Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

COMPLETED Experiment 1

Caricato da

Yi YiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

COMPLETED Experiment 1

Caricato da

Yi YiCopyright:

Formati disponibili

Material Science and Solid State Laboratory (Experiment

8) 2015

Faculty of Industrial Science and Technology

Material Technology Programme

MATERIAL SCIENCE & SOLID STATE LABORATORY

(BSP 2422)

Semester 1 2015/2016

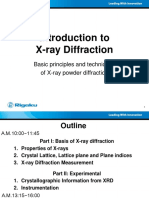

Title of Experiment: X-Ray Structural Analysis

Date of Experiment: 4th November 2015

Date of Submission: 19th November 2015

Instructors Name : En Halim bin Paboh

Group of Member

Name

ID

1. NADIA SABRINA BINTI MOHAMAD AZMI

SC14013

2. LAU PUI PUI

SC14036

3. TAN YI JIE

SC14041

4.

5.

Group No.

: 6

Section

: 01G

Marks

Part A

Part B

TOTAL

:

55

45

100

Material Science and Solid State Laboratory (Experiment

8) 2015

FACULTY OF

INDUSTRIAL

SCIENCE AND

TECHNOLOGY

INDUSTRY

Experiment 1: X-Ray Structural Analysis

NADIA SABRINA BINTI MOHAMAD AZMI

SC14013

LAU PUI PUI

SC14036

TAN YI JIE

SC14041

Universiti Malaysia Pahang,

Lebuhraya Tun Razak

26300 Kuantan

Pahang Darul Makmur

Tel.:09-5492501, fax: 09-5492544

E-mail: yytan996@gmail.com

Submitted: 19th November 2015

Abstract: This experiment is X-ray structural analysis. The purpose of conducting this

experiment is to use of X-ray diffraction techniques for investigating various types of crystal

structure encountered in metallic materials. Theoretically, X-ray diffraction techniques are a very

useful characterization tool to study non-destructively, the crystallographic structure, chemical

composition and physical properties of metallic and ceramic materials. Besides, it can also be

used to measure various structural properties of these crystalline phrases such as strain, grain

size, phase composition and defect structure. X-Ray diffraction is also used to determine the

thickness of thin films as well as the atomic arrangements on various planes within the structures.

Three basic crystal structures encountered in metallic materials are the Body-Centered Cubic

(CFC), Face-Centered Cubic (FCC) and Hexagonal Close-Packed (HCP).

Keywords: X-ray diffraction, crystallographic, metallic, ceramic, crystalline, grain, thin film, BodyCentered Cubic, Face-Centered Cubic, Hexagonal Close-Packed

1. Introduction

X-ray crystallography is a tool used to identify

the atomic and molecular structure of a

crystal, in which the crystalline atoms cause a

beam of incident X-rays to diffract into many

specific directions. By measuring the angles

and intensities of these diffracted beams, a

crystallographer can produce a three-

dimensional picture of the density of electrons

within the crystal. From this electron density,

the mean positions of the atoms in the crystal

can be determined, as well as their chemical

bonds, their disorder and various other

information. Crystals are regular arrays of

atoms and X-rays can be considered waves of

electromagnetic radiation. Atoms scatter Xray waves, primarily through the atoms'

Material Science and Solid State Laboratory (Experiment

8) 2015

electrons.

Figure 1: The reflection of X-ray beam by the (hkl)

planes of a crystal. No reflected at an arbitrary angle of

incidence.

Figure 4: Sample output

2. Materials and method

2.1 Apparatus and material

The apparatus needed for this experiment

is Rigaku Miniflex XRD machine.

The material needed for this experiment is

commercial sample (titanium dioxide).

Figure 2: At the Bragg angle, the reflected rays are in

phase and reinforce one another.

Figure 3: Schematic representation of the in-phase

condition.

A regular array of scatters produces a regular

array of spherical waves. Although these

waves cancel one another out in most

directions through destructive interference,

they add constructively in a few specific

directions, determined by Bragg's law:

n = 2d sin

Here d is the spacing between diffracting

planes, is the incident angle, n is any integer,

and is the wavelength of the beam. These

specific directions appear as spots on the

diffraction pattern called reflections. Thus, Xray diffraction results from an electromagnetic

wave (the X-ray) impinging on a regular array

of scatters (the repeating arrangement of

atoms within the crystal).

2.2 Method

1. The apparatus is set up as shown in the

figure below.

2. Prepare the sample used.

Titanium dioxide, TiO2 was put into

the slide. Wear the gloves while

preparing the slide.

3. Make sure the slide is all occupied

evenly by titanium dioxide, TiO2.

4. Remove excessive powder by using

tissue paper.

5. Slowly insert the sample into the XRD

machine.

6. Wait the sample approximately one

hour, and then take it out and record

the result.

7. The results are recorded in the graph

and table below.

Figure 5: X-ray Diffraction machine

Material Science and Solid State Laboratory (Experiment

8) 2015

Pea

k

1

2

3

4

Figure 6: Automatic voltage regulator and cooler

attached with X-ray diffraction machine

3. Result

5

6

7

8

9

10

11

12

Graph 1: The graph of intensity of the diffracted beam

against diffraction angle 2

The following equations were used to count dspacing and lattice parameter.

=2 dsin ---------- eq.1

d=

----------- eq.2

2 sin

given that =1.5418

a

d=

2

h +k 2+ l2

a = d h2 +k 2 +l 2 -------- eq.3

13

14

Relativ

e

intensit

y

sin

25.36

3

3495

0.22

0

36.98

8

200

37.83

6

743

38.61

3

225

48.07

0

1040

53.92

2

615

55.09

5

630

62.15

6

108

62.71

5

492

68.79

6

212

70.34

4

225

74.09

0

16

75.09

4

346

76.05

9

96

hkl

Lattice

parameter

, a ()

(101

)

4.955

3.504

0.31

7

(103

)

7.691

2.432

0.32

4

(004

)

9.516

2.379

0.33

1

(112

)

5.705

2.329

0.40

7

(200

)

3.788

1.894

0.45

3

(105

)

8.673

1.701

0.46

2

(211

)

4.088

1.669

0.51

6

(213

)

5.590

1.494

0.52

0

(204

)

6.632

1.483

0.56

5

(116

)

8.408

1.364

0.57

6

(220

)

3.784

1.338

0.60

2

(107

)

9.058

1.281

0.60

9

(215

)

6.934

1.266

0.61

6

(301

)

3.956

1.251

dspacing,

d

()

Table 2: Various data about the peak

1. The highest peak is (101), followed by

(200) and (004).

2. To determine the structure of crystal, take

the sum of h, k and l.

( h+k + l )=( 1+0+1 )=2

Since the sum of h, k and l is an even

number, thus the structure is a BCC

structure.

Material Science and Solid State Laboratory (Experiment

8) 2015

4. Lab Requirements

1. [1 1 1] denoted the direction and (1 1

1) denoted to a plane. <1 1 1> is the

family of directions and {1 1 1} is the

family of planes.

2. The inter-planar spacing, d for sets of

{1 2 1} planes in iron, where a =

0.2865nm.

a

d h kl = 2 2 2

h +k +l

0.2865 nm

2 2 2

1 +2 + 1

0.1170 nm

3. The angle where iron diffracts Cu-K

X-rays of wavelength 0.1541 nm.

n=2 dsin

n

sin =

2d

1(0.1541nm )

2(0.1170 nm)

0.6585

=41.19

4. The lattice parameter for BCC iron.

4 R= 3 a

4R

a=

3

4(0.1241nm)

3

0.2866 nm

5. (1 1 1) plane in a FCC unit cell

6. (1 1 0) plane in a BCC unit cell

5. Discussion

The schematic of X-ray apparatus is shown as

below.

Figure 2: Schematic of X-ray apparatus

From the experiment, the values of 2 for

some of the peaks were obtained to be 25.36,

36.99, 37.84, 38.62, 48.07, 53.92, and

55.10.

The Miller indices found for each peak was

(101), (103), (004), (112), (200), (105) and

(211) respectively.

The d-spacing was also calculated to be

3.504, 2.432, 2.379, 2.329, 1.894,

1.701 and 1.669 respectively.

There were some errors during carry out the

experiment. One of the errors was that the

Titanium dioxide (Ti O2 ) powder was not

spread evenly and there may be dents or holes

on the surface of the powder which may

influence the reading obtained. Beside this,

powder may contaminate with impurities such

as dust and small insects.

Several precautions that can be taken to avoid

the error occur are to ensure that the machine

does not emit any strange odor, the door of the

Rigaku Miniflex XRD machine must also be

close tight when the experiment is being

carried out. Furthermore, the procedure in the

Material Science and Solid State Laboratory (Experiment

8) 2015

lab manual and instruction of lab instructor

must be followed.

a=d

To improve the experiment, the suggestion for

this experiment is to change the titanium

dioxide (Ti O2 ) powder every so often to

avoid having contaminants in the powder.

Other than this,the safety operation of

equipment must be ensured by checking the

condion of the Rigaku Miniflex XRD machine

regularly.

=4.955

6. Conclusion

In conclusion, the highest peak was (101),

followed by (200) and (004). The crystalline

structure of Titanium oxide (Ti O2 ) was

body centered cubic structure (BCC).

7. Acknowledgement

A token of appreciation to Dr Rasidi bin

Roslan and the laboratory assistants for all the

guidance in the process of completing this

journal. Not forgetting all my group members

whom give full commitment in conducting the

experiment and completing this journal.

8. Reference

[1] Bavarian lab, X-ray Structural Analysis,

2014.

[2] Frederic P. Miller, Agnes F. Vandome,

John McBrewster (2010), Braggs Law

9. Appendix

Calculations

For peak (101)

From eq 2:

d=

2 sin

given that =1.5418

1.5418

d=

2(0.220)

=3.504

From eq 3:

h2 +k 2 +l2

=3.504 12+0 2+1 2

For peak (103)

1.5418

d=

2(0.317)

=2.432

a=d h2 +k 2 +l 2

=2.432 12+0 2+ 32

=7.691

For peak (004)

1.5418

d=

2(0.324)

=2.379

a=d h2 +k 2 +l 2

=2.379

=9.516

02 +02 +4 2

For peak (112)

1.5418

d=

2(0.331)

=2.329

a=d h2 +k 2 +l 2

=2.329

=5.705

12+12 +22

For peak (200)

1.5418

d=

2(0.407)

=1.894

a=d h2 +k 2 +l 2

=1.894

=3.788

2+ 02 +02

For peak (105)

1.5418

d=

2(0.453)

=1.701

a=d h2 +k 2 +l 2

=1.701

=8.673

12+0+ 52

Material Science and Solid State Laboratory (Experiment

8) 2015

For peak (211)

1.5418

d=

2(0.462)

=1.669

a=d h2 +k 2 +l 2

=1.669

=4.088

22+12 +12

For peak (213)

1.5418

d=

2(0.516)

=1.494

a=d h2 +k 2 +l 2

=1.494

=5.590

22+22 +0 2

For peak (107)

1.5418

d=

2(0.602)

=1.281

a=d h2 +k 2 +l 2

=1.281

=9.058

12+0 2+7 2

For peak (215)

1.5418

d=

2(0.609)

=1.266

a=d h2 +k 2 +l 2

=1.266

=6.934

22+12 +52

22+ 0+4 2

For peak (116)

1.5418

d=

2(0.565)

=1.364

a=d h2 +k 2 +l 2

=1.364

=8.408

=1.338

=3.784

22+12 +32

For peak (204)

1.5418

d=

2(0.520)

=1.483

a=d h2 +k 2 +l 2

=1.483

=6.632

For peak (220)

1.5418

d=

2(0.576)

=1.338

a=d h2 +k 2 +l 2

12+12 +6 2

For peak (301)

1.5418

d=

2(0.616)

=1.251

a=d h2 +k 2 +l 2

=1.251

=3.956

32+ 02 +12

Potrebbero piacerti anche

- BSP 3452 Advance Material Laboratory Experiment 5: Synthesis and Size Determination of Polymer Fibrous Mat Using Electrospinning Executive SummaryDocumento1 paginaBSP 3452 Advance Material Laboratory Experiment 5: Synthesis and Size Determination of Polymer Fibrous Mat Using Electrospinning Executive SummaryYi YiNessuna valutazione finora

- Papermaking and Processing Plywood, Artificial Board and Timber Processing High Density and High Grade TextilesDocumento1 paginaPapermaking and Processing Plywood, Artificial Board and Timber Processing High Density and High Grade TextilesYi YiNessuna valutazione finora

- Executive Summary of Exp 3Documento2 pagineExecutive Summary of Exp 3Yi YiNessuna valutazione finora

- List of Semicon CompanyDocumento3 pagineList of Semicon CompanyYi YiNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- XRDDocumento26 pagineXRDAnonymous dvuYynfXNessuna valutazione finora

- 1 XRDDocumento44 pagine1 XRDMaheep upadhyayNessuna valutazione finora

- B.Tech First Year: Course Name: Engineering PhysicsDocumento72 pagineB.Tech First Year: Course Name: Engineering PhysicsDhyey DESAIIINessuna valutazione finora

- SudheerDocumento17 pagineSudheerkrishcvrNessuna valutazione finora

- X-Ray Analysis: by A. Monroe Snider, Jr. 1Documento17 pagineX-Ray Analysis: by A. Monroe Snider, Jr. 1abdul hamidNessuna valutazione finora

- Materials Science Questions and AnswersDocumento7 pagineMaterials Science Questions and Answersد.حاتممرقهNessuna valutazione finora

- BraggsLawandX RaydiffractionDocumento9 pagineBraggsLawandX RaydiffractionAshton Poovarasu JhonsonNessuna valutazione finora

- 11 Bragg Reflection Lattice ConstantsDocumento6 pagine11 Bragg Reflection Lattice ConstantsFelipe Ignacio Albornoz CastañedaNessuna valutazione finora

- Matter Waves and Davisson-Germer ExperimentDocumento2 pagineMatter Waves and Davisson-Germer ExperimentNatheesh TpNessuna valutazione finora

- XRD TheoryDocumento7 pagineXRD TheoryAdarta MuhNessuna valutazione finora

- Introduction To X Ray Diffraction PDFDocumento21 pagineIntroduction To X Ray Diffraction PDFShahbaz AhmedNessuna valutazione finora

- Multidirectionally Distributed Feedback Photonic Crystal LasersDocumento8 pagineMultidirectionally Distributed Feedback Photonic Crystal LasersJohn pengNessuna valutazione finora

- REPORTATULFINALDocumento36 pagineREPORTATULFINALNimesh PereraNessuna valutazione finora

- Structures of Solids & X - Ray DiffractionDocumento14 pagineStructures of Solids & X - Ray DiffractionAnonymous t7MdBjnONessuna valutazione finora

- Basic of XRD - 161130 PDFDocumento68 pagineBasic of XRD - 161130 PDFHugo Ezra XimenesNessuna valutazione finora

- Tirta Ardhi Winata - Thesaurus XRDDocumento2 pagineTirta Ardhi Winata - Thesaurus XRDellin_tirtaNessuna valutazione finora

- E975 1578226-1 PDFDocumento7 pagineE975 1578226-1 PDFnayefamkNessuna valutazione finora

- Hologram MaterialsDocumento45 pagineHologram MaterialssheiiNessuna valutazione finora

- Basicsof XRDDocumento64 pagineBasicsof XRDsriharivelaga100% (9)

- X Ray Crystallography and Its ApplicatioDocumento13 pagineX Ray Crystallography and Its ApplicatioManoj PrakashNessuna valutazione finora

- FYP Proposal Edited)Documento26 pagineFYP Proposal Edited)Cheah Woi Leong100% (1)

- Laue EquationsDocumento3 pagineLaue EquationsVinodh SrinivasaNessuna valutazione finora

- Lecture 8 Physics I 27.01.22Documento95 pagineLecture 8 Physics I 27.01.22indulal lalNessuna valutazione finora

- Experimental Detemination of Crystal StructureDocumento40 pagineExperimental Detemination of Crystal StructureAASHIR AHMAD JASKANINessuna valutazione finora

- Chapter 5 X-Rays (PP 126-147)Documento22 pagineChapter 5 X-Rays (PP 126-147)Muhammad Ashfaq AhmedNessuna valutazione finora

- Theoretical Basics 2 Experimental Setup 5 Carrying Out The Experiment 6 Analysis 8 Discussion 10 Data Sheet 11Documento10 pagineTheoretical Basics 2 Experimental Setup 5 Carrying Out The Experiment 6 Analysis 8 Discussion 10 Data Sheet 11Deepak ArunNessuna valutazione finora

- Crystal StructuresDocumento266 pagineCrystal StructuresNidhi SharmaNessuna valutazione finora

- Diffraction of X-Rays by CrystalsDocumento10 pagineDiffraction of X-Rays by CrystalsAgnivesh SharmaNessuna valutazione finora

- Sample Online Q Bank EmtlDocumento37 pagineSample Online Q Bank EmtlkinseyprincyNessuna valutazione finora

- Chapter Two, The Structure of Crystalline Solids PDFDocumento23 pagineChapter Two, The Structure of Crystalline Solids PDFOmar Abu MahfouthNessuna valutazione finora