Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Road To Jepang Revisi Fix

Caricato da

Indra RiadiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Road To Jepang Revisi Fix

Caricato da

Indra RiadiCopyright:

Formati disponibili

Modification of Cassava Flour with Lactic Acid

and Ethanol in UV Rotary Dryer for Increase the

Value of Baking Expansion

Indri Wahyuningtyas #1, M.Rodiansyah #2, Juhnizar Buminata #3,

Dr. Siswo Sumardiono, ST., MT.*

#*Chemical Engineering Department, Diponegoro University

Prof. Sudharto St, Tembalang, Semarang, 50239, Indonesia

#1

indri.wahyuningtyas@yahoo.com

#2

mrodiansyah@gmail.com

#3

juhnizar@gmail.com

Abstract Indonesia has very high level of consumption of

wheat in the form of a wheat flour, the consumption rate of

wheat flour in Indonesia each year has increased from 4,76

million tons in the year 2010 be 5,05 million tons in 2012.

The consumption levels have not been supported by the

availability of raw material grain. In the other side

Indonesia has the big potential on cassava production for

cassava starch, but until now the efficient methode for

modify cassava starch to make its properties equivalent as

wheat flour is have not founded yet. The main purpose of

this research is to increase baking expansion ability from

cassava flour. The methode which is used for this research is

modification of cassava starch with ethyl lactate and rotary

UV dryer system. The dependent variables are ethanol and

lactate acid concentration, speed round of rotary,

temperature of the dry air. The dependent variables are

type and quantity of cassava starch, drying process time,

and the type of UV irradiation. For over all, the results show

that modified strach has a better charactheristic than the

native strach. From the analysis, the best value of swelling

power, sollubility, baking expansion, viscosity, carboxyl and

carbonyl are 13,40 g/g; 12,40%; 8,38 ml/gr; 428 cP; 0,259%;

and 0,261%. FTIR analysis results indicate there is an

increase in the carbonyl group (C-O) at 1072.37 cm-1 to be

1078.16 cm-1 and a decrease in hydroxyl group (OH) at

3452.53 cm-1 to be 3419.74 cm-1. SEM analysis results also

showed that the modified starch granule size is smaller

compared with native starch with successive values of 8.938

m - 16.903 m and 4.8 m - 15.6 m.

Keywords cassava starch, esterification, rotary UV dryer,

baking expansion

I. INTRODUCTION

Indonesia has the very high level of consumption of

wheat in the form of a wheat flour, the consumption rate of

wheat flour in Indonesia each year has increased from 4.76

million tons in the year 2010 be 5.05 million tons in 2012 [3].

The consumption levels have not been supported by the

availability of raw material grain. Data from APTINDO at

2013, show that Indonesia still get the wheat from import and

the total number of that import always increase from 5.47

million tons in 2010 and became 6.25 million tons in 2012. As

we know that wheat flour cant be replaced by any type of

flour. Meanwhile, Indonesia has a big potential for cassava

which is can be transformed to cassava flour but there are no

modification technique yet for modification cassava flour to

has a same properties like wheat flour.

Indonesia had 1.22 million hectares of cassava plant in

2008 and increased in 2012 to 1.29 million hectares. Indonesia

also has a high productivity of cassava which was 19.98

million tons in 2007 and increased to 22.67 million tons in

2012 [21]. Those factors make Indonesia as a country that has

84.32% of average export number since 2007 to 2011 [8].

Based on that productivity number, cassava flour has a good

chance in food industry and another chemical industry.

There are 17% of amylose and 83% of amylopectin in

cassava flour [33], [36], meanwhile in wheat flour there are

25% of amylose and 75% of amylopectin [25]. The difference

of amylose and amylopectin composition in some flour will

affect to its texture and characteristic in some food that will be

produced [42]. The biggest obstacle that cassava flour has for

replace the wheat flour are the small of baking expantion

number, hard to dissolved in water [17], need a long time in

cooking process, the paste that produced is hard and not

transparent, the properties is too sticky, and can resist with

some acid [23], those things are the reasons why cassava flour

cant replace wheat flour yet. Because of that, the

modification is really needed to increase the properties of

cassava flour.

In general there are three methods that mostly applicated

in cassava flour modification process [19], by chemical

process with acid hydrolysis [4],[40], oxidation [35],

esterification [13], crosslinking [4]. By physical process with

drying, extrution, heating, cooling, cooking, and other

physical treatment [6], [32]. Also by enzymatic with adding

some enzyme to process like amylase and glucoamylase [24],

[10], [39].

In this research the cassava flour modification will be

done by the combination of ethyl lactate esterification process

also drying process by rotary system with UV light. The

research that use rotary UV system has been already done

before with the general result is flour from modification

process has a better properties than the native cassava flour.

This drying system try to combine rotary system, dry air, and

radiation from UV light, and the drying result is expected to

produced more uniform product. This research is expected to

produced cassava flour modification with the properties that

can be used to replaced wheat flour.

II. PROCEDURE

The main materials which are used in this research are

cassava starch, lactate acid (pa) Merck, Ethanol 96% Merck,

and aquadest. The additional materials are hydroxylamine

chloride, NaOH, and HCl.

The main tools in this research are two reactors and rotary

UV dryer. These two reactors are using a stirrer, beaker glass,

and magnetic stirrer. Figure 3.1 is showing the main tools of

this research.

B. Drying Process with UV Rotary Dryer

Cassava flour, which is produced from the esterification

process then be dried with UV Rotary Dryer. The dry air

temperature (5000C, 650C, and 800C) and rotation velocity

(20rpm, 30rpm, and 40rpm) are controlled based on the

variables. After the drying process, modificated cassava flour

is sifted in 100 mesh to get more uniform size of flour

powder.

C. Solubility Analysis

The dried modificated cassava flour (1gr) is dissolved

into 20ml aquadest, then heated in a water bath at 60oC for 30

minutes. The supernatant is separated by centrifuge at

3000rpm for 20 minutes, then the 10ml of that supernatant is

dried in oven. The value of solubility is calculated by the

equation below [22]

D.

Swelling Power Analysis

The dried modificated cassava flour (0.1gr) is dissolved

into 10ml aquadest, then heated in a water bath at 60oC for 30

minutes. The supernatant is separated by centrifuge at

2500rpm for 15 minutes. The value of swelling power is

calculated by the equation below [24]

E.

Viscosity Analysis

The viscosity analysis is done by heating process until

reach the temperature 80oC. The value of viscosity is

calculated by using a Viscometer Brookfield with the velocity

and spindle number which are appropriate. [2]

F.

SEM

FTIR

Baking Expansion Analysis

The modificated cassava starch (20gr) is mixed with

butter, egg, and after 5 minutes of mixing process the mixture

is heated in an oven at 170oC for 20 minutes. After the bread

is cooled, then to make it vacuum the bread is coated with

paraffin for the specific volume measurement process. The

value of baking expansion is calculated by dividing the

volume with the weight of bread.

III. RESULTS AND DISCUSSION

Fig. 1 Process Diagram of Cassava Flour Modification

A. Ester Preparation and Esterification Process

Lactic acid and ethanol are mixed with a variable

concentration are 0.75% and 1% (v/v) in 1000 ml aquadest,

then wait until 24 hours.400gr of cassava flour is dissolved

into ester solution and stirred by a magnetic stirrer at scale 8.

The esterification process is done for 20 minutes at 25oC.

A.

The Influence of Rotation Velocity, Drying

Temperature, and Ester Solution Concentration to

Swelling Power.

Fig. 2 The Effect of Temperature to Swelling Power

Fig. 3 The Effect of Rotation to Swelling Power

Fig. 4 The Effect of Ester Concentration to Swelling Power

The swelling power for each variable ranges from 7,513,4 g/g. The highest swelling power, 13,4 gr/gr, is obtained

from 40 rpm rotation velocity, 800C drying temperature, and

0,75% v/v concentration. Acid treatment caused amyl and

amyl pectin of starch partly elaborated [1]. Besides, it is

assumed that the swelling power increasing is caused by

hydrophilic character of the granule of starch, so it is able to

absorb water [24], and it is swelled when heated because of

the water [43].

When observed from the UV rotary rotation velocity, it

did not bring a quite significant result. It is appropriate to

research conducted by Chaudhuri et. Al., (2009) stated that

UV rotary rotation velocity did not significantly influence, so

the starch granule is not easily hydrated by water [34]. The

higher the ester concentration, the lower the swelling power of

modified starch. Acidity addition to the starch will be

followed by carbonyl (C-O) and carboxyl (C-O-O-H) cluster

addition. Carbonyl cluster influenced the amyl degradation

process. The higher the amyl degradation process is, the fewer

the paste is formed [20]. It might not show pasting profile

[28], which is finally made the swelling decrease.

B.

The Influence of Rotation Velocity, Drying

Temperature, and Ester Solution Concentration to

Baking Expansion.

Fig. 5 The Effect of Temperature to Baking Expamsion

Fig. 6 The Effect of Rotation to Baking Expansion

Fig. 7 The Effect of Ester Concentration to Baking Expansion

Baking expansion of flour can be stated in specific

volume of baked flour dough [15]. It showed that modified

tapioca brought a good baking expansion character. The

specific volume ranges from 6,64 to 8,38 ml/gr while that of

pure tapioca is 4,13 ml/gr. It agreed with [15] and [41]

research stated that the combination between lactic acid and

UV may increase the baking expansion 8,08 ml/gr and 9,0612,23 ml/gr respectively. It is related to previous discussion of

swelling power increasing which is caused by hydrophilic

character of starch granule, so it can absorb water. The more

the water is bounded, the more the baking expansion is

occurred. It is due to the increasing of water evaporation and

pressure [7], [41].

UV rotary velocity is not significantly influenced the

baking expansion. It is agreed with [9] research stated that

UV rotary velocity does not influence the heat transfer. While

baking, water turned into vapor [1]. It caused high pressure

produced high expansion impetus [7], [41].

The influence of ester concentration to baking expansion

is shown by Table 4.1. The higher the ester concentration is,

the higher the hydroxyl cluster of starch will be replaced.

Starch degradation will be easily happened on pH acid [38].

Besides, lactic acid can help starch co-polymerisation process

[12]. It may widen the inter-molecule bound apart, so water

will easily enter into the starch molecule. It affected in the

increasing of starch granule while the baking process

occurred. The increasing volume of tapioca florescence can be

seen at Figure 4.1.

(a)

(b)

(c)

Figure 4.1 Dough after baked

(a) wheat flour (b) modified tapioca (c) native tapioca

C. The Influence of Rotation Velocity, Drying Temperature,

and Ester Solution Concentration to Viscosity.

Fig. 8 The Effect of Temperature to Viscosity

Fig. 9 The Effect of Rotation to Viscosity

higher effect in decreasing the viscosity tapioca. [35] stated

that starch oxidation is starch modification turning hydroxyl

cluster of starch molecule into carbonyl and carboxyl cluster.

Both clusters influence to the viscosity of formed pasta [30].

This phenomenon caused starch molecule degradation

producing modified flour with low viscosity [30].

In this research, dry temperature increased the amount of

carbonyl and carboxyl cluster. Carbonyl cluster influenced the

amyl degradation process. The higher the amyl degradation

process is, the fewer the paste is formed [20] It might not

show pasting profile [28], [2].

D.

The Influence of Rotation Velocity, Drying Temperature,

and Ester Solution Concentration to Solubility

.

Fig. 11 The Effect of Temperature to Solubility

Fig. 12 The Effect of Ester Concentration to Solubility

Fig. 10 The Effect of Ester Concentration to Viscosity

Ester solution, mixed between lactic acid and ethanol,

was used in this research. Table 4.1 stated that the average

viscosity of modified starch ranged between 428 to 664 cP.

Generally, viscosity value of modified tapioca is lower than

that of pure tapioca. It agreed with [14] research which stated

that UV may decrease the viscosity of corn flour. [15] stated

that combination between lactic acid and UV light gives

Fig. 13 The Effect of Rotation to Solubility

The solubility value on each variable ranged from 3.6%

to 23.6%. Generally, the solubility of modified starch is

higher than that of pure starch which has 3,8% solubility

value. It is because of the stretching of starch structure when

being heated. Besides, amyl and amyl pectin chain is degraded

UV radiation of dryer, and hydrolysis process using lactic acid

Abs

. 8

3000

2500

2000

1750

1500

1250

1000

750

4000

3500

Strach Ester

0

1

1 .0 5

500

1/cm

Fig. 16 FTIR Analysis of Modified Tapioca and Native

8

. 6

A b s

0 .9

Tapioca

0 .7 5

. 2

. 8

. 3

. 6

. 3

0 .6

Figure 16 shows the FTIR analysis result on pure

tapioca and on modified tapioca with 40 rpm rotation velocity,

80 oC dry temperature, and 0.75%v/v ester concentration as

the variables. Based on those analyses, it can be concluded

that pure and modified tapioca has similar fundamental

clusters. Instead, the curve and peak detected is almost similar

either. It is due to the same components of both forms of

tapioca, which are amyl and amyl pectin [11], [13].

Based on the absorbance peak, a carbonyl cluster (C-O)

1

increasing

from 1072.37 cm-1 to 1078.16 cm-1, and a hydroxyl

cluster (O-H) increasing from 3452.53 cm-1 to 3419.74 cm-1

Abs

occurred.

The increasing of starch carbonyl cluster was caused

by starch modification involving etherification reaction, so it

0.5

increased

the ester of the starch which changed starch function

from hydroxyl ester to carbonyl ester [26], [18], and [31].

1

The Influence of Rotation Velocity, Fed Capacity, and

Drying Temperature of Rotary UV through SEM

Analysis to the Size and Form of Starch Granule.

The morphology of the surface of pure tapioca and

modified tapioca using 40 rpm rotation velocity, 80 oC dry

temperature, and 0.75%v/v ester concentration with 2000

times zooming. Figure 14 and 15 shows the structure of pure

tapica and modified tapioca surface.

F. The Comparison Between Modified Tapioca Using

Combination of Lactic Acid Hydrolysis and UV Rotary

Dryer and Pure Tapioca Using FTIR (Fourier Transform

Infrared Spectroscopy) Analysis

E.

stated that starch surface destruction is caused by amorf

hydrolysis which happened mostly in amylose.

may decrease the starch molecule weight and increase its

solubility [16], [27].

The other factor causing the increasing of its solubility is

ester concentration. The higher the ester concentration added,

the higher the solubility is. Acidity addition to the starch will

be followed by carbonyl (C-O) and carboxyl (C-O-O-H)

cluster addition. Carbonyl cluster influenced the amyl

degradation process. The higher the amyl degradation process

is, the fewer the paste is formed [20]. It also caused the

decrease of its solubility. Meanwhile, the influence of rotary

UV used, similar to the previous analyses, did not bring a

quite significant result.

0 .4 5

0 .3

0 .1 5

3 5 0 0

3 0 0 0

2 5 0 0

2 0 0 0

1 7 5 0

1 5 0 0

1 2 5 0

1 0 0 0

7 5 0

5 0 0

1 /c m

Fig.14 SEM Analysis (2000x) of Native Tapioca

1157.24

1072.37

1359.76

1419.56

1643.30

2933.68

4 0 0 0

S tra c h E s te r

3452.53

IV. CONCLUSIONS

0

Fig.15 SEM Analysis (2000x) of Modified Tapioca

Figure 14 and 15 shows that the surface of pure tapioca

granule is soft without any scratch [22], while that of modified

tapioca is scraped with many cracks [10], [32]. It is almost

unwell-ordered, so it may influence its functional and

physical-chemistry character. Pure tapioca particle size is

about 8,938 m 16,903 m. It is almost similar to Goncalves

et al., (2014) stated that the size is about 12 m 28 m, and

[37] about 15,01 m. It is quite different to that of modified

tapioca, which ranges about 4.8m- 15.6m.

It is agreed with [40] and [41] who stated that the

combination between lactic acid hydrolysis and UV

irradiation may smaller the size of the starch granule. [5]

The4000 modification

of

in

3500

3000

2500 tapioca,

2000

1750lactic

1500 acid

1250 and

1000 ethanol

750

500

Native-Strach

UV rotary

dryer influences the physical-chemistry of tapioca.1/cm

The best modification result is obtained in 40rpm rotation

velocity, 800C temperature, and 0,75% v/v concentration. The

result of swelling power, baking expansion, solubility,

viscosity, carboxyl cluster, and carbonyl cluster is 13,4 gr/gr;

8,38 ml/gr; 428 cP; 12,4 %; 0,259%; and 0,261% respectively.

FTIR analysis results show that there are carboxyl cluster

increasing (C-O) from 1072.37 cm-1 to 1078.16 cm-1, and

hydroxyl decreasing (O-H) from 3452.53 cm-1 to 3419.74 cm1

. SEM analysis results also show that modified tapioca

granule is smaller than modified pure tapioca. The size is

8,938 m 16,903 and 4.8m- 15.6m respectively.

ACKNOWLEDGEMENT

In this occasion we would like to thank to The Almighty

God who has blessed us, Dr. Siswo Sumardiono, S.T, M.T. as

the Head of Chemical Engineering Department of Diponegoro

University, and as our advisor, and all parties who have

helped us on finishing this research and journal.

[21]

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

Ambarsari, I., Haryadi., Cahyanto, M.Nur. 2011. Karakteristik Tepung

Hasil Modifikasi Chip Ubikayu Dengan Asam Laktat Dan Hidrogen

Peroksida.

Anindya, Agnes Swasti., dan Haryadi. 2014. Okdidasi Hancuran

Singkong Menggunakan H2O2 Dan Asam Laktat dengan Katalisator

Ferrous Sulfate Heptahydrate Untuk Meningkatkan Baking Expansion.

Jurusan Teknologi Pangan dan Hasil Pertanian, Universitas Gajah

Maja, Yogyakarta.

APTINDO. 2013. Overview Industri Tepung Terigu Nasional

Indonesia. Jakarta

Atichokudomchai, N., dan Varavinit, S. 2003. Characterization And

Utilization Of Acid-Modified Cross-Linked Tapioca Starch In

Pharmaceutical Tablets. Carbohydrate Polymers. 53: 263270.

Atichokudomchai, N., Varavinit, S., dan Chinachoti, P. 2004. A Study

Of Ordered Structure In Acid-Modified Tapioca Starch By 13 C CP /

MAS Solid-State NMR. Carbohydrate Polymers. 58: 383389.

Bergthaller, W. 2004. Development in potato starches. Dalam: A.C.

Eliasson (Ed). Starch in Food: Structure, Function, and Application.

CRC Press, Boca Raton, Florida.

Bertolini, a. C., Mestres, C., Colonna, P., dan Raffi, J. 2001. Free

Radical Formation In UV- And Gamma-Irradiated Cassava Starch.

Carbohydrate Polymers. 44: 269271.

Billah, T. 2012. Statistik Konsumsi Pangan Tahun 2012. Pusat Data

Dan Sistem Informasi Pertanian Sekretariat Jendral Kementrian

Pertanian: Jakarta.

Chaudhuri, Bodhisattwa., Muzzio, Fernando J., dan Tomassone,

M.Silvina. Experimentally validated computations of heat transfer in

granular materials in rotary calciners. Powder Technology. 198: 6-15.

Chen, Y., Huang, S., Tang, Z., Chen, X., dan Zhang, Z. 2011.

Structural Changes Of Cassava Starch Granules Hydrolyzed By A

Mixture Of -Amylase And Glucoamylase. Carbohydrate Polymers.

85: 272275.

Demiate, I. M., Dupuy, N., Huvenne, J. P., Cereda, M. P., dan

Wosiacki, G. 2000. Relationship Between Baking Behavior Of

Modified Cassava Starches And Starch Chemical Structure

Determined By FTIR Spectroscopy. Carbohydrate Polymers. 42: 149

158.

Dias, A. R. G., Zavareze, E. D. R., Elias, M. C., Helbig, E., da Silva,

D. O., dan Ciacco, C. F. 2011. Pasting, Expansion And Textural

Properties Of Fermented Cassava Starch Oxidised With Sodium

Hypochlorite. Carbohydrate Polymers. 84: 268275.

Eguchi, S., Kitamoto, N., Nishinari, K., dan Yoshimura, M. 2013.

Food Hydrocolloids Effects Of Esteri Fi Ed Tapioca Starch On The

Physical And Thermal Properties Of Japanese White Salted Noodles

Prepared Partly By Residual Heat. Food Hydrocolloids. 111.

Fiedorowicz, M., Tomasik, P., Lim, S., dan Korea, S. 1999. Molecular

Distribution And Pasting Properties Of UV-Irradiated Corn Starches.

Starch/ Strke. 51: 126131.

Franco, C. M. L., Ogawa, C., Rabachini, T., Rocha, T. D. S., Cereda,

M. P., dan Jane, J. 2010. Effect Of Lactic Acid And UV Irradiation On

The Cassava And Corn Starches. Brazilian Archieves Of Biology And

Technology. 53: 443454.

Henry F., L.C. Costa, Chodur, C.A. (2010). Influence of Ionizing

Radiation on Physical Properties of Native and Chemically Modified

Starches. Radiation Physics and Chemistry: 75-82.

Herawati, H. 2012. Teknologi Proses Produksi Food Ingredient Dari

Tapioka Termodifikasi. Jurnal Litbang Pertanian. 31: 68-76.

Jerachaimongkol, S., Chonhenchob, V., Naivikul, O., dan

Poovarodom, N. 2006. Modification Of Cassava Starch By

Esterification And Properties Of Cassava Starch Ester Films.

Kasetsart. 151: 148151.

Kaur, B., Arif, F., Bhat, R., dan Karim, A. A. 2012. Progress In Starch

Modification In The Last Decade. Food Hydrocolloids. 26: 398404.

Kesselmans. Annen., Ido, Pleter Blecker., Ten, Boer. 2004. Oxidation

of Starch. United States Patent no 6.777.548.B1

[22]

[23]

[24]

[25]

[26]

[27]

[28]

[29]

[30]

[31]

[32]

[33]

[34]

[35]

[36]

[37]

[38]

[39]

[40]

[41]

Kementerian Pertanian. 2012. Road Map Peningkatan Produktivitas

Ubi Kayu Tahun 2010-2014. Direktorat Jendral Tanaman Pangan,

Kementerian Pertanian, Jakarta.

Khatoon, Sakina., Sreerama, Y.N., Raghavendra, D., Bhattacharya,

Suvendu., Bhat, K.K. 2009. Properties of enzyme modified corn, rice

and tapioca starches. Food Research International 42: 14261433.

Koswara, S. 2009. Teknologi Modifikasi Pati. Ebook Pangan.

Le, Q., Lee, C., Kim, Y., Lee, S., Zhang, R., Withers, S. G., Kim, Y.,

dan Park, K. 2009. Amylolytically-Resistant Tapioca Starch Modified

By Combined Treatment Of Branching Enzyme And Maltogenic

Amylase. Carbohydrate Polimers. 75: 914.

Majzoobi, M., Rowe, A. J., Connock, M., Hill, S. E., dan Harding, S.

E. 2003. Partial Fractionation Of Wheat Starch Amylose And

Amylopectin Using Zonal Ultracentrifugation. Carbohydrate Polymers.

52: 269274.

Makmoon T.A., Foungfuchat, N. dan Jiratumnukul. 2013. Modified

Tapioca Starch As Rheology Modifier Inacrylic Dispersion System

Progessing Organic Coatings. 76: 959-962.

Omojola M.O., Manu M., Thomas S.A. (2011). Effect of Acid

Hydrolysis on The Physicochemical Properties of Cola Starch. African

Journal of Pure and Applied Chemistry Vol. 5(9): 307-315.

PalmaRodriguez, H. M., AgamaAcevedo, E., MendezMontealvo,

G., GonzalezSoto, R. A., VernonCarter, E. J., & BelloPrez, L. A.

2012. Effect of acid treatment on the physicochemical and structural

characteristics of starches from different botanical sources.

StarchStrke, 64: 115-125.

Pudjihastuti, Isti. 2010. Pengembangan Proses Inovatif Kombinasi

Reaksi Hidrolisis Asam Dan Reaksi Photokimia UV Untuk Produksi

Pati Termodifikasi Dari Tapioka. Magister Teknik Kimia, Fakultas

Teknik, Universitas Diponegoro. Semarang

Pudjihastuti, I., dan Sumardiono, S. 2011. Pengembangan Proses

Inovatif Kombinasi Reaksi Hidrolisis Asam Dan Reaksi Photokimia

UV Untuk Produksi Pati Termodifikasi Dari Tapioka. Prosiding

Seminar Nasional Teknik Kimia "Kejuangan". Yogyakarta.

Rajan, A., Sudha, J. D., dan Abraham, T. E. 2008. Enzymatic

Modification Of Cassava Starch By Fungal Lipase. Industrial Crops

And Products. 27: 5059.

Ren, G., Li, D., Wang, L., zkan, N., dan Mao, Z. 2010.

Morphological Properties And Thermoanalysis Of Micronized

Cassava Starch. Carbohydrate Polymers. 79: 101105.

Rickard, J.E., J.M.V. Blanshard, and M. Asaoka. 1992. Effects Of

Cultivar And Growth Season On The Gelatinization Properties Of

Cassava (Manihot Esculenta) Starch. J. Sci. Food Agric. 59: 5358.

Rukmi, W., dan Siwi, K. 2010. Studi Perubahan Sifat Fisik dan Kimia

Tepung Ubi Jalar Putih (Ipoema batatas Var Sukuh) sebagai Efek

Modifikasi Menggunakan Metode Heat Moisture Treatment.Teknologi

Hasil Pertanian, Universitas Brawijaya. Malang.

Sangseethong, K., Termvejsayanon, N., dan Sriroth, K. 2010.

Characterization Of Physicochemical Properties Of Hypochlorite- And

Peroxide-Oxidized Cassava Starches. Carbohydrate Polymers. 82:

446453.

Santayanon, R., dan Wootthikanokkhan, J. 2003. Modification Of

Cassava Starch By Using Propionic Anhydride And Properties Of The

Starch-Blended Polyester Polyurethane. Carbohydrate Polymers. 51:

1724.

Spada, J. C., Marczak, L. D. F., Tessaro, I. C., & Norea, C. P. Z.

2012. Microencapsulation of -carotene using native pinho starch,

modified pinho starch and gelatin by freeze-drying. International [1]

Journal of Food Science and Technology 47: 186-194.

Sumardiono, S., Riska, L., Pudjihastuti, I., dan Jos, Bakti. 2014. Effect

of Esterification on Cassava Starch: Physicochemical Properties and

Expansion Ability. Department of Chemical Engineering. University of

Diponegoro, Semarang.

Udomrati, S., dan Gohtani, S. 2014. Enzymatic Esterification Of

Tapioca Maltodextrin Fatty Acid Ester. Carbohydrate Polimers. 99:

379384.

Vatanasuchart, Nednapis, & Naivikul, O. 2003. Effects of Different UV

Irradiation on Properties of Cassava Starch and Biscuit Expansion.

Vatanasuchart, N., Naivikul, O., Charoenrein, S., dan Sriroth, K. 2005.

Molecular Properties Of Cassava Starch Modified With Different UV

Irradiations To Enhance Baking Expansion. Carbohydrate Polimers.

61: 8087.

[42]

[43]

Xie, F., Yu, L., Su, B., Liu, P., Wang, J., Liu, H., dan Chen, L. 2009.

Rheological

Properties

Of

Starches

With

Different

Amylose/Amylopectin Ratios. Journal of Cereal Science. 49: 371377.

Zhu, Fan. 2014. Composition, Structure, Physicochemical

Properties,And Modifications Of Cassava Starch. Carbohydrate

Polymers.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Kenwood Chef A901 - User ManualDocumento65 pagineKenwood Chef A901 - User Manualjaycobie92% (13)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- INSANITY Elite Nutrition PlanDocumento52 pagineINSANITY Elite Nutrition PlanBenny Castro100% (1)

- Corn Products Cook BookDocumento53 pagineCorn Products Cook Bookbsaracco1100% (5)

- 4 Bread Baking ChecklistsDocumento4 pagine4 Bread Baking ChecklistsCarol ToffanelliNessuna valutazione finora

- Bakery Project Start-Up Business Plan - PDF - Economic Growth - BreadsDocumento40 pagineBakery Project Start-Up Business Plan - PDF - Economic Growth - BreadsTaaha Acmad86% (7)

- Bifinett KH 1170 (LIDL)Documento11 pagineBifinett KH 1170 (LIDL)Rui CruzNessuna valutazione finora

- Exercises On Mix Material N Labor VarianceDocumento3 pagineExercises On Mix Material N Labor Variancewww.harinihariniNessuna valutazione finora

- Ofe Nsala SoupDocumento3 pagineOfe Nsala SoupBlessing AfolabiNessuna valutazione finora

- Culinary Courses AND Recipes: By: David VillartaDocumento16 pagineCulinary Courses AND Recipes: By: David VillartaDavid VillartaNessuna valutazione finora

- CHAPTER 1 BCPC As BreadDocumento11 pagineCHAPTER 1 BCPC As Breadteachs07Nessuna valutazione finora

- Nutritional Quality of Bread From Mixture of Arrowroot Flour (Marantha Arundinacea L.) and Wheat FlourDocumento4 pagineNutritional Quality of Bread From Mixture of Arrowroot Flour (Marantha Arundinacea L.) and Wheat FlourDanaNessuna valutazione finora

- 2012 - Grille Cheese Academy Recipe-Book PDFDocumento24 pagine2012 - Grille Cheese Academy Recipe-Book PDFFrédyWehnerNessuna valutazione finora

- Acid Alkaline Chart PDFDocumento6 pagineAcid Alkaline Chart PDFCentaur Archer100% (1)

- Ultra Fluffy Milk Bread RollsDocumento3 pagineUltra Fluffy Milk Bread RollswaNessuna valutazione finora

- Clase 3-Countable - UncountableDocumento30 pagineClase 3-Countable - UncountableMoises LópezNessuna valutazione finora

- Bakare Et Al, 2016 - Rheological, Baking, and Sensory Properties of Composite Bread Dough With Breadfruit and Wheat FlourDocumento15 pagineBakare Et Al, 2016 - Rheological, Baking, and Sensory Properties of Composite Bread Dough With Breadfruit and Wheat FlourArinamelia PsNessuna valutazione finora

- Pizza RecipeDocumento3 paginePizza RecipesrvanderplasNessuna valutazione finora

- BPP Self CheckDocumento6 pagineBPP Self CheckHestia HDNessuna valutazione finora

- Excerpt and Recipe From Classic Sourdoughs, RevisedDocumento18 pagineExcerpt and Recipe From Classic Sourdoughs, RevisedThe Recipe Club61% (18)

- Homemade Romany CreamsDocumento3 pagineHomemade Romany CreamsSamsiariah AliyasNessuna valutazione finora

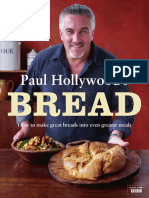

- Paul Hollywood's Bread Episode 1Documento16 paginePaul Hollywood's Bread Episode 1Istrebitelj XNessuna valutazione finora

- Easy Cheesecake RecipeDocumento3 pagineEasy Cheesecake RecipeJudi Ann MagsacayNessuna valutazione finora

- Traditional Foods and Beverages in Eastern Tigray of EthiopiaDocumento12 pagineTraditional Foods and Beverages in Eastern Tigray of EthiopiaDevNessuna valutazione finora

- Rec 04 Describing DishesDocumento4 pagineRec 04 Describing DisheskamelingNessuna valutazione finora

- Project Report On Flour Mill Plant Whole Wheat Flour Chakki AttaDocumento5 pagineProject Report On Flour Mill Plant Whole Wheat Flour Chakki AttaAshutosh SinghNessuna valutazione finora

- Mugen Bread Maker RecipeeDocumento22 pagineMugen Bread Maker RecipeeIr FaizalNessuna valutazione finora

- Fruit Bread FS-1Documento68 pagineFruit Bread FS-1Princes Ann MarcianoNessuna valutazione finora

- Galletas de MasecaDocumento8 pagineGalletas de MasecaCSCNessuna valutazione finora

- Aishwarya Mahajan 11Documento6 pagineAishwarya Mahajan 11fb.anikamehraNessuna valutazione finora

- Lesson 3-Past Continuous-TeacherDocumento20 pagineLesson 3-Past Continuous-Teacheryasuri del rosario Ramirez AcuñaNessuna valutazione finora