Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

sis8BBC111prt PDF

Caricato da

marsh2002Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

sis8BBC111prt PDF

Caricato da

marsh2002Copyright:

Formati disponibili

Copyright 1991, 2013 Caterpillar Inc. All Rights Reserved.

Page 1 of 4

AXL 966GII WHEEL LOADER Testing & Adjusting

Media Number RENR4387-07 Publication Date 2003/10/01 Update Date 2003/10/07

Transmission Control (Shift Lever) - Test

SMCS Code: 3065-038

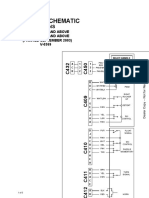

Illustration 100

Problems with the transmission direction and speed control lever will cause the machine to respond incorrectly to the actions

of the lever. Some problems with the transmission direction and speed control lever will cause the transmission to remain in

the present speed and direction when a problem is detected. Other problems with the transmission direction and speed control

lever will cause the transmission to shift to neutral.

1.

View the status.

a. Use the Caterpillar Electronic Technician (ET) to view the status "Group 1 Gear Lever Parameters".

b. Actuate the transmission direction and speed control lever through all speeds in forward and reverse. Verify the

positions on the display of the ET.

c. Operate the machine in all speeds and all directions. All speeds and all directions may not be available.

Expected Result: The fault is NOT present.

Results:

OK - The fault is NOT present. Suspect an intermittent fault. STOP.

NOT OK - The fault is still present. Document the positions which are not correct on the display of the ET. Proceed to Step

2.

file://C:\SIS\TMP\sis8BBC1prt.html

25/05/2013

Copyright 1991, 2013 Caterpillar Inc. All Rights Reserved.

Page 2 of 4

2.

Check the harness.

a. Check the harness connectors and the harness from the transmission direction and speed control lever to the power

train electronic control module (ECM).

b. Thoroughly inspect the connectors for the transmission direction and speed control lever and the connectors for the

power train ECM.

c. Visually inspect the harness wiring from the transmission direction and speed control lever to the power train ECM.

d. Use the ET to view the status "Group 1 Gear Lever Parameters".

e. Actuate the transmission direction and speed control lever through all speeds in forward and reverse. Verify the

positions on the display for the ET.

f. Operate the machine in all speeds and all directions. All speeds and all directions may not be available.

Expected Result: The harness and harness connectors are correct. The fault is NOT present.

Results:

OK - The harness and the harness connectors are correct. The fault is NOT present. Proceed to Step 3.

NOT OK - The harness and/or the harness connectors are NOT correct and the fault is still present. Repair the machine

harness and/or the harness connectors. If necessary, replace the machine harness and/or the harness connectors. Ensure that

all the seals are properly in place. Also, check that the connectors mate completely. Verify that the repair eliminates the

problem. Clear all diagnostic codes. STOP.

3.

Check the voltage.

a. Disconnect the transmission direction and speed control lever from the machine harness.

b. With the key start switch in the ON position, measure the voltage between pin 1 and pin 3 of the 12-pin connector

for the transmission direction and speed control lever.

Expected Result: System voltage is present.

Results:

OK - System voltage is present. Proceed to Step 4.

NOT OK - System voltage is NOT present. There is a problem with the power supply to the transmission direction and

speed control lever. Check the fuse for the transmission direction and speed control lever and the associated harness. STOP.

4.

Check the continuity.

file://C:\SIS\TMP\sis8BBC1prt.html

25/05/2013

Copyright 1991, 2013 Caterpillar Inc. All Rights Reserved.

Page 3 of 4

a. Ensure that the key start switch is in the OFF position.

b. The transmission direction and speed control lever and the power train ECM are disconnected from the machine

harness.

c. Check for continuity from pin 1 on the 12-pin connector of the transmission direction and speed control lever to all

active pins on the 12-pin connector, except pin 3.

Expected Result: Continuity is NOT present.

Results:

OK - Continuity is NOT present. Proceed to Step 5.

NOT OK - Continuity is present. The problem is in the harness. Repair the harness or replace the harness.

5.

Check the continuity.

a. Check for continuity from pin 3 on the 12-pin connector of the transmission direction and speed control lever to all

active pins of the 12-pin connector, except pin 1.

Expected Result: Continuity is NOT present.

Results:

OK - Continuity is NOT present. Proceed to Step 6.

NOT OK - Continuity is present. The problem is in the harness. Repair the harness or replace the harness. STOP.

6.

Check the transmission direction and speed control lever.

a. Reconnect the connectors for the power train ECM.

b. Create a jumper wire that can short from pin 1 to two of the other pins on the connector for the transmission

direction and speed control lever.

c. The key start switch should be in the ON position.

d. Use the ET to display "Group 1 Gear Lever Parameters". Conduct the following items and view the parameters on

the ET.

Connect the jumper from pin 1 to pins 5 and 7. The gear lever should read "1".

Connect the jumper from pin 1 to pins 5 and 8. The gear lever should read "2".

file://C:\SIS\TMP\sis8BBC1prt.html

25/05/2013

Copyright 1991, 2013 Caterpillar Inc. All Rights Reserved.

Page 4 of 4

Connect the jumper from pin 1 to pins 5 and 9. The gear lever should read "3".

Connect the jumper from pin 1 to pins 5 and 11. The gear lever should read "4".

Connect the jumper from pin 1 to pins 6 and 7. The gear lever should read "1R".

Connect the jumper from pin 1 to pins 6 and 8. The gear lever should read "2R".

Connect the jumper from pin 1 to pins 6 and 9. The gear lever should read "3R".

Connect the jumper from pin 1 to pins 6 and 11. The gear lever should read "4R".

Connect the jumper from pin 1 to pins 11 and 12. The gear lever should read "N".

Expected Result: All the gear parameters read correct.

Results:

OK - All gear parameters read correct. Replace the transmission direction and speed control lever and verify correct

operation. STOP.

NOT OK - All gear parameters DO NOT read correct. It is unlikely that the power train ECM is faulty. Exit this procedure

and perform this CID FMI again. If the cause of the fault is not found, replace the power train ECM. Refer to Testing and

Adjusting, "Electronic Control Module (Power Train) - Replace" for more information on replacing the power train ECM.

STOP.

Copyright 1991, 2013 Caterpillar Inc.

All Rights Reserved.

file://C:\SIS\TMP\sis8BBC1prt.html

25/05/2013

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Holden Commodore Engine Control Module InformationDocumento80 pagineHolden Commodore Engine Control Module InformationJosé Luiz CitolinoNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Transmission Wiring PDFDocumento1 paginaTransmission Wiring PDFmarsh2002Nessuna valutazione finora

- 5.2 OutriggerDocumento11 pagine5.2 Outriggermarsh2002Nessuna valutazione finora

- Solution Manual For Construction Planning and Scheduling 4 e Jimmie W Hinze Isbn 10 0132473984 Isbn 13 9780132473989Documento28 pagineSolution Manual For Construction Planning and Scheduling 4 e Jimmie W Hinze Isbn 10 0132473984 Isbn 13 9780132473989ooetheca.babiism.jomi3100% (49)

- Blink Code List For WP12 Diesel EnginesDocumento12 pagineBlink Code List For WP12 Diesel Enginesmarsh2002Nessuna valutazione finora

- Engine Wiring Diagram: 2800 SeriesDocumento2 pagineEngine Wiring Diagram: 2800 Seriesmarsh2002100% (4)

- This Content Is Currently Not Available!Documento1 paginaThis Content Is Currently Not Available!marsh2002Nessuna valutazione finora

- sisEB48887f374479loader g2Documento1 paginasisEB48887f374479loader g2marsh2002Nessuna valutazione finora

- sisEB48f374479loader g2444Documento1 paginasisEB48f374479loader g2444marsh2002Nessuna valutazione finora

- sisEB48f375554479loader g2Documento1 paginasisEB48f375554479loader g2marsh2002Nessuna valutazione finora

- sisEB48f374479loader g2Documento1 paginasisEB48f374479loader g2marsh2002Nessuna valutazione finora

- Product Model and NameplateDocumento4 pagineProduct Model and Nameplatemarsh2002Nessuna valutazione finora

- DTC P0778 Pressure Control Solenoid "B" Electrical (Shift Solenoid Valve SL2)Documento3 pagineDTC P0778 Pressure Control Solenoid "B" Electrical (Shift Solenoid Valve SL2)marsh2002Nessuna valutazione finora

- 966G II Wheel Loader AXJ00001-UP (MACHINE) POWERED BY 3176 Engine (SEBP3279 - 63) - Document StructureDocumento5 pagine966G II Wheel Loader AXJ00001-UP (MACHINE) POWERED BY 3176 Engine (SEBP3279 - 63) - Document Structuremarsh2002Nessuna valutazione finora

- The Slewing Mechanism, Which Can Realized 360° Full-Circle Slewing, Consists of The Hydraulic Motor, The Planet-Gear Reducer, The Brake, The Driving Gear and The Slewing Ring and So OnDocumento3 pagineThe Slewing Mechanism, Which Can Realized 360° Full-Circle Slewing, Consists of The Hydraulic Motor, The Planet-Gear Reducer, The Brake, The Driving Gear and The Slewing Ring and So Onmarsh2002Nessuna valutazione finora

- OperationDocumento4 pagineOperationmarsh2002Nessuna valutazione finora

- D375a-5 SN.18052 ... (JPN) VHMS Specification.2Documento1 paginaD375a-5 SN.18052 ... (JPN) VHMS Specification.2marsh2002Nessuna valutazione finora

- BleedingDocumento2 pagineBleedingmarsh2002Nessuna valutazione finora

- Main Technical SpecificationsDocumento10 pagineMain Technical Specificationsmarsh2002Nessuna valutazione finora

- Important InstructionDocumento2 pagineImportant Instructionmarsh2002Nessuna valutazione finora

- 11 Appendix : Standard Hand Signals For Lifting OperationDocumento4 pagine11 Appendix : Standard Hand Signals For Lifting Operationmarsh2002Nessuna valutazione finora

- TroubleshootingDocumento6 pagineTroubleshootingmarsh2002Nessuna valutazione finora

- V 0368 6Documento6 pagineV 0368 6marsh2002Nessuna valutazione finora

- MY16 Captiva Product InformationDocumento7 pagineMY16 Captiva Product Informationmarsh2002Nessuna valutazione finora

- Deep Foundation Sensor Part NoDocumento1 paginaDeep Foundation Sensor Part Nomarsh2002Nessuna valutazione finora

- 751 Wiring Schematic: OptionsDocumento6 pagine751 Wiring Schematic: Optionsmarsh2002Nessuna valutazione finora

- MID 039 - CID 0070 - FMI 02: Shutdown SISDocumento5 pagineMID 039 - CID 0070 - FMI 02: Shutdown SISmarsh2002Nessuna valutazione finora

- 966 F Loader444 PDFDocumento14 pagine966 F Loader444 PDFmarsh2002Nessuna valutazione finora

- V 0368 6Documento6 pagineV 0368 6marsh2002Nessuna valutazione finora

- Cummins Solonied Part NoDocumento2 pagineCummins Solonied Part Nomarsh2002Nessuna valutazione finora

- Tibbo2 Tps Catalogue EngDocumento4 pagineTibbo2 Tps Catalogue EngseacerNessuna valutazione finora

- Networks Pre Connection AttacksDocumento15 pagineNetworks Pre Connection AttacksSoweirdNessuna valutazione finora

- In-Sight Vision Systems - Catalogo de HerramientasDocumento52 pagineIn-Sight Vision Systems - Catalogo de HerramientasManuel HTNessuna valutazione finora

- Prep at Ease: Internship/Project (3180701)Documento19 paginePrep at Ease: Internship/Project (3180701)Shail HiraniNessuna valutazione finora

- Aten KVM Switch ManualDocumento86 pagineAten KVM Switch ManualDiNessuna valutazione finora

- Design and Implement Special Stack Data Structure - Added Space Optimized Version - GeeksforGeeksDocumento35 pagineDesign and Implement Special Stack Data Structure - Added Space Optimized Version - GeeksforGeekslongphiycNessuna valutazione finora

- Ah en Emalytics Installation Guide 109859 en 07Documento8 pagineAh en Emalytics Installation Guide 109859 en 07thamer al-salekNessuna valutazione finora

- Cae PDFDocumento56 pagineCae PDFChetan HcNessuna valutazione finora

- Mobile First Architecture - Customer PresentationDocumento39 pagineMobile First Architecture - Customer PresentationLeonardo MenesesNessuna valutazione finora

- Trigno Wireless System Users Guide (MAN-012!2!6)Documento43 pagineTrigno Wireless System Users Guide (MAN-012!2!6)DaxterChaw100% (1)

- Student Campus Placement Prediction Analysis Using ChiSquared Test On Machine Learning Algorithms-IJRASETDocumento10 pagineStudent Campus Placement Prediction Analysis Using ChiSquared Test On Machine Learning Algorithms-IJRASETIJRASETPublicationsNessuna valutazione finora

- STUDENT ID: 25211207696: Exercise (Lab) 6Documento6 pagineSTUDENT ID: 25211207696: Exercise (Lab) 6Long Trần HoàngNessuna valutazione finora

- Group A CN Assignment 3Documento13 pagineGroup A CN Assignment 3Usama RaheemNessuna valutazione finora

- Drive SiemensDocumento368 pagineDrive SiemensFabio PioNessuna valutazione finora

- Iot Lecture PDFDocumento423 pagineIot Lecture PDFshubhamNessuna valutazione finora

- Servicing The Philips Family Ultrasound Epiq 5/7 (2.5 Day)Documento1 paginaServicing The Philips Family Ultrasound Epiq 5/7 (2.5 Day)Mai Thanh SơnNessuna valutazione finora

- Quemador WG-30Documento16 pagineQuemador WG-30chuyNessuna valutazione finora

- Non-Linear Time History Analysis of Tall Building Having Mass, Stiffness and Vertical Geometric IrregularityDocumento28 pagineNon-Linear Time History Analysis of Tall Building Having Mass, Stiffness and Vertical Geometric IrregularitySaba 2413Nessuna valutazione finora

- Battery Backup: DC Converter (For A10) Quick Installation GuideDocumento3 pagineBattery Backup: DC Converter (For A10) Quick Installation GuideMessias AzlanNessuna valutazione finora

- 300 Embedded Programming Problems by Yashwanth Naidu TDocumento85 pagine300 Embedded Programming Problems by Yashwanth Naidu TSai Krishna K VNessuna valutazione finora

- PW40 LavadorDocumento80 paginePW40 LavadorHamann AlejandroNessuna valutazione finora

- SDN 101 GuideDocumento10 pagineSDN 101 Guideemeka ozuomeNessuna valutazione finora

- Kevin Lun ResumeDocumento1 paginaKevin Lun Resumeapi-270258424Nessuna valutazione finora

- 새 텍스트 문서 - 복사본 - 복사본Documento7 pagine새 텍스트 문서 - 복사본 - 복사본DyrdNessuna valutazione finora

- HBR The Smart-Talk TrapDocumento12 pagineHBR The Smart-Talk Traprazvan.vranceanuNessuna valutazione finora

- OPTIKA DOWNLOAD LINK SOFTWARES Technical Datasheet ENDocumento2 pagineOPTIKA DOWNLOAD LINK SOFTWARES Technical Datasheet ENmister curiosityNessuna valutazione finora

- XT2235-x (Devon 4G - Moto g32) - MB Schematics - L3 RepairDocumento44 pagineXT2235-x (Devon 4G - Moto g32) - MB Schematics - L3 RepairluumNessuna valutazione finora

- T24 VersionsDocumento26 pagineT24 VersionsCHARLES TUMWESIGYE100% (1)

- Vikram M Shah AadharDocumento1 paginaVikram M Shah AadharPhaneendra KumarNessuna valutazione finora