Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Aluminum Chloride Production

Caricato da

AlexCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Aluminum Chloride Production

Caricato da

AlexCopyright:

Formati disponibili

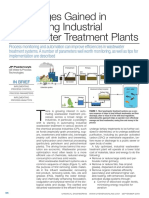

Technology Profile

Aluminum Chloride Production

By Intratec Solutions

luminum chloride (AlCl3) is

among the most widely used

Lewis acids in industry, and is

also one of the most powerful. The compound is employed as a

catalyst in the manufacture of a multitude of organic chemicals produced

by several different reaction mechanisms, including isomerization, alkylation and polymerization.

The main applications of AlCl3 are

in the production of ethylbenzene and

dyes. AlCl3 catalyzes the ethylation of

benzene with ethylene to yield ethylbenzene, which, in turn, is used in the

production of styrene. In the dyestuffs

industry, AlCl3 is used as a catalyst in

the production of anthraquinone and

its derivatives, as well as in the production of pigments.

The process

The following paragraphs describe a

conventional process for anhydrous

AlCl3 production from aluminum metal and chlorine. Figure 1 presents a

simplified flow diagram of the process.

Reaction. The reaction takes place in

ceramic-lined, tube-shaped reactors

containing molten aluminum. Chlorine gas is injected below the surface

of the molten aluminum pool, leading

to the formation of aluminum chloride vapor in a highly exothermic and

practically instantaneous reaction.

The reaction occurs at 670850C.

The temperature is maintained in this

range by controlling the feedrates of

chlorine and aluminum and by cooling

the reactor walls with water.

The AlCl3 vapor from the reactors is

fed to air-cooled condensers, which are

vertical cylinders with conical bottoms.

Aluminum,

chlorine

Metal

chlorination

Chlorine, carbon

monoxide,

alumina

Catalytic

chlorination

Chlorination

Aluminum,

hydrogen chloride

n Raw material n Pathway n Main product

FIGURE 2. Several possible production pathways exist for AlCl3

As the AlCl3 vapor comes into contact

with the condenser walls, it loses its

heat of sublimation, and is deposited

on the walls. The deposited solid AlCl3

is withdrawn from the condenser walls

at regular intervals, and subsequently

conveyed to holding silos.

Crushing and sizing. AlCl3 crystals

from the holding silos are crushed and

sized by sieving under a dry-air atmosphere. After sizing, the AlCl3 product

is obtained.

Scrubber. The condensing, crushing

and sizing operations, as well as storage facilities, are designed to avoid

the entrance of moist atmospheric air.

To achieve this, a vent system linked

to those pieces of equipment directs

the offgas (containing unreacted chlorine and uncondensed gases) to a

caustic scrubber. The scrubbed gas is

vented to the atmosphere, while the

scrubbers bottom stream is treated

as wastewater.

AlCl3 pathways

Initially, aluminum chloride was produced on a commercial scale from

calcined bauxite and coke. New routes

have emerged, however, that present

advantages over the bauxite process.

The advantages are derived from a re-

duced occurrence of reactor corrosion

and from the production of a higherpurity product. Currently, the most important raw materials for AlCl3 production are either aluminum metal or pure

aluminum oxide. Figure 2 presents different pathways for AlCl3 production.

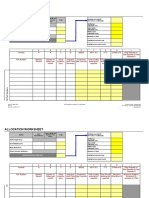

Economic performance

The total capital investment estimated

to construct a plant based on the process in Figure 1 with capacity to produce 5,000 metric ton per year of AlCl3

in the U.S. is about $8 million (data

from the second quarter of 2013). This

capital investment includes fixed capital, working capital and additional capital requirements.

This column is based on Aluminum Chloride Production Process

Cost Analysis, a report published

by Intratec. It can be found at: www.

intratec.us/analysis/aluminum-chloride-production-cost.

n

Edited by Scott Jenkins

Editors note: The content for this column is supplied by Intratec Solutions LLC (Houston; www.intratec.us) and edited

by Chemical Engineering. The analyses and models presented

are prepared on the basis of publicly available and nonconfidential information. The content represents the opinions

of Intratec only. More information about the methodology for

preparing analysis can be found, along with terms of use, at

www.intratec.us/che.

Caustic soda

make-up

Wastewater

1. Reactor

2. Condenser

3. Holding silo

4. Crusher

5. Sizing equipment

6. Caustic scrubber

7. Cooling tower

CW = Cooling water

2

3

CW

Bauxite, coke,

chlorine

Anhydrous

aluminum chloride

Offgas

Aluminum

scrap

Chlorination

CW

Aluminum

chloride

Chlorine

FIGURE 1. This figure shows a conventional process for the production of AlCl3 from aluminum and chlorine

CHEMICAL ENGINEERING

WWW.CHEMENGONLINE.COM

OCTOBER 2016

41

Potrebbero piacerti anche

- (GUNSMITHING) The .22 PistolDocumento18 pagine(GUNSMITHING) The .22 PistolMago Invisivel88% (25)

- The PA Bible Addn 03 Microphones PDFDocumento4 pagineThe PA Bible Addn 03 Microphones PDFjosiasns5257100% (1)

- Apollo Experience Report Electronic Systems Test Program Accomplishments and ResultsDocumento70 pagineApollo Experience Report Electronic Systems Test Program Accomplishments and ResultsBob AndrepontNessuna valutazione finora

- AGA Purging.2001 PDFDocumento157 pagineAGA Purging.2001 PDFLeDzung100% (1)

- Supplier Run Rate CalculatorDocumento9 pagineSupplier Run Rate CalculatordcevipinNessuna valutazione finora

- Bernette Ramirez Mariano Bernette Ramirez MarianoDocumento1 paginaBernette Ramirez Mariano Bernette Ramirez Marianomia palacioNessuna valutazione finora

- Recovery of Metals From Aluminum Dross and Saltcake: J.Y. Hwang, X. Huang, and Z. XuDocumento16 pagineRecovery of Metals From Aluminum Dross and Saltcake: J.Y. Hwang, X. Huang, and Z. XuSatyaranjan SahuNessuna valutazione finora

- Onsite Nitrogen Generation Via PSA TechnologyDocumento4 pagineOnsite Nitrogen Generation Via PSA TechnologyAlexNessuna valutazione finora

- Project 2 Phthalic AnhydrideDocumento14 pagineProject 2 Phthalic Anhydridel7ani100% (2)

- Propane To Acrylic AcidDocumento231 paginePropane To Acrylic AcidCluisantony Jayco DizeNessuna valutazione finora

- Measuring Dust and Fines in Polymer PelletsDocumento6 pagineMeasuring Dust and Fines in Polymer PelletsAlexNessuna valutazione finora

- Plant Functional Safety Requires IT SecurityDocumento5 paginePlant Functional Safety Requires IT SecurityAlexNessuna valutazione finora

- Plant Functional Safety Requires IT SecurityDocumento5 paginePlant Functional Safety Requires IT SecurityAlexNessuna valutazione finora

- Aluminum Chloride ProductionDocumento1 paginaAluminum Chloride ProductionAlexNessuna valutazione finora

- Sodium Bicarbonate Carbon CaptureDocumento15 pagineSodium Bicarbonate Carbon CaptureDimitriNessuna valutazione finora

- AODD Pumps in Chemical ProcessesDocumento7 pagineAODD Pumps in Chemical ProcessesAlexNessuna valutazione finora

- 2017CHE008 DetailedProcessDescription1Documento17 pagine2017CHE008 DetailedProcessDescription1Xi Liinett AqkoNessuna valutazione finora

- Advances in Cryogenic Air SeparationDocumento25 pagineAdvances in Cryogenic Air SeparationTGrey027Nessuna valutazione finora

- Chlorine Production From NaCl (Chlor-Alkali)Documento1 paginaChlorine Production From NaCl (Chlor-Alkali)Alex100% (1)

- Chlorine Production From NaCl (Chlor-Alkali)Documento1 paginaChlorine Production From NaCl (Chlor-Alkali)Alex100% (1)

- Phenol PlantDocumento33 paginePhenol PlantrakeshNessuna valutazione finora

- HCL ScrubberDocumento2 pagineHCL Scrubbersundhar100% (2)

- LLPDE Production Using A Gas-Phase ProcessDocumento1 paginaLLPDE Production Using A Gas-Phase ProcessAlexNessuna valutazione finora

- Chlor Alkali TechnologyDocumento19 pagineChlor Alkali TechnologyRamakrishna ReddyNessuna valutazione finora

- Internship ReportDocumento39 pagineInternship ReportNaumanTahir100% (1)

- UreaDocumento18 pagineUreaDian Anggraini PurbaNessuna valutazione finora

- Class 2 Plant DesignDocumento73 pagineClass 2 Plant DesignPratanu Kayet100% (1)

- Final Project Updated 2Documento80 pagineFinal Project Updated 2Abdulwahid SultanNessuna valutazione finora

- The Benefits of Two-Stage DryingDocumento3 pagineThe Benefits of Two-Stage DryingAlexNessuna valutazione finora

- The Benefits of Two-Stage DryingDocumento3 pagineThe Benefits of Two-Stage DryingAlexNessuna valutazione finora

- RISC Vs CISCDocumento13 pagineRISC Vs CISCBehin SamNessuna valutazione finora

- Preliminary Design Chemical Plant LAB PDFDocumento9 paginePreliminary Design Chemical Plant LAB PDFgeorge cabreraNessuna valutazione finora

- Control of Evaporator in The Production of UreaDocumento15 pagineControl of Evaporator in The Production of Ureatariq fareedNessuna valutazione finora

- Project 4 Acrylic AcidDocumento16 pagineProject 4 Acrylic AcidN193746100% (3)

- Solvent Extraction of Palladium From Chloride Media by TBPDocumento6 pagineSolvent Extraction of Palladium From Chloride Media by TBPMoreno MarcatiNessuna valutazione finora

- Absorption of Formaldehyde in WaterDocumento135 pagineAbsorption of Formaldehyde in WaterBer GuzNessuna valutazione finora

- Vortex Breakers in Practice - 201606Documento2 pagineVortex Breakers in Practice - 201606JQuest229100% (4)

- IoT - Building Blocks, Applications and ChallengesDocumento60 pagineIoT - Building Blocks, Applications and ChallengesRamanamurthy Saripalli0% (1)

- BEP Pages 5 16Documento12 pagineBEP Pages 5 16Amy LauNessuna valutazione finora

- Considerations For Estimating The Costs of Pilot-Scale FacilitiesDocumento9 pagineConsiderations For Estimating The Costs of Pilot-Scale FacilitiesAlexNessuna valutazione finora

- Ultrasonic Atomizing Nozzle SystemsDocumento40 pagineUltrasonic Atomizing Nozzle SystemsAnonymous H8hysGxA100% (1)

- Project Report On Aluminium Chloride SolutionDocumento9 pagineProject Report On Aluminium Chloride SolutionEIRI Board of Consultants and PublishersNessuna valutazione finora

- Park Et Al, 1997 - Production of Poly (Aluminum Chloride) and Sodium Silicate From ClayDocumento5 paginePark Et Al, 1997 - Production of Poly (Aluminum Chloride) and Sodium Silicate From ClayianphilanderNessuna valutazione finora

- Note of Aluminium ChlorideDocumento6 pagineNote of Aluminium ChlorideashwinikrishnaNessuna valutazione finora

- High Purity AluminaDocumento13 pagineHigh Purity AluminaNilay JoshiNessuna valutazione finora

- Process Flow Diagram New PDFDocumento5 pagineProcess Flow Diagram New PDFdinurj100% (1)

- Crystallization Equipment (Crystallizers) : Swenson-Walker CrystallizerDocumento5 pagineCrystallization Equipment (Crystallizers) : Swenson-Walker CrystallizerJustin Paul CongeNessuna valutazione finora

- Chemicals Zetag MSDS Powder Magnafloc 1011 - 0810Documento6 pagineChemicals Zetag MSDS Powder Magnafloc 1011 - 0810PromagEnviro.comNessuna valutazione finora

- Internship ReportDocumento31 pagineInternship ReportKaran KaushalNessuna valutazione finora

- Design of A Plant To Produce Sodium Hydroxide,, L' .Documento6 pagineDesign of A Plant To Produce Sodium Hydroxide,, L' .KaizerNessuna valutazione finora

- CAL As Is Study Production Process 1.2.1Documento12 pagineCAL As Is Study Production Process 1.2.1Tharmaraj MuralikrishnanNessuna valutazione finora

- Production of 250 MTPD Sodium HydroxideDocumento18 pagineProduction of 250 MTPD Sodium HydroxideAlia KhanNessuna valutazione finora

- Om AcetaldehydeDocumento7 pagineOm AcetaldehydeAlejandro De la Rubia MarcosNessuna valutazione finora

- 5-Amination by ReductionDocumento21 pagine5-Amination by ReductionM Fahad Shahid Ali100% (1)

- Material BalanceDocumento6 pagineMaterial BalanceMehran Rasheed GorayaNessuna valutazione finora

- Production of Acrylonitrile by Ammoxidation of PropyleneDocumento33 pagineProduction of Acrylonitrile by Ammoxidation of PropyleneJ José B VelasquezNessuna valutazione finora

- Project Report Draft On "Isopropyl Alcohol" BY: Jariwala Divyangkumar Rajeshkumar Exam No-701022 Roll No:-821Documento22 pagineProject Report Draft On "Isopropyl Alcohol" BY: Jariwala Divyangkumar Rajeshkumar Exam No-701022 Roll No:-821Arpit PatelNessuna valutazione finora

- Acetaldehyde Energy 2520 BalanceDocumento10 pagineAcetaldehyde Energy 2520 Balanceapi-3714811100% (1)

- N-Butane To Maleic AnhydrideDocumento6 pagineN-Butane To Maleic AnhydrideNomeacuerdo Yo MismoNessuna valutazione finora

- Industrial Training 1Documento32 pagineIndustrial Training 1KumarShiveshNessuna valutazione finora

- IntroductionDocumento3 pagineIntroductionMohsen MohammadNessuna valutazione finora

- Reactor Design 1Documento8 pagineReactor Design 1Daneyal BabarNessuna valutazione finora

- Kinetics of The Oxidation of Ethylene by Aqueous Palladium (I1) ChlorideDocumento5 pagineKinetics of The Oxidation of Ethylene by Aqueous Palladium (I1) ChlorideAbdullah Yildirim100% (1)

- Industrial Repor1Documento33 pagineIndustrial Repor1Truly SelenatorNessuna valutazione finora

- Energy Transport Notes 2Documento102 pagineEnergy Transport Notes 2Faisal MumtazNessuna valutazione finora

- 0203 2 TocDocumento7 pagine0203 2 Tocعمر الاسمريNessuna valutazione finora

- Cost Estimation - Acetone Plant 1 PDFDocumento2 pagineCost Estimation - Acetone Plant 1 PDFDhananjay pathareNessuna valutazione finora

- Production of Oxalic Acid Term PaperDocumento16 pagineProduction of Oxalic Acid Term PaperSanket SutharNessuna valutazione finora

- Project Report Mitesh & GRPDocumento35 pagineProject Report Mitesh & GRPDishantNessuna valutazione finora

- Seminar Report On Fusion Power PlantDocumento33 pagineSeminar Report On Fusion Power Plantnavin shukla100% (1)

- Shantanu DasDocumento10 pagineShantanu DasarunkdevassyNessuna valutazione finora

- Li 2017Documento8 pagineLi 2017zibaNessuna valutazione finora

- Aspirin PDFDocumento3 pagineAspirin PDFRayan FuadNessuna valutazione finora

- Arl Internship ReportDocumento19 pagineArl Internship ReportChaudhry RashidNessuna valutazione finora

- EDTA Titration CalculationsDocumento2 pagineEDTA Titration CalculationsMuhammed IslahuddinNessuna valutazione finora

- Dee CDocumento15 pagineDee CAnderson David ValenciaNessuna valutazione finora

- 2012GEPESZET Dynamic Mass Balance For AaiDocumento12 pagine2012GEPESZET Dynamic Mass Balance For AaiLukas DionNessuna valutazione finora

- 11a. Chlor-AlkaliDocumento4 pagine11a. Chlor-Alkalimuhammad omerNessuna valutazione finora

- Hazards of Chlorine: Safety ReviewDocumento4 pagineHazards of Chlorine: Safety ReviewTushar Kanti JhaNessuna valutazione finora

- Glossary: Appendix IDocumento4 pagineGlossary: Appendix IEd MartiNessuna valutazione finora

- Alum ExptDocumento10 pagineAlum ExptRivy Valen PabesakNessuna valutazione finora

- CHE EP - Field Troubleshoot 101 and How To Get The Job Done - June 2016Documento7 pagineCHE EP - Field Troubleshoot 101 and How To Get The Job Done - June 2016John UrdanetaNessuna valutazione finora

- An Up-Close Look at Electropositive FiltrationDocumento8 pagineAn Up-Close Look at Electropositive FiltrationAlex100% (1)

- Beyond Gravity - Centrifugal Separations in CPI OperationsDocumento8 pagineBeyond Gravity - Centrifugal Separations in CPI OperationsAlexNessuna valutazione finora

- Cybersecurity Defense For Industrial Process-Control SystemsDocumento6 pagineCybersecurity Defense For Industrial Process-Control SystemsAlexNessuna valutazione finora

- Microreactors - Lessons Learned From Industrial ApplicationsDocumento9 pagineMicroreactors - Lessons Learned From Industrial ApplicationsAlexNessuna valutazione finora

- Air-Pollution Control - Assessing The OptionsDocumento9 pagineAir-Pollution Control - Assessing The OptionsAlexNessuna valutazione finora

- Challenges of Handling Filamentous and Viscous Wastewater SludgeDocumento7 pagineChallenges of Handling Filamentous and Viscous Wastewater SludgeAlexNessuna valutazione finora

- Challenges of Handling Filamentous and Viscous Wastewater SludgeDocumento7 pagineChallenges of Handling Filamentous and Viscous Wastewater SludgeAlexNessuna valutazione finora

- Managing SIS Process Measurement Risk and CostDocumento8 pagineManaging SIS Process Measurement Risk and CostAlexNessuna valutazione finora

- Design of Experiments (DoE) - How To Handle Hard-To-Change Factors Using A Split PlotDocumento4 pagineDesign of Experiments (DoE) - How To Handle Hard-To-Change Factors Using A Split PlotAlex100% (1)

- Coupler Technologies For Secure Chemical HandlingDocumento6 pagineCoupler Technologies For Secure Chemical HandlingAlexNessuna valutazione finora

- Advantages Gained in Automating Industrial Wastewater Treatment PlantsDocumento7 pagineAdvantages Gained in Automating Industrial Wastewater Treatment PlantsAlexNessuna valutazione finora

- Removal of Air From Water Lines by Hydraulic Means (P.E. Wisner) (1975)Documento16 pagineRemoval of Air From Water Lines by Hydraulic Means (P.E. Wisner) (1975)Alex0% (1)

- Advantages Gained in Automating Industrial Wastewater Treatment PlantsDocumento7 pagineAdvantages Gained in Automating Industrial Wastewater Treatment PlantsAlexNessuna valutazione finora

- Effect of Pressurization and Expulsion of Entrapped Air in PipelinesDocumento167 pagineEffect of Pressurization and Expulsion of Entrapped Air in PipelinesAlexNessuna valutazione finora

- Agglomeration ProcessesDocumento1 paginaAgglomeration ProcessesAlex100% (1)

- On Gas Transport in Downward Slopes of Sewerage Mains PDFDocumento11 pagineOn Gas Transport in Downward Slopes of Sewerage Mains PDFAlexNessuna valutazione finora

- Resistor DatasheetDocumento10 pagineResistor DatasheetEndradno KurniaNessuna valutazione finora

- Spirex": Onepiece Spiral Flexible CouplingDocumento1 paginaSpirex": Onepiece Spiral Flexible CouplingHazim HazimNessuna valutazione finora

- PR RTXDocumento27 paginePR RTXletanbaospkt06100% (1)

- AMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Documento5 pagineAMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Andre SanarNessuna valutazione finora

- Architecture Concerns of TST and NATO TST ToolDocumento9 pagineArchitecture Concerns of TST and NATO TST Tooldorupara718747Nessuna valutazione finora

- Module 3 Density Altitude ExperimentDocumento3 pagineModule 3 Density Altitude ExperimentIvan100% (1)

- Hepworth Clay DoPs - Full SetDocumento54 pagineHepworth Clay DoPs - Full SetAnonymous XYAPaxjbYNessuna valutazione finora

- MH16 Series ROOFTOP AC Manual REV 2013Documento19 pagineMH16 Series ROOFTOP AC Manual REV 2013caleb perezNessuna valutazione finora

- Survey MODULE 4Documento16 pagineSurvey MODULE 4InsurrectionNessuna valutazione finora

- Harmonic Oscillations of Spiral Springs - Springs Linked in Parallel and SeriesDocumento5 pagineHarmonic Oscillations of Spiral Springs - Springs Linked in Parallel and SeriesJose GalvanNessuna valutazione finora

- Un 2 Terrazzo FlooringDocumento6 pagineUn 2 Terrazzo FlooringRNessuna valutazione finora

- GAPS Guidelines: Deep Fat FryersDocumento4 pagineGAPS Guidelines: Deep Fat FryersAsad KhanNessuna valutazione finora

- PSD Installation Manual Moore IndustriesDocumento16 paginePSD Installation Manual Moore IndustriesnohjadNessuna valutazione finora

- Poloyagan Integrated School Monitoring Tool On Aip ImplementationDocumento3 paginePoloyagan Integrated School Monitoring Tool On Aip ImplementationLALAINE BONILLANessuna valutazione finora

- Potsdam Village Police Dept. Blotter April 12, 2018Documento2 paginePotsdam Village Police Dept. Blotter April 12, 2018NewzjunkyNessuna valutazione finora

- Dry ContactsDocumento2 pagineDry ContactsDiwakar MishraNessuna valutazione finora

- Nust Entrance TestDocumento16 pagineNust Entrance TestShawn Parker80% (30)

- AAAC Guideline For Apartment and Townhouse Acoustic Rating 2010Documento10 pagineAAAC Guideline For Apartment and Townhouse Acoustic Rating 2010Benjamín AlainNessuna valutazione finora

- Eee25 2018syllabusDocumento4 pagineEee25 2018syllabusEmman Joshua BustoNessuna valutazione finora

- Types of Processors and RAM'sDocumento26 pagineTypes of Processors and RAM'sSneha NairNessuna valutazione finora

- MMPB 730 RerollDocumento4 pagineMMPB 730 RerollLuis Padilla SandovalNessuna valutazione finora