Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Block de Motor - Especificaciones c15 PDF

Caricato da

FJ OscarTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Block de Motor - Especificaciones c15 PDF

Caricato da

FJ OscarCopyright:

Formati disponibili

6/8/2015

C15OnhighwayEngineSDP00001UP(SEBP441962)Sistemasycomponentes

Pantallaanterior

Bienvenido:r080thm6

Producto:TRUCKENGINE

Modelo:C15TRUCKENGINESDP

Configuracin:C15OnhighwayEngineSDP00001UP

Pautasdereutilizacinyrecuperacin

SpecificationsforCylinderBlockAssembliesonCSeriesEngines{1201}

NmerodemedioSEBF900726

Caterpillar:ConfidentialYellow

Fechadepublicacin04/06/2015

Fechadeactualizacin04/06/2015

i06193706

SpecificationsforCylinderBlockAssembliesonCSeriesEngines{1201}

SMCS1201

Engine:C10AllC9andC9AllC11AllC12andC12AllC13andC13AllC15andC15AllC16andC16AllC18andC18All

C27AllC32AllC7All

MarineEngine:

C30MARINE(S/N:CLX1UP)

Introduction

Table1

Revision

SummaryofChangesinSEBF9007

25

CorrectedconversionforC9blockspecificationsin2

24

r080thm6

Caterpillar:ConfidentialYellow

Addednewserialnumberprefixes.

CorrectedtolerancesforC13,C27/C32,andC30inRowDofTable2.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/productsearch/productheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp

1/19

6/8/2015

C15OnhighwayEngineSDP00001UP(SEBP441962)Sistemasycomponentes

23

Updatedreferencestothermalspraydocuments

22

CorrectedtheSpecification(A)forC10,C11,C12,andC13enginesinTable2.

21

Addednewserialnumberprefixes.

20

AddedIllustrations4and5toprovidebetterexamplesofmeasuringspecifications.Alsoupdatedandcheckedspecifications

inTable2.

1519

Addednewserialnumberprefixes.

2015CaterpillarAllRightsReserved.ThisguidelineisfortheuseofCatdealersonly.Unauthorizeduseofthisdocumentorthe

proprietaryprocessesthereinwithoutpermissionmaybeviolationofintellectualpropertylaw.Informationcontainedinthisdocumentis

consideredCaterpillar:ConfidentialYellow.

ThisReuseandSalvageGuidelinecontainsthenecessaryinformationinordertoallowadealertoestablishapartsreusabilityprogram.

ReuseandsalvageinformationenablesCaterpillardealersandcustomerstobenefitfromcostreductions.Everyefforthasbeenmadein

ordertoprovidethemostcurrentinformationthatisknowntoCaterpillar.Continuingimprovementandadvancementofproductdesign

mighthavecausedchangestoyourproductwhicharenotincludedinthispublication.ThisReuseandSalvageGuidelinemustbeusedwith

thelatesttechnicalinformationthatisavailablefromCaterpillar.

Forquestionsoradditionalinformationconcerningthisguideline,submitaformforfeedbackintheServiceInformationSystem.Inorderto

addressanurgentissue,usethefollowingresourcesinordertocommunicateyourrequesttoCaterpillarRepairProcessEngineering:

CaterpillarDealerTechnicalCommunicator

DealerSolutionNetwork

CaterpillarTechnicalRepresentative

KnowledgeNetwork

CanceledPartNumbersandReplacedPartNumbers

Thisdocumentmayincludecanceledpartnumbersandreplacedpartnumbers.UseNPRonSISforinformationaboutcanceledpart

numbersandreplacedpartnumbers.NPRwillprovidethecurrentpartnumbersforreplacedparts.

ImportantSafetyInformation

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/productsearch/productheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp

2/19

6/8/2015

Illustration1

C15OnhighwayEngineSDP00001UP(SEBP441962)Sistemasycomponentes

g02139237

Worksafely.Mostaccidentsthatinvolveproductoperation,maintenance,andrepairarecausedbyfailuretoobservebasicsafetyrulesor

precautions.Anaccidentcanoftenbeavoidedbyrecognizingpotentiallyhazardoussituationsbeforeanaccidentoccurs.Apersonmustbe

alerttopotentialhazards.Thispersonshouldalsohavethenecessarytraining,skills,andtoolsinordertoperformthesefunctionsproperly.

Safetyprecautionsandwarningsareprovidedinthisinstructionandontheproduct.Ifthesehazardwarningsarenotheeded,bodilyinjury

ordeathcouldoccurtoyouortootherpersons.Caterpillarcannotanticipateeverypossiblecircumstancethatmightinvolveapotential

hazard.Therefore,thewarningsinthispublicationandthewarningsthatareontheproductarenotallinclusive.Ifatool,aprocedure,a

workmethodoroperatingtechniquethatisnotspecificallyrecommendedbyCaterpillarisused,youmustensurethatitissafeforyouand

forotherpeopletouse.Youshouldensurethattheproductwillnotbedamagedortheproductwillnotbemadeunsafebytheoperation,

lubrication,maintenanceortherepairproceduresthatareused.

Improperoperation,lubrication,maintenanceorrepairofthisproduct

canbedangerousandcouldresultininjuryordeath.

Donotoperateorperformanylubrication,maintenanceorrepairon

thisproduct,untilyouhavereadandunderstoodtheoperation,

lubrication,maintenanceandrepairinformation.

Safetyprecautionsandwarningsareprovidedinthismanualandontheproduct.Ifthesehazardwarningsarenotheeded,bodilyinjuryor

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/productsearch/productheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp

3/19

6/8/2015

C15OnhighwayEngineSDP00001UP(SEBP441962)Sistemasycomponentes

deathcouldoccurtoyouortootherpersons.

Thehazardsareidentifiedbythesafetyalertsymbolwhichisfollowedbyasignalwordsuchasdanger,warning,orcaution.The

"WARNING"safetyalertsymbolisshownbelow.

Illustration2

g00008666

Thissafetyalertsymbolmeans:

Payattention!

Becomealert!

Yoursafetyisinvolved.

Themessagethatappearsunderthesafetyalertsymbolexplainsthehazard.

Operationsthatmaycauseproductdamageareidentifiedby"NOTICE"labelsontheproductandinthispublication.

Caterpillarcannotanticipateeverypossiblecircumstancethatmightinvolveapotentialhazard.Thesafetyinformationinthis

documentandthesafetyinformationonthemachinearenotallinclusive.Youmustdeterminethatthetools,procedures,work

methods,andoperatingtechniquesaresafe.Youmustdeterminethattheoperation,lubrication,maintenance,andrepair

procedureswillnotdamagethemachine.Also,youmustdeterminethattheoperation,lubrication,maintenance,andrepair

procedureswillnotmakethemachineunsafe.

Theinformation,thespecifications,andtheillustrationsthatexistinthisguidelinearebasedoninformationwhichwasavailableatthetime

ofpublication.Thespecifications,torques,pressures,measurements,adjustments,illustrations,andotheritemscanchangeatanytime.

Thesechangescanaffecttheservicethatisgiventotheproduct.Obtainthecomplete,mostcurrentinformationbeforeyoustartanyjob.

Caterpillardealerscansupplythemostcurrentinformation.

Summary

Thisguidelinecontainsthespecificationsthatarenecessaryfordeterminingthereusabilityofacylinderblock.

Beforeyoureuseacylinderblockassembly,checkforleaks,forcracks,andforflatness.Allcomponentsofthecylinderblockmustmeet

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/productsearch/productheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp

4/19

6/8/2015

C15OnhighwayEngineSDP00001UP(SEBP441962)Sistemasycomponentes

therecommendedspecificationsinthisguidelinebeforebeingreused.

References

ReferenceContaminationControlGuidelines,PEBJ0002,"CaterpillarDealerContaminationControlComplianceGuide".

ReferenceSpecialInstruction,REHS2133,"CylinderBlockSalvageProcedureForUsingBELZONACERAMICR".

ReferenceSpecifications,RENR9797,"C27IndustrialEnginesandC32IndustrialandPetroleumEngines".

ReferenceSpecifications,RENR9802,"C7EngineforCaterpillarBuiltMachines".

ReferenceReuseandSalvageGuidelines,SEBF2120,"ThermalSprayProceduresforEngineCylinderBlockTopDeckSurface".

ReferenceReuseandSalvageGuidelines,SEBF8068,"InspectionandReuseGuidelineofCylinderLinersinCatEngines".

ReferenceReuseandSalvageGuidelines,SEBF9008,"ProcedureforReconditioningCylinderBlockson3400andCSeriesEngines".

ReferenceReuseandSalvageGuidelines,SEBF9213,"MeasuringtheDistancetoTopDeckofC15,C16,C18,3400,C27andC32

Engines".

ReferenceReuseandSalvageGuidelines,SEBF9238,"FundamentalsofArcSprayforReconditioningComponents".

ReferenceReuseandSalvageGuidelines,SEBF9240,"FundamentalsofFlameSprayforReconditioningComponents".

ReferenceReuseandSalvageGuidelines,SELD0458,"CylinderBlockPitting".

ReferenceSpecifications,SENR9852,"C11andC13IndustrialEngines".

ReferenceSpecifications,SENR9867,"C9EngineforCaterpillarBuiltMachines".

ReferenceSpecifications,SENR5033,"3412EandC30Engines".

ReferenceSpecifications,SENR9812,"C15OnhighwayEngine".

ReferenceSpecialInstruction,SMHS8418,"CylinderBlockCleaningProcedure".

GeneralSpecifications

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/productsearch/productheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp

5/19

6/8/2015

C15OnhighwayEngineSDP00001UP(SEBP441962)Sistemasycomponentes

MainBearingBores

Checkthesizeofthemainbearingboresbyusingthe1P3537DialBoreGaugeGroup.CheckTable2inordertomakesurethatthebore

sizeforthemainbearingsmeetsthespecifications.Thisdimensionisusedafterthecrankshaftisremovedandthebearingcapsare

assembledandtightenedaccordingtothespecificationsinthisservicemanual.

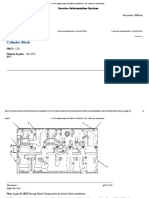

RefertoIllustration3,4,5,6,and7withTable2foridentificationofseverallocationsanddimensionsthatarefrequentlyreferencedduring

thereconditioningofacylinderblock.

FrontFace

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/productsearch/productheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp

6/19

6/8/2015

C15OnhighwayEngineSDP00001UP(SEBP441962)Sistemasycomponentes

Illustration3

g02221255

ThisisanexampleofaC7orC9CylinderBlock

RefertoTable2forspecificationsofthecylinderblock.

(A)Dimensionfromcenterlineofcrankshaftboretotopofblock

(B)CylinderLinerBoreSize

(C)Boreforfrontcamshaftbearing

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/productsearch/productheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp

7/19

6/8/2015

C15OnhighwayEngineSDP00001UP(SEBP441962)Sistemasycomponentes

(D)Widthofcylinderblockformainbearingcap

(E)Boreformainbearings

(F)Dimensionfromcenterlineofcrankshaftboretopanrail

Illustration4

g03409923

ThisisanexampleofaC10orC12CylinderBlock

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/productsearch/productheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp

8/19

6/8/2015

C15OnhighwayEngineSDP00001UP(SEBP441962)Sistemasycomponentes

(A)Dimensionfromcenterlineofcrankshaftboretotopofblock

(B)CylinderLinerBoreSize

(C)Boreforfrontcamshaftbearing

(D)Widthofmainbearingcap

(D)Widthofcylinderblockformainbearingcap

(E)Boreformainbearings

(F)Dimensionfromcenterlineofcrankshaftboretopanrail

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/productsearch/productheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp

9/19

6/8/2015

C15OnhighwayEngineSDP00001UP(SEBP441962)Sistemasycomponentes

Illustration5

g03410063

ThisisanexampleofaC11orC13CylinderBlock

(A)Dimensionfromcenterlineofcrankshaftboretotopofblock

(B)CylinderLinerBoreSize

(C)Boreforfrontcamshaftbearing

(D)Widthofmainbearingcap

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/productsearch/productheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp

10/19

6/8/2015

C15OnhighwayEngineSDP00001UP(SEBP441962)Sistemasycomponentes

(D)Widthofcylinderblockformainbearingcap

(E)Boreformainbearings

(F)Dimensionfromcenterlineofcrankshaftboretopanrail

Illustration6

g02222355

ThisisanexampleofaC15,C16,orC18CylinderBlock.

RefertoTable2forspecificationsofthecylinderblock.

(A)Dimensionfromcenterlineofcrankshaftboretotopofblock

(B)CylinderLinerBoreSize

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/productsearch/productheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp

11/19

6/8/2015

C15OnhighwayEngineSDP00001UP(SEBP441962)Sistemasycomponentes

(C)Boreforfrontcamshaftbearing(notshown)Refertothecylinderheaddocument

(D)Widthofmainbearingcap

(D)Widthofcylinderblockformainbearingcap

(E)Boreformainbearings

(F)Dimensionfromcenterlineofcrankshaftboretopanrail

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/productsearch/productheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp

12/19

6/8/2015

C15OnhighwayEngineSDP00001UP(SEBP441962)Sistemasycomponentes

Illustration7

g02219394

ThisisanexampleofaC27,C32,orC30CylinderBlock

RefertoTable2forspecificationsofthecylinderblock.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/productsearch/productheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp

13/19

6/8/2015

C15OnhighwayEngineSDP00001UP(SEBP441962)Sistemasycomponentes

(A)Dimensionfromcenterlineofcrankshaftboretotopofblock

(B)CylinderLinerBoreSize

(C)Boreforfrontcamshaftbearing

(D)Widthofmainbearingcap

(D)Widthofcylinderblockformainbearingcap

(E)Boreformainbearings

(F)Dimensionfromcenterlineofcrankshaftboretopanrail

Table2

DimensionsonFrontFaceofCylinderBlock(1)

Item

Description

C7

Dimensionfrom

centerlineofcrankshaft

boretotopofblock

322.00

0.17mm

(12.677

0.007inch)

C9/C9

C10/C

12

C11

C13

C15/C16/C

18/C18

C27/C32

C30

356.50

0.15mm

(14.035

0.006

inch)

387.00

0.15mm

(15.236

0.006

inch)

387.00

0.15mm

(15.236

0.006

inch)

387.00

0.15mm

(15.236

0.006

inch)

425.450.15

mm

(16.7500.006

inch)

419.10

0.15mm

(16.500

0.006

inch)

419.10

0.15mm

(16.500

0.006

inch)

Minimum

321.83mm

(12.670

inch)

356.35

mm

(14.029

inch)

386.85

mm

(15.230

inch)

386.85

mm

(15.230

inch)

386.85

mm

(15.230

inch)

425.02mm

(16.733inch)(2)

425.450.15

mm(16.750

0.006inch)(3)

418.80

mm

(16.488

inch)(1)

419.10

0.15mm

(16.500

0.006

inch)(2)

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/productsearch/productheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp

418.67

mm

(16.483

inch)

14/19

6/8/2015

C15OnhighwayEngineSDP00001UP(SEBP441962)Sistemasycomponentes

Cylinderboreinblock

orboreforliner

Boreforfrontcamshaft

bearing

110.025+

0.025

0.010mm

(4.3317+

0.0010

0.0004inch)

129.00

0.03mm

(5.079

0.001

inch)

151.50

0.03mm

(5.965

0.001

inch)

151.50

0.03mm

(5.965

0.001

inch)

151.50

0.03mm

(5.965

0.001

inch)

70.000

70.000

0.025

0.025mm

mm

(2.7559

(2.7559

0.0010inch)

0.0010

inch)

80.950

0.025

mm

(3.18700

0.00098

inch)

85

0.015

mm

(3.34645

0.00059

inch)

85

0.025

mm

(3.34645

0.00098

inch)

70.000

69.000

0.038

0.038mm

mm

(2.7165

(2.7559

0.0015inch)

0.0015

inch)

80.950

0.025

mm

(3.18700

0.00098

inch)

85

0.015

mm

(3.34645

0.00059

inch)

85

0.025

mm

(3.34645

0.00098

inch)

175.000

0.020

mm

(6.8898

0.0008

inch)

175.000

0.020

mm

(6.8898

0.0008

inch)

178.00

0.020

mm

(7.008

0.0008

inch)

178.00

0.020

mm

(7.008

0.0008

inch)

178

178

Boreforremaining

camshaftbearings

Widthofmainbearing

cap

159.995

0.020mm

(6.2990

0.0008inch)

160.0mm

(6.29920

inch)

158.737 158.737

158.7370.025

0.025mm 0.025mm

mm

(6.2495 (6.2495

(6.24950.0010

0.0010

0.0010

inch)

inch)

inch)

76.835

0.018mm

(3.0250

0.0007

inch)

76.835

0.018mm

(3.0250

0.0007

inch)

76.835

0.018mm

(3.0250

0.0007

inch)

76.835

0.018mm

(3.0250

0.0007

inch)

215.9

215.90.02mm 0.02mm

(8.49998

(8.49998

0.00079inch) 0.00079

inch)

215.9

0.02mm

(8.49998

0.00079

inch)

Reference

Cylinderhead

Reference

Cylinderhead

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/productsearch/productheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp

15/19

6/8/2015

C15OnhighwayEngineSDP00001UP(SEBP441962)Sistemasycomponentes

+

Widthofcylinderblock 0.018mm

formainbearingcap

(0.00071

inch)

0.023mm

(0.00091

inch)

Boreformainbearings

175.000

0.018

mm

(6.8898

0.0007

inch)

175.000

0.018

mm

(6.8898

0.0007

inch)

0.023

mm

(7.00786

0.00091

inch)

0.023

mm

(7.00786

0.00091

inch)

112.000

0.013

mm

(4.4094

0.0005

inch)

116.000

0.013

mm

(4.5669

0.0005

inch)

116.000

0.013

mm

(4.5669

0.0005

inch)

116.000

0.013

mm

(4.5669

0.0005

inch)

129.891 129.891

129.8910.013

0.013mm 0.013mm

mm

(5.1138 (5.1138

(5.11380.0005

0.0005

0.0005

inch)

inch)

inch)

95.508

0.013mm

NA

(3.7601

0.0005inch)

116.508

0.013

mm

(4.5869

0.0005

inch)

116.508

0.013

mm

(4.5869

0.0005

inch)

116.508

0.013

mm

(4.5869

0.0005

inch)

130.526 130.526

130.5260.013

0.013mm 0.013mm

mm

(5.1388 (5.1388

(5.13880.0005

0.0005

0.0005

inch)

inch)

inch)

110.00.10

mm

(4.33

0.004inch)

110.0

0.10mm

(4.33

0.004

inch)

120.00

0.20mm

(4.724

0.008

inch)

120.00

0.20mm

(4.724

0.008

inch)

120.00

0.20mm

(4.724

0.008

inch)

165.100.10

mm

(6.5000.004

inch)

165.10

0.10mm

(6.500

0.004

inch)

165.10

0.10mm

(6.500

0.004

inch)

3.2

micro

meters

125

micro

inches

3.2micro

meters

125

micro

inches

3.2micro

meters

125

micro

inches

3.2micro

meters

125

micro

inches

3.2micro

3.2micrometers meters

125microinches 125

micro

inches

3.2micro

meters

125

micro

inches

95.000

0.013mm

(3.7402

0.0005inch)

Boreforoversized

mainbearings

Dimensionfrom

centerlineofcrankshaft

boretopanrail

3.2micro

Surfacefinishofthetop meters

deck

125micro

inches

215.9

215.90.02mm 0.02mm

(8.49998

(8.49998

0.00079inch) 0.00079

inch)

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/productsearch/productheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp

215.9

0.02mm

(8.49998

0.00079

inch)

16/19

6/8/2015

C15OnhighwayEngineSDP00001UP(SEBP441962)Sistemasycomponentes

(1)

SpecificationsandtolerancesintheabovetablearefororiginalpartnumbersonlyanddonotapplytoRemanpartnumbers.

(2)

ForNONbrakeenginesonly.

(3)

ForCatBrakeenginesonly.

TighteningProcedureforMainBearingCapBolts

Installthebearingcapsinthecorrectorderofsequence.Thebearingcapsneedtobetightenedfromthefronttotherear.Checkthe

Identifyingmarksonthecapsandtheblockbeforetightening.

1. Lubricatetheboltthreadsandthewasherfacewith2P2506ThreadLubricant.

2. Tightentheboltsinaccordancewiththepropertorquespecifications.Refertotheappropriatespecificationsmanualforthetorque

specifications.

ReconditioningtheCylinderBlock

MeasurementofCylinderBlockTopDeck

Itisimportanttoknowifthedeckofthecylinderblockhaseverbeenmachined.Use6V7840DeckCheckingToolAstoaccurately

determinetheheightofthecylinderblock.Thetwomainbearingboresthatcontactthelowerbarmustbethesamesize.Specialcalculations

mustalsobemadeiftheseboreshavebeenmachinedforoversizedbearings.Formoreinformation,refertoSpecialInstruction,SEHS8187,

"Usingthe6V7840DeckCheckingToolAs".Also,refertoReuseandSalvageGuidelines,SEBF9213,"MeasuringtheDistancetothe

TopDeckofC15,C15,C16,C18,3400,C27,andC32Engines"

CylinderLinerProjection

RefertotheappropriateDisassemblyandAssemblymanualformoreinformationonestablishinglinerprojection.

RemovalofMaterial

Itiscriticaltomaintainthecompressionratiowhenthecylinderblockisreconditioned.Theratioisincreasedasmaterialisremovedfrom

thetopdeckofthecylinderblock.

Removetheminimumamountofmaterialwhenthetopdeckofthecylinderblockismachinedinordertoeliminatedamage.RefertoTable

2forreconditioningspecifications.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/productsearch/productheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp

17/19

6/8/2015

C15OnhighwayEngineSDP00001UP(SEBP441962)Sistemasycomponentes

RepairingtheTopDeckoftheCylinderBlockwithThermalSpray

Thermalspraycanbeusedtorestorethecontactsurfacestotheoriginaldimensions.AnacceptableprocessistheMETCO6PII

ThermospraySystem.Formoreinformation,refertothethermalspraydocumentsinthe""References""section.

Flatness

Theflatnessofthetopdeckmustbeheldfortheentiresurface.Therecanbenomorethan0.05mm(0.002inch)overany150.00mm

(6.000inch)span.

Note:The0.05mm(0.002inch)toleranceforflatnesscannotbeincreasedbyincreasingthe150.00mm(6.000inch)length.RefertoTable

2forspecifications.

SurfaceFinish

Themaximumsurfacefinishfortheentiretopdeckis3.2micrometers(125.00microinches).

Inspectthesurfaceofthetopdeckforanysignsofdamage.Thesurfacemustbefreeofnicks,gouges,oranydamagethatcouldcause

incorrectseatingofthelinerorincorrectsealingofthegasket.RefertoTable2forspecifications.

RepairDamagetotheBlock

Threemethodsofcastingrepairareavailable.Therearespecificapplicationsforeachmethod.onlyselectthemethodthatwasapprovedfor

therepairthatisneeded.Carefullyfollowtheguidelinesforeachrepairmethod.

Note:TheblockshouldalwaysbethoroughlycleanedfollowingLochNStichandCastIronWelding.

LockNStitch

HolesintheblockthatarecausedbyfailureofasinglerodorcracksinacastingmayberepairedusingLockNStitchrepairkits.These

repairkitsareavailablefromCaterpillar.Theserepairsshouldonlybemadeinareasthatarenotstructural.Permanentsealedrepairscanbe

achievedbyutilizingthismethod.Instructionsforusecanbefoundinthefollowingguideline:ReuseandSalvageGuidelines,SEBF8882,

"UsingLockNStitchProceduresforCastingRepair".

CastIronWelding

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/productsearch/productheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp

18/19

6/8/2015

C15OnhighwayEngineSDP00001UP(SEBP441962)Sistemasycomponentes

AnewprocedureforcoldweldingthatwasdevelopedbyCaterpillarpermitsrepairbyweldingofCaterpillarcastings.Specialweldingrods

withahighcontentofnickelalloyarerequiredforasuccessfulrepair.TheseweldingrodsareavailablethroughCaterpillar.Instructionsand

partnumberstheelectrodesforweldingcracksandholesintheblockthatarenotstructuralissuesaregiveninSpecialInstruction,

SEHS8919,"SalvageWeldProcedureforCastIronCylinderBlocks".

BelzonaCeramicRMetal

Thismaterialisatwoelementpolymerwhichcanbeusedtorepairporosityorpittinginablock.Thiscompositeshouldonlybeusedin

theseapplicationsbecauseofthelowstrengthofthematerial.InstructionsforthismaterialcanbefoundinSpecialInstruction,SEHS8869,

"CylinderBlockSalvageProcedureUsingBelzonaCeramicRMetal".

RepairstotheblockwithBelzonaproductsshouldnotbeplacedincontactwithstrongcausticchemicalsatelevatedtemperatures.

Copyright19932015CaterpillarInc.

Todoslosderechosreservados.

RedprivadaparalicenciadosdelSIS.

ThuAug06201510:20:53GMT0500(Horaest.Pacfico,Sudamrica)

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/productsearch/productheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp

r080thm6

19/19

Potrebbero piacerti anche

- Diesel Generator Set QSX15 Series Engine: Power GenerationDocumento4 pagineDiesel Generator Set QSX15 Series Engine: Power GenerationsdasdNessuna valutazione finora

- PartsBook - DT25c (89 99) DT30c (88 97)Documento65 paginePartsBook - DT25c (89 99) DT30c (88 97)JOSE EMILIO VAZQUEZ GONZALEZNessuna valutazione finora

- CT120 6986522 enUS Om 04-10Documento214 pagineCT120 6986522 enUS Om 04-10Henry HuayhuaNessuna valutazione finora

- Toyota 3fDocumento3 pagineToyota 3fJuan RamosNessuna valutazione finora

- Camshaft Gear - Remove and InstallDocumento4 pagineCamshaft Gear - Remove and InstallAndy PircaNessuna valutazione finora

- 2007 250SXFDocumento43 pagine2007 250SXFMartin ValderramaNessuna valutazione finora

- Effect of Performance and Emissions On DI Diesel Engine Using Ethanol Diesel BlendsDocumento9 pagineEffect of Performance and Emissions On DI Diesel Engine Using Ethanol Diesel BlendsNgocTinhPhamNessuna valutazione finora

- 06 Aeraid Flywheel ManualDocumento108 pagine06 Aeraid Flywheel ManualBen HammonNessuna valutazione finora

- R065E2Documento7 pagineR065E2Mk MakyNessuna valutazione finora

- Fuel Filters For Stanadyne Fuel SystemsDocumento4 pagineFuel Filters For Stanadyne Fuel SystemsAli Tavakoli NiaNessuna valutazione finora

- Caterpillar Engine Service Manual CT S Eng d353Documento7 pagineCaterpillar Engine Service Manual CT S Eng d353CarlosNessuna valutazione finora

- Lucas Fault Diagnosis Service ManualDocumento48 pagineLucas Fault Diagnosis Service ManualStephen RöhmNessuna valutazione finora

- GreenMech - User Manual - ChipMaster 220 Manual EnglishDocumento74 pagineGreenMech - User Manual - ChipMaster 220 Manual EnglishMihai PopaNessuna valutazione finora

- SM-800.40 FlexAirValve PDFDocumento31 pagineSM-800.40 FlexAirValve PDFJIM CAMPBELLNessuna valutazione finora

- Minor Sweeping Machines: Technical Operating and Basic Maintenance InstructionsDocumento46 pagineMinor Sweeping Machines: Technical Operating and Basic Maintenance InstructionsBogdan NgrNessuna valutazione finora

- PDF Ade 364 Ade366 Workshop Manual Abbypdf CompressDocumento220 paginePDF Ade 364 Ade366 Workshop Manual Abbypdf CompressANTONIO CRUZNessuna valutazione finora

- Axilok InstallatTuercasDocumento1 paginaAxilok InstallatTuercasalxsscabal100% (1)

- Fuel Lift Pump Remote Mounting Kit RevisionDocumento2 pagineFuel Lift Pump Remote Mounting Kit RevisionMike PerryNessuna valutazione finora

- Diesel Pump and TimingDocumento60 pagineDiesel Pump and TimingMickye Mickyedj100% (3)

- BT-50 en OrganizedDocumento40 pagineBT-50 en OrganizedPao RodNessuna valutazione finora

- Air Compressor PDS 100S PDFDocumento65 pagineAir Compressor PDS 100S PDFTomy Efraim SitumorangNessuna valutazione finora

- Ref Pecas IvecoDocumento7 pagineRef Pecas IvecoPaulo SoaresNessuna valutazione finora

- Bobcat Online Parts CatalogueDocumento74 pagineBobcat Online Parts CatalogueHervé ChédruNessuna valutazione finora

- Yfm350s Yfm350s Yfm350s Yfm350s Yfm350: (5yt1) (5yt2) (5yt3) (5yt1) (5yt1)Documento75 pagineYfm350s Yfm350s Yfm350s Yfm350s Yfm350: (5yt1) (5yt2) (5yt3) (5yt1) (5yt1)David Castro GasteluNessuna valutazione finora

- RepairManual NEF M100 M150 P3D32N003E Mar06Documento172 pagineRepairManual NEF M100 M150 P3D32N003E Mar06manuel segovia100% (1)

- Honda Goldwing gl1100 1980 To 1982 Honda Parts Manual PDFDocumento195 pagineHonda Goldwing gl1100 1980 To 1982 Honda Parts Manual PDFnuno araujoNessuna valutazione finora

- Cylinder Liner ProjectionDocumento4 pagineCylinder Liner ProjectionFernando Daniel Saez VillarrealNessuna valutazione finora

- Nanni 5.25 Base EngineDocumento211 pagineNanni 5.25 Base EnginecarylangleyNessuna valutazione finora

- Improved Nozzles and Lines For New Scroll Fuel Systems (NSFS)Documento11 pagineImproved Nozzles and Lines For New Scroll Fuel Systems (NSFS)betoven8437Nessuna valutazione finora

- Eparts MBE 900 4000 Reference Card PDFDocumento21 pagineEparts MBE 900 4000 Reference Card PDFAmilcar RodasNessuna valutazione finora

- 2004 Polaris Parts ManualDocumento67 pagine2004 Polaris Parts ManualAngela TullochNessuna valutazione finora

- Kohler Quick Reference GuideDocumento41 pagineKohler Quick Reference GuideJohn Jones IIINessuna valutazione finora

- Powerhouse: PH3100RI Digital Inverter Generator Shop ManualDocumento69 paginePowerhouse: PH3100RI Digital Inverter Generator Shop ManualRene Bourgoin100% (1)

- Nissan CD17Documento3 pagineNissan CD17jose luis calixto requisNessuna valutazione finora

- Operation and Installation ManualDocumento105 pagineOperation and Installation ManualNAVEDTRA12204Nessuna valutazione finora

- SB373AR2Documento8 pagineSB373AR2GiovaniBalzaniNessuna valutazione finora

- Safety Recall H03 Front Control Module: Dealer Service Instructions ForDocumento9 pagineSafety Recall H03 Front Control Module: Dealer Service Instructions ForobazmssamiNessuna valutazione finora

- Introduction of V-MAC® Dealer Programming SoftwareDocumento17 pagineIntroduction of V-MAC® Dealer Programming SoftwareHamilton MirandaNessuna valutazione finora

- Owners Handbook BUKH U125Documento79 pagineOwners Handbook BUKH U125Alexandros KontosNessuna valutazione finora

- Specifications: 800D Industrial EngineDocumento28 pagineSpecifications: 800D Industrial EngineJacques Van NiekerkNessuna valutazione finora

- AC Machine ManualDocumento25 pagineAC Machine ManualmainesquirrelNessuna valutazione finora

- 1973 AMC Technical Service ManualDocumento21 pagine1973 AMC Technical Service Manualfernan blancoNessuna valutazione finora

- 2012 Fisker Karma Owner HandbookDocumento152 pagine2012 Fisker Karma Owner HandbookRitesh PatelNessuna valutazione finora

- Wastegate Turbocharger Operation DiagnosticDocumento6 pagineWastegate Turbocharger Operation DiagnosticHamilton MirandaNessuna valutazione finora

- Combatting Heavy Equipment TheftDocumento36 pagineCombatting Heavy Equipment TheftLU YONessuna valutazione finora

- Fuller Transmissions TRTS0920: Troubleshooting GuideDocumento206 pagineFuller Transmissions TRTS0920: Troubleshooting GuideJhon Mamani100% (1)

- Manual Honda Gx270 Gx340 Gx390Documento96 pagineManual Honda Gx270 Gx340 Gx390PriourNessuna valutazione finora

- Diesel Fuel Injection Pump Disassemble Retainer Tools For SaleDocumento3 pagineDiesel Fuel Injection Pump Disassemble Retainer Tools For SaleChrisNessuna valutazione finora

- 1.8l ENGINEDocumento304 pagine1.8l ENGINEjoao xavierNessuna valutazione finora

- VorlandiDocumento24 pagineVorlandiKieran RyanNessuna valutazione finora

- Kubota B6100EDocumento128 pagineKubota B6100EPatty Elmore-DrakeNessuna valutazione finora

- Uenr0996 03 00 - Manuals Service Modules - SpecificationsDocumento586 pagineUenr0996 03 00 - Manuals Service Modules - Specificationsmostafa aliNessuna valutazione finora

- Installation Procedure: EVC-E Volvo Penta IPS Triple: Typical Installation / Main StationDocumento2 pagineInstallation Procedure: EVC-E Volvo Penta IPS Triple: Typical Installation / Main StationMehdi Ben AbdelkaderNessuna valutazione finora

- Catalogo Wix PesadoDocumento56 pagineCatalogo Wix PesadoSeveriano Gustavo Gutierrez MontesNessuna valutazione finora

- 3024C Crankshaft - InstallDocumento2 pagine3024C Crankshaft - Installmiguel_catNessuna valutazione finora

- 2010 Kawasaki kx450f ManualDocumento170 pagine2010 Kawasaki kx450f ManualDalllin HolltNessuna valutazione finora

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Da EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Valutazione: 5 su 5 stelle5/5 (1)

- DML 7611 TantahuatayDocumento12 pagineDML 7611 TantahuatayFJ OscarNessuna valutazione finora

- SEBF8049 - Visual Inspection of The Piston (1214, 1214) PDFDocumento92 pagineSEBF8049 - Visual Inspection of The Piston (1214, 1214) PDFFJ OscarNessuna valutazione finora

- SEBF8054 - Procedure To Measure and To Straighten Bent Crankshafts (0760, 1202) PDFDocumento33 pagineSEBF8054 - Procedure To Measure and To Straighten Bent Crankshafts (0760, 1202) PDFFJ OscarNessuna valutazione finora

- DML - 7611-Tantahuatay PDFDocumento622 pagineDML - 7611-Tantahuatay PDFFJ Oscar100% (1)

- Desinstalacion Del Cover Delantero-C15 PDFDocumento3 pagineDesinstalacion Del Cover Delantero-C15 PDFFJ OscarNessuna valutazione finora

- Housing de Volante-C15 PDFDocumento4 pagineHousing de Volante-C15 PDFFJ Oscar0% (1)

- Housing de La Parte Delantera Del Motor-C15 PDFDocumento4 pagineHousing de La Parte Delantera Del Motor-C15 PDFFJ Oscar0% (1)

- Arbol de Levas General - Especificaciones c15 PDFDocumento31 pagineArbol de Levas General - Especificaciones c15 PDFFJ OscarNessuna valutazione finora

- Cigueñal - Especificaciones c15 PDFDocumento3 pagineCigueñal - Especificaciones c15 PDFFJ OscarNessuna valutazione finora

- Bolque de Cilindros - Especificaciones c15 PDFDocumento8 pagineBolque de Cilindros - Especificaciones c15 PDFFJ OscarNessuna valutazione finora

- Polea y Damper-C15 PDFDocumento4 paginePolea y Damper-C15 PDFFJ OscarNessuna valutazione finora

- Arbol de Levas General - Especificaciones c15 PDFDocumento31 pagineArbol de Levas General - Especificaciones c15 PDFFJ OscarNessuna valutazione finora

- Instalacion Del Cover Delantero-C15 PDFDocumento3 pagineInstalacion Del Cover Delantero-C15 PDFFJ OscarNessuna valutazione finora

- Desinstalacion Del Cover Delantero-C15 PDFDocumento3 pagineDesinstalacion Del Cover Delantero-C15 PDFFJ OscarNessuna valutazione finora

- Housing de Volante-C15 PDFDocumento10 pagineHousing de Volante-C15 PDFFJ OscarNessuna valutazione finora

- Manual Del Estudiante - D7R 2 PDFDocumento106 pagineManual Del Estudiante - D7R 2 PDFFJ Oscar75% (4)

- Tablas de Desgaste Enero 2010 PDFDocumento2.403 pagineTablas de Desgaste Enero 2010 PDFAstaroth_1810Nessuna valutazione finora

- Operation & Maintenance Manual For DPIS-1-HED (SN 202839) PDFDocumento257 pagineOperation & Maintenance Manual For DPIS-1-HED (SN 202839) PDFFJ OscarNessuna valutazione finora

- Reading Task CardsDocumento2 pagineReading Task CardscatnappleNessuna valutazione finora

- TX Open RS232 - 485 Module (TXI2.OPEN)Documento8 pagineTX Open RS232 - 485 Module (TXI2.OPEN)harishupretiNessuna valutazione finora

- Summative-Test-3-5 Tve ExploratoryDocumento3 pagineSummative-Test-3-5 Tve ExploratoryMjnicole MartejaNessuna valutazione finora

- Chapter 9 Audit SamplingDocumento47 pagineChapter 9 Audit SamplingYenelyn Apistar CambarijanNessuna valutazione finora

- Keywords: Communication, Technology, Collaborative, Evaluative Learning, InnovativeDocumento11 pagineKeywords: Communication, Technology, Collaborative, Evaluative Learning, InnovativeNnamani EmmanuelNessuna valutazione finora

- FC2060Documento10 pagineFC2060esnNessuna valutazione finora

- Agile Marketing Reference CardDocumento2 pagineAgile Marketing Reference CardDavid BriggsNessuna valutazione finora

- Competing Models of Entrepreneurial IntentionsDocumento22 pagineCompeting Models of Entrepreneurial IntentionsAsri Aneuk HimabisNessuna valutazione finora

- Curriculum Vitae H R VijayDocumento8 pagineCurriculum Vitae H R VijayvijaygowdabdvtNessuna valutazione finora

- EC312 Object Oriented ProgrammingDocumento3 pagineEC312 Object Oriented ProgrammingJazir HameedNessuna valutazione finora

- SHPXXX 20 IS XX 13Documento240 pagineSHPXXX 20 IS XX 13Geyciane PinheiroNessuna valutazione finora

- Multiage Education in Small School SettingsDocumento19 pagineMultiage Education in Small School SettingsMichelle Ronksley-PaviaNessuna valutazione finora

- Nxivm: 2nd Superseding IndictmentDocumento32 pagineNxivm: 2nd Superseding IndictmentTony Ortega100% (2)

- Finman General Assurance Corporation Vs - The Honorable Court of AppealsDocumento2 pagineFinman General Assurance Corporation Vs - The Honorable Court of AppealsNorie De los ReyesNessuna valutazione finora

- Case Chart Complete (Business Law)Documento29 pagineCase Chart Complete (Business Law)LimShuLingNessuna valutazione finora

- CDCS Self-Study Guide 2011Documento21 pagineCDCS Self-Study Guide 2011armamut100% (2)

- BGD Country en Excel v2Documento2.681 pagineBGD Country en Excel v2Taskin SadmanNessuna valutazione finora

- 7MWTW1710YM0Documento8 pagine7MWTW1710YM0Izack-Dy JimZitNessuna valutazione finora

- Statement 1577731252322 PDFDocumento11 pagineStatement 1577731252322 PDFPriyanka ParidaNessuna valutazione finora

- Supply DemandProblems With Solutions, Part 1Documento16 pagineSupply DemandProblems With Solutions, Part 1deviNessuna valutazione finora

- CH 3 Revision Worksheet 2 Class 6 CSDocumento1 paginaCH 3 Revision Worksheet 2 Class 6 CSShreyank SinghNessuna valutazione finora

- Sahara International Petrochemical Company (SIPCHEM)Documento2 pagineSahara International Petrochemical Company (SIPCHEM)shahbaz1979Nessuna valutazione finora

- E14r50p01 800 MhaDocumento4 pagineE14r50p01 800 Mha'Theodora GeorgianaNessuna valutazione finora

- Power Dense and Robust Traction Power Inverter For The Second Generation Chevrolet Volt Extended Range EDocumento8 paginePower Dense and Robust Traction Power Inverter For The Second Generation Chevrolet Volt Extended Range Ejrz000Nessuna valutazione finora

- Sparse ArrayDocumento2 pagineSparse ArrayzulkoNessuna valutazione finora

- Bali Hai LawsuitDocumento14 pagineBali Hai LawsuitLas Vegas Review-JournalNessuna valutazione finora

- South West Mining LTD - Combined CFO & HWA - VerDocumento8 pagineSouth West Mining LTD - Combined CFO & HWA - Verapi-3809359Nessuna valutazione finora

- AFAR Problems PrelimDocumento11 pagineAFAR Problems PrelimLian Garl100% (8)

- Suggested Answers Spring 2015 Examinations 1 of 8: Strategic Management Accounting - Semester-6Documento8 pagineSuggested Answers Spring 2015 Examinations 1 of 8: Strategic Management Accounting - Semester-6Abdul BasitNessuna valutazione finora

- Quality ManualDocumento34 pagineQuality Manualchao gao100% (9)