Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

QSP - 08 - Risk Assessment, Management and Contingency Planning Rev 0

Caricato da

MariaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

QSP - 08 - Risk Assessment, Management and Contingency Planning Rev 0

Caricato da

MariaCopyright:

Formati disponibili

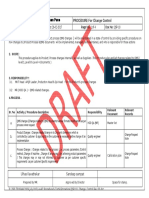

QSP-08 RISK ASSESSMENT,

MANAGEMENT AND CONTINGENCY PLANNING

Q.S.P-08

RISK ASSESSMENT, MANAGEMENT AND

CONTINGENCY PLANNING

Rev

0

Issued To

Title

Date

Signed By

ManagementTeam

27/05/14

DATE

SECTIONS REVIEWED

PREPARED

APPROVED BY

270514

FirstIssue

Date of Issue: 27/05/2014

Date of Print: 18/06/2014

QSP / 08 Rev 0

27/05/2014

Page 1 of 11

QSP-08 RISK ASSESSMENT,

MANAGEMENT AND CONTINGENCY PLANNING

Procedure

No.QSP - 08

RISK ASSESSMENT, MANAGEMENT AND

CONTINGENCY PLANNING

1. PURPOSE AND SCOPE

Toestablishmethodsforidentifyingandcontrollingrisksassociatedwithimpactondelivery,qualityofproduct,

andcostrequirementsassociatedwiththe manufactureanddeliveryofproductsinaccordancewithcustomer

and/or regulatory requirements. This procedure shall support ###### Quality Policy and assist in achieving

establishedQualityObjectives.

The procedure identifies the techniques, tools and their application for risk identification, assessment and

mitigation.

2. REFERENCES

3. DEFINITIONS

Date of Issue: 27/05/2014

Date of Print: 18/06/2014

RIS/01 Risk Register A listing of known or perceived risks within the operating

systematCadengwhichmayimpactonproductdeliveryand/orquality

RIS/02RiskAssessmentFormAformusedtorecorddataandinformationrelated

toriskassessment

RiskAnuncertaineventorconditionwhichmayimpactondeliveryand/orqualityof

product

Acceptable Risk Risk that is understood and agreed to by the organization

management and the customer, and is not considered sufficient to impact on the

definedsuccesscriteriawithintheapprovedlevelofresources.

ContingencyPlan Plan(s)determinedtominimizetheidentifiedrisk(Mitigation)

Harm Physical injury or damage to the health of people, or damage to property

and/ortheenvironment

Risk Analysis systematic use of available information to identify hazards and to

estimatetherisk

RiskAssessmentoverallprocesscomprisingariskanalysisandariskevaluation

Risk Evaluation judgment, on the basis of risk analysis, of whether a risk is

acceptableornot

RiskControlprocessthroughwhichdecisionsarereachedandprotectivemeasures

areimplementedforreducingrisksto,ormaintainingriskswithinacceptablelevels

Risk Management systematic application of management policies, procedures and

practicestothetasksofanalyzing,evaluatingandcontrollingrisk

LikelihoodThechanceofaneventoccurring

Consequencetheoutcomeofaneventaffectingobjectives

Grandfathering to be exempt from a new ruling due to a positive history and/or

proventrackrecord.

Residual Risk the risk which remains after actions have been taken to mitigate an

initialrisk

ContingencyPlanAbackuporalternatemeasurewhichcanbeusedifanunplanned

eventoccurswhichmayimpactondeliveryorqualityofproduct

QSP / 08 Rev 0

27/05/2014

Page 2 of 11

QSP-08 RISK ASSESSMENT,

MANAGEMENT AND CONTINGENCY PLANNING

4. PROCEDURE

4.1 - General

TheQualityManagementSystemat######,inconjunctionwithAPI,Customerand

Connection Licensor specifications, provides for numerous process controls

designed to ensure conformance to requirements. While these controls may be

adequatetomitigatelowtomoderatelevelrisksassociatedwiththemanufacturing

environment, this procedure shall be used to identify the significant risks to

achieving objectives, and to analyze, evaluate, and apply suitable risk treatment

measures.

For routine tasks such as standard threading and connection makeup, risk

management is conducted informally between the members of the management

team.Risksinvolvedinthesesortoftaskshavebeenrecognisedovermanyyearsof

operation,andarewellknowntoallconcerned.Theformalriskassessmentprocess

described in this procedure applies to tasks or projects which require ###### to

step outside familiar territory, and necessitate the implementation of procedures

notcommonlyutilised.

This procedure should be used in conjunction with other established procedures

andprocessesthroughouttheorganization,suchassales,quoting,contractreview,

production planning, purchasing, manufacturing, and inspection to provide an

integratedplanformanagingriskthroughoutproductrealization.

For the purposes of this process, the components of risk shall be identified as

follows:

Afuturerootcause(yettohappen),which,ifeliminatedorcorrected,

wouldpreventapotentialconsequencefromoccurring,

Aprobability(orlikelihood)assessedatthepresenttime,ofthatfuture

rootcauseoccurring,and

Theconsequence(oreffect)ofthatfutureoccurrence

NoteRisksshouldnotbeconfusedwithissues.Ifarootcauseisdescribedinthe

pasttense,therootcausehasalreadyoccurred,andhence,itisanissuethatneeds

toberesolved,butitisnotarisk.IssuesareresolvedthroughCorrectiveor

PreventiveActionsasdescribedinQSP/05SystemsMonitoringandImprovement.

4.2 - Responsibilities

Date of Issue: 27/05/2014

Date of Print: 18/06/2014

ToassistwithRiskManagement,theQualityManagermaintainsaRiskRegister,

(RIS/01),whichlistsallknownsignificanteventswhichmayimpactonproduct

deliveryand/orquality.AssociatedrisktreatmentsandContingencyPlanscurrently

usedtoreducetherisktoacceptablelevelsintheseareasareamonginformation

includedintheRiskRegister.

Recordsofriskassessmentandmanagement,includingactionstaken,shallbe

maintainedasperQSP/04DocumentControlandRecordsManagement.

The General Manager shall retain ultimate authority and responsibility for Risk

Management. The Quality Manager is responsible to ensure that the risk

managementframeworkisestablished,implemented,monitored,andreviewedfor

improvement.

TheProductionManagerandtheGeneralmanagershallberesponsibleto:

Establish, use, and assist in the maintenance of the risk management

process.

Ensurethattheriskmanagementprocessiscommunicatedandintegrated

throughout the organization, and that risks are identified, managed and

QSP / 08 Rev 0

27/05/2014

Page 3 of 11

QSP-08 RISK ASSESSMENT,

MANAGEMENT AND CONTINGENCY PLANNING

monitoredinaccordancewiththisprocess.

Ensure that adequate resources from all necessary disciplines are

allocatedtosupportthisprocess.

Ensure that risk treatment strategies are developed, implemented and

controlsmaintained.

Employeesatalllevelsshallberesponsibletomanagerisksinaccordancewiththis

processintheirrespectiveareasofconcern.

4.3 - Risk Criteria

Riskcriteriaaredefinedintermsofthefollowing2elements:

1. Thelikelihoodofanevent(rootcause)occurring,and;

2. Theconsequenceofthatevent(rootcause)occurring

Thesecriteriashallbeusedlaterintheprocesstoevaluatethesignificanceofthe

risk.

4.3.1 - Likelihood

TheLevelof Likelihoodelementshall bedeterminedusingthe criteriaspecifiedin

the following Levels of Likelihood Criteria Table (Fig 1.), and assigned a Level

Number. The level should be determined by evaluating all available information,

both current and historical, or by estimating the probability of occurrence using

experience and judgment as a guide. Every effort should be made to ensure the

determinedLevelisaccurate.

LIKELIHOOD

LEVEL

LIKELIHOOD

PROBABILITY

Remote

10%

Unlikely

30%

Probable

50%

HighlyProbable

70%

NearCertainty

90%

Fig1.

4.3.2 - Consequence

Date of Issue: 27/05/2014

Date of Print: 18/06/2014

TheLevelofConsequenceelementshallbedeterminedusingthecriteriaspecified

in the following Levels and Types of Consequence Criteria table (Fig 2.), and

assignedaLevelNumber.Whilecosthasbeenincludedinthesecriteria,andshould

be considered in the quoting and estimating stages, the inclusion of cost criteria

shouldbeevaluatedforuseafterawardofcontract,(seesection4.8.1).

QSP / 08 Rev 0

27/05/2014

Page 4 of 11

QSP-08 RISK ASSESSMENT,

MANAGEMENT AND CONTINGENCY PLANNING

CONSEQUENCE

LEVEL

PRODUCTQUALITY

DELIVERYSCHEDULE

COST

InsignificantRequires minor

rework to bring into full conformity.

NoImpact

1%

Increase

MinorRequires significant

rework to bring into full conformity.

MinorImpact - Internal

schedule slip. Still able to meet

original delivery schedule and

quantity

5%

Increase

ModerateExtensive rework

or remake. Cannot be reworked to

meet conformity requirements.

Requires customer concession to

"Use as is"

SomeImpact Requires

minor schedule (< 7 days) or

quantity concession from

customer.

5%

Increase

MajorMultiple scrapped parts.

MajorImpact Requires

Multiple parts require repair to

restore to acceptable condition.

Requires customer approval.

major schedule (> 7 days) or

quantity concession from

customer. Minor impact to

Customer production schedule.

Customer required Milestones

10%

Increase

SevereAll parts scrapped.

Unable to produce conforming

parts. Unable to obtain required

materials or services.

Catastrophic Unable to

deliver parts. Major impact to

customer production or

program schedule.

20%

Increase

Fig2.

4.3.3 - Overall Risk

Score

TheoverallRiskLevelisdeterminedusingtheRiskAssessmentScoringChart(Fig3.),

andisassignedaLevelofLow(L),Moderate(M),orHigh(H).

LIKELIHOOD

RISKASSESSMENTSCORINGCHART

5

Near

Certainty

4

Highly

Probably

3

Probable

2

Unlikely

1

Remote

1

Insignificant

2

Minor

3

Moderate

4

Major

5

Severe

CONSEQUENCE

Fig3.

Date of Issue: 27/05/2014

Date of Print: 18/06/2014

QSP / 08 Rev 0

27/05/2014

Page 5 of 11

QSP-08 RISK ASSESSMENT,

MANAGEMENT AND CONTINGENCY PLANNING

4.3.4 - Existing Risk

Controls

Existing risk controls (refer to RIS/01 Risk Register) are evaluated against the

following criteria to determine effectiveness, and whether further actions may be

necessary.

EXISTINGCONTROLSASSESSMENT

EFFECTIVE

Indicateseffectiveriskcontrolsareinplaceresultingin

minimalnetrisk.

ADEQUATE

Indicatesriskcontrolsareinplaceandgenerallyeffective,

however,anopportunityforrefinementexiststofurther

reducerisk.Evaluateforfurtherrisktreatment.

FAIR

POOR

Indicatesriskcontrolsarepresentlybeingdeveloped,or

areonlypartiallyeffective.Applicationofrisktreatmentis

requiredtomitigaterisk.

Indicatesriskcontrolshavenotyetbeendeveloped,or

areineffective.Applicationofrisktreatmentisrequired

asamatterofpriority.

Fig4.

Date of Issue: 27/05/2014

Date of Print: 18/06/2014

QSP / 08 Rev 0

27/05/2014

Page 6 of 11

QSP-08 RISK ASSESSMENT,

MANAGEMENT AND CONTINGENCY PLANNING

4.4 - Process Structure

Fig5.

Date of Issue: 27/05/2014

Date of Print: 18/06/2014

QSP / 08 Rev 0

27/05/2014

Page 7 of 11

QSP-08 RISK ASSESSMENT,

MANAGEMENT AND CONTINGENCY PLANNING

4.5 - Risk Identification

Thepurposeofthisstepistoidentifytheriskstoachievingobjectivessotheymay

be managed. Generally this will take place during the Quote and Contract Review

stages;howeverrisksshouldbecontinuouslyreevaluatedthroughouttheproduct

realization process. It is critical to identify risks as early in the life of a project as

possible, because a risk not identified at this stage may be excluded from further

analysis.

Tools for identifying risks may include Fault Tree Analysis (FTA), Failure Mode and

EffectsAnalysis(FMEA),HistoricalDataAnalysis,Brainstorming,informedopinions

andexpertadvicefromemployeesandreputablesourceswithinthemining,andoil

andgasindustry,stakeholderinput.

Potentialsourcesofriskinclude:

Requirements Customer identified or Industry determined special

requirements

Technology The degree to which existing technology has demonstrated

sufficient maturity to be realistically capable of meeting performance

objectives

Deliveryofnonconformingproduct

Production/FacilitiesTheabilitytoachieveperformanceobjectivesbased

onavailablemanufacturingresourcesandprocesses

SupplierperformanceTheabilityofmaterialsupplierstodelivercompliant

productstoadesignatedschedule

OutsourcesTasksTheabilities,experience,knowledge,andavailability,of

outsourcedprocesssuppliers

CostTheabilityofoursystemtoachievecostobjectives.Thisincludesthe

effects of errors in estimating techniques used, the cost of poor quality

associatedwithcustomerfurnishedmaterialsandotherfinancialorbudget

effects

Management The degree to which plans and strategies exist and are

realistic and consistent. Staffing and supervision should be sufficient to

executethetask

AvailabilityofCompetentpersonnel

ScheduleThesufficiencyoftimeallocatedtoachieveobjectives.Shortlead

timesfromcustomers,longleadtimesfromsuppliers,etc.

Having identified what events might occur, it is necessary to determine the root

causesfortheseevents.Theremaybemanywaysaneventcanhappen,however,

using the 5 Why process will allow you to determine the root cause for each

event.

Rootcauses(Risks)shallbedocumentedinRIS/02RiskAssessmentForm.

4.6 - Risk Analysis

Oncetherootcauseshavebeenidentified,theywillneedtobeanalyzedintermsof

theirLikelihoodtooccur,andtheseverityofConsequencesshouldtheyoccur.This

isaccomplishedusingtheLikelihoodandConsequenceCriteriachartsestablishedin

sections4.3.1and4.3.2ofthisprocedure.

EachrootcauseshallbeassignedaLikelihoodLevelandaConsequenceLevelscore.

Thesewillbeusedtoevaluatetheoverallriskassessmentscore,whichinturnwill

determinefurtheraction.

ScoresshallbedocumentedinRIS/02RiskAssessmentForm.

Date of Issue: 27/05/2014

Date of Print: 18/06/2014

QSP / 08 Rev 0

27/05/2014

Page 8 of 11

QSP-08 RISK ASSESSMENT,

MANAGEMENT AND CONTINGENCY PLANNING

4.7 - Risk Evaluation

Usingthescoresdevelopedinsection4.6for"Likelihood"and"Consequence",use

the Risk Assessment Scoring chart to obtain a Risk Assessment Rating. This will

correspond to one of three (3) overall levels of risk, Low (Green), Moderate

(Yellow),orHigh(Red).

ForRisksratingintheLow(Green)category,Risktreatmentisnotrequired.Monitor

andReviewforfuturetreatment.

For Risks rating in the Moderate (Yellow) category, existing controls must be

evaluated for effectiveness. For controls assessed to be less than Adequate,

further risk treatment is required. For controls assessed to be only Adequate,

evaluateforfurtherrisktreatment.(Cost/BenefitRisk/Reward,etc.).

All Risks rating in the High (Red) category shall require risk treatment and / or

furtheranalysis.

OverallRiskRatingsshallbedocumentedinRIS/02RiskAssessmentForm.

4.7.1 - Contingency

Planning

The Quality manager maintains a Risk Register (RIS/01), which identifies all known

significantriskswhichmayimpactondeliveryandqualityofproduct.Includedinthe

Risk Register is a Contingency Plan, which identifies a solution which can be

implemented should a specified event occur. A Contingency Plan mitigates the

consequencesofanunplannedeventtakingplace,andisaformofrisktreatment.

TheexistenceofaContingencyPlancanbeusedtoreduceanunacceptableriskinto

anacceptablerisk.

The Contingency Plan shall encompass the significant risk scenarios associated with

the following:

Facility/equipment availability and maintenance

Supplier performance and Material availability/Supply

Delivery of Non-Conforming Product

Availability of Competent personnel

The Contingency Plan shall include authorities and responsibilities, and both internal

and external communication controls.

The risk scenarios and the actions required shall be updated if required based on

new risks identified.

All other information in this plan shall be updated whenever there is a change in

responsibilities, authorities and/or communication controls.

This contingency plan shall be communicated to all personnel and shall be accessible

to all employees via the Master List of Forms and Documents (DC/01).

4.8 - Risk Treatment

Risktreatmentisprocessofidentifyingtheoptionsformodifyingrisks,selectingand

implementing those options in the form of a risk treatment plan. Once

implemented,treatmentsprovideormodifyriskcontrols.

Risktreatmentinvolvesthecyclicalprocessof:

developingarisktreatment

Decidingwhetherresidualrisklevelsareacceptable

Ifnotacceptable,developinganewrisktreatment

Assessingtheeffectivenessofthattreatment

Risk treatment options are not necessarily mutually exclusive or appropriate in all

circumstances.Theavailableoptionscaninclude:

Avoidingtheriskbydecidingnottostartorcontinueanactivity

Accepting,orevenincreasingtheriskinordertopursueanopportunity

Removingthesourceoftherisk

Date of Issue: 27/05/2014

Date of Print: 18/06/2014

QSP / 08 Rev 0

27/05/2014

Page 9 of 11

QSP-08 RISK ASSESSMENT,

MANAGEMENT AND CONTINGENCY PLANNING

4.8.1 - Selection of Risk

Treatment Options

ChangingtheLikelihoodoftheriskoccurring

ChangingtheConsequenceoftheriskoccurring(Contingency)

Sharingtheriskwithanotherpartyorparties

Retainingtheriskbyinformeddecision

1. Selectingthemostappropriatetreatmentoptionsinvolvesbalancingthecostsof

implementation against the benefits derived. In general, the cost of managing

risk needs to be commensurate with the benefits obtained. When evaluating

costversusbenefit,thecontextshouldbetakenintoaccount.Itisimportantto

considerallcosts,bothdirectandindirect,andallbenefitswhethertangibleor

intangible.

2. Decisionsshouldaccountfortheneedtoconsidercarefullythoserarebutsevere

risks that may warrant risk treatment, that are not justifiable on strictly

economic grounds. Customer, regulatory, or legal requirements may override

simplecost/benefitanalysis.

3. If budgetary constraints exist, the treatment plan should clearly specify the

priority order in which treatments should be implemented. Consider the full

impactofnottakingactionagainstanycostsavings.

4. If after treatment residual risk remains, this risk should be evaluated and a

decision should be made about whether to retain this risk, or repeat the risk

treatmentprocess.

4.8.2 - Preparing and

Implementing

Treatment Plans

Thepurposeofthetreatmentplanistodocumenthowthechosenoptionswillbe

implemented.Theplanmaybedocumentedinanyformat,andmayrequireseveral

formats,however,shouldbeavailabletoallconcernedstakeholdersandcontainas

aminimum:

Theproposedactions

Resourcerequirements

Assignedresponsibilities

Timingandschedulingrequirements

Performancemeasures

Reportingandmonitoringrequirements

Treatment plans should be integrated with other management processes such as

Quoting, Contract Review, Production Planning, Manufacturing, and Verification

activities.

Once a risk treatment has been implemented, all information related to the

assessment and subsequent treatment plan shall be determined and recorded on

theRiskAssessmentForm(RIS/02)bythedesignatedperson.

The designated person shall complete all remaining relevant sections of the Risk

AssessmentFormandforwardittotheQualityManager.

The QA shall transfer the information to the Risk Register (RIS/01) and maintain

relevantdocuments.

AsignificantriskmaybeincludedinContingencyPlan.

4.9 - Monitor and

Review

Date of Issue: 27/05/2014

Date of Print: 18/06/2014

Ongoing review is essential to ensure that the management plan remains relevant

andeffective.ThefactorsthataffecttheLikelihoodandConsequencesofanevent

may change, as may the factors that affect the suitability or cost of the treatment

QSP / 08 Rev 0

27/05/2014

Page 10 of 11

QSP-08 RISK ASSESSMENT,

MANAGEMENT AND CONTINGENCY PLANNING

options.OtherprocessmonitoringsuchasQualityandDeliveryperformance,aswell

as actual progress against treatment plan should provide information about the

effectivenessoftheriskmanagementprocess.

Informationgatheredduringriskassessmentsshallbecollatedandanalysedbefore

being presented at Management Review Meetings for discussion with a view to

possibleimprovementstotheQualityManagementsystem

Date of Issue: 27/05/2014

Date of Print: 18/06/2014

QSP / 08 Rev 0

27/05/2014

Page 11 of 11

Potrebbero piacerti anche

- Process Approach A Complete Guide - 2019 EditionDa EverandProcess Approach A Complete Guide - 2019 EditionNessuna valutazione finora

- ##-QSP-05 Risk Assessment and ManagementDocumento11 pagine##-QSP-05 Risk Assessment and Managementrajiv100% (2)

- Procedure Risk ManagementDocumento2 pagineProcedure Risk ManagementAnbuNessuna valutazione finora

- Iso 17025 - Corrective Action Request Form (Completed)Documento1 paginaIso 17025 - Corrective Action Request Form (Completed)Jesse100% (1)

- Supplier Self-Assessment: ISO 9001:2015 QMSDocumento4 pagineSupplier Self-Assessment: ISO 9001:2015 QMSArieHerdyanto50% (2)

- Internal-Quality-Audit ProcedureDocumento6 pagineInternal-Quality-Audit ProcedureHamza Sharif Adam100% (1)

- Quality Manual 9001-2008 Elsmar 1Documento13 pagineQuality Manual 9001-2008 Elsmar 1luis miguel perez cruzNessuna valutazione finora

- Audit Report Template 13Documento5 pagineAudit Report Template 13Ahmed HosneyNessuna valutazione finora

- PR018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2Documento9 paginePR018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2uks444100% (1)

- Quality Risk ManagementDocumento5 pagineQuality Risk ManagementA VegaNessuna valutazione finora

- Q2-760-01-Control of Monitoring and Measuring DevicesDocumento5 pagineQ2-760-01-Control of Monitoring and Measuring DevicesAlineNessuna valutazione finora

- COMP-OPP-02 Procedure For Control and Validation of Service ProvisionDocumento6 pagineCOMP-OPP-02 Procedure For Control and Validation of Service ProvisionISODCC DSPINessuna valutazione finora

- SOP For IQADocumento25 pagineSOP For IQAMuhammad As'adNessuna valutazione finora

- E Internal Audit Procedure Section 5Documento3 pagineE Internal Audit Procedure Section 5Ngonidzashe Zvarevashe100% (1)

- CLAUSE 8.5 Production and Service ProvisionDocumento10 pagineCLAUSE 8.5 Production and Service ProvisionNavnath TamhaneNessuna valutazione finora

- Internal Audit SOPDocumento4 pagineInternal Audit SOPIftikhar Khan100% (1)

- 10.1 ImprovementDocumento8 pagine10.1 ImprovementVijayendran VijayNessuna valutazione finora

- QAS P008 Control of Non-Conforming Processes, Services or Products ProcedureDocumento2 pagineQAS P008 Control of Non-Conforming Processes, Services or Products Proceduredanaka007Nessuna valutazione finora

- Job Description / Roles & ResponsibilitiesDocumento2 pagineJob Description / Roles & ResponsibilitiesParveen (Atam Valves)Nessuna valutazione finora

- Coral Laboratories Limited: Plot No 27-28, Pharmacity, Selaqui, Dehradun 248197 (Uttarakhand) SOP/QA/071 R-02 1 of 2Documento2 pagineCoral Laboratories Limited: Plot No 27-28, Pharmacity, Selaqui, Dehradun 248197 (Uttarakhand) SOP/QA/071 R-02 1 of 2QA Doon100% (1)

- 01 Quality Objectives SummaryDocumento1 pagina01 Quality Objectives SummaryDenny Dagger100% (1)

- MCI 01 Management ReviewDocumento3 pagineMCI 01 Management ReviewalexrferreiraNessuna valutazione finora

- ISO 13485 ComparisonDocumento6 pagineISO 13485 ComparisonMikeNessuna valutazione finora

- QSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207Documento34 pagineQSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207SureshNessuna valutazione finora

- ISO 9001-2015 Supplier Audit Checklist SAMPLEDocumento2 pagineISO 9001-2015 Supplier Audit Checklist SAMPLEFaisal0% (1)

- QMS 3Documento11 pagineQMS 3Ram MohanNessuna valutazione finora

- QSP-10 Change Control Rev 02Documento4 pagineQSP-10 Change Control Rev 02ukavathekarNessuna valutazione finora

- Management Review Meeting FormatDocumento2 pagineManagement Review Meeting FormatThusitha LakpriyaNessuna valutazione finora

- Appendix 1 - Quality Objectives: Zanzibar Bureau of StandardsDocumento3 pagineAppendix 1 - Quality Objectives: Zanzibar Bureau of StandardsMariel GentilesNessuna valutazione finora

- QSP 02 - Record Control ProcedureDocumento5 pagineQSP 02 - Record Control ProcedureVivek V100% (1)

- Procedure For Selection and Supplier DevelopmentDocumento5 pagineProcedure For Selection and Supplier DevelopmentQuality Unit 1 Ajay Pandey100% (3)

- 4-04-1 Contract ReviewDocumento4 pagine4-04-1 Contract Reviewjeric bañaderaNessuna valutazione finora

- Control of Monitoring and Measuring EquipmentDocumento6 pagineControl of Monitoring and Measuring EquipmentJaved Iqbal0% (1)

- Management Review ProcedureDocumento3 pagineManagement Review Procedurechahi100% (1)

- Quality Procedures PDFDocumento171 pagineQuality Procedures PDFTo Minh NhatNessuna valutazione finora

- Product Realization (Quality Control)Documento16 pagineProduct Realization (Quality Control)Khaled AbdelbakiNessuna valutazione finora

- Procedure For Internal AuditsDocumento2 pagineProcedure For Internal AuditsLuke J LandryNessuna valutazione finora

- Corrective and Preventive ActionDocumento3 pagineCorrective and Preventive ActionmurugesanNessuna valutazione finora

- SOP-03 (Employee Performance Monitoring)Documento6 pagineSOP-03 (Employee Performance Monitoring)FarhanNessuna valutazione finora

- Internal AuditsDocumento9 pagineInternal Audits李哲祥100% (1)

- ISO27k Nonconformity Corrective Preventive Action FormDocumento3 pagineISO27k Nonconformity Corrective Preventive Action FormJasim's BhaignaNessuna valutazione finora

- ISO 19011 Audit ManagementDocumento38 pagineISO 19011 Audit ManagementRamesh GanapathyNessuna valutazione finora

- Sebros QMS ManualDocumento44 pagineSebros QMS ManualRambir KaushikNessuna valutazione finora

- RMR-HSMS-P-014 OHS Management System Internal AuditDocumento5 pagineRMR-HSMS-P-014 OHS Management System Internal AuditkamranNessuna valutazione finora

- Internal Audit NC ReportDocumento1 paginaInternal Audit NC Reportmorshed_mahamud7055Nessuna valutazione finora

- A6. Control of Nonconforming ProductDocumento6 pagineA6. Control of Nonconforming ProductStanley MtamboNessuna valutazione finora

- IEC-OP-02 OP For Internal & External CommunicationDocumento4 pagineIEC-OP-02 OP For Internal & External CommunicationnomanNessuna valutazione finora

- QSP 8.4 Control of Externally Provided Processes (Preview)Documento4 pagineQSP 8.4 Control of Externally Provided Processes (Preview)Centauri Business Group Inc.67% (3)

- Page 01 of 02 Rev. No.: 00 Date: - : Title: Context of OrganizationDocumento8 paginePage 01 of 02 Rev. No.: 00 Date: - : Title: Context of OrganizationAnkur100% (1)

- Quality Management System Manual QM-QUA-001: Nelson-Miller IncDocumento34 pagineQuality Management System Manual QM-QUA-001: Nelson-Miller IncAbd Zouhier100% (1)

- ISO 9001 Operational Procedure QOP-56-01 Management Review PT ASADocumento5 pagineISO 9001 Operational Procedure QOP-56-01 Management Review PT ASAqidohsNessuna valutazione finora

- P018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2Documento9 pagineP018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2Álvaro Martínez Fernández100% (1)

- COTO Log - Rev 0Documento39 pagineCOTO Log - Rev 0debasishNessuna valutazione finora

- Turtle Diagram - Internal AuditDocumento1 paginaTurtle Diagram - Internal Auditsyahir etNessuna valutazione finora

- 15 (QSP-QA - 07) Process & Product AuditDocumento3 pagine15 (QSP-QA - 07) Process & Product AuditBASAVA ENGINEERING100% (1)

- Internal Quality Audit Plan Dilg Region 10Documento8 pagineInternal Quality Audit Plan Dilg Region 10Cess AyomaNessuna valutazione finora

- 1.1.1. Quality Risk Assessment. 1.1.1.1. Introduction & ScopeDocumento6 pagine1.1.1. Quality Risk Assessment. 1.1.1.1. Introduction & ScopeKannan MurugesanNessuna valutazione finora

- Cracking the Case of ISO 9001:2015 for Manufacturing: A Simple Guide to Implementing Quality Management in ManufacturingDa EverandCracking the Case of ISO 9001:2015 for Manufacturing: A Simple Guide to Implementing Quality Management in ManufacturingNessuna valutazione finora

- Quality Risk Management Plan: ApprovalsDocumento8 pagineQuality Risk Management Plan: Approvalsnsk79in@gmail.comNessuna valutazione finora

- TOT Risk Register WorkingDocumento9 pagineTOT Risk Register WorkingPhuong HuynhNessuna valutazione finora

- QSP - 09 - Management of Change Rev 0 PDFDocumento4 pagineQSP - 09 - Management of Change Rev 0 PDFPhuong HuynhNessuna valutazione finora

- RIS 02 - Risk Assessment Form Rev 0 PDFDocumento1 paginaRIS 02 - Risk Assessment Form Rev 0 PDFPhuong HuynhNessuna valutazione finora

- MOC 02 - Request For Change Form Rev 0 PDFDocumento1 paginaMOC 02 - Request For Change Form Rev 0 PDFPhuong HuynhNessuna valutazione finora

- 1st Shipment Detailed List of PlatesDocumento2 pagine1st Shipment Detailed List of PlatesPhuong HuynhNessuna valutazione finora

- Wowlibrary Gmaw Fcaw Mcaw WeldingDocumento6 pagineWowlibrary Gmaw Fcaw Mcaw WeldingPhuong HuynhNessuna valutazione finora