Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Check Plate

Caricato da

jlfyCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Check Plate

Caricato da

jlfyCopyright:

Formati disponibili

Operation & Maintenance Manual

Cheek Plates

Cheek Plates

Upper Cheek Plate Removal

The cheek plates, in addition to acting as wear

liners for the crushing chamber, also hold the

stationary jaw die in place on the frame by pressing

on the sides of the die and holding it up tight

against the frame.

1) Lockout & Tagout crusher drive.

If the crusher is left to operate with loose cheek

plates, the stationary jaw will move, causing

excessive wear on the jaw and frame as well as

reducing the capacity of the crusher. To operate

properly, the cheek plates should be driven down

tight and the bolts be kept well tightened to hold

them firmly against the sides of the frame and the

stationary jaw.

DANGER

Failure to Lockout & Tagout will

result in death or severe personal

injury.

2) Install chains or slings to upper cheek plate

using holes on the top of plate or, if no holes

are present, fashion a hook and eye assembly

to fasten to each plate. This may require

welding a lifting hook or eye to the plate.

The crusher may have both upper cheek plates and

one or more lower cheek plates while other

crushers may have a single cheek plate on each

side (depending upon the crusher size). Generally

more wearing action occurs on the lower cheek

plates and they will have to be replaced more often

than the upper plates. Never allow the plates to

become worn completely through or let wear take

place on the crusher frame.

WARNING

Caution should be used during the

following procedures and proper

personal protection equipment and

tools are to be used to ensure

personnel and equipment safety.

When welding mild steel to

manganese jaw dies or cheek

plates, proper welding procedures

and standards are to be observed

(such as ASTM A128 / A128M).

In particular, use a stainless 310

welding rod (or equivalent), 5/32

inch (3.97 mm) in diameter; make a

number of passes rather than one

large pass; no pre-heating or afterwelding heating (keep welded

surfaces below 500F (260C);

follow all safety precautions when

lifting.

NOTICE

3) With a suitable lifting device, put slight

tension on chains or slings to keep cheek plate

in place.

CAUTION

Before replacement of cheek plates, it is

best to adjust the machine to its most open

adjustment setting as this will allow the

most room to work.

CRSH-OM-0003ENG(OCT-2014)

4) Remove bolts from cheek plate.

7 - 28

Model CT-Series Jaw Crushers

Operation & Maintenance Manual

Cheek Plates

5) Remove upper cheek plate from crusher

frame. If it does not come free when bolts are

removed, it may be necessary to strike the

plate to jar it loose.

5) Remove lower cheek plate from crusher

frame. If it does not come free when bolts are

removed, it may be necessary to strike the

plate to jar it loose.

6) Set upper cheek plate aside.

6) Set lower cheek plate aside.

7) Repeat above procedure to remove each upper

plate.

7) Repeat above procedure to remove each lower

plate.

Lower Cheek Plate Removal

Installation of Lower Cheek Plate

1) Once upper cheek plate is removed, fashion a

hook and eye assembly to fasten to each lower

cheek plate. This may require welding a

lifting hook or eye to the plate.

Before installation of lower cheek plates into

crusher, make sure stationary jaw die is aligned

properly in the frame in relationship to swing jaw

die. For installation of stationary jaw, see

procedure in this section.

WARNING

When welding mild steel to

manganese jaw dies or cheek

plates, proper welding procedures

and standards are to be observed

(such as ASTM A128 / A128M).

In particular, use a stainless 310

welding rod (or equivalent), 5/32

inch (3.97 mm) in diameter; make a

number of passes rather than one

large pass; no pre-heating or afterwelding heating (keep welded

surfaces below 500F (260C);

follow all safety precautions when

lifting.

1) Fashion a hook and eye assembly to fasten to

each lower cheek plate. This may require

welding a lifting hook or eye to the plate.

WARNING

When welding mild steel to

manganese jaw dies or cheek

plates, proper welding procedures

and standards are to be observed

(such as ASTM A128 / A128M).

In particular, use a stainless 310

welding rod (or equivalent), 5/32

inch (3.97 mm) in diameter; make a

number of passes rather than one

large pass; no pre-heating or afterwelding heating (keep welded

surfaces below 500F (260C);

follow all safety precautions when

lifting.

2) Install chains or slings to lower cheek plate

using the hook or eye assembly fastened to

plate.

3) With a suitable lifting device, put slight

tension on chains or slings to keep cheek plate

in place.

2) Install chains or slings to lower cheek plate

using the hook or eye assembly fastened to

plate.

4) Remove bolts from cheek plate.

CRSH-OM-0003ENG(OCT-2014)

7 - 29

Model CT-Series Jaw Crushers

Operation & Maintenance Manual

Cheek Plates

3) With a suitable lifting device, lift cheek plate

into place in crusher frame.

4) Using a suitable driver and bar, drive plate

into place tight up against jaw die.

5) Install bolts and snug them up to keep plate in

place.

6) Using the same methods listed above, install

remaining lower cheek plate.

7) When both side lower cheek plates are in

place and tight against the stationary jaw die,

tighten all bolts to the proper torque.

8) With both lower cheek plates in place, proceed

to installation of upper cheek plates.

Installation of Upper Cheek Plate

1) Install chains or slings to upper cheek plate

using holes on the top.

2) With a suitable lifting device, lift cheek plate

into place.

3) Install bolts and snug them up to keep plate in

place.

4) Using a suitable driver, drive plate into place

tight up against jaw die.

5) Repeat above procedure to install each upper

plate.

6) When both side upper cheek plates are in

place and tight against the stationary jaw die,

tighten all bolts to the proper torque.

7) When all cheek plates are in place and tight,

remove crusher drive Lockout & Tagout.

CRSH-OM-0003ENG(OCT-2014)

7 - 30

Model CT-Series Jaw Crushers

Operation & Maintenance Manual

Stationary Jaw Die

Tightening Cheek Plates

Cheek plates may become loose, permitting the

stationary jaw die to move and cause wear to both

the die and crusher frame. Check periodically to

make sure the cheek plates are tight against the

stationary jaw die. If the stationary jaw die moves

during crushing operation, the cheek plates should

be tightened. The following method permits

tightening of the lower plates without removing

the upper plates.

1) Lockout & Tagout crusher drive.

DANGER

Failure to Lockout & Tagout will

result in death or severe personal

injury.

2) Loosen bolts on the upper cheek plates until

they are loose enough to allow the plates to be

lifted up.

8) Using a suitable driver, drive upper plate

down until very tight against the jaw die.

9) Tighten bolts on the upper cheek plate to the

proper torque.

10) Repeat these steps for each side.

11) When all cheek plates are in place and tight,

remove crusher drive Lockout & Tagout.

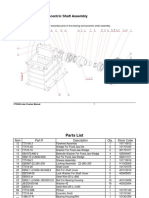

Stationary Jaw Die

The stationary jaw die is locked in a rigid position

against the back of the crusher frame by the cheek

plates and tapered wedges at the top of the crusher

frame. See (Figure 7 - 27) The stationary jaw die

may be reversed by rotating it top-to-bottom to

gain additional wear life. The worn side of the jaw

die must not be allowed to wear too thin as this will

weaken that side of the die and could potentially

cause damage to the crusher.

3) With a suitable lifting device, lift upper cheek

plate approximately 1/2 inch (12.7 mm) and

place a piece of steel plate or bar as a spacer

between it and the lower cheek plate.

4) Loosen the lower cheek plate bolts slightly

until they are snug, but not tight, and will

allow the plate to be driven down.

5) Using a suitable driver, drive upper plate

down until the lower plate is driven down very

tight against the jaw die.

6) Tighten bolts on the lower cheek plate to the

proper torque.

1 - Stationary Jaw Die

2 - Stationary Jaw Die Wedges

3 - Cheek Plates

7) Remove the steel spacer from between the

plates.

Figure 7 - 27 Typical Stationary Jaw Die & Wedge

Arrangement

CRSH-OM-0003ENG(OCT-2014)

7 - 31

Model CT-Series Jaw Crushers

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- GekkoDocumento6 pagineGekkojlfyNessuna valutazione finora

- 2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenanceDocumento3 pagine2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenancejlfyNessuna valutazione finora

- GekkoDocumento6 pagineGekkojlfyNessuna valutazione finora

- Digital PresureDocumento11 pagineDigital PresurejlfyNessuna valutazione finora

- Selenoid eDocumento9 pagineSelenoid ejlfyNessuna valutazione finora

- Seguridad y TransporteDocumento6 pagineSeguridad y TransportejlfyNessuna valutazione finora

- Filtro de AireDocumento7 pagineFiltro de AirejlfyNessuna valutazione finora

- Falcon c1000Documento9 pagineFalcon c1000jlfyNessuna valutazione finora

- Rinse AUTO Is The Standard Operating Mode For Most ApplicationsDocumento6 pagineRinse AUTO Is The Standard Operating Mode For Most ApplicationsjlfyNessuna valutazione finora

- 5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForceDocumento4 pagine5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForcejlfyNessuna valutazione finora

- C1000-R3.1 Installation, Operations, and Maintenance ManualDocumento8 pagineC1000-R3.1 Installation, Operations, and Maintenance ManualjlfyNessuna valutazione finora

- Jaw Part3Documento6 pagineJaw Part3jlfy100% (1)

- Operation & Maintenance Manual What Is Lockout & Tagout?: This Page Intentionally Left BlankDocumento6 pagineOperation & Maintenance Manual What Is Lockout & Tagout?: This Page Intentionally Left BlankjlfyNessuna valutazione finora

- Appendix A - Torque Specs Torque Charts: Standard Bolt Torque Metric Bolt TorqueDocumento6 pagineAppendix A - Torque Specs Torque Charts: Standard Bolt Torque Metric Bolt TorquejlfyNessuna valutazione finora

- Jaw Part2Documento6 pagineJaw Part2jlfyNessuna valutazione finora

- Jaw Part1Documento7 pagineJaw Part1jlfy0% (1)

- Operation & Maintenance Manual Belt Drive Troubleshooting: CRSH-OM-0003ENG (OCT-2014) B - 3 Model CT-Series Jaw CrushersDocumento4 pagineOperation & Maintenance Manual Belt Drive Troubleshooting: CRSH-OM-0003ENG (OCT-2014) B - 3 Model CT-Series Jaw CrushersjlfyNessuna valutazione finora

- PitmanDocumento7 paginePitmanjlfyNessuna valutazione finora

- Operation & Maintenance Manual Maintenance Checks: This Page Intentionally Left BlankDocumento6 pagineOperation & Maintenance Manual Maintenance Checks: This Page Intentionally Left BlankjlfyNessuna valutazione finora

- Chancadora TrioDocumento123 pagineChancadora Triojlfy100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 10 Catalog Krisbow9 Machine Toll AccDocumento16 pagine10 Catalog Krisbow9 Machine Toll AccEnrique da MattaNessuna valutazione finora

- 02-SAMSS-012 (Weld Overlay Fitting, Flanges and Spool Pieces)Documento10 pagine02-SAMSS-012 (Weld Overlay Fitting, Flanges and Spool Pieces)ALINessuna valutazione finora

- GLACIER LAr Tank Design (Deliverable 2.2)Documento76 pagineGLACIER LAr Tank Design (Deliverable 2.2)atiqulaNessuna valutazione finora

- Powder Production Methods: - Mechanical Crushing and Grinding - Mechanical AlloyingDocumento14 paginePowder Production Methods: - Mechanical Crushing and Grinding - Mechanical AlloyingSalvador Tinoco VRsNessuna valutazione finora

- Mechanical Design EngineerDocumento2 pagineMechanical Design Engineerapi-291346174Nessuna valutazione finora

- DefectsDocumento26 pagineDefectsbobblytastic100% (1)

- Preventing Mechanical FailuresDocumento15 paginePreventing Mechanical Failuresmarcalasan0% (1)

- A Yarn Manufacturing Spinning Mill List 2019 v5Documento44 pagineA Yarn Manufacturing Spinning Mill List 2019 v5Tabassum RezaNessuna valutazione finora

- Knight Frank India Warehousing and Logistics India Warehousing Market Report 2018 5326 Knight FrankDocumento68 pagineKnight Frank India Warehousing and Logistics India Warehousing Market Report 2018 5326 Knight FrankRavi TejaNessuna valutazione finora

- Graphic OrganizerDocumento1 paginaGraphic Organizerapi-270328839Nessuna valutazione finora

- Construction Material Management PDFDocumento19 pagineConstruction Material Management PDFBala SubramaniamNessuna valutazione finora

- F701 SDocumento2 pagineF701 SSubin AnandanNessuna valutazione finora

- MCP 101 Lab Manual 2016Documento66 pagineMCP 101 Lab Manual 2016Sankalp GargNessuna valutazione finora

- RisksDocumento19 pagineRisksCUTto1122Nessuna valutazione finora

- Processo Lavagem - 7. Pulp Washing 12 Session 7Documento66 pagineProcesso Lavagem - 7. Pulp Washing 12 Session 7Ricardo MendesNessuna valutazione finora

- Copper Technology RoadmapDocumento50 pagineCopper Technology RoadmapleniucvasileNessuna valutazione finora

- CWI Module 3Documento2 pagineCWI Module 3Basil M. Ikhleif100% (1)

- Toyota Production SystemDocumento32 pagineToyota Production SystemWawang SukmoroNessuna valutazione finora

- Gas Metal Arc WeldingDocumento3 pagineGas Metal Arc Weldingvarun100% (1)

- Roofing: Single Ply Roofing: Modified Bitumen Plastic Fabrication Civil Engineering Tunnelling FlooringDocumento2 pagineRoofing: Single Ply Roofing: Modified Bitumen Plastic Fabrication Civil Engineering Tunnelling FlooringНенад КнежевићNessuna valutazione finora

- The Performance Meets The Promise: Vectra Series Models GL & XLDocumento12 pagineThe Performance Meets The Promise: Vectra Series Models GL & XLNicolás Villarin100% (1)

- C2microsoft Office PowerPoint 97-2003 Presentation-1Documento18 pagineC2microsoft Office PowerPoint 97-2003 Presentation-1swaroop belwalkarNessuna valutazione finora

- ARMCO Iron BrochureDocumento12 pagineARMCO Iron BrochureprincedrdoNessuna valutazione finora

- CH 031Documento54 pagineCH 031ambermuNessuna valutazione finora

- 2014 Speed Report 025 Fortificação de Alimentos Básicos em MoçambiqueDocumento39 pagine2014 Speed Report 025 Fortificação de Alimentos Básicos em MoçambiqueMauro VieiraNessuna valutazione finora

- Unique Requirements Checklist-ISO/TS 16949Documento9 pagineUnique Requirements Checklist-ISO/TS 16949zubairsgcNessuna valutazione finora

- Oracle EAM Training ContentsDocumento4 pagineOracle EAM Training ContentsAnonymous oSTh85100% (1)

- Martensitic Stainless Steel EN 1.4021-QT 700Documento2 pagineMartensitic Stainless Steel EN 1.4021-QT 700LebasNessuna valutazione finora

- Perfect EngineersDocumento8 paginePerfect EngineersKeerthanaKamachiNessuna valutazione finora