

5B

9A

26

1A

50

54

01100001

11010101

10011110

01011110

01011011

10011010

00100110

00011010

01010000

01010100

00000001

00000001

00000001

00000001

00000001

00000001

00000001

00000001

00000001

00000001

00000001

00000001

00000001

00000001

30 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

LP156WH4

Liquid Crystal Display

Product Specification

APPENDIX A. Enhanced Extended Display Identification Data (EEDIDTM)

Byte

(Hex)

36

37

56

38

Horizontal Active

(lower 8 bits)

1366 Pixels

57

39

Horizontal Blanking(Thp-HA)

(lower 8 bits)

126 Pixels

58

3A

Horizontal Active / Horizontal Blanking(Thp-HA) (upper 4:4bits)

59

3B

Vertical Avtive

60

3C

Vertical Blanking (Tvp-HA) (DE Blanking typ.for DE only panels)

61

3D

Vertical Active : Vertical Blanking (Tvp-HA)

62

3E

Horizontal Sync. Offset (Thfp)

36 Pixels

63

3F

Horizontal Sync Pulse Width (HSPW)

48 Pixels

64

40

Vertical Sync Offset(Tvfp) : Sync Width (VSPW)

65

41

Horizontal Vertical Sync Offset/Width

66

42

Horizontal Image Size (mm)

344 mm

67

43

Vertical Image Size

194 mm

68

44

Horizontal Image Size / Vertical Image Size

69

45

Horizontal Border = 0 (Zero for Notebook LCD)

70

46

Vertical Border = 0

(Zero for Notebook LCD)

Non-Interlace, Normal display, no stereo, Digital Separate ( Vsync_NEG, Hsync_NEG ), DE only

note : LSB is set to '1' if panel is DE-timing only. H/V can be ignored.

Flag

Flag

Timing Descriptor #1

Byte

(Dec)

54

55

47

72

73

48

49

74

4A

75

4B

76

4C

77

4D

78

4E

79

4F

80

50

81

51

82

52

83

53

84

54

85

55

86

56

87

57

88

58

89

90

91

59

5A

5B

92

5C

93

5D

94

5E

95

5F

96

60

97

61

98

62

99

63

100

64

101

65

102

66

103

67

104

68

105

69

106

6A

107

6B

Timing Descriptor #3

Timing Descriptor #2

71

Ver. 1.0

2/3

Value

(Hex)

Value

(Bin)

58

1B

56

7E

50

00

0E

30

24

30

35

00

58

C2

10

00

00

01011000

19

00011001

00

00

Flag

00

Data Type Tag (Descriptor Defined by manufacturer )

00

Flag

00

Descriptor Defined by manufacturer

00

Descriptor Defined by manufacturer

00

Descriptor Defined by manufacturer

00

Descriptor Defined by manufacturer

00

Descriptor Defined by manufacturer

00

Descriptor Defined by manufacturer

00

Descriptor Defined by manufacturer

00

Descriptor Defined by manufacturer

00

Descriptor Defined by manufacturer

00

Descriptor Defined by manufacturer

00

Descriptor Defined by manufacturer

00

Descriptor Defined by manufacturer

00

Descriptor Defined by manufacturer

00

Flag

00

Flag

00

Flag

00

Data Type Tag ( ASCII String )

FE

Flag

00

ASCII String

L

4C

ASCII String

G

47

ASCII String

20

ASCII String

D

44

ASCII String

i

69

ASCII String

s

73

ASCII String

p

70

ASCII String

l

6C

ASCII String

a

61

ASCII String

y

79

Manufacturer P/N(If<13 char--> 0Ah, then terminate with ASC code 0Ah,set remaining char = 20h 0A

Manufacturer P/N(If<13 char--> 0Ah, then terminate with ASC code 0Ah,set remaining char = 20h 20

Manufacturer P/N(If<13 char--> 0Ah, then terminate with ASC code 0Ah,set remaining char = 20h 20

00000000

Field Name and Comments

Pixel Clock/10,000 (LSB)

Pixel Clock/10,000 (MSB)

70 MHz @ 60Hz

768 Lines

14 Lines

(upper 4:4bits)

3 Lines : 5 Lines

(upper 2bits)

(mm)

Feb. 28, 2012

00011011

01010110

01111110

01010000

00000000

00001110

00110000

00100100

00110000

00110101

00000000

01011000

11000010

00010000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

11111110

00000000

01001100

01000111

00100000

01000100

01101001

01110011

01110000

01101100

01100001

01111001

00001010

00100000

00100000

31 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

Global LCD Panel Exchange Center

www.panelook.com

LP156WH4

Liquid Crystal Display

Product Specification

Checksum

Timing Descriptor #4

APPENDIX A. Enhanced Extended Display Identification Data (EEDIDTM)

Byte

(Dec)

108

109

Byte

(Hex)

6C

6D

Flag

Flag

110

6E

Flag

111

6F

Data Type Tag ( ASCII String )

112

70

Flag

113

71

ASCII String

114

72

ASCII String

115

Field Name and Comments

3/3

Value

(Hex)

Value

(Bin)

00

00

00

FE

00

4C

50

31

35

36

57

48

34

2D

54

4C

4E

31

00000000

00000000

00000000

11111110

00000000

01001100

01010000

73

ASCII String

116

74

ASCII String

117

75

ASCII String

118

76

ASCII String

119

77

ASCII String

120

78

ASCII String

121

79

ASCII String

122

7A

ASCII String

123

7B

ASCII String

124

7C

ASCII String

125

7D

ASCII String

126

7E

Extension flag (# of optional 128 panel ID extension block to follow, Typ = 0)

00

00000000

127

7F

Check Sum (The 1-byte sum of all 128 bytes in this panel ID block shall = 0)

83

10000011

Ver. 1.0

Feb. 28, 2012

00110001

00110101

00110110

01010111

01001000

00110100

00101101

01010100

01001100

01001110

00110001

32 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory! www.panelook.com

Potrebbero piacerti anche

- Lab Report Experiment 5Documento4 pagineLab Report Experiment 5Czarina mantuano100% (2)

- LP156WF1Documento29 pagineLP156WF1helpquickNessuna valutazione finora

- Inverter E171781Documento6 pagineInverter E171781Aldemir Fernando BattagliaNessuna valutazione finora

- LP156WH4 Tla1Documento31 pagineLP156WH4 Tla1Cristian ValentinNessuna valutazione finora

- LP156WH4 TLN2Documento31 pagineLP156WH4 TLN2herveldNessuna valutazione finora

- Lp156wh3-Tll3 Final Cas Ver1 0 (110304)Documento28 pagineLp156wh3-Tll3 Final Cas Ver1 0 (110304)Trijeth DatlaNessuna valutazione finora

- LG LP156WH2 FinalDocumento31 pagineLG LP156WH2 FinalMakhtar SeyeNessuna valutazione finora

- Asus G552VW-XO376T 1080p Screen LP156WF6-SPB1 DatasheetDocumento42 pagineAsus G552VW-XO376T 1080p Screen LP156WF6-SPB1 DatasheetSerge PallaNessuna valutazione finora

- Lm270wf5 Ssa1 LGDocumento34 pagineLm270wf5 Ssa1 LGHeadri ZausNessuna valutazione finora

- Specification FOR Approval: 15.4" Wxga TFT LCD TitleDocumento31 pagineSpecification FOR Approval: 15.4" Wxga TFT LCD TitleDaniel GómezNessuna valutazione finora

- 15.6Documento39 pagine15.6ady_gligor7987Nessuna valutazione finora

- Specification FOR Approval: 10.1" HD TFT LCD TitleDocumento27 pagineSpecification FOR Approval: 10.1" HD TFT LCD TitlenicusorceldurNessuna valutazione finora

- Lc215eue Tca1Documento34 pagineLc215eue Tca1Jorge AzrackoNessuna valutazione finora

- FOR Approval Specification: Title 37.0" Wuxga TFT LCDDocumento32 pagineFOR Approval Specification: Title 37.0" Wuxga TFT LCDmediaguru1Nessuna valutazione finora

- Specification FOR Approval: 15.6" FHD TFT LCD TitleDocumento34 pagineSpecification FOR Approval: 15.6" FHD TFT LCD TitleflatformNessuna valutazione finora

- LP154WX4 TlabDocumento31 pagineLP154WX4 TlabsuzukkNessuna valutazione finora

- T260XW02 V6 AuoDocumento29 pagineT260XW02 V6 Auomhmd193Nessuna valutazione finora

- HV320WXC-100 Preliminary SpecDocumento27 pagineHV320WXC-100 Preliminary SpecMilorad PajovicNessuna valutazione finora

- LTA320AP08 SamsungDocumento27 pagineLTA320AP08 SamsungJuan HerreraNessuna valutazione finora

- LG - Philips Lc420w02-Sla1 Lcdpanel DatasheetDocumento28 pagineLG - Philips Lc420w02-Sla1 Lcdpanel DatasheetJeffrey EvansNessuna valutazione finora

- Lc420euf SDF2Documento43 pagineLc420euf SDF2Radu BriaNessuna valutazione finora

- LC320W01 Sla1Documento33 pagineLC320W01 Sla1Robert TocaNessuna valutazione finora

- Acer S190WL S196WL 2chip 20120602 A00 Service ManualDocumento66 pagineAcer S190WL S196WL 2chip 20120602 A00 Service ManualDoru RazvanNessuna valutazione finora

- Lc470wul Sbm1 DatasheetDocumento41 pagineLc470wul Sbm1 DatasheetsorosororiNessuna valutazione finora

- LC420WUEDocumento36 pagineLC420WUEMarius IggyNessuna valutazione finora

- LTA320AP05 SamsungDocumento26 pagineLTA320AP05 SamsungAndy AnsahNessuna valutazione finora

- Model No.: N070Lge Suffix: L21: Product SpecificationDocumento26 pagineModel No.: N070Lge Suffix: L21: Product SpecificationMarian GheorghiescuNessuna valutazione finora

- Lm170e01 G5Documento28 pagineLm170e01 G5iammiaNessuna valutazione finora

- LG - Philips Lc470wu1-Sla1 Lcdpanel DatasheetDocumento27 pagineLG - Philips Lc470wu1-Sla1 Lcdpanel DatasheetServis ElektronikNessuna valutazione finora

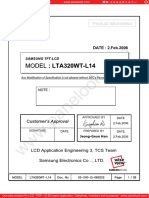

- Global LCD Panel Datasheet: LTA320WT-L14Documento28 pagineGlobal LCD Panel Datasheet: LTA320WT-L14Andrzej GomulaNessuna valutazione finora

- Display LP101WS1-TLA1 PDFDocumento28 pagineDisplay LP101WS1-TLA1 PDFnelusabieNessuna valutazione finora

- LTY400HM10 SamsungDocumento25 pagineLTY400HM10 SamsungManjesh BabyNessuna valutazione finora

- FOR Approval Specification: 47.0" Wuxga TFT LCD TitleDocumento28 pagineFOR Approval Specification: 47.0" Wuxga TFT LCD TitleIonescu CristinaNessuna valutazione finora

- LP141WX1 Tle1Documento27 pagineLP141WX1 Tle1Simed EweiNessuna valutazione finora

- LC320WXN Sca1Documento43 pagineLC320WXN Sca1aldoNessuna valutazione finora

- Acer Al2002w (ET) PDFDocumento60 pagineAcer Al2002w (ET) PDFAmanda MillerNessuna valutazione finora

- LC171W03 C4 PDFDocumento28 pagineLC171W03 C4 PDFsorintvrNessuna valutazione finora

- MODEL: LTA320AP32: Product InformationDocumento27 pagineMODEL: LTA320AP32: Product InformationSaul MuñozNessuna valutazione finora

- Specification FOR Approval: 15.4" Wuxga TFT LCD TitleDocumento32 pagineSpecification FOR Approval: 15.4" Wuxga TFT LCD Titlenetman_84Nessuna valutazione finora

- Lc420eud Sca2Documento40 pagineLc420eud Sca2Masimba1Nessuna valutazione finora

- Panel LG Display LC470EUN-PEF1 0 (DS) PDFDocumento39 paginePanel LG Display LC470EUN-PEF1 0 (DS) PDFaldo_suvi100% (2)

- Specifications Approval Sheet: Product DescriptionDocumento16 pagineSpecifications Approval Sheet: Product Descriptionเกียรติศักดิ์ ภูมิลาNessuna valutazione finora

- Product Specification: LCD Sales & Marketing Team Samsung Display Co., LTDDocumento23 pagineProduct Specification: LCD Sales & Marketing Team Samsung Display Co., LTDVictorManuelBernalBlancoNessuna valutazione finora

- Samsung Secret LCD Panel Specs and DetailsDocumento25 pagineSamsung Secret LCD Panel Specs and DetailsJonas SouzaNessuna valutazione finora

- Samsung TFT-LCD Model: Lta320an12 DiagramDocumento27 pagineSamsung TFT-LCD Model: Lta320an12 DiagramJesus E Lopez BNessuna valutazione finora

- LTY400HM01Documento28 pagineLTY400HM01plasma plasmaNessuna valutazione finora

- LM215WF3 Sda1Documento35 pagineLM215WF3 Sda1rems69Nessuna valutazione finora

- Product Description: T400Hw02 TFT-LCD Panel With Rohs GuaranteeDocumento31 pagineProduct Description: T400Hw02 TFT-LCD Panel With Rohs GuaranteeNachiket KshirsagarNessuna valutazione finora

- Acer Computers Al2002 Al2002 Service Guide 2a765faDocumento60 pagineAcer Computers Al2002 Al2002 Service Guide 2a765faKryphos Drgn0% (1)

- LC171W03 C4 PDFDocumento29 pagineLC171W03 C4 PDFAnderson Duarte100% (1)

- FOR Approval Specification: 42.0" Wxga TFT LCD TitleDocumento28 pagineFOR Approval Specification: 42.0" Wxga TFT LCD Titlerems69Nessuna valutazione finora

- LM181E04 Liquid Crystal Display SpecificationDocumento28 pagineLM181E04 Liquid Crystal Display Specificationbachett100% (1)

- 19-inch WXGA LCD Display SpecificationDocumento32 pagine19-inch WXGA LCD Display SpecificationmiltoncgNessuna valutazione finora

- Samsung 40-inch LCD Panel Spec SheetDocumento27 pagineSamsung 40-inch LCD Panel Spec SheetJAMES SMITH VALDERRAMANessuna valutazione finora

- N156B6 L08Documento31 pagineN156B6 L08JozefNessuna valutazione finora

- AUO 42 Inch Led Panel DataDocumento32 pagineAUO 42 Inch Led Panel DataVenkatesh SubramanyaNessuna valutazione finora

- Vdocuments - MX - Service Mnaualaoc 712si I Module Diagramas LCD Color Monitor Aoc 712siDocumento56 pagineVdocuments - MX - Service Mnaualaoc 712si I Module Diagramas LCD Color Monitor Aoc 712siBvm BvmmNessuna valutazione finora

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDa EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsValutazione: 3.5 su 5 stelle3.5/5 (6)

- MPM3510A r1.0 PDFDocumento22 pagineMPM3510A r1.0 PDFAldemir Fernando BattagliaNessuna valutazione finora

- MPM3510A r1.0 PDFDocumento22 pagineMPM3510A r1.0 PDFAldemir Fernando BattagliaNessuna valutazione finora

- Audio 1997 02 PDFDocumento100 pagineAudio 1997 02 PDFAldemir Fernando BattagliaNessuna valutazione finora

- Philips 1969-01 CM3 Radio-Audio-Television 939916106901Documento406 paginePhilips 1969-01 CM3 Radio-Audio-Television 939916106901Aldemir Fernando BattagliaNessuna valutazione finora

- MX25L12873F, 3V, 128Mb, v1.2 PDFDocumento98 pagineMX25L12873F, 3V, 128Mb, v1.2 PDFAldemir Fernando BattagliaNessuna valutazione finora

- Bt134 Series e NXPDocumento8 pagineBt134 Series e NXPJorge Junior Briceño UrónNessuna valutazione finora

- Dual Synchronous, Step-Down Controller With 5-V and 3.3-V LdosDocumento31 pagineDual Synchronous, Step-Down Controller With 5-V and 3.3-V LdosAldemir Fernando BattagliaNessuna valutazione finora

- Software Updates (New and Changed Functions) Software Updates (New and Changed Functions)Documento13 pagineSoftware Updates (New and Changed Functions) Software Updates (New and Changed Functions)Aldemir Fernando BattagliaNessuna valutazione finora

- Software Updates (New and Changed Functions) Software Updates (New and Changed Functions)Documento13 pagineSoftware Updates (New and Changed Functions) Software Updates (New and Changed Functions)Aldemir Fernando BattagliaNessuna valutazione finora

- Cat Luk Repset 2015-16 UsDocumento404 pagineCat Luk Repset 2015-16 Usjackvicosa5781Nessuna valutazione finora

- NECMicrocontroller GuideDocumento8 pagineNECMicrocontroller GuideAldemir Fernando BattagliaNessuna valutazione finora

- Positive Voltage Regulator Ics: FeaturesDocumento56 paginePositive Voltage Regulator Ics: FeaturesJabang Aru SaputroNessuna valutazione finora

- n25q 64mb 1 8v 65nmDocumento81 paginen25q 64mb 1 8v 65nmAldemir Fernando BattagliaNessuna valutazione finora

- Turn Off The Inverter Protection - 1453108338292Documento14 pagineTurn Off The Inverter Protection - 1453108338292Aldemir Fernando Battaglia86% (7)

- 2000 Service Manual PDFDocumento1.970 pagine2000 Service Manual PDFAldemir Fernando BattagliaNessuna valutazione finora

- TCS20DPR Datasheet en 20110207Documento7 pagineTCS20DPR Datasheet en 20110207Aldemir Fernando BattagliaNessuna valutazione finora

- AF4502CDocumento8 pagineAF4502CbehzadNessuna valutazione finora

- w25q64fw Revd 032513Documento96 paginew25q64fw Revd 032513Aldemir Fernando BattagliaNessuna valutazione finora

- DMN66D0LDW 7Documento5 pagineDMN66D0LDW 7Aldemir Fernando BattagliaNessuna valutazione finora

- High-Speed Complementary MOSFET Power InverterDocumento9 pagineHigh-Speed Complementary MOSFET Power InverteropenscribdformeNessuna valutazione finora

- 7N60Documento8 pagine7N60Aldemir Fernando BattagliaNessuna valutazione finora

- Data Sheet P2003EVGDocumento5 pagineData Sheet P2003EVGEdgar SilveiraNessuna valutazione finora

- HD Tune Help33Documento7 pagineHD Tune Help33Aldemir Fernando BattagliaNessuna valutazione finora

- Black and White TV Video Output Applications High-Voltage Switching Applications Driver Stage Audio Amplifier ApplicationsDocumento5 pagineBlack and White TV Video Output Applications High-Voltage Switching Applications Driver Stage Audio Amplifier ApplicationsAldemir Fernando BattagliaNessuna valutazione finora

- Transistor Specifications and CharacteristicsDocumento5 pagineTransistor Specifications and CharacteristicsAldemir Fernando BattagliaNessuna valutazione finora

- Color TV Vertical Deflection Output Applications Color TV Class-B Sound Output ApplicationsDocumento5 pagineColor TV Vertical Deflection Output Applications Color TV Class-B Sound Output ApplicationsCornelNessuna valutazione finora

- Apl 5913Documento19 pagineApl 5913Aldemir Fernando Battaglia100% (1)

- PD1503YVS: Dual N-Channel Enhancement Mode MOSFETDocumento7 paginePD1503YVS: Dual N-Channel Enhancement Mode MOSFETAldemir Fernando BattagliaNessuna valutazione finora

- Ejercicios Propuestos Temas Hasta Primer PrevioDocumento2 pagineEjercicios Propuestos Temas Hasta Primer PrevioJuan De DiosNessuna valutazione finora

- Seedburo Germinator Controls and Monitoring InstrumentsDocumento2 pagineSeedburo Germinator Controls and Monitoring InstrumentsJhony Rengifo SolsolNessuna valutazione finora

- WTS 12 ElectrodynamicsDocumento28 pagineWTS 12 ElectrodynamicsTondani100% (1)

- Bridge Operational ClassificationDocumento1 paginaBridge Operational ClassificationFrancis DomingoNessuna valutazione finora

- Sooad ManualDocumento19 pagineSooad ManualRakhiNessuna valutazione finora

- Extrusion-Spheronization Process Variables and CharacterizationDocumento57 pagineExtrusion-Spheronization Process Variables and CharacterizationKhanh Le0% (1)

- Checklist of Requirements in The Application For Mechanical Installation/s of Industrial FacilitiesDocumento1 paginaChecklist of Requirements in The Application For Mechanical Installation/s of Industrial FacilitiesoliciakimNessuna valutazione finora

- Presentation FileDocumento10 paginePresentation FileInnoVentureCommunityNessuna valutazione finora

- Catalogo - CATUDocumento132 pagineCatalogo - CATUxis-zeroNessuna valutazione finora

- Lightning Protection System Testing & Commissioning Method StatementDocumento3 pagineLightning Protection System Testing & Commissioning Method Statementvin ssNessuna valutazione finora

- Nurul Ain - nurulain@gmail.comDocumento32 pagineNurul Ain - nurulain@gmail.comMuhamad FarhanNessuna valutazione finora

- Gilding Manual PDFDocumento14 pagineGilding Manual PDFIva VazNessuna valutazione finora

- Pump HydraulicsDocumento5 paginePump HydraulicsSiddharth Kharat100% (1)

- Fire Drencher System - Base-Engineer PDFDocumento2 pagineFire Drencher System - Base-Engineer PDFpequenita34100% (1)

- Variable Frequency Drive Using IR215xDocumento7 pagineVariable Frequency Drive Using IR215xartyomNessuna valutazione finora

- Core 3Documento2 pagineCore 3RidhiNessuna valutazione finora

- Trigonox101 PdsDocumento3 pagineTrigonox101 PdsPaula RiveraNessuna valutazione finora

- FST DFS Ge-EgdDocumento5 pagineFST DFS Ge-EgdEric DunnNessuna valutazione finora

- Premium Swab Rigs Since 1925Documento8 paginePremium Swab Rigs Since 1925fabricio3fabricio-1Nessuna valutazione finora

- D3755-14 Standard Test Method For Dielectric BreakdowDocumento6 pagineD3755-14 Standard Test Method For Dielectric Breakdowjose flores100% (1)

- Revit Domoty 1Documento1 paginaRevit Domoty 1SAN RAKSANessuna valutazione finora

- A Rope of Mass 0.65 KG Is Stretched Between Two Supports 30 M Apart. If The Tension in The Rope Is 120 N, How Long Will It Take A Pulse To Travel From One Support To The Other?Documento6 pagineA Rope of Mass 0.65 KG Is Stretched Between Two Supports 30 M Apart. If The Tension in The Rope Is 120 N, How Long Will It Take A Pulse To Travel From One Support To The Other?peyying12Nessuna valutazione finora

- Biological ExerciseDocumento6 pagineBiological ExerciseTanmoy BasakNessuna valutazione finora

- List of Diagnostic Trouble Code (DTC)Documento5 pagineList of Diagnostic Trouble Code (DTC)Dev Vrat BohraNessuna valutazione finora

- Signals and Systems - MjrobertsDocumento3 pagineSignals and Systems - Mjrobertspriyakanthr5883100% (1)

- Isolation of Caffeine from TeaDocumento6 pagineIsolation of Caffeine from TeaDaisy Joyce Seroje BuslonNessuna valutazione finora

- A380-LEVEL III - ATA 42 Integrated Modular Avionics - Avionics DaDocumento66 pagineA380-LEVEL III - ATA 42 Integrated Modular Avionics - Avionics DaAbolfazl Mazloomi100% (11)

- Emp2 Box Pressure TransmitterDocumento8 pagineEmp2 Box Pressure TransmitterAsif HameedNessuna valutazione finora

- d-Copia3500MF 4500MF 5500MFsmY113351-4Documento1.051 pagined-Copia3500MF 4500MF 5500MFsmY113351-4ctecisbNessuna valutazione finora