Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Buroughs BAR GRAPH Display

Caricato da

radovanovd0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

23 visualizzazioni4 pagineApplication Notes

Copyright

© © All Rights Reserved

Formati disponibili

PDF o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoApplication Notes

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

23 visualizzazioni4 pagineBuroughs BAR GRAPH Display

Caricato da

radovanovdApplication Notes

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

Sei sulla pagina 1di 4

Burroughs 4y3

BULLETIN NO. BG101C

July 1976

Application Notes

BAR GRAPH DISPLAY FOR INSTRUMENTS

INTRODUCTION

The Burroughs SELF-SCAN® bar graph displays are

flat panel indicators that provide analog displays with

digital accuracy. While bar graphs can be designed

and manufactured in almost any configuration, this

application note describes two dual linear bar graphs

anda circular bar graph. These 3 devices, as well as

most custom displays, are basically identical in opera-

tion and construction. These displays can have such

diverse applications as:

Process Control

Automobile Displays

Panel Meters

Depth Indicators

Aircraft Displays

Level Indicators

The soft neon orange glow characteristic of gas dis-

charge display technology provides a display that is

uniformly bright, yet pleasing to the eye, while the

display has sufficient contrast to be viewed comfor-

tably under high ambient illumination. Added

features of low-cost drive circuitry and low power

consumption make this all-electronic display an ideal

solution to nearly any problem.The extremely rugged

display may be incorporated in equipment subject to

severe shock and vibration with ease.

DESCRIPTION

‘The bar graph panels are manufactured using ad-

vanced thick film technology for high reliability.

Burroughs’ internal addressing technique used in the

igure 1. SELF SCAN

Bar Graph Displays

SELF-SCAN panels eliminates a majority of the ad-

dressing electronics required for a comparable

matrixed display. Figure 1 shows the bar graph dis-

plays described here. There are two dual linear bar

graphs: one with 100 elements in each bar for 1%

resolution, the other with 200 elements in each bar

for 14% resolution. The circular bar has 120 elements

on 3-degree centers with every 5th element

elongated.

CONSTRUCTION

The bar graph panels are constructed of a rear sub-

strate, spacer, and glass front plate as shown inFigure

2. The desired segment patterns screened onto the

substrate using a conductive ink. A black dielectric

mask is also screened onto the substrate to create a

light-absorbent background, enhancing the contrast

ratio. The front glass has two transparent anodes and

anode contacts applied for the dual linear bar graph

displays (one transparent anode and anode contact

for the circular bar graph). A spacer is placed between

the front and rear surfaces. The entire display is then

sealed and filled with a neon gas mixture. All pane!

connections are made through a connector assembly

that slides between the opposing surfaces of the sub-

strate and front glass, and mates with the printed

contacts that are on one end of the panel.

THEORY OF OPERATION

The display segments are illuminated by using the

glow transfer principle, where the glow is established

atthe reset cathode and then transferred sequentially

to the desired segment of the panel at approximately

70 cycles per second.

Figure 3 is a combined isometric and block diagram

designed to demonstrate the circuitry required for a

dual linear bar graph. Figure 4 demonstrates the cir-

cuitry required for a circular bar graph.

When the panel is energized, the +250V potential

between the keep-alive anode and cathode es-

tablishes a glow discharge at this area.

The phase generator controls the transferral of the

glow along the bar. The phase generator for the linear

GLASS PLATE

Nove.

spacer

carHones,

‘suaSTRATE

bar graphs is a three-phase plus reset circuit; for the

circular bar graph, itis a five-phase plus reset circuit.

To initiate a scan, the reset transistor Q1 is turnedon,

subsequently grounding the reset cathode. The reset

and phase drive anodes are connected to the +250V

source through limiting resistors. When the reset

cathode is grounded, ionization of the gas occurs at

this one cathode.

The counter advances on the next clock pulse, and

phase 1 transistor Q2 is turned on, while the reset

cathode is returned to the off condition.

NOTE

The following description is written for a

dual linear bar graph, The circular bar

operates in a similar fashion, although

there are 5 phases instead of 3and the Sth

phase is held on for two clock pulses.

Transistor Q2, coupled to the phase 1 bus, grounds

every third cathode, and ionization rapidly transfers

on the surface of cathode 1, while at the same time,

ionization is no longer supported at the reset cathode.

The glow will only occur at the adjacent or nearest

grounded cathode because once ionization occurs at

this cathode, the anode voltage drops, due to current

flow, to a level high enough to support ionization at

the desired cathode but too low to cause ionization at

any other grounded cathode.

The next clock pulse turns off transistor Q2 and turns

on transistor Q3, removing the ground from phase 1

cathodes and simultaneously grounding the phase 2

cathode bus, and transferring the glow to the second

cathode, Similarly, the next clock pulse turns off

phase 2 and grounds the phase 3 cathode bus.

SCREENED

CATHODE,

SEGMENTS

SCREENED

INTERNAL

S-PHASE.

SussING

Figure 2

PANEL CONSTRUCTION

+250v

input

SIGNAL 1

companaron

KEEP-ALIVE ANODE

SCREENED CATHODE SEGMENTS

‘SCREENED INTERNAL

KEEP-ALIVE CATHODE S+PHASE BUSSING

input compararoR

SIGNAL 2: RESET SEGNENT

REF. VOLTAGE

(FULL Bak

LENGHTH) or

RAMP

GENERATOR

passe [92

GENERATOR]

23

Figure 3

LINEAR BAR GRAPH CIRCUIT

‘coMPARATOR

nur KEEP-ALIVE

SIGNAL Vamaaat

+250v

. KEEP-ALIVE CATHODE ‘RESET SEGMENT

REF, VOLTAGE,

(rut par oR

tenets?

TReseT 2cLocK

PULSES wibe)

RAMP

[GENERATOR

mance [82

| GENERATOR | 5

95] (as 182 cock PuLses WIDE)

js) on

Figure 4

CIRCULAR BAR GRAPH CIRCUIT

As the counter advances, the cathode busses are se-

quentially grounded, causing the glow to transfer

along the panel. When the counter determines that a

sufficient number of clock pulses have been

generated to scan every cathode element, the reset

pulse generator is enabled, grounding the reset tran-

sistor Q1, and the scan cycle begins again.

To eliminate perceptible flickering, the scan rate

should be approximately 70 cycles per second, or ap-

proximately 14.2 mS per scan. Each cathode is then

on for the period shown in Table 1

Table 1. CATHODE “ON” TIMES (70 Hz Scan)

Number of

Bars Scanned

Any One Cathode

“On” Time

100 142 us

120 119 us

200 Thus

Since the phase 1 bus is connected to cathodes 1.4.7,

etc. whenever cathode 1 is grounded, so are cathodes

4and 7. However, the glow only appears at cathode 1

When cathode 1 is turned off, the glow transfers to

cathode 2 and ionization at cathode 1 begins to decay.

‘When cathodes 1 and 4 are again grounded (two clock

pulses later) the ionization has had to decay below a

point where a glow will again form on cathode 1

For further information, write to Burroughs Corporation, Electronic Components Di

of all our spect

ssles/applications assistance number, (201) 757-3400 in New Jersey, or (714) 835-7335 in Cal

Therefore, if a different scan rate is selected, the

period that each cathode must remain off before that

bus is grounded again is between 100 and 150 us.

BAR LENGTH CONTROL

In the dual linear bar graph panels, like cathode

segments for both channels are connected to three

common busses. A separate anode serves each

column of cathodes. A cathode in either channel will

glow whenever voltage greater than the ionization

voltage is applied between it and the anode for that

channel

In the circular bar graph panels, the cathode

segments are connected to five common phases and

a single anode serves all cathodes. A cathode will

glow whenever voltage greater than the ionization

voltage is applied between it and the anode.

The bar length is determined by terminating the glow

after the desired number of clock pulses. This is ac:

complished by turning the anode driver on at the

beginning of the reset period and turning it off at the

desired count.

DRIVE CIRCUITS

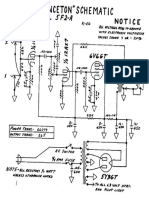

Figures 3 and 4 illustrate typical drive circuits as

provided in the Bar Graph Designer's Kits available

from Burroughs. This Kit contains all discrete com-

ponents and printed circuit board to enable you to

rapidly build an evaluation model to adapt the bar

graph to your program needs. For further informa:

tion on the kits, see Bulletin No. 5006.

ision, P. 0. Box 1226, Plainfield, New Jersey 07061;

nia, For overseas

Inquiries, write Burroughs ECD Internetional, Astronaut House, Feltham, Middlesex, England; or call (01) 890-9441 in England,

{reedom trom patent rights of ot

"This dato sheet

Potrebbero piacerti anche

- RCF Transducers PDFDocumento15 pagineRCF Transducers PDFradovanovdNessuna valutazione finora

- How To French Polish Classical Guitars PDFDocumento29 pagineHow To French Polish Classical Guitars PDFradovanovdNessuna valutazione finora

- Fender Princeton 5f2a SCHDocumento1 paginaFender Princeton 5f2a SCHradovanovdNessuna valutazione finora

- TL Audio 82 SchematicsDocumento8 pagineTL Audio 82 Schematicsradovanovd100% (1)

- Studer A727Documento170 pagineStuder A727radovanovdNessuna valutazione finora

- China Menu DecoderDocumento1 paginaChina Menu DecoderradovanovdNessuna valutazione finora

- TLA M1 SchematicsDocumento6 pagineTLA M1 SchematicsradovanovdNessuna valutazione finora

- Tannoy 1976 BrochureDocumento13 pagineTannoy 1976 BrochureradovanovdNessuna valutazione finora

- High Stepping Automatic Coil WinderDocumento7 pagineHigh Stepping Automatic Coil WinderradovanovdNessuna valutazione finora

- Soundcraft B400DDocumento12 pagineSoundcraft B400DradovanovdNessuna valutazione finora

- Canon PS A550 SM (Part)Documento19 pagineCanon PS A550 SM (Part)radovanovdNessuna valutazione finora

- Avo Douglas Coil Winding MachineDocumento20 pagineAvo Douglas Coil Winding Machineradovanovd50% (2)

- CHDK v1.3.0Documento73 pagineCHDK v1.3.0radovanovdNessuna valutazione finora

- Traktor Kontrol S4 MK2 Manual EnglishDocumento233 pagineTraktor Kontrol S4 MK2 Manual Englishradovanovd100% (1)

- Jolpaz Davidov Ranko RisojevicDocumento18 pagineJolpaz Davidov Ranko RisojevicradovanovdNessuna valutazione finora

- Pei Mei's Chinese Cooking Cards - SoupDocumento50 paginePei Mei's Chinese Cooking Cards - Soupradovanovd100% (4)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)