Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

38TKB 4W

Caricato da

Elvis FariasTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

38TKB 4W

Caricato da

Elvis FariasCopyright:

Formati disponibili

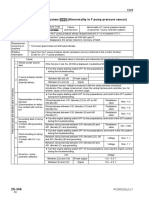

38TKB

Air Conditioning Unit

Wiring Diagrams

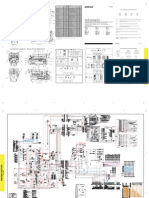

CONNECTION DIAGRAM

*CH

SCHEMATIC DIAGRAM (LADDER FORM)

(NOTE #9)

RED

or

BLK

RED or BLK

BLK

*DSV

BLK

BLK

L1

208/230 1

POWER

SUPPLY

BLK

11

23

L2

EQUIP

GND

21

23

CONT

COMP

BLU

S

C

H

R

YEL

+t

YEL

*ST

BRN

CONT

1

*SC

5

(NOTE #8) *SR

EQUIP

GND

1

*CH

*SR

CONT

OFM

C

F

BLK

VIO

BLK

*LPS

BLK

YEL

T2

YEL

IFR

C

R

*HPS

*LPS

*DTS

T2

LOGIC

T1

*LLS

EXTERNAL

POWER

SUPPLY

24 V

T3

* CTD

Y

IFR

G

(NOTE #3)

R

G

Y

INDOOR THERMOSTAT

(NOTE #6)

23

CONT

T3

BRN

BLK

CAP

23

(NOTE #14)

LOGIC

T1

L2

*ST

+t

*SC

*LLS

BLK

COMP

S

* CTD

BLU

BLU

C

21

11

YEL

*DTS

BLU

*DSV

L1

YEL

BRN

OFM

BLK

BLU

(NOTE #14)

*HPS

CAP

YEL

BRN

BLU

BLU

BLU

R

INDOOR

THERMOSTAT

INDOOR BLOWER MOTOR

EXTERNAL POWER SUPPLY 24 V

-LEGENDNOTES:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

Symbols are electrical representation only.

Compressor and fan motor furnished with inherent thermal protection.

To be wired in accordance with National Electric N.E.C. and local codes.

N.E.C. class 2, 24V circuit, min. 40 VA required, 60 VA on units installed with LLS.

Use copper conductors only.

Connection for typical cooling only thermostat. For other arrangements see

installation instructions.

If indoor section has a transformer with a grounded secondary, connect the

grounded side to the BRN lead.

When start relay and start capacitor are installed, start thermistor is not used.

CH not used on all units.

If any of the original wire, as supplied, must be replaced, use the same or

equivalent wire.

Check all electrical connections inside control box for tightness.

Do not attempt to operate unit until service valves have been opened.

Do not rapid cycle compressor. Compressor must be off 3 minutes to allow pressures

to equalize between high and low side before starting.

Wire not present if HPS, LPS, DTS or CTD are used.

FACTORY POWER WIRING

IFR

INDOOR FAN RELAY

FIELD POWER WIRING

*LLS

LIQ. LINE SOLENOID VALVE

FACTORY CONTROL WIRING

*LPS

LOW PRESSURE SWITCH

FIELD CONTROL WIRING

OFM

OUTDOOR FAN MOTOR

COMPONENT CONNECTION

*SC

START CAPACITOR

FIELD SPLICE

*SR

START RELAY

JUNCTION

*ST

START THERMISTOR

CONT

CONTACTOR

CAP

CAPACITOR (DUAL RUN)

*CH

CRANKCASE HEATER

COMP

COMPRESSOR

*CTD

COMPRESSOR TIME DELAY

*DSV

DISCH. SOLENOID VALVE

*DTS

DISCHARGE TEMP. SWITCH

IDF

INDOOR FAN

*HPS

HIGH PRESSURE SWITCH

* MAY BE FACTORY OR FIELD INSTALLED.

320918-401 REV. B

A95080

Fig. 138TKB018-048 208-230v, 1 Phase, 60 Hertz

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

PC 101

Catalog No. 563-818

Printed in U.S.A.

Form 38TKB-4W

Pg 1

1-96

Replaces: 38TKB-3W

Tab 3a 2a

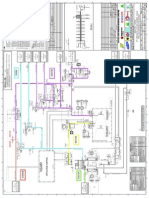

CONNECTION DIAGRAM

SCHEMATIC DIAGRAM (LADDER FORM)

(NOTE #9)

*CH

RED

or

BLK

RED or BLK

208/230 1

POWER

SUPPLY

BLK

*DSV

BLK

COMP BLU

S

C

H

BLK

L1

BLK

11

13

L2

EQUIP

GND

21

23

CONT

YEL

YEL

CAP

+t

*ST

BRN

*SC

BRN

OFM

BLK

(NOTE #8)

2

5

*SR

EQUIP

GND

11

*ST

+t

*SC

1

*CH

*SR

CONT

OFM

BLK

VIO

T2

BLK

BLK

YEL

YEL

*HPS

*DTS

*LPS

T2

LOGIC

BRN

T1

*LLS

BLK

IFR

C

R

*LLS

EXTERNAL

POWER

SUPPLY

24 V

Y

IFR

INDOOR

THERMOSTAT

INDOOR BLOWER MOTOR

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

EXTERNAL POWER SUPPLY 24 V

-LEGEND-

NOTES:

1.

2.

3.

4.

INDOOR THERMOSTAT

(NOTE #6)

T3

CTD

(NOTE #3)

Y

13

23

CONT

T3

* CTD

BLK

CAP

(NOTE #14)

LOGIC

T1

BLU

BLU

L2

21

*LPS

*DTS

BLU

COMP

R

CONT

BRN

BLU

(NOTE #14)

*HPS

YEL

*DSV

L1

YEL

YEL

BLU

BLU

BLU

Symbols are electrical representation only.

Compressor and fan motor furnished with inherent thermal protection.

To be wired in accordance with National Electric N.E.C. and local codes.

N.E.C. class 2, 24V circuit, min. 40 VA required, 60 VA on units installed

with LLS.

Use copper conductors only.

Connection for typical cooling only thermostat. For other arrangements

see installation instructions.

If indoor section has a transformer with a grounded secondary, connect

the grounded side to the BRN lead.

When start relay and start capacitor are installed, start thermistor is not used.

CH not used on all units.

If any of the original wire, as supplied must be replaced, use the same

or equivalent wire.

Check all electrical connections inside control box for tightness.

Do not attempt to operate unit until service valves have been opened.

Do not rapid cycle compressor. Compressor must be off 3 minutes to

allow pressures to equalize between high and low side before starting.

Wire not present if HPS, LPS, DTS or CTD are used.

FACTORY POWER WIRING

IFR

INDOOR FAN RELAY

FIELD POWER WIRING

*LLS

LIQ. LINE SOLENOID VALVE

FACTORY CONTROL WIRING

*LPS

LOW PRESSURE SWITCH

FIELD CONTROL WIRING

OFM

OUTDOOR FAN MOTOR

COMPONENT CONNECTION

*SC

START CAPACITOR

FIELD SPLICE

*SR

START RELAY

JUNCTION

*ST

START THERMISTOR

CONT

CONTACTOR

CAP

CAPACITOR (DUAL RUN)

*CH

CRANKCASE HEATER

COMP

COMPRESSOR

*CTD

COMPRESSOR TIME DELAY

*DSV

DISCH. SOLENOID VALVE

*DTS

DISCHARGE TEMP. SWITCH

IDF

INDOOR FAN

*HPS

HIGH PRESSURE SWITCH

* MAY BE FACTORY OR FIELD INSTALLED.

320929-401 REV. B

A95081

Fig. 238TKB060 208-230v, 1 Phase, 60 Hertz

Copyright 1996 CARRIER Corp. 7310 W. Morris St. Indianapolis, IN 46231

38tkb4w

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

PC 101

Catalog No. 563-818

Printed in U.S.A.

Form 38TKB-4W

Pg 2

1-96

Replaces: 38TKB-3W

Tab 3a 2a

Potrebbero piacerti anche

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsDa EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsValutazione: 3 su 5 stelle3/5 (2)

- 38tkb 4wCARRIERDocumento2 pagine38tkb 4wCARRIERSyed Noman AhmedNessuna valutazione finora

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- 38byb 1 PhaseDocumento2 pagine38byb 1 Phasemy nameNessuna valutazione finora

- Wiring Carrier 38ckc-c3wDocumento2 pagineWiring Carrier 38ckc-c3wRay Ravel100% (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- Wiring Diagram: 24ABC6 Baset16 Air Conditioner With Puronr RefrigerantDocumento2 pagineWiring Diagram: 24ABC6 Baset16 Air Conditioner With Puronr Refrigeranttidjani73Nessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- 38tdb 3wiring DiagramDocumento4 pagine38tdb 3wiring DiagramMakWilliamsNessuna valutazione finora

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142Da EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142Nessuna valutazione finora

- 24apa5 2wDocumento2 pagine24apa5 2wSyed Noman AhmedNessuna valutazione finora

- GT Trips List (Generic)Documento13 pagineGT Trips List (Generic)Ovais Siddiqui100% (6)

- Analog Circuit Design Volume Three: Design Note CollectionDa EverandAnalog Circuit Design Volume Three: Design Note CollectionValutazione: 3 su 5 stelle3/5 (2)

- Renr1242 02Documento2 pagineRenr1242 02Mohamed Abdelazim Bakr Adam100% (2)

- Wells Thermostat IDDocumento18 pagineWells Thermostat IDJuan A Aguilera ANessuna valutazione finora

- Datablade - Små Sorte - R290 (Propan) GBDocumento40 pagineDatablade - Små Sorte - R290 (Propan) GBNoman AhmedNessuna valutazione finora

- 3512 Electronico PDFDocumento2 pagine3512 Electronico PDFPedro Zafra85% (13)

- E Schema 3500BDocumento2 pagineE Schema 3500Blimkokchiang809100% (1)

- C 13Documento2 pagineC 13amateur123456100% (10)

- THP9045 Wiring Module: FeaturesDocumento12 pagineTHP9045 Wiring Module: FeaturesIBJSC.comNessuna valutazione finora

- Schematic C9 Mass Transit Bus EngineDocumento2 pagineSchematic C9 Mass Transit Bus EngineJorge Enrique Jiménez ManzoNessuna valutazione finora

- 71A CompressorDocumento36 pagine71A CompressorGustavoNessuna valutazione finora

- 22 1739 04 - 02012010XXDocumento16 pagine22 1739 04 - 02012010XXMartinez MarNessuna valutazione finora

- Salon Tipi 1 Faz ServisDocumento51 pagineSalon Tipi 1 Faz ServisaydintarakNessuna valutazione finora

- B 84567 SB Mm1 DSR ST 60 0021 1 Aoc GTG Fuel Gas HeaterDocumento7 pagineB 84567 SB Mm1 DSR ST 60 0021 1 Aoc GTG Fuel Gas HeaterpragatheeskNessuna valutazione finora

- Product Data: 38CKE 50Hz Air Conditioner With R - 410a Refrigerant Single and Three Phase 1 - 1/2 To 5 TonsDocumento26 pagineProduct Data: 38CKE 50Hz Air Conditioner With R - 410a Refrigerant Single and Three Phase 1 - 1/2 To 5 Tonsalmig200Nessuna valutazione finora

- Com 069 Agk 2030 EdDocumento14 pagineCom 069 Agk 2030 EdSimamora Samuel HansenNessuna valutazione finora

- Reducing ValveDocumento11 pagineReducing ValveFluidPowerConsultantNessuna valutazione finora

- Goodman Outdoor T-Stat I&O Manual March06Documento8 pagineGoodman Outdoor T-Stat I&O Manual March06dominicanomd4018Nessuna valutazione finora

- Goodman Airhandler ManualDocumento8 pagineGoodman Airhandler Manualjotace469Nessuna valutazione finora

- Plano Electricidad Cat 325Documento2 paginePlano Electricidad Cat 325aguadojorgeNessuna valutazione finora

- 3406C Eng SchematicDocumento4 pagine3406C Eng Schematicmurugu197983% (12)

- SF 000128024 PDFDocumento19 pagineSF 000128024 PDFJorge GelabertNessuna valutazione finora

- Especificaciones Equipos Paquetes PDFDocumento8 pagineEspecificaciones Equipos Paquetes PDFDavid BallenNessuna valutazione finora

- Botones Killark PDFDocumento59 pagineBotones Killark PDFnikodemis100% (2)

- 2222Documento5 pagine2222Octavio RamosNessuna valutazione finora

- PNIDDocumento1 paginaPNIDamitrai86Nessuna valutazione finora

- 24abb32 PDFDocumento4 pagine24abb32 PDFErnesto Garcia100% (1)

- FTM 181 Manual Rev 3Documento3 pagineFTM 181 Manual Rev 3Brandi ChandlerNessuna valutazione finora

- Mitsubishi Evaporadora MSH A18 A24NDDocumento28 pagineMitsubishi Evaporadora MSH A18 A24NDfrigotecniaNessuna valutazione finora

- Coleman RV 12 Volt Thermistat ACDocumento18 pagineColeman RV 12 Volt Thermistat ACsthoma20100% (1)

- 38hdt PDDocumento12 pagine38hdt PDDoan Tien Do100% (1)

- XdexdedcccDocumento6 pagineXdexdedcccOctavio RamosNessuna valutazione finora

- Diagrama CatDocumento2 pagineDiagrama Catastecnica100% (2)

- Asssssss SramdfdfdDocumento6 pagineAsssssss SramdfdfdOctavio RamosNessuna valutazione finora

- Cat - Dcs.sis - Controller 3412 XDocumento2 pagineCat - Dcs.sis - Controller 3412 XKariem R Noweer67% (3)

- Plano Electrico 330 ELDocumento2 paginePlano Electrico 330 ELJulio CRNessuna valutazione finora

- Danfoss Compressors r600 BrochureDocumento6 pagineDanfoss Compressors r600 BrochureSyed Noman Ahmed100% (6)

- C 9 C9SDocumento4 pagineC 9 C9SEduardo Alvarez100% (1)

- 3-77-06 Field Weld Ends Pumps& Valves Conrolled Circulation & CC UnitsDocumento10 pagine3-77-06 Field Weld Ends Pumps& Valves Conrolled Circulation & CC UnitsJKKNessuna valutazione finora

- Mitsubishi MSZ Hj35vaDocumento32 pagineMitsubishi MSZ Hj35vadimgou2Nessuna valutazione finora

- MitsubishiDocumento35 pagineMitsubishiAlfredoJoseRayaNessuna valutazione finora

- Beko 14.2 PDFDocumento33 pagineBeko 14.2 PDFMos CraciunNessuna valutazione finora

- Senr1256 01Documento2 pagineSenr1256 01omarNessuna valutazione finora

- LG SM S09amDocumento8 pagineLG SM S09amViorel CioataNessuna valutazione finora

- Renr7885renr7885-04 SisDocumento2 pagineRenr7885renr7885-04 SisGerman SoccaNessuna valutazione finora

- Cat Dcs Sis ControllerDocumento2 pagineCat Dcs Sis ControllerHector Eli SaucedoNessuna valutazione finora

- 38CKC Product DataDocumento26 pagine38CKC Product DataCarlos Enrique Godoy Sifontes0% (1)

- X-DriveED3RSubmittalDocumento9 pagineX-DriveED3RSubmittalElvis FariasNessuna valutazione finora

- Do Fairytales Create False Expectations On RealityDocumento1 paginaDo Fairytales Create False Expectations On RealityElvis FariasNessuna valutazione finora

- Parkview at Palmetto Bay - LG-VRF - Submittal DataDocumento38 pagineParkview at Palmetto Bay - LG-VRF - Submittal DataElvis FariasNessuna valutazione finora

- Tuttle and Bailey AdministrationDocumento8 pagineTuttle and Bailey AdministrationElvis FariasNessuna valutazione finora

- Split System Refrigeranr Pipe GuideDocumento10 pagineSplit System Refrigeranr Pipe GuideElvis FariasNessuna valutazione finora

- R22 Link PDFDocumento2 pagineR22 Link PDFElvis FariasNessuna valutazione finora

- Energy Recovery Ventilation (Erv) Engineering Manual: ERV Indoor Units 470 To 1,180 CFMDocumento34 pagineEnergy Recovery Ventilation (Erv) Engineering Manual: ERV Indoor Units 470 To 1,180 CFMElvis FariasNessuna valutazione finora

- h11-515 - Rev - 6 Ruud Wiring PicDocumento12 pagineh11-515 - Rev - 6 Ruud Wiring PicElvis FariasNessuna valutazione finora

- Temperature Limit Control Switches - Auto ResetDocumento22 pagineTemperature Limit Control Switches - Auto ResetElvis FariasNessuna valutazione finora

- Therm o Disc Complete Catalog 1-10-19 en Us 5312494Documento206 pagineTherm o Disc Complete Catalog 1-10-19 en Us 5312494Elvis FariasNessuna valutazione finora

- Opteon XP40 (R-449A) Refrigerant: Safety Data SheetDocumento16 pagineOpteon XP40 (R-449A) Refrigerant: Safety Data SheetElvis Farias0% (1)

- D-4000-10 Ground MonitorDocumento3 pagineD-4000-10 Ground MonitorLuisIgnacioGarciaRivasNessuna valutazione finora

- Siemens MXL IQ Operation Installation ManualDocumento218 pagineSiemens MXL IQ Operation Installation Manuallouiswang1964100% (1)

- Kerax 330 P4X4Documento6 pagineKerax 330 P4X4sulimanNessuna valutazione finora

- Kodiaq Accessories en 0617Documento33 pagineKodiaq Accessories en 0617Cane CirpoNessuna valutazione finora

- Mosquito KillerDocumento15 pagineMosquito KillerTecheureka SolutionsNessuna valutazione finora

- How To Detect Insulation Failures in Electrical EquipmentDocumento7 pagineHow To Detect Insulation Failures in Electrical EquipmentchandruuncleNessuna valutazione finora

- Generation of High Voltages & CurrentsDocumento46 pagineGeneration of High Voltages & Currentssaikarthick023Nessuna valutazione finora

- Service Code in Electrical System (Abnormality in F Pump Pressure Sensor) E224Documento4 pagineService Code in Electrical System (Abnormality in F Pump Pressure Sensor) E224ariy yuli styawan100% (1)

- Electronic Systems and Design - Quiz 1FDocumento5 pagineElectronic Systems and Design - Quiz 1FAshly EspaldonNessuna valutazione finora

- American Wire Gauge (AWG)Documento8 pagineAmerican Wire Gauge (AWG)Marija DjenicNessuna valutazione finora

- Defence Engine: 261-336 KW (350-450 HP) 1491-1850 NM (1100-1364 LB-FT)Documento2 pagineDefence Engine: 261-336 KW (350-450 HP) 1491-1850 NM (1100-1364 LB-FT)Aamir ArainNessuna valutazione finora

- Ship Particular TB STA 1 - 3000 HPDocumento1 paginaShip Particular TB STA 1 - 3000 HPMichael GunawanNessuna valutazione finora

- Leega LG 75cDocumento4 pagineLeega LG 75cracso100% (1)

- 2d Insulation Resistance Monitor 6Documento6 pagine2d Insulation Resistance Monitor 6john smithNessuna valutazione finora

- History of ComputerDocumento5 pagineHistory of ComputerGlad RoblesNessuna valutazione finora

- Tanvo 45LDocumento4 pagineTanvo 45LTom AvidNessuna valutazione finora

- W-4600CPR - Rev03Documento156 pagineW-4600CPR - Rev03william.carvalhoNessuna valutazione finora

- Siemens Optipoint Manual Accessories MultilanguagesDocumento177 pagineSiemens Optipoint Manual Accessories MultilanguagesHaefelin ArnaudNessuna valutazione finora

- SM D65EX, PX, WX-15E0 69001 Up SEN00046-06Documento1.214 pagineSM D65EX, PX, WX-15E0 69001 Up SEN00046-06Mariano Jaramillo RosalesNessuna valutazione finora

- Maspric ATS - M V02 LowresDocumento25 pagineMaspric ATS - M V02 LowresvenkatNessuna valutazione finora

- Ajuste de Eaton EmbragueDocumento5 pagineAjuste de Eaton EmbragueHamilton Miranda100% (1)

- Instruction Manual: Raytech Usa, IncDocumento57 pagineInstruction Manual: Raytech Usa, IncRuben Dario Gutierrez MontenegroNessuna valutazione finora

- Information Sheet ERC216: Relay 16A, 2NO, 230V 50HzDocumento2 pagineInformation Sheet ERC216: Relay 16A, 2NO, 230V 50HztongaiNessuna valutazione finora

- 070 Operating Manual Control and Monitoring SystemDocumento780 pagine070 Operating Manual Control and Monitoring SystemBudhita MahaprasetyaNessuna valutazione finora

- IPS2000 Mifare IC Card Parking System PDFDocumento4 pagineIPS2000 Mifare IC Card Parking System PDFGabriel LunaNessuna valutazione finora

- Vertiv Chilled Water CCU IOM ManualDocumento193 pagineVertiv Chilled Water CCU IOM Manualabeon augustineNessuna valutazione finora

- KCCEC List of EquipmentDocumento45 pagineKCCEC List of Equipmentahmedsaber2007Nessuna valutazione finora

- BOSCH D JETRONIC Fuel Injection of Renault 17 TSDocumento18 pagineBOSCH D JETRONIC Fuel Injection of Renault 17 TSRaul Quispe Ramirez60% (5)

- Byv 32Documento5 pagineByv 32chawkigenieNessuna valutazione finora

- Man Rec Severing ToolDocumento10 pagineMan Rec Severing ToolNgoc NguyenNessuna valutazione finora