Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Kempinski Hilti Rc-O

Caricato da

sobhiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Kempinski Hilti Rc-O

Caricato da

sobhiCopyright:

Formati disponibili

Profis Anchor 2.7.

www.hilti.us

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

1

Kempinski

10/18/2016

Specifier's comments:

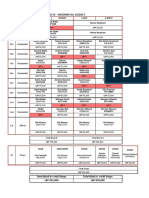

1 Input data

Anchor type and diameter:

HIT-RE 500 V3 + HIS-N B7 1/2

Effective embedment depth:

hef,act = 12.5 cm, hnom = 12.5 cm

Material:

ASTM A 193 Grade B7

Evaluation Service Report:

ESR-3814

Issued I Valid:

6/1/2016 | 1/1/2017

Proof:

Design method ACI 318-08 / Chem

Stand-off installation:

eb = 0.0 cm (no stand-off); t = 0.6 cm

Anchor plate:

lx x ly x t = 16.0 cm x 27.0 cm x 0.6 cm; (Recommended plate thickness: not calculated

Profile:

Square HSS (AISC); (L x W x T) = 15.2 cm x 15.2 cm x 0.3 cm

Base material:

cracked concrete, 2500, fc' = 2466 psi; h = 1066.8 cm, Temp. short/long: 0/0 C

Installation:

hammer drilled hole, Installation condition: Dry

Reinforcement:

tension: condition B, shear: condition B; no supplemental splitting reinforcement present

Seismic loads (cat. C, D, E, or F)

edge reinforcement: none or < No. 4 bar

no

Geometry [cm] & Loading [daN, daNm]

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.7.1

www.hilti.us

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

2

Kempinski

10/18/2016

2 Load case/Resulting anchor forces

Load case: Design loads

Anchor reactions [daN]

Tension force: (+Tension, -Compression)

Anchor

Tension force

Shear force

Shear force x

1

0.0

750.0

0.0

2

0.0

750.0

0.0

max. concrete compressive strain:

- []

max. concrete compressive stress:

- [N/mm2]

resulting tension force in (x/y)=(0.0/0.0):

0.0 [daN]

resulting compression force in (x/y)=(0.0/0.0): 0.0 [daN]

Shear force y

750.0

750.0

3 Tension load

Capacity f Nn [daN] Utilization bN = Nua/f Nn

N/A

N/A

Steel Strength*

Load Nua [daN]

N/A

Bond Strength**

N/A

N/A

N/A

N/A

Sustained Tension Load Bond Strength*

N/A

N/A

N/A

N/A

Concrete Breakout Strength**

N/A

N/A

N/A

N/A

* anchor having the highest loading

**anchor group (anchors in tension)

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Status

N/A

Profis Anchor 2.7.1

www.hilti.us

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

3

Kempinski

10/18/2016

4 Shear load

Capacity f Vn [daN] Utilization bV = Vua/f Vn

2841.1

27

Load Vua [daN]

750.0

Steel Strength*

Steel failure (with lever arm)*

Pryout Strength (Concrete Breakout

Strength controls)**

N/A

N/A

N/A

N/A

1500.0

8953.0

17

OK

N/A

N/A

N/A

N/A

Concrete edge failure in direction **

* anchor having the highest loading

Status

OK

**anchor group (relevant anchors)

4.1 Steel Strength

Vsa

= ESR value

f Vsteel Vua

refer to ICC-ES ESR-3814

ACI 318-08 Eq. (D-2)

Variables

Ase,V [cm2]

0.92

futa [N/mm2]

827.64

Calculations

Vsa [daN]

4735.1

Results

f steel

0.600

Vsa [daN]

4735.1

f Vsa [daN]

2841.1

Vua [daN]

750.0

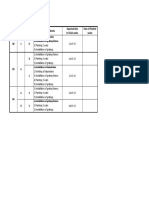

4.2 Pryout Strength (Concrete Breakout Strength controls)

Vcpg

= kcp

[(AA ) y

Nc

Nc0

ec,N

y ed,N y c,N y cp,N Nb

ACI 318-08 Eq. (D-31)

f Vcpg Vua

ANc

see ACI 318-08, Part D.5.2.1, Fig. RD.5.2.1(b)

ANc0 = 9 h2ef

1

2 e'N 1.0

y ec,N =

1+

3 hef

ca,min

1.0

y ed,N = 0.7 + 0.3

1.5hef

ca,min 1.5hef

,

1.0

y cp,N = MAX

cac

cac

1.5

'

Nb

= kc l fc hef

)

)

ACI 318-08 Eq. (D-2)

ACI 318-08 Eq. (D-6)

ACI 318-08 Eq. (D-9)

ACI 318-08 Eq. (D-11)

ACI 318-08 Eq. (D-13)

ACI 318-08 Eq. (D-7)

Variables

kcp

2

hef [cm]

12.5

ec1,N [cm]

0.0

ec2,N [cm]

0.0

ca,min [cm]

y c,N

1.000

cac [cm]

16.7

kc

17

l

1

f'c [psi]

2466

ANc0 [cm2]

1406.25

y ec1,N

1.000

y ec2,N

1.000

y ed,N

1.000

f concrete

0.700

f Vcpg [daN]

8953.0

Vua [daN]

1500.0

Calculations

ANc [cm2]

2193.75

Results

Vcpg [daN]

12790.0

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

y cp,N

1.000

Nb [daN]

4099.3

Profis Anchor 2.7.1

www.hilti.us

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

4

Kempinski

10/18/2016

5 Warnings

Load re-distributions on the anchors due to elastic deformations of the anchor plate are not considered. The anchor plate is assumed to be

sufficiently stiff, in order not to be deformed when subjected to the loading!

Input data and results must be checked for agreement with the

existing conditions and for plausibility!

Condition A applies when supplementary reinforcement is used. The factor is increased for non-steel Design Strengths except Pullout

Strength and Pryout strength. Condition B applies when supplementary reinforcement is not used and for Pullout Strength and Pryout

Strength. Refer to your local standard.

Design Strengths of adhesive anchor systems are influenced by the cleaning method. Refer to the INSTRUCTIONS FOR USE given in the

Evaluation Service Report for cleaning and installation instructions

The ACI 318-08 version of the software does not account for adhesive anchor special design provisions corresponding to overhead

applications.

Checking the transfer of loads into the base material and the shear resistance are required in accordance with ACI 318 or the relevant

standard!

Fastening meets the design criteria!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.7.1

www.hilti.us

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

5

Kempinski

Page:

Project:

Sub-Project I Pos. No.:

Date:

10/18/2016

6 Installation data

Anchor plate, steel: Anchor type and diameter: HIT-RE 500 V3 + HIS-N B7 1/2

Profile: Square HSS (AISC); 15.2 x 15.2 x 0.3 cm

Installation torque: 4.1 daNm

Hole diameter in the fixture: df = 1.5 cm

Hole diameter in the base material: 2.2 cm

Plate thickness (input): 0.6 cm

Hole depth in the base material: 12.5 cm

Recommended plate thickness: not calculated

Minimum thickness of the base material: 17.0 cm

Drilling method: Hammer drilled

Cleaning: Compressed air cleaning of the drilled hole according to instructions for use is required

6.1 Recommended accessories

Drilling

Suitable Rotary Hammer

Properly sized drill bit

Cleaning

Compressed air with required

accessories to blow from the bottom of

the hole

Proper diameter wire brush

y

8.0

3.0

8.0

Setting

Dispenser including cassette and mixer

Torque wrench

21.0

13.5

13.5

3.0

8.0

8.0

Coordinates Anchor cm

Anchor

1

2

x

0.0

0.0

y

-10.5

10.5

c-x

-

c+x

-

c-y

-

c+y

-

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.7.1

www.hilti.us

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

6

Kempinski

10/18/2016

7 Remarks; Your Cooperation Duties

Any and all information and data contained in the Software concern solely the use of Hilti products and are based on the principles, formulas

and security regulations in accordance with Hilti's technical directions and operating, mounting and assembly instructions, etc., that must be

strictly complied with by the user. All figures contained therein are average figures, and therefore use-specific tests are to be conducted

prior to using the relevant Hilti product. The results of the calculations carried out by means of the Software are based essentially on the

data you put in. Therefore, you bear the sole responsibility for the absence of errors, the completeness and the relevance of the data to be

put in by you. Moreover, you bear sole responsibility for having the results of the calculation checked and cleared by an expert, particularly

with regard to compliance with applicable norms and permits, prior to using them for your specific facility. The Software serves only as an

aid to interpret norms and permits without any guarantee as to the absence of errors, the correctness and the relevance of the results or

suitability for a specific application.

You must take all necessary and reasonable steps to prevent or limit damage caused by the Software. In particular, you must arrange for

the regular backup of programs and data and, if applicable, carry out the updates of the Software offered by Hilti on a regular basis. If you do

not use the AutoUpdate function of the Software, you must ensure that you are using the current and thus up-to-date version of the Software

in each case by carrying out manual updates via the Hilti Website. Hilti will not be liable for consequences, such as the recovery of lost or

damaged data or programs, arising from a culpable breach of duty by you.

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Potrebbero piacerti anche

- Machine RoomDocumento6 pagineMachine RoomRonnie De Joya AguirreNessuna valutazione finora

- SAMPLE HILTI SolutionDocumento6 pagineSAMPLE HILTI SolutionJester AbucayNessuna valutazione finora

- Canopy M16 HIT-RE500Documento5 pagineCanopy M16 HIT-RE500marchus09Nessuna valutazione finora

- 1 Input Data: Profis Anchor 2.5.2Documento5 pagine1 Input Data: Profis Anchor 2.5.2jasekan.dcNessuna valutazione finora

- Connection d01 1Documento6 pagineConnection d01 1Win ThanNessuna valutazione finora

- 290mm Thick Slab and 540mm EcenDocumento6 pagine290mm Thick Slab and 540mm EcenihpeterNessuna valutazione finora

- 1 Input Data: WWW - HiltiDocumento5 pagine1 Input Data: WWW - HiltiCibotaru MihaiNessuna valutazione finora

- H 200mm Thick Slab - Pa2Documento6 pagineH 200mm Thick Slab - Pa2ihpeterNessuna valutazione finora

- 1 Input Data: WWW - Hilti.inDocumento5 pagine1 Input Data: WWW - Hilti.inpudumaiNessuna valutazione finora

- Rowad Debugging MachineDocumento6 pagineRowad Debugging MachineRonnie De Joya AguirreNessuna valutazione finora

- 1 Input Data: Profis Anchor 2.2.4Documento6 pagine1 Input Data: Profis Anchor 2.2.4Safiueddin A. SafiueddinNessuna valutazione finora

- PROFIS Anchor 2.2.6: WWW - Hilti.inDocumento6 paginePROFIS Anchor 2.2.6: WWW - Hilti.inmeetvinayak2007Nessuna valutazione finora

- Beam End Connection ReportDocumento6 pagineBeam End Connection ReportHibri HalimNessuna valutazione finora

- Hilti AnchorDocumento6 pagineHilti AnchorantonioNessuna valutazione finora

- 250x16 Shs Column Base - Pa2123Documento5 pagine250x16 Shs Column Base - Pa2123ihpeterNessuna valutazione finora

- Anchor Bolt PDFDocumento7 pagineAnchor Bolt PDFRonnie Albert MonteroNessuna valutazione finora

- Pipe Rack Hilti Bolt CalculationsDocumento6 paginePipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVNessuna valutazione finora

- 1 Input Data: Profis Anchor 2.6.6Documento6 pagine1 Input Data: Profis Anchor 2.6.6Collin NguNessuna valutazione finora

- 1 Input Data: WWW - Hilti.co - UkDocumento6 pagine1 Input Data: WWW - Hilti.co - UkihpeterNessuna valutazione finora

- Hilti Connection ReportDocumento7 pagineHilti Connection ReportFrancisco BonillaNessuna valutazione finora

- 1 Input Data: Profis Anchor 2.6.0Documento2 pagine1 Input Data: Profis Anchor 2.6.0Collin NguNessuna valutazione finora

- 1 Input Data: Profis Anchor 2.4.6Documento6 pagine1 Input Data: Profis Anchor 2.4.6Naresh KumarNessuna valutazione finora

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocumento6 paginePROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNessuna valutazione finora

- PROFIS Anchor 2.2.0: WWW - Hilti.deDocumento6 paginePROFIS Anchor 2.2.0: WWW - Hilti.deCollin NguNessuna valutazione finora

- 6x12 BaseDocumento2 pagine6x12 Basejmwalker90Nessuna valutazione finora

- Shaft B, Hb1 Kempinski 11-1-17.pa2Documento7 pagineShaft B, Hb1 Kempinski 11-1-17.pa2sobhiNessuna valutazione finora

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocumento6 paginePROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNessuna valutazione finora

- Hilti Bolt DesignDocumento7 pagineHilti Bolt Designcheligp1981Nessuna valutazione finora

- PROFIS Anchor 2.1.4: WWW - Hilti.atDocumento5 paginePROFIS Anchor 2.1.4: WWW - Hilti.atfrog15Nessuna valutazione finora

- Hilti AnchorDocumento5 pagineHilti AnchorGopi KrishnanNessuna valutazione finora

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocumento6 paginePROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNessuna valutazione finora

- Hilti - Profis Anchor Design Report 594Documento5 pagineHilti - Profis Anchor Design Report 594Madhu GuptaNessuna valutazione finora

- Hilti Monitor - Pa2Documento2 pagineHilti Monitor - Pa2Asaru DeenNessuna valutazione finora

- Profis Rebar ReportDocumento5 pagineProfis Rebar ReportSowmya MajumderNessuna valutazione finora

- PES Hilti M10 HSA Report RunnerDocumento4 paginePES Hilti M10 HSA Report RunnerCollin NguNessuna valutazione finora

- Hilti Monitor - Pa2Documento2 pagineHilti Monitor - Pa2Asaru DeenNessuna valutazione finora

- 4597 AAB SC 07 Addendum 2 R0v0 78Documento1 pagina4597 AAB SC 07 Addendum 2 R0v0 78danieldumapitNessuna valutazione finora

- PROFIS Anchor 2.0.7: WWW - Hilti.usDocumento5 paginePROFIS Anchor 2.0.7: WWW - Hilti.usadelhelmiNessuna valutazione finora

- PROFIS Anchor 2.0.7Documento4 paginePROFIS Anchor 2.0.7Miky CastenNessuna valutazione finora

- Anchor Top Section - Pa2Documento2 pagineAnchor Top Section - Pa2albertNessuna valutazione finora

- What To Do If A Drill String Failure OccursDocumento5 pagineWhat To Do If A Drill String Failure Occursislam atifNessuna valutazione finora

- Condeck HP Composite Decking Product Technical ManualDocumento48 pagineCondeck HP Composite Decking Product Technical ManualTamara KnoxNessuna valutazione finora

- 1 Input Data: WWW - Hilti.co - UkDocumento2 pagine1 Input Data: WWW - Hilti.co - UkkarlrossmannNessuna valutazione finora

- ReportDocumento2 pagineReportpravincs_007Nessuna valutazione finora

- Anchor Design - Hilti (HP)Documento6 pagineAnchor Design - Hilti (HP)Harikrishnan PNessuna valutazione finora

- Check For Anchor Bolt of Cladding Fixation: (Refer Specification Vol. 2 03025 Page 3)Documento3 pagineCheck For Anchor Bolt of Cladding Fixation: (Refer Specification Vol. 2 03025 Page 3)ARYANessuna valutazione finora

- 1 Input Data: Profis Anchor 2.7.5Documento2 pagine1 Input Data: Profis Anchor 2.7.5muathNessuna valutazione finora

- Flupec Catalog Etansari Translatie PDFDocumento446 pagineFlupec Catalog Etansari Translatie PDFRadu VasileNessuna valutazione finora

- Cable Tray & AccessoriesDocumento11 pagineCable Tray & AccessoriesVikas TanejaNessuna valutazione finora

- B3L01 - Detail 1Documento7 pagineB3L01 - Detail 1vikramjain66Nessuna valutazione finora

- 1 Input Data: WWW - Hilti.co - UkDocumento3 pagine1 Input Data: WWW - Hilti.co - UkshoebNessuna valutazione finora

- Tornillo para ConcretoDocumento5 pagineTornillo para Concretomiguel angelNessuna valutazione finora

- Offcon DNV Zorro SkidDocumento7 pagineOffcon DNV Zorro SkidRAMSINGH CHAUHANNessuna valutazione finora

- 1 Input Data: Profis Anchor 2.7.5Documento2 pagine1 Input Data: Profis Anchor 2.7.5muathNessuna valutazione finora

- Anubar SpecDocumento8 pagineAnubar SpecSHIVAJI CHOUDHURYNessuna valutazione finora

- PES Hilti M10 HSA ReportDocumento4 paginePES Hilti M10 HSA ReportCollin NguNessuna valutazione finora

- 1 Input Data: Profis Anchor 2.8.5Documento1 pagina1 Input Data: Profis Anchor 2.8.5cherian johneyNessuna valutazione finora

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreDa EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreValutazione: 4.5 su 5 stelle4.5/5 (11)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDa EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionValutazione: 4.5 su 5 stelle4.5/5 (2)

- BOQ CAT Steel Bridge 24062021Documento1 paginaBOQ CAT Steel Bridge 24062021sobhiNessuna valutazione finora

- Cat Bridge Cover 10Documento1 paginaCat Bridge Cover 10sobhiNessuna valutazione finora

- Cat Bridge Cover Detail 4Documento1 paginaCat Bridge Cover Detail 4sobhiNessuna valutazione finora

- Calculation Note Fire Escape Stairs 02032022Documento22 pagineCalculation Note Fire Escape Stairs 02032022sobhiNessuna valutazione finora

- Pipe and Tube RailingsDocumento10 paginePipe and Tube RailingssobhiNessuna valutazione finora

- Facade Calculation NoteDocumento9 pagineFacade Calculation NotesobhiNessuna valutazione finora

- Autodesk Robot IDCDocumento405 pagineAutodesk Robot IDCsobhiNessuna valutazione finora

- CASA 55 - INCOMES For 12/2017: Total Block B + Half Shops Total Block A + Half Shops LBP 925,000 LBP 850,000Documento7 pagineCASA 55 - INCOMES For 12/2017: Total Block B + Half Shops Total Block A + Half Shops LBP 925,000 LBP 850,000sobhiNessuna valutazione finora

- 1 Input DataDocumento6 pagine1 Input DatasobhiNessuna valutazione finora

- 20-123 Stainless Steel and Metal Works BOQDocumento4 pagine20-123 Stainless Steel and Metal Works BOQsobhiNessuna valutazione finora

- To Sobhe Report (2) 19-09-2019Documento4 pagineTo Sobhe Report (2) 19-09-2019sobhiNessuna valutazione finora

- 1-KAIG - Nursery REPORT-rev.01Documento32 pagine1-KAIG - Nursery REPORT-rev.01sobhiNessuna valutazione finora

- Existing Ipe200 Existing Upn 125: Road Level Road LevelDocumento1 paginaExisting Ipe200 Existing Upn 125: Road Level Road LevelsobhiNessuna valutazione finora

- Block Catwalk Remaining Works Expected Date To Finish Works Date of Finished WorksDocumento1 paginaBlock Catwalk Remaining Works Expected Date To Finish Works Date of Finished WorkssobhiNessuna valutazione finora

- VOC Emissions Test ReportDocumento3 pagineVOC Emissions Test ReportsobhiNessuna valutazione finora

- Eurofins Product Testing PDFDocumento1 paginaEurofins Product Testing PDFsobhiNessuna valutazione finora

- Annex AllemandDocumento13 pagineAnnex AllemandsobhiNessuna valutazione finora

- Client:-Al Arabia Project: - M F Bridge Led Sign: Existing Ipe200 Existing Upn 125Documento1 paginaClient:-Al Arabia Project: - M F Bridge Led Sign: Existing Ipe200 Existing Upn 125sobhiNessuna valutazione finora

- Front Elevation: Road Level Road Level Road LevelDocumento1 paginaFront Elevation: Road Level Road Level Road LevelsobhiNessuna valutazione finora

- Title Page: Project: Structure B4 - F2Documento18 pagineTitle Page: Project: Structure B4 - F2sobhiNessuna valutazione finora

- Lover Album LyricsDocumento34 pagineLover Album LyricsMichael PlanasNessuna valutazione finora

- AP Physics Test: Electricity and Magnetism-Solutions: Multiple Choice QuestionsDocumento6 pagineAP Physics Test: Electricity and Magnetism-Solutions: Multiple Choice QuestionsChen JohnNessuna valutazione finora

- A Review On Battery Management System For Electric VehiclesDocumento6 pagineA Review On Battery Management System For Electric Vehiclesomkar chitnisNessuna valutazione finora

- International SubcontractingDocumento2 pagineInternational SubcontractingCatherine JohnsonNessuna valutazione finora

- Freedom As A Foundation of EthicsDocumento3 pagineFreedom As A Foundation of EthicsGrant Jomar SiadorNessuna valutazione finora

- Untitled DocumentDocumento6 pagineUntitled DocumentrameezshyamaleeNessuna valutazione finora

- Curicullum Vitae Hendri Zand Franxiscus LahaguDocumento3 pagineCuricullum Vitae Hendri Zand Franxiscus LahaguSepta Yudistira Inggil PambudiNessuna valutazione finora

- Colorado Wing - Sep 2012Documento32 pagineColorado Wing - Sep 2012CAP History LibraryNessuna valutazione finora

- RediFlex Hoses Data SheetDocumento2 pagineRediFlex Hoses Data SheetNordson Adhesive Dispensing SystemsNessuna valutazione finora

- Lesson 3.1 Algebraic TermsDocumento4 pagineLesson 3.1 Algebraic TermsCresencia Juliana DaluzNessuna valutazione finora

- Naplan Year 9 PracticeDocumento23 pagineNaplan Year 9 PracticetonynuganNessuna valutazione finora

- The Book of Paradise - Volume IIDocumento964 pagineThe Book of Paradise - Volume IItriamazikamno100% (3)

- Defeat Cancer NaturallyDocumento94 pagineDefeat Cancer NaturallyRknuviprasys Low100% (3)

- Eng Mech Lesson 1-2 PDFDocumento17 pagineEng Mech Lesson 1-2 PDFAlliza Kaye CasullaNessuna valutazione finora

- Septage Management Guide 1Documento43 pagineSeptage Management Guide 1Ria Tiglao FortugalizaNessuna valutazione finora

- Galactic Federations, Councils Secret Space Programs (Michael Salla) (Z-Library)Documento289 pagineGalactic Federations, Councils Secret Space Programs (Michael Salla) (Z-Library)Junior VeigaNessuna valutazione finora

- C8 Flyer 2021 Flyer 1Documento7 pagineC8 Flyer 2021 Flyer 1SANKET MATHURNessuna valutazione finora

- Underground-Sprayed Concrete BrochureDocumento12 pagineUnderground-Sprayed Concrete BrochureEngTamerNessuna valutazione finora

- Poems by Cawein, Madison Julius, 1865-1914Documento126 paginePoems by Cawein, Madison Julius, 1865-1914Gutenberg.orgNessuna valutazione finora

- Craig - 4353 TX CobraDocumento3 pagineCraig - 4353 TX CobraJorge ContrerasNessuna valutazione finora

- 2 2 1 1 5b Equipmend Data Sheets CommDocumento40 pagine2 2 1 1 5b Equipmend Data Sheets CommMilic MilicevicNessuna valutazione finora

- Essay, How Microscopes Have Contributed To Our Understanding of Living OrganismsDocumento2 pagineEssay, How Microscopes Have Contributed To Our Understanding of Living Organismslinanqikiki82% (11)

- Elementary Statistics A Step by Step Approach 9th Edition Bluman Solutions ManualDocumento23 pagineElementary Statistics A Step by Step Approach 9th Edition Bluman Solutions Manuala305894328100% (3)

- Cross Border Pack 2 SumDocumento35 pagineCross Border Pack 2 SumYến Như100% (1)

- Astm D6321-98-2004Documento3 pagineAstm D6321-98-2004Thyagu LingamurthyNessuna valutazione finora

- STAT 713 Mathematical Statistics Ii: Lecture NotesDocumento152 pagineSTAT 713 Mathematical Statistics Ii: Lecture NotesLiban Ali MohamudNessuna valutazione finora

- Lisca - Lingerie Catalog II Autumn Winter 2013Documento76 pagineLisca - Lingerie Catalog II Autumn Winter 2013OvidiuNessuna valutazione finora

- Massage Intake FormDocumento2 pagineMassage Intake Formapi-253959832Nessuna valutazione finora

- Animal Instinct (Em, Original) Acordes GuitarraDocumento2 pagineAnimal Instinct (Em, Original) Acordes GuitarraGustavoNessuna valutazione finora

- Exam Materials ScienceDocumento10 pagineExam Materials ScienceChimzoe CatalanNessuna valutazione finora