Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

53 59

Caricato da

Eric FerreiraTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

53 59

Caricato da

Eric FerreiraCopyright:

Formati disponibili

TOTAL AGILE DESIGN SYSTEM FOR SUPPLY CHAIN

EVALUATION

M.BALAJI1, DR. V.VEL MURUGAN2, N.R.ARUN KUMAR3

1

Senior grade Assistant professor, Department of Mechanical Engineering, Kumaraguru College of

Technology, Coimbatore 641049, India

2

Principal, Sree Sakthi Engineering College, Coimbatore 641104, India

3

PG Industrial engineering scholar, Kumaraguru College of Technology, Coimbatore 641049, India

E-mail: balpurush@rediffmail.com

Abstract: Global markets are now becoming volatile in most industries and the importance of their abilities

to adapt to rapid and unexpected changes have surfaced. Modern organizations have to respond quickly to

their customers dynamic demands without compromising on quality, productivity and cost. Achieving agility

lies in designing agile-friendly processes and thus firms need to concentrate on their supply chains and its

enablers in the attempt of redressing themselves as responsive supply chains. To evaluate the levels of supply

chain agility, a scoring model called Total Agile Design System (TADS) is proposed. TADS as a

methodology identifies supply chain enablers and prioritizes them in lines of achieving supply chain agility.

In this scoring model, agility index before implementation of TADS is measured and discussed. The results

validate the proposed model and lend evidence to the current thinking of impinging agile concepts in

traditional supply chains for competitive advantage and survival.

Keywords: Responsive supply chains, TADS, Agility index, competitive advantage.

elimination to the maximum possibility of turning

the industrys supply chain in to an agile entity.

I. INTRODUCTION

Modern organizations are facing enormous

challenges and competition in the market due to

rapid changes in customers taste and diversity.

Organizations are in adverse need of reconstructing

the process of the relationships between supply and

demand. Organizations are forced to respond

quickly in time with customer requirements to

become agile. Agility is used to highlight the rapid

reaction potential of a supply chain on market

changes and customer demands. Agility is the

successful blend of speed, flexibility, innovation,

proactiveness, quality and profitability through the

integration of resources and best practices in an

organization to provide customer-driven products

and services in a fast changing market environment.

In the present trend, the determination of supply

chain agility would indicate a firms organizational

superiority. This paper proposes a model called

TADS which as a tool quantifies the agility based on

the various agile criteria framed within an

organization's boundaries.

II. PAST LITERATURE

According to Ashish Agarwal et al. [2], flexibility is

needed in any supply chain to encounter the

uncertainty in manufacturing. In their paper a

conceptual framework has been developed

encapsulating

market

sensitiveness,

process

integration, information driver and flexibility

measures of supply chain performance. Exploration

has been done on lead time, cost, quality, leanness

and service levels in fast moving consumer goods

business.

Angappa gunasekaran et al. [11] in their paper orient

that Agile manufacturing(AM) and Supply chain

management(SCM)

complement each other in

objectives

for

improving

organizational

competitiveness. An attempt to integrate AM and

SCM in creating a responsive supply chain has been

done which can be employed as a competitive

strategy in a networked economy of virtual

organizations.

TADS is an agile measurement tool incorporated

with questionnaires to measure agility from the

confined list of 14 agile criteria. A parameter named

agility index has been coined to tabulate the agility

level of supply chains and the need for

implementing TADS. Prioritization of agile criteria

with least scores has been dwelled upon and

corresponding drag factors have been considered for

Eleonora Bottani [10] links competitive basis, agile

attributes and agile enablers for achieving

competitive characteristics. His approach is based

on quality function deployment (QFD) methodology

were he has built a House of quality on a new

product development field. Fuzzy logics are later

International Conference on Emerging Trends in Engineering and Techno - Sciences (ETETS)-22nd Dec 2013-ISBN: 978-93-81693-52-0

53

.Total Agile Design System for Supply Chain Evaluation

used to translate linguistic judgments to correlate

relationships into numerical values.

Yahaya Y.Yusuf et al. [20] in his paper evaluates

the dimensions of agile supply chain competitive

objectives and business performance in the UK

North Sea upstream oil and gas industry. 880 supply

chain managers were given questionnaires and KS

statistical test was done on the data received from

their responses. Non response bias analysis was

conducted through one way ANOVA analysis to

identify the important attributes of supply chain

agility.

According to Gunasekaran [12], as product life

shortens higher product quality becomes mandatory

for survival. Markets become highly diversified and

continuous and unexpected changes become the key

factors for success. He has identified seven key

enablers for agile manufacturing and developed a

conceptual framework for the development of agile

manufacturing system and shown directions for

future research.

III. AGILE SUPPLY CHAIN (ASC) CRITERIA

Yusuf et al. [19] reviews emerging patterns in

supply chain integration and explores the

relationship between emerging patterns and

attainment of competitive objectives. In his work, a

survey has been done involving 600 companies in

the UK and a conceptual model has been developed

followed by a multiple regression model to study the

relationships among the selected variables.

ASC criteria are wagons of agility which have the

potential to drive supply chains towards agility.

Based on the rich literature and research findings of

past, the research paper identifies 14 criteria shown in

Table I. The proposed criteria will nevertheless prove

vital in assessing and improving agility levels of the

supply chain on screen.

Table I. Agile supply chain Criteria

S.NO

CRITERION

REFERENCE

1 Culture of Change

2 Organizational Structure

3 Customer Relationship Management

Bohdana Sherehiy et al. [4]

Ali N. Mashayekhi et al. [1]

4

5

6

7

Production Planning

Process Integration

Materials Management

Mohd. Asif Hasan et al. [13]

Ching-Torng Lin et al. [5]

Rick Dove et al. [15]

Distribution Management/Networks

Vinodh .S et al. [16]

David Z. Zhang et al. [7]

8 Employee Involvement

9 Information Integration

10

Supplier Relationship management

Vinodh .S et al. [17]

Ching-Torng Lin et al. [5]

11 Marketing Sensitiveness

12 Customer order fulfillment process

Yi-Hong Tseng, Ching tong lin. [21]

Mohammad D. AL-Tahat and Khaled M. Bataineh [14]

Douglas M. Lambert et al. [8]

13 Customer Reaction and Proactive Anticipations Vinodh S et al. [18]

Assessment

14 Customer Service Management

Douglas M. Lambert et al. [8]

IV. TOTAL AGILE DESIGN SYSTEM (TADS)

METHODOLOGY

the apportionment of scores among the defined list of

ASC criteria [3] [6] [9].

The results of the literature review on Supply Chain

Agility reveal that there have been limited attempts

for evaluating agility levels of supply chains. TADS

has been considered [17] for agile customization

when the production process needs to be customized

according to the dynamic requirements of the

customers. TADS quantify the supply chain agility of

the organization by adopting new technological

advancements. This agile quantification tool uses a

questionnaire based approach method and facilitates

Agility index can be used to assess the agility levels

of a supply chain on a 2000 score scale. A TADS

team of 10 members were identified and explained

about the features of agile quantification tool and

ASC criteria. Later the questionnaires pertaining to

all criteria were given to them and with their

responses, the agility index is computed based on

agility scores using the formula for Agility index.

Agility index = Total score / 2000 [17] The agility

scores open the possibilities of identifying the drag

International Conference on Emerging Trends in Engineering and Techno - Sciences (ETETS)-22nd Dec 2013-ISBN: 978-93-81693-52-0

54

.Total Agile Design System for Supply Chain Evaluation

factors and suggest remedial measures for their

elimination in order to strengthen the weaker ASC as

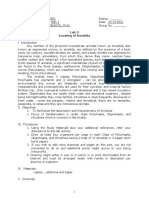

depicted in Figure I.

Identification of

Agile supply chain criteria

Development of Total Agile Design System

quantification tool and Agility index measurement

Agility index measurement before Total

Agile Design System implementation

Identification of Drag factors and

suggesting remedial measures for their

elimination

Agility index measurement after Total

Agile Design System implementation

Figure I. TADS Methodology

V. ABOUT THE ORGANIZATION

INDUSTRY STRUCTURE

and thus fear the loss of customer goodwill in longer

run.

AND

The firm located in Tamil Nadu, India is a specialist

in the design, development and production of

automated material handling equipments. In addition,

the company provides a comprehensive service

ranging from consultancy to total project

management and a 24 hour service logistic support.

Inspite, the firm is challenged in trading off between

demand and supply with its traditional supply chain

VI. MEASUREMENT OF AGILITY INDEX

In order to measure agility index an agile

quantification tool developed in a previous researches

was adopted [17]. Agile quantification tool has its

root on the 14 criterion that determines the agility

level of an organization and is disseminated across a

total score of 2000 as shown in Table II.

Table II. Distribution of Scores for Agile Criteria

Criterion

number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Criterion

Marks

Culture of Change

Organizational Structure

Customer Relationship Management

Production Planning

Process Integration

Materials Management

Distribution Management

Employee Involvement

Information Integration

Supplier Relationship Management

Marketing Sensitiveness

Customer order fulfillment process

Customer Reaction and Proactive Anticipations Assessment

Customer Service Management

150

200

100

150

150

150

150

100

150

100

100

200

200

100

2000

TOTAL SCORE

International Conference on Emerging Trends in Engineering and Techno - Sciences (ETETS)-22nd Dec 2013-ISBN: 978-93-81693-52-0

55

.Total Agile Design System for Supply Chain Evaluation

This questionnaire enables the responders to indicate

the agility level from the point of view of agile

criterion. One such sample questionnaire pertaining

to the criterion Production Planning is shown in Table

III.

Table III. Questionnaire Pertaining To Production Planning Criteria

Criterion 4: Production Planning Questionnaire

Production planning is a pre-production activity which coordinates the organizations resources towards

the attainment of pre-specified goals in the most efficient manner. Production planning is concerned

with determination, acquisition and arrangement of facilities necessary to manufacture a product in

sufficient quantities in lines with market demand.

1) Are the route sheets properly communicated to the shop floor?

(a) Yes

(b) No

2) Are the labours aware of method study procedures in production?

(a) Yes

(b) No

3) Does the production plan follow the sales forecasting results?

(a) Yes

(b) No

4) What is the approximate rate of customer acceptance of the product?

(a) More than 90%

(b) Less than 90 %

5) Comment on the level of industrial safety.

(a) Good

(b) Satisfactory

(c) Poor

6) Are ergonomics considered during the design of material handling equipments?

(a) Yes

(b) In some cases

(c) No

7) Does the organization follow EOQ concepts in purchasing?

(a) Yes

(b) No

8) Is the machine loading balanced?

(a) Yes

(b) No

9) Does the work manager allocate work based on specialization?

(a) Yes

(b) No

10) Are the finished goods checked for quality?

(a) Yes

(b) No

After the responder completes the questionnaire, a

score allotment table

(Table IV) has to be refereed in order to convert the

responses into scores and for computing the agility

index.

Table IV. Score Allotment Table Pertaining To Production Planning Criterion

score pertaining to ASC criteria production planning

is shown in Table V. Likewise, the mean scores were

calculated by referring to the responses of the TADS

team members against the corresponding ASC as

shown in Table VII. The total score was estimated as

1247 out of 2000 and thus the agility index before

TADS implementation was 0.6235.

VII. ASSESSMENT OF AGILITY LEVEL

BEFORE TADS IMPLEMENTATION

The implementation study began by measuring agility

index before TADS implementation in the

organization. The responses of TADS team members

were recorded and the scores were tabulated. The

International Conference on Emerging Trends in Engineering and Techno - Sciences (ETETS)-22nd Dec 2013-ISBN: 978-93-81693-52-0

56

.Total Agile Design System for Supply Chain Evaluation

Table V. Score for Production Planning Criterion before Implementation of TADS

Score for Production Planning before implementation of TADS

Total score out of 150

Questions

Experts

Expert 1

Expert 2

Expert 3

Expert 4

Expert 5

Expert 6

Expert 7

Expert 8

Expert 9

Expert 10

10

20

20

20

20

20

20

20

20

20

0

15

15

15

15

15

15

15

15

15

15

15

0

0

15

15

0

0

15

0

0

10

10

10

10

10

10

10

10

15

15

05

05

05

05

05

05

05

05

10

05

15

10

15

10

10

15

15

0

0

10

0

15

0

0

0

0

0

15

0

15

15

15

0

0

0

15

15

0

15

15

0

0

20

20

20

0

0

20

0

0

10

0

0

10

10

10

10

10

10

10

105

90

85

105

90

90

90

110

85

85

Total Score for Production Planning criterion

935

Average Score for Production Planning before implementation of TADS

The TADS implementation study carried out i n t h e

f i r m integrates functional sections of the firm such

as design, materials supply, production, distribution

and sales. The objective was to provide the right

number of products and service to the right places at

the right time in order to meet the desired level of

customer service requirements and enable overall

supply chain profitability.

TADS methodology aims in achieving agility through

strategic partnerships, integrating resources, forming

seamless

business

environments,

continuous

innovations, leveraging human skills and integration

of information technology. If the company has the

=935/10=93.5

potential to overcome the series of hurdles by

implementing TADS, its supply chain is expected to

progress on agile forefronts.

VIII. DRAG FACTORS AND REMEDIAL

MEASURES

Various drag factors that detonated the achievement

of ASC were identified and addressed. Some of the

notable drag factors and remedial measures for

Production Planning criteria are exhibited in Table

VI.

Table VI. Drag Factors and Remedial Measures for Production planning criterion

Sl.No.

Drag factors

Remedial measures for elimination

Imbalanced inventory

management systems

Ensuring continuous supply of materials through Aggregate

planning, Master production scheduling, Materials requirements

Planning and capacity planning, training staff on JIT concepts.

Improper Production

Control which leads to

inefficient production

systems

Frequent Line balancing, adopting KANBAN pull production,

expediting the process flow.

An important consideration is that, when an

organization implements all these remedial

measures, the organization can become an ASC with

significant improvement in agility levels. These

remedial policies could be used to remove the

undesired effects on the implementation of TADS

and in creating a responsive and ASC.

International Conference on Emerging Trends in Engineering and Techno - Sciences (ETETS)-22nd Dec 2013-ISBN: 978-93-81693-52-0

57

.Total Agile Design System for Supply Chain Evaluation

TABLE VII. TADS Score summary

Criterio

n

number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

ASC Criterion

Total

Score

Culture of Change

150

Organizational Structure

200

Customer Relationship

150

Management

Production Planning

150

Process Integration

100

Materials Management

150

Distribution

150

Management/Networks

Employee Involvement

100

Information Integration

150

Supplier Relationship

100

Management

Marketing Sensitiveness

100

Customer order

200

fulfillment process

Customer Reaction

200

Customer Service

100

Management

Total Scores

2000

AGILITY INDEX

Score Obtained Before

TADS Implementation

Percentage of Agility

before TADS

101.5

121.5

67.67

60.75

98

65.33

93.5

61

93

62.33

61.00

62.00

94

62.67

60.5

89.5

60.50

59.67

64

64.00

61

61.00

122.5

61.25

115

57.50

71.5

71.50

1247

=1247/2000 =0.6235

(before TADS)

IX. CONCLUSIONS & FUTURE WORK

62.35

REFERENCES

[1]. Ali N. Mashayekhi ,Abbas Toloie Eshlaghy , Ali

Rajabzadeh , Mir Majid Razavian Determination

constructs validity of an agile organization model by using

factor analysis, Journal of Industrial Engineering

International, vol. 7(14), pp. 75-89, 2011.

A total agile design system certainly has the tendency

to tap the potential opportunities in a turbulent supply

chain environment. It also opens the window of micro

studying the drag factors in Agility implementations

which have never surfaced in most researches in

recent past. This research has also contributed

towards a better understanding of achieving agility

and related concepts in the context of managing

disruption risks in supply chains.

[2]. Ashish Agarwal, Ravi Shankar, M.K. Tiwari, Modeling the

metrics of lean, agile and leagile supply chain-An ANPbased approach, European Journal of Operational

Research, vol. 173, pp. 211225, 2006.

[3]. Anantatmula V, Kanungo S,Structuring the underlying

relations among the knowledge management outcomes, J

Knowl Manag, vol. 10(4), pp.2542,2006.

The findings are of direct relevance to harness supply

chain agility levels in responding to market changes.

Importantly, it makes the supply chain more

profitable and flexible.

[4]. Bohdana Sherehiy, Waldemar Karwowski, John K. Layer

A review of enterprise agility: Concepts, frameworks, and

attributes, International Journal of Industrial Ergonomics,

vol. 37, pp. 445460, 2007.

By eventually implementing TADS in future, the

Agility index can be calculated with the same skill set

and questionnaires. Successful implementation will

drive the agility index from 0.6235 to a much higher

margin for the firm under consideration.

[5]. Ching-Torng Lin, Hero Chiu, Po-Young Chu, Agility

index in the supply chain, International Journal of

Production Economics, vol.100, pp.285299, 2006.

[6]. Chieh-Wen S, Shen M-J, Chen M-C, Special interest tour

preferences and voluntary simplicity lifestyle, International

Journal of Culture, Tourism and Hospitality Research,

vol.2(4),pp. 389409, 2008.

The advantage of TADS is to create the most value,

not simply for the organizations, but for the entire

supply chain network including the end customer.

[7]. David Z. Zhang, Towards theory building in agile

manufacturing strategies- Case studies of an agility

taxonomy , International Journal of Production Economics,

vol.131, pp. 303312, 2011.

At the onset, what is needed in this volatile market is

the redesigning of the supply chains to achieve lean

status, flexibility and most importantly the evaluation

of the flexibility with the help of agile quantification

tools.

[8]. Douglas M. Lambert, Martha C. Cooper, Issues in Supply

Chain Management, Industrial Marketing Management,

vol. 29, pp. 6583, 2000.

International Conference on Emerging Trends in Engineering and Techno - Sciences (ETETS)-22nd Dec 2013-ISBN: 978-93-81693-52-0

58

.Total Agile Design System for Supply Chain Evaluation

[9]. Dorabjee S, Lumlee CE, Cartwright S Culture, Innovation

and successful development of new medicinesan

exploratory study of the pharmaceutical industry, Leadersh

Organ Dev J, vol. 19 (4), 199210, 1998.

[16]. Vinodh .S, Devadasan .S.R, Vimal K.E.K, Deepak Kumar,

Design of agile supply chain assessment model and its case

study in an Indian automotive omponents manufacturing

organization, Journal of Manufacturing System,2013.

[10]. Eleonora Bottani A fuzzy QFD approach to achieve

agility, Int. J. Production Economics, vol.119, pp.380390,

2009.

[17]. Vinodh .S & Sundararaj G. & Devadasan S. R. Measuring

organisational agility before and after implementation of

TADS International Journal Advanced Manufacturing

Technology, vol. 47,pp. 809818, 2010.

[11]. Angappa Gunasekaran, Lai KH, T.C. Edwin Cheng

Responsive supply chain a competitive strategy in a

networked economy, The International Journal of

Management Science, vol. 36, pp. 549564,2008.

[18]. Vinodh .S, Sundararaj.G, Devadasan S. R, Kuttalingam.D

and Meenakshi Sundaram P.L and Rajanagam .D

Enhancing competitiveness through CAD phase of Total

Agile Design System, Int. J. Process Management and

Benchmarking, vol. 2(3),pp. 197-220,2008.

[12]. Gunasekaran A, Agile manufacturing: enablers and an

implementation framework, Int J Prod Res, vol. 36(5), pp.

12231247, 1998.

[19]. Y.Y. Yusuf, A. Gunasekaran, E.O. Adeleye, K.

Sivayoganathan Agile supply chain capabilities:

Determinants of competitive objectives, European Journal

of Operational Research, 159, 379392, 2004.

[13]. Mohd. Asif Hasan, Joseph Sarkis,Ravi Shankar, Agility

and production flow layouts , An analytical decision

analysis Computers & Industrial Engineering,vol-62, pp.

898907, 2012.

[20]. Yahaya Y.Yusuf, Angappa Gunasekaran, AhmedMusa,

Mohammed Dauda, Nagham M.El-Berishy, Shuang Cang,

A relational study of supply chain agility, competitiveness

and business performance in the oil and gas industry,

International Journal of Production Economics, 2012.

[14]. Mohammad D. AL-Tahat and Khaled M. Bataineh,

Statistical Analyses and Modeling of the Implementation

of Agile Manufacturing Tactics in Industrial Firms,

Mathematical Problems in Engineering, vol.2012, pp.1-23,

2012.

[21]. Yi-Hong Tseng and Ching-Torng Lin, Enhancing

enterprise agility by deploying agile drivers, capabilities and

providers, Information Sciences, vol. 181, pp.36933708,

2011.

[15]. Rick Dove, Tools for Analyzing and Constructing Agility,

Agility Forum, PA96-01, pp. 1-13, Jan 1996.

International Conference on Emerging Trends in Engineering and Techno - Sciences (ETETS)-22nd Dec 2013-ISBN: 978-93-81693-52-0

59

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Forklift Truck Risk AssessmentDocumento2 pagineForklift Truck Risk AssessmentAshis Das100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Research Methods NotesDocumento20 pagineResearch Methods Notessunil_birman100% (1)

- Celiac DiseaseDocumento14 pagineCeliac Diseaseapi-355698448100% (1)

- Qualitative Research DesignDocumento32 pagineQualitative Research DesignOlga VerbochkaNessuna valutazione finora

- Sutton 2014Documento28 pagineSutton 2014Eric FerreiraNessuna valutazione finora

- Research in International Business and Finance: SciencedirectDocumento16 pagineResearch in International Business and Finance: SciencedirectEric FerreiraNessuna valutazione finora

- Critical Perspectives On Accounting: John FlowerDocumento17 pagineCritical Perspectives On Accounting: John FlowerEric FerreiraNessuna valutazione finora

- Exploring The Perception On Using The Competition Based Learning Winning Video As A Pedagogical Tool in An Accounting CourseDocumento12 pagineExploring The Perception On Using The Competition Based Learning Winning Video As A Pedagogical Tool in An Accounting CourseEric FerreiraNessuna valutazione finora

- Academy of ManagementDocumento18 pagineAcademy of ManagementEric FerreiraNessuna valutazione finora

- Lockhart 2000Documento31 pagineLockhart 2000Eric FerreiraNessuna valutazione finora

- European Accounting Review: To Cite This Article: Salvador Carmona & Luca Zan (2002) SpecialDocumento16 pagineEuropean Accounting Review: To Cite This Article: Salvador Carmona & Luca Zan (2002) SpecialEric FerreiraNessuna valutazione finora

- J Omega 2004 06 002Documento15 pagineJ Omega 2004 06 002Eric FerreiraNessuna valutazione finora

- PP279 Morgan DelDocumento11 paginePP279 Morgan DelEric FerreiraNessuna valutazione finora

- Harris 2002Documento7 pagineHarris 2002Eric FerreiraNessuna valutazione finora

- Q I S C: M S P P: Uality Ncentives and Upply Hains Anaging Almonella in ORK RoductionDocumento6 pagineQ I S C: M S P P: Uality Ncentives and Upply Hains Anaging Almonella in ORK RoductionEric FerreiraNessuna valutazione finora

- PDFDocumento24 paginePDFEric FerreiraNessuna valutazione finora

- Measuring Performance of SCDocumento18 pagineMeasuring Performance of SCKo Gree KyawNessuna valutazione finora

- Accounting, Organizations and Society: Dutch Fayard, Lorraine S. Lee, Robert A. Leitch, William J. KettingerDocumento3 pagineAccounting, Organizations and Society: Dutch Fayard, Lorraine S. Lee, Robert A. Leitch, William J. KettingerEric FerreiraNessuna valutazione finora

- 10 1 1 103 6286Documento19 pagine10 1 1 103 6286Eric FerreiraNessuna valutazione finora

- Revisão Sistemátiva e Revisão NarrativaDocumento2 pagineRevisão Sistemátiva e Revisão NarrativaJoão Alfaya Dos SantosNessuna valutazione finora

- Will Ian Son Transaction Cost Economics An IntroductionDocumento34 pagineWill Ian Son Transaction Cost Economics An Introductiongscosta8938Nessuna valutazione finora

- SSRN Id1015691Documento22 pagineSSRN Id1015691Eric FerreiraNessuna valutazione finora

- Cooper, Slagmulder - 1998 - The Scope of Strategic Cost ManagementDocumento2 pagineCooper, Slagmulder - 1998 - The Scope of Strategic Cost ManagementEric FerreiraNessuna valutazione finora

- Interorganizational Trust: Origins, Dysfunctions and Regulation of RigiditiesDocumento22 pagineInterorganizational Trust: Origins, Dysfunctions and Regulation of RigiditiesEric FerreiraNessuna valutazione finora

- Conjectures Regarding Empirical Managerial Accounting Research 2001 Journal of Accounting and EconomicsDocumento17 pagineConjectures Regarding Empirical Managerial Accounting Research 2001 Journal of Accounting and EconomicsLilian BrodescoNessuna valutazione finora

- Manu Fact BasedDocumento18 pagineManu Fact BasedEric FerreiraNessuna valutazione finora

- Will Ian Son Transaction Cost Economics An IntroductionDocumento34 pagineWill Ian Son Transaction Cost Economics An Introductiongscosta8938Nessuna valutazione finora

- Fossey Et Al Evaluating Qual ResearchDocumento16 pagineFossey Et Al Evaluating Qual ResearchEric FerreiraNessuna valutazione finora

- Article - 3 - Cost - Drivers.32781613 (1) - 2Documento14 pagineArticle - 3 - Cost - Drivers.32781613 (1) - 2Eric FerreiraNessuna valutazione finora

- Noreen JMAR 1991Documento11 pagineNoreen JMAR 1991Eric FerreiraNessuna valutazione finora

- Schroedindiger Eqn and Applications3Documento4 pagineSchroedindiger Eqn and Applications3kanchankonwarNessuna valutazione finora

- Ca2Documento8 pagineCa2ChandraNessuna valutazione finora

- Progressing Cavity Pump Overhaul GuideDocumento5 pagineProgressing Cavity Pump Overhaul Guidesdsds-54Nessuna valutazione finora

- P&id BoilerDocumento1 paginaP&id BoilerBagus AryowibowoNessuna valutazione finora

- Lab Manual Cape Bio Unit 1 2023Documento37 pagineLab Manual Cape Bio Unit 1 2023drug123addict25Nessuna valutazione finora

- Uji Deteksi Biofilm Dari Isolat Klinik Kateter Urin Bakteri Entercoccus Dibandingkan Dengan Tube MethodDocumento27 pagineUji Deteksi Biofilm Dari Isolat Klinik Kateter Urin Bakteri Entercoccus Dibandingkan Dengan Tube MethodIyannyanNessuna valutazione finora

- Speech for pecha kuchaDocumento6 pagineSpeech for pecha kuchaaira mikaela ruazolNessuna valutazione finora

- Science Section A UPSRDocumento2 pagineScience Section A UPSRvinno8556% (9)

- Coloi Eeml Disease: Original ArticlesDocumento67 pagineColoi Eeml Disease: Original ArticlesLuisAngelPonceTorresNessuna valutazione finora

- Enviroclean 25 LTRDocumento1 paginaEnviroclean 25 LTRMaziyarNessuna valutazione finora

- 2021 - Tet Purchase Behavior Report - INFOCUSDocumento15 pagine2021 - Tet Purchase Behavior Report - INFOCUSGame AccountNessuna valutazione finora

- Is Revalida ExamDocumento11 pagineIs Revalida ExamRodriguez, Jhe-ann M.Nessuna valutazione finora

- Fatigue Life Prediction of A320-200 Aileron Lever Structure of A Transport AircraftDocumento4 pagineFatigue Life Prediction of A320-200 Aileron Lever Structure of A Transport AircraftMohamed IbrahimNessuna valutazione finora

- Downstream Processing and Bioseparation - Recovery and Purification of Biological Products PDFDocumento313 pagineDownstream Processing and Bioseparation - Recovery and Purification of Biological Products PDFgonbio67% (3)

- Abiotic and Biotic Factors DFDocumento2 pagineAbiotic and Biotic Factors DFgiselleNessuna valutazione finora

- QUESTION A2 and A3 Examples PDFDocumento24 pagineQUESTION A2 and A3 Examples PDFDemian VeNessuna valutazione finora

- Personality Types and Character TraitsDocumento5 paginePersonality Types and Character TraitspensleepeNessuna valutazione finora

- Knowing Annelida: Earthworms, Leeches and Marine WormsDocumento4 pagineKnowing Annelida: Earthworms, Leeches and Marine WormsCherry Mae AdlawonNessuna valutazione finora

- MUCLecture 2021 10311889Documento11 pagineMUCLecture 2021 10311889Ramon Angelo MendezNessuna valutazione finora

- Lectura Isaac NewtonDocumento2 pagineLectura Isaac NewtonCESAR MAURICIO RODRIGUEZNessuna valutazione finora

- Semen RetentionDocumento3 pagineSemen RetentionMattNessuna valutazione finora

- Anxiolytics Sedatives Hypnotics Pharm 3Documento38 pagineAnxiolytics Sedatives Hypnotics Pharm 3Peter Harris100% (1)

- My Medications ListDocumento5 pagineMy Medications Listhussain077Nessuna valutazione finora

- Supply Chain Management: Tata Tea's Global OperationsDocumento15 pagineSupply Chain Management: Tata Tea's Global OperationsAmit Halder 2020-22Nessuna valutazione finora

- 4thinternationalconferencetheimportanceofplace Proceedings 2017 PDFDocumento428 pagine4thinternationalconferencetheimportanceofplace Proceedings 2017 PDFnerko86Nessuna valutazione finora

- Datasheet Optris XI 410Documento2 pagineDatasheet Optris XI 410davidaldamaNessuna valutazione finora

- Datta Das FET ExplanationDocumento2 pagineDatta Das FET ExplanationJulie HaydenNessuna valutazione finora

- 2nd Quarter Summative Test in MusicDocumento2 pagine2nd Quarter Summative Test in MusicIverAlambraNessuna valutazione finora