Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

NSL LOLER Matrix PDF

Caricato da

del3333Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

NSL LOLER Matrix PDF

Caricato da

del3333Copyright:

Formati disponibili

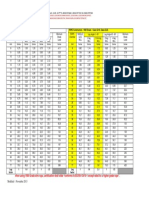

LIFTING EQUIPMENT LEGISLATION MATRIX

CRANES (PEDESTAL / MOBILE)

CRANES (PEDESTAL / MOBILE)

(20t-50t) BS2452/7121 / BS EN 13001

CRANES (PEDESTAL / MOBILE)

(OVER 50t) BS2452/7121 / BS EN 13001

ELECTRIC OVERHEAD TRAVELLING CRANES

BS466 /7121 BS EN 13001

MARINE LIFEBOAT DAVITS

BS MA41

DAVIT BLOCKS & ASSOC. EQUIPMENT

BS MA41

FORKLIFT TRUCKS

BS.ISO 5057/BS EN 1726-1/2

PALLET STACKERS

BS5777 / 5778 / ISO 5766

PALLET TRUCKS

BS ISO 509 (1996)

OTHER

3.5:1

4:1

4.5:1

5:1

6:1

6.5:1

7:1

8:1

10:1

30

THESE MAY VARY SLIGHTLY

DEPENDENT ON

MANUFACTURERS

OTHER

12

FULL FABRICATION PACKAGE

12

STRESS CALCULATIONS

CALIBRATION CERTIFICATE

MTHS M M

DESTRUCTION SAMPLE CERT.

S.I. 1890

BS EN 12079 1999

LOLER SI 1998 No 2307

LOLER SI 2006 No 2184

CERT. OF CONFORMITY / TEST

10

OTHER

SWL x 25

50 100 300 3

REFER TO I.L.O. PAMPHLET 188

10 25

EXCESS

LOAD (t)

SWL x 22

EVERY 5 Y EARS (see note: 4)

QUADRENNIALLY

AFTER REPAIR / MODIFICATION

% ABOVE SWL

FACTORS OF SAFETY

BS2655 / BS5655 / BS5656

11 SUSPENDED CRADLES

BS2830 / 5974

12 POWERED HOISTS

(ELECTRIC) BS466 / BS EN 13001

13 POWERED HOISTS

(PNEUMATIC) DIN F.E.M. 9.751

14 MANUAL HOISTS

(CHAIN BLOCKS) BS3243 / BS EN 13157

15 LEVER HOISTS

(PULLIFTS) BS4898 / BS EN 13157

16 WIRE ROPE HOISTS

LIFTING APPLIANCES

PROOF LOADS

DOCUMENTATION

REQUIREMENTS

PERIODIC

EXAM. REQ.

PROOF LOAD TESTING

(UNDER 20t) BS2452/7121 / BS EN 13001

10 PERSONNEL & GOODS LIFTS

("TIRFORS") BS EN 13157

17 WIRE ROPES FOR ABOVE

BS302 / BS EN 12385

18 BEAM TROLLEYS

BS EN 13157

19 BEAM CLAMPS

BS EN 13157

20 PLATE CLAMPS

21 SINGLE SHEAVE BLOCKS

(UP TO 25t) BS4536/4018 / BS EN 13157

22 SINGLE SHEAVE BLOCKS

(OVER 25t) BS4536 / BS EN 13157

23 MULTI - SHEAVE BLOCKS

(UP TO 25t) BS4536 / BS EN 13157

24 MULTI - SHEAVE BLOCKS

(OVER 25t) BS4536 / BS EN 13157

25 CRANE HOOK BLOCKS

(UP TO 25t) BS4536 / BS EN 13157

26 CRANE HOOK BLOCKS

(OVER 25t) BS4536 / BS EN 13157

27 WINCH

(PNEUMATIC BS MA31 / ISO 3078

28 WINCH

(MAN-RIDING)

29 WINCH

(MANUAL) BS3701 / BS EN 13157

30 WINCH

(DAVIT) BS EN 13157

31 STABBING BOARDS

32 RUNWAY BEAMS

BS2853

33 LIFTING BEAMS

(see note 1)

(UP TO & INC 3t) BS EN 13001

(see note 1)

34 LIFTING BEAMS

(OVER 3 UP TO & INC 6t) BS EN 13001

(see note 1)

35 LIFTING BEAMS

(OVER 6 UP TO & INC 20t) BS EN 13001

(see note 1)

36 LIFTING BEAMS

(OVER 20 UP TO & INC 40t) BS EN 13001

(see note 1)

37 LIFTING BEAMS

(OVER 40t) BS EN 13001

(see note 1)

38 HYDRAULIC RAMS & JACKS

39 MANUAL JACKS

LIFTING ACCESSORIES

LOAD

IND.

LIFTING EQUIPMENT

ANNUALLY

MANUFACTURING

CODES / STANDARDS

EQUIPMENT TYPE

PRIOR TO FIRST USAGE

INITIAL

EXAM/TEST

40 TRANSIT CONTAINERS

BS7072 / BS EN 12079 -1999

41 TRANSIT CONTAINERS

S I 1984 No. 1890

42 MOBILE WORK PLATFORMS

BS7171 / BS EN 280 - 2001

43 FABRICATED PADEYES & CLAMPS

BS EN 13001

44 DYNAMOMETERS / CRANE WEIGHERS

BS1610 / BS EN 10002

45 LOAD CELLS

BS1610 / BS EN 10002

46 SAFE LOAD INDICATORS / RCIs

BS7262 (1990)

(see note 1)

(see note 2)

47 WIRE ROPE

BS302 / BS EN 12385

48 WIRE ROPE

(ON PASSENGER LIFTS) BS302 / BS EN 12385

49 WIRE ROPE

(DIVING OPERATIONS) BS302 / BS EN 12385

50 WIRE ROPE

(MAN - RIDING WINCHES) BS302 / BS EN 12385

51 WIRE ROPE SLINGS

BS1290 / BS EN 13414/1-3

52 WIRE ROPE SLINGS

(MULTI - LEG) BS1290 / BS EN 13414/1-3

53 CHAIN SLINGS-GRADE 80

BS EN 818-1 / ISO 3076

54 CHAIN HOOKS & FITTINGS - GRADE 80

ISO 8539

55 POLYESTER SLINGS

BS EN 1492 PT 1, 2 & 4

56 SHACKLES - ALLOY

(UP TO 25t) RR-C-27 1D TYPE IV

57 SHACKLES - ALLOY

(OVER 25t) RR-C-27 1D TYPE IV

58 SHACKLES - HIGHER TENSILE

(UP TO 25t) ISO 2415

59 SHACKLES - HIGHER TENSILE

(OVER 25t) ISO 2415

60 EYEBOLTS

61 EYEBOLTS

62 RIGGING SCREWS

(BRITISH) BS4278

(U.S.)

(BRITISH) BS4429

63 RIGGING SCREWS (TURNBUCKLES)

64 OPEN WEDGE SOCKETS

(U.S.) FF-T-791-TYPE 1 FORM 1

(BRITISH) BS7166 / BS EN 13411-6

65 OPEN WEDGE SOCKETS

(U.S.) RR-S-55OD TYPE C

LEGEND

NOTE 1: LIFTING SUPPORT STEELWORK SUCH AS RUNWAY BEAMS, LIFTING

BEAMS, LIFTING FRAMES, PADEYES ETC WITH NO MOVING PARTS

SHALL HAVE THEIR PERIODICITY EXTENDED TO 12 MONTHS AS

STATUTORY REQUIREMENTS

LONG AS:

COMPANY POLICY INCLUDES LIFTING MACHINES IN 6-MONTHLYS

REFER TO SPECIFIC DESIGN CODES

INITIAL FACTORY TEST

FUNCTION TEST ONLY

AMERICAN PATTERN BLOCKS

REFER TO L.R.O.S./D.N.V. PROCEDURE

DESCENT RATE MUST ALSO FALL BETWEEN 90-180 FT/MIN.

Reducing

Risks

MUST BE CALIBRATED ANNUALLY

SAMPLE TO BE DESTRUCTED TO VERIFY MATERIALS

F.O.S. VARIES - REFER TO BS5655/PD 6500

METAL END FITTINGS ONLY

THEY ARE NOT USED FOR SUPPORTING PERSONNEL.

ii)

THEIR USE IS INFREQUENT TO THE EXTENT THAT WEAR IS

NOT AN ADVERSE FACTOR AND

iii)

THEY ARE ADEQUATELY COATED/PROTECTED SO THAT

CORROSION IS NOT AN ADVERSE FACTOR.

NOTE 2: IN ADDITION TO THE ANNUAL EXAMINATION, SAFE LOAD

INDICATORS MUST BE FUNCTION CHECKED ON A DAILY BASIS AND

AT THE DISCRETION OF THE INSPECTION BODY

ACCEPTED PRACTICE

i)

2010

CHECKED FOR CALIBRATION WEEKLY.

NOTE 3: FOR LIFTING. LOWERING OR SUPPORTING PERSONNEL, LIFTING

EQUIPMENT, I.E. LIFTING APPLIANCES AND LIFTING ACCESSORIES

MUST BE VISUALLY EXAMINED BY A COMPETENT PERSON AT

INTERVALS NOT EXCEEDING 6 MONTHS AND BY THE USER

PLUS N.D.T. REPORT

IMMEDIATELY BEFORE USE.

NOTE 4:

NSL 42 Queens Road Aberdeen AB15 4YE

Tel: +44(0)1224 208988 Fax: +44(0)1224 208044

e-mail: info@nsl-aber deen.com web site: www.nsl-aberdeen.com

Copyright North Sea Lifting Limited 1989 (REVISED 2010)

SI 2006 NO 2184 (MARINE VERSION OF LOLER) REQUIRES THAT ALL

SHIPS LIFTING EQUIPMENT MUST BE TESTED BY A COMPETENT

PERSON EVERY 5 YEARS.

Potrebbero piacerti anche

- NSL Loler MatrixDocumento1 paginaNSL Loler MatrixBrian McIntoshNessuna valutazione finora

- NSL Loler MatrixDocumento1 paginaNSL Loler MatrixJogi Oscar SinagaNessuna valutazione finora

- BS 07121-2-4-2013Documento36 pagineBS 07121-2-4-2013Abdel Rahman SalahNessuna valutazione finora

- Instructions For The Safe Use Of: Wire Rope SlingsDocumento2 pagineInstructions For The Safe Use Of: Wire Rope SlingsStuartWilliamGlennieNessuna valutazione finora

- Bs 7121 Part2-2003 (Code of Practice For Safe Use of Cranes-IDocumento1 paginaBs 7121 Part2-2003 (Code of Practice For Safe Use of Cranes-ISmeb PoltNessuna valutazione finora

- Unit 1.14 - Shackles: 1.1 Body and Pin Forging 1.2 Heat Treatment 1.3 FinishDocumento8 pagineUnit 1.14 - Shackles: 1.1 Body and Pin Forging 1.2 Heat Treatment 1.3 Finisheetua100% (2)

- Guidance on design, inspection and use of water bagsDocumento7 pagineGuidance on design, inspection and use of water bagsGaniyuNessuna valutazione finora

- LEEA ACADEMY STEP NOTES - Foundation - Aug2018 - v1.8 Print PDFDocumento72 pagineLEEA ACADEMY STEP NOTES - Foundation - Aug2018 - v1.8 Print PDFSelva GanapathiNessuna valutazione finora

- Lifting Standards List: Item Description Standard / Last Edition Remarks 1 2 3 4Documento1 paginaLifting Standards List: Item Description Standard / Last Edition Remarks 1 2 3 4Ahmed Awwad100% (1)

- BSEN 1492-4 2004 Textile SlingsDocumento46 pagineBSEN 1492-4 2004 Textile SlingsCashew Pandaram100% (1)

- Guidance CE Marking Lifting Products No Harmonized StandardDocumento9 pagineGuidance CE Marking Lifting Products No Harmonized StandardDeepak RMNessuna valutazione finora

- Don't Gamble With Your Lifting Equipment: LMM LMP RCSDocumento78 pagineDon't Gamble With Your Lifting Equipment: LMM LMP RCSdsn_sarma0% (1)

- Crosby Rigging EquipmentDocumento20 pagineCrosby Rigging EquipmentJason MillerNessuna valutazione finora

- BS en 13414-1 2003 PresentationDocumento6 pagineBS en 13414-1 2003 PresentationAlbadeel Inspection & Conformity Co. ltd100% (1)

- LEEA-062 General Guidance To The Manufacturer of Lifting Equipment To The Development of Instructions For Use Version 1 April 2015 PDFDocumento11 pagineLEEA-062 General Guidance To The Manufacturer of Lifting Equipment To The Development of Instructions For Use Version 1 April 2015 PDFUlviyye ElesgerovaNessuna valutazione finora

- LEEA Handbook PDFDocumento1 paginaLEEA Handbook PDFparamarthasom1974Nessuna valutazione finora

- BS en 13414 1 PDFDocumento3 pagineBS en 13414 1 PDFAbbey Quarm50% (6)

- Web-Sling-Recommended-Operating-and-Inspection-GuidelineDocumento12 pagineWeb-Sling-Recommended-Operating-and-Inspection-GuidelineibrahimNessuna valutazione finora

- LEEA 059 5 Guidance To Documentation & Marking Part5Documento23 pagineLEEA 059 5 Guidance To Documentation & Marking Part5GaniyuNessuna valutazione finora

- LEEA-015 BSI Reference Library List - Version 09 - Jan 2021Documento32 pagineLEEA-015 BSI Reference Library List - Version 09 - Jan 2021GaniyuNessuna valutazione finora

- Pad LEEA-048 Guidance On The Design Testing and Inspection of Fabricated Pad EyesDocumento3 paginePad LEEA-048 Guidance On The Design Testing and Inspection of Fabricated Pad EyesAnirudh S. Goel83% (6)

- Wire Rope Slings Wire Rope SlingsDocumento6 pagineWire Rope Slings Wire Rope SlingsegyinspectoryahooNessuna valutazione finora

- zoomlion-truck-QY100 HDocumento16 paginezoomlion-truck-QY100 Hالبديري بهاءNessuna valutazione finora

- International Standards Compared To ASME B30 May 2014Documento26 pagineInternational Standards Compared To ASME B30 May 2014dsnsarmaNessuna valutazione finora

- Guidance on Verifying Runway Beam StrengthDocumento42 pagineGuidance on Verifying Runway Beam StrengthTiago CastelaniNessuna valutazione finora

- Foundation Course (FOU) : DescriptionDocumento15 pagineFoundation Course (FOU) : DescriptionVinu VincentNessuna valutazione finora

- No. 8 - Chain & Chain SlingsDocumento11 pagineNo. 8 - Chain & Chain SlingsAhmed AtefNessuna valutazione finora

- BS en 13414-2-2003 + A2-2008Documento26 pagineBS en 13414-2-2003 + A2-2008Horas CanmanNessuna valutazione finora

- Rigcheck Card: Rigging Equipment Working Load LimitsDocumento12 pagineRigcheck Card: Rigging Equipment Working Load Limitsjinyuan74100% (2)

- Banksman SlingerDocumento9 pagineBanksman SlingerPirlo PoloNessuna valutazione finora

- Synthetic Polyester Roundslings: Recommended Standard SpecificationDocumento38 pagineSynthetic Polyester Roundslings: Recommended Standard SpecificationDiegoNessuna valutazione finora

- Rating of Lifting GearDocumento10 pagineRating of Lifting GeareetuaNessuna valutazione finora

- LEI Mod2 Procedures PDFDocumento56 pagineLEI Mod2 Procedures PDFTrust Emma100% (2)

- Modular Spreader Systems for Safe, Cost-Effective LiftingDocumento8 pagineModular Spreader Systems for Safe, Cost-Effective LiftingPSKUMAR2012Nessuna valutazione finora

- LEEA-059-1 Documentation and Marking - Part 1 Manual Lifting Machines - Version 2 PDFDocumento14 pagineLEEA-059-1 Documentation and Marking - Part 1 Manual Lifting Machines - Version 2 PDFopreamihNessuna valutazione finora

- BS 07121-2-9 PDFDocumento40 pagineBS 07121-2-9 PDFZain AliNessuna valutazione finora

- SI-01 - R03 Banksman-Crane Operations PDFDocumento64 pagineSI-01 - R03 Banksman-Crane Operations PDFFatih D. PrasetioNessuna valutazione finora

- Iso4310 1981Documento6 pagineIso4310 1981somsak9100% (2)

- Wire Rope GuideDocumento30 pagineWire Rope GuideAnonymousNessuna valutazione finora

- Spreader Bar to Wire Rope ReportsDocumento10 pagineSpreader Bar to Wire Rope ReportsDefid Harfiedz Doank100% (1)

- Crane & Rigging Safety: D/d Ratio & Multi-Part Braided SlingsDocumento1 paginaCrane & Rigging Safety: D/d Ratio & Multi-Part Braided SlingskaniniuserNessuna valutazione finora

- LEEA - Instruction For Safe Use of Flat Woven Webbing SlingsDocumento2 pagineLEEA - Instruction For Safe Use of Flat Woven Webbing Slingsdonnyars1979Nessuna valutazione finora

- Sae J 765 (1990-10) Crane Load Stability Test Code PDFDocumento8 pagineSae J 765 (1990-10) Crane Load Stability Test Code PDFAdrianNessuna valutazione finora

- BS 7121-1Documento43 pagineBS 7121-1suranga100% (2)

- Din en 13414 2 2003Documento22 pagineDin en 13414 2 2003utopian_player100% (1)

- Mobile CraneDocumento82 pagineMobile Cranehessian123100% (3)

- Sling Table To BS en 13414 For IWRCDocumento1 paginaSling Table To BS en 13414 For IWRCMahmoudElrashedy100% (1)

- SAEJ987 V 001Documento22 pagineSAEJ987 V 001hemnNessuna valutazione finora

- Verification of Lifting EquipmentDocumento14 pagineVerification of Lifting EquipmentsurnaikNessuna valutazione finora

- Wire Rope Discard CriteriaDocumento14 pagineWire Rope Discard CriteriaDhanraj Patil100% (1)

- Sabs GuideDocumento3 pagineSabs Guidealextentwenty0% (1)

- Slings Standards RequirementsDocumento15 pagineSlings Standards RequirementsBinoy GopinathanNessuna valutazione finora

- BS 3243 Hand Oprated Chain Blocks PDFDocumento15 pagineBS 3243 Hand Oprated Chain Blocks PDFPD AWSSIESPNessuna valutazione finora

- BS 7121-3-2017+a1-2019 PDFDocumento74 pagineBS 7121-3-2017+a1-2019 PDFAsh Turner100% (12)

- No. 47 Crane Rail InspectionDocumento3 pagineNo. 47 Crane Rail InspectionDaniel ConwayNessuna valutazione finora

- BS en 12644-2 Cranes Information For Use and Testing - MarkinDocumento10 pagineBS en 12644-2 Cranes Information For Use and Testing - MarkinMohamed Farouk50% (2)

- Wire Rope SlingsDocumento5 pagineWire Rope SlingsEr Faiyaz AhmedNessuna valutazione finora

- LEEA Academy MCE Module Quiz Paper - ANSWERS Mar20Documento39 pagineLEEA Academy MCE Module Quiz Paper - ANSWERS Mar20Rana Danish100% (1)

- Wstda Threads Th-1Documento13 pagineWstda Threads Th-1lsgmzNessuna valutazione finora

- NSL Loler MatrixDocumento1 paginaNSL Loler MatrixAndrew Grimes100% (1)

- A Ins CoughDocumento218 pagineA Ins CoughMarkHenryStonesNessuna valutazione finora

- BS 7121-PART4-1997 (Code of Practice For Safe Use of Cranes-L PDFDocumento26 pagineBS 7121-PART4-1997 (Code of Practice For Safe Use of Cranes-L PDFFaheem KhanNessuna valutazione finora

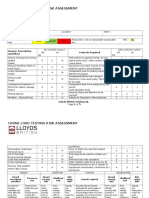

- Crane Load Testing Risk AssessmentDocumento5 pagineCrane Load Testing Risk Assessmentdel3333100% (4)

- Velosi Training Courses 2009-2010-2011Documento54 pagineVelosi Training Courses 2009-2010-2011del3333Nessuna valutazione finora

- Crane Lifting CapacityDocumento3 pagineCrane Lifting CapacityKamran AbidNessuna valutazione finora

- Crane Load Testing Risk AssessmentDocumento5 pagineCrane Load Testing Risk Assessmentdel3333100% (4)

- Eg 3360-01 Crawler Crane DefectDocumento1 paginaEg 3360-01 Crawler Crane Defectdel3333Nessuna valutazione finora

- EG 3360-01 Crawler Crane Inspection Check ListDocumento24 pagineEG 3360-01 Crawler Crane Inspection Check Listdel3333100% (3)

- As 1891.1 - Industrial Fall-Arrest Systems and Devices Pt.1 Harnesses and Ancillary EquipmentDocumento52 pagineAs 1891.1 - Industrial Fall-Arrest Systems and Devices Pt.1 Harnesses and Ancillary Equipmentdel3333100% (2)

- BS 302-4 1987 Wire RopesDocumento12 pagineBS 302-4 1987 Wire Ropesdel3333Nessuna valutazione finora

- As 1576.1 - Scaffolding Pt.1 General RequirementsDocumento20 pagineAs 1576.1 - Scaffolding Pt.1 General Requirementsdel3333Nessuna valutazione finora

- SAIPEM 3000 OFFSHORE HEAVY LIFT VESSELDocumento8 pagineSAIPEM 3000 OFFSHORE HEAVY LIFT VESSELdel3333Nessuna valutazione finora

- Applied Econometrics ModuleDocumento142 pagineApplied Econometrics ModuleNeway Alem100% (1)

- Readiness of Barangay Masalukot During TyphoonsDocumento34 pagineReadiness of Barangay Masalukot During TyphoonsJerome AbrigoNessuna valutazione finora

- Cache Memory in Computer Architecture - Gate VidyalayDocumento6 pagineCache Memory in Computer Architecture - Gate VidyalayPAINNessuna valutazione finora

- Business Plan - Docx 3-Star Hospitality and Tourism Devt Centre in Mbarara - UgandaDocumento49 pagineBusiness Plan - Docx 3-Star Hospitality and Tourism Devt Centre in Mbarara - UgandaInfiniteKnowledge100% (9)

- Right To Resist Unlawful ArrestDocumento1 paginaRight To Resist Unlawful ArrestThoth AtlanteanNessuna valutazione finora

- Convert MS Word Documents to LinuxDocumento16 pagineConvert MS Word Documents to Linux8043 Nitish MittalNessuna valutazione finora

- Soft SkillsDocumento117 pagineSoft Skillskiran100% (1)

- An-7004 IGBT Driver Calculation Rev00Documento8 pagineAn-7004 IGBT Driver Calculation Rev00Raghuram YaramatiNessuna valutazione finora

- BSC in EEE Full Syllabus (Credit+sylabus)Documento50 pagineBSC in EEE Full Syllabus (Credit+sylabus)Sydur RahmanNessuna valutazione finora

- Zellner Bayesian AnalysisDocumento4 pagineZellner Bayesian AnalysisfoopeeNessuna valutazione finora

- Balanced Modulator and Demodulator ExperimentDocumento6 pagineBalanced Modulator and Demodulator ExperimentShubham SharmaNessuna valutazione finora

- Spec 2 - Activity 08Documento6 pagineSpec 2 - Activity 08AlvinTRectoNessuna valutazione finora

- Soal Pat Inggris 11Documento56 pagineSoal Pat Inggris 11dodol garutNessuna valutazione finora

- Ex 1-3 Without OutputDocumento12 pagineEx 1-3 Without OutputKoushikNessuna valutazione finora

- 2019-03-30 New Scientist PDFDocumento60 pagine2019-03-30 New Scientist PDFthoma leongNessuna valutazione finora

- The Little Book of Deep Learning: An Introduction to Neural Networks, Architectures, and ApplicationsDocumento142 pagineThe Little Book of Deep Learning: An Introduction to Neural Networks, Architectures, and Applicationszardu layakNessuna valutazione finora

- Term Paper Mec 208Documento20 pagineTerm Paper Mec 208lksingh1987Nessuna valutazione finora

- Table of Forces For TrussDocumento7 pagineTable of Forces For TrussSohail KakarNessuna valutazione finora

- Carbon Trust Certification OverviewDocumento2 pagineCarbon Trust Certification OverviewMatt MaceNessuna valutazione finora

- LK BMHS 30 September 2021Documento71 pagineLK BMHS 30 September 2021samudraNessuna valutazione finora

- PROTON Preve 2012 On 4 DR Sal 1.6 Premium (CFE) AUTO 138Bhp (A) (04/12-)Documento12 paginePROTON Preve 2012 On 4 DR Sal 1.6 Premium (CFE) AUTO 138Bhp (A) (04/12-)bluhound1Nessuna valutazione finora

- 60 Years of Cannes Lions Infographics: The 50sDocumento9 pagine60 Years of Cannes Lions Infographics: The 50sSapientNitroNessuna valutazione finora

- CS221 - Artificial Intelligence - Machine Learning - 3 Linear ClassificationDocumento28 pagineCS221 - Artificial Intelligence - Machine Learning - 3 Linear ClassificationArdiansyah Mochamad NugrahaNessuna valutazione finora

- Fifeville Plan: Building A Connected CommunityDocumento92 pagineFifeville Plan: Building A Connected CommunityAl DiNessuna valutazione finora

- University of Cebu-Main Campus Entrepreneurship 100 Chapter 11 QuizDocumento3 pagineUniversity of Cebu-Main Campus Entrepreneurship 100 Chapter 11 QuizAnmer Layaog BatiancilaNessuna valutazione finora

- Bataan Peninsula State University - Balanga Campus: Certificate of RegistrationDocumento1 paginaBataan Peninsula State University - Balanga Campus: Certificate of RegistrationMichael PeraltaNessuna valutazione finora

- R20qs0004eu0210 Synergy Ae Cloud2Documento38 pagineR20qs0004eu0210 Synergy Ae Cloud2Слава ЗавьяловNessuna valutazione finora

- SSPC Paint 25 BCSDocumento6 pagineSSPC Paint 25 BCSanoopkumarNessuna valutazione finora

- Computer Application in Business NOTES PDFDocumento78 pagineComputer Application in Business NOTES PDFGhulam Sarwar SoomroNessuna valutazione finora