Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sloting Machine

Caricato da

Patel NikhilCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sloting Machine

Caricato da

Patel NikhilCopyright:

Formati disponibili

1.

INTRODUCTION

Highly industrial cities are mainly established with

the entrepreneurship of local peoples, apart from

public sector undertaking. Small-scale production

units are often equipped with either one or the other

general-purpose machine tools, but they find

it difficult to have different machining machines for

various machining operations. This is because it may

require more space, with high expenses. For

instance, there are a number of tools producing

round and taper holes. But many components in

engineering require square or rectangular holes.

At present,

square and rectangular holes are produced using

CNC

P. Mayilsamy, P. Sabitha Rani

machines[4] or spark erosion[1] or slotting

machines[7], but a quality machine tool to produce

square and polygon holes at minimum cost are not

available. This project is an attempt to design and

fabricate an attachment for drilling machine

which would produce square and polygon holes

much more easily than the current methods. This

project is actually designed to fit in an existing

drilling machine, an attachment which can be used

for making slots or square holes in components of

small scale production units. This attachment can

be attached to either a drilling machine or vertical

milling machine. Similar designs can be made for

any size and any number of

IJRIET | March 2015, Available @ http://www.ijriet.com

_Page:17

sides to avoid lot of setting time and pre-machining

procedures involved in current methods and very

useful in case of mass production.

provides a very substantial and rugged design

which is adapted to provide a wide range of

speeds. It is suitable for

2. PREVIOUS WORKS

2.1

Multi

machine

process

The history of antimatter begins in 1928 with a

young

This machine (designed by R.Maguteeswaran et al.,

2014) [3] can perform three operations - drilling,

slotting and shaping, in a single machine. This

concept reduces the work time and save the cost of

machining. Here, instead of using a slotting machine

and a shaping machine, special arrangements are

made in the drilling machine for slotting operation

and shaping operation to be carried out. By using this

machine, the investment cost for slotting and shaping

machines in the industries can be minimized.

The multi process, machine can be operated by

attaching the drilling machine with the bevel gear

and cam mechanism arrangements. The bevel gear is

used for perpendicular power transmission from the

motor by connecting to the drill chuck, to the shaft

which is connected to a cam arrangement on the

other side. The cam arrangement converts rotary

motion

into reciprocating motion and the

reciprocating motion is used for the slotting and

shaping operation. The slotting tool and shaping tool

are guided by a horizontal guide bush. The work

table is mounted on a hydraulic bottle jack piston

rod hence when the bottle jack handle is pumped

the table height can be adjusted according to the

requirement when the after the process is completed

the pressure should be released through the

pressure relief valve to make the table come down.

The table is mounted with a vice to hold the work

piece.

2.2 Drill Slotter

A drill slotter,(Ernest J.Allen,1919) [2] is an

invention, which gives an inexpensive attachment

for a drilling machine whereby simple slotting or

other similar operations may be performed thus

obviating the necessity of having an entirely separate

and expensive machine for this purpose. It

P. Mayilsamy, P. Sabitha Rani

IJRIET | March 2015, Available @ http://www.ijriet.com

Page:18

various types of work, and can be manufactured and

sold at a very small price than ordinarily charged for

the actual machines used for the same work. It is

claimed to be so light in weight such that it can be

readily lifted on to or off the drill table. It can also be

secured in place or detached in a very few minutes.

The device can be used to make all kinds of jobs that

are ordinarily done by a large slotting machine.

3. SLOTTING ATTACHMENT

A slotting attachment is one that can take up small

slotting jobs by attaching itself to a drilling machine.

The main features of this attachment are:

It can be readily fixed onto an already existing

drilling machine.

It can be easily fixed on to and removed from the

drilling machine.

It is very economical when compared to the

other means of slotting.

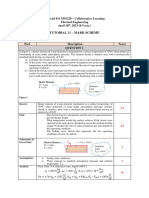

3.1 Design

The basic requirements of a small scale industry in

order to use this slotting attachment are:

A pillar drilling machine [6] usually called pillar

drills, which are similar to table top drilling

machines, but larger in size and higher capacity.

Here, the drill-feed and the work table movement are

done manually. Figure 1typically shows a pillar drill.

P. Mayilsamy, P. Sabitha Rani

IJRIET | March 2015, Available @ http://www.ijriet.com

Page:19

Figure: 2 Gear pairs

Figure: 1 Pillar Drill

Dividing table, a precision work positioning

device which enables the operator to drill or cut

work at exact intervals around a fixed axis and

enable regular work positioning at divisions for

which indexing plates are not necessary.

The main components used in the design of the

attachment constitute of a worm gear [1] which is

attached to the main shaft that rotates with the drill

spindle, which is in turn attached to a socket that is

chucked with the drill spindle. This worm gear is

paired with a spur gear which is locked with a

horizontal shaft. Thus the horizontal crank shaft

rotates, as the gear pair gets into motion when

the drill spindle rotates. Figure 2 illustrates the

gear pairs.

At one end of the crank shaft a connecting strip is

attached eccentrically, which is connected to a tool

holder at the other end. The tool holder moves

through a definite path that is defined for it, and

attached to the frame. The tool holder holds the

single point tool at its bottom end, as shown in Figure

3.The whole mechanism is placed inside a frame,

which is rigid enough to support the whole assembly,

and has provision for fixing the attachment in on the

work table of the drilling machine.

Since there are 18 teeth on the spur gear, for the

crank shaft to complete one revolution, the drill

spindle has to rotate 18 times. For every one

revolution of the crank shaft, the tool completes one

stroke vertically. Thus the cutting velocity of the

slotting tool is reduced to about 18 times from the

rotating speed of the spindle. For example, if the

required cutting speed of the slotting tool is

50strokes/min, then the drill spindle has to be set to

about 900rpm. The length of stroke of the cutting tool

depends upon the radius of eccentricity that connects

the connecting strip to the crank shaft i.e., when the

eccentric radius on crank is r, then the stroke length

of the cutting tool is 2r.

Figure: 3 The attachment

3.2 Main features

The main features of this attachment are

that:

It consists of very simple parts for transmitting

the motion of the drill spindle to the slotting tool,

thus reducing the complex nature of the attachment.

Unlike the multi process machine and the drill

slotter mentioned above, this design avoids the bevel

gears which decreases the complexity of the design.

This also reduces slippage of the mating gears.

The cost of this product is very low when

compared to any other means of producing square

holes or slots

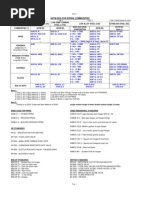

The fabricated slotter attachment in working

condition at a small scale industry where a drilling

machine is available is shown in Figure 4.

Figure: 4 The slotting attachment in

working condition

4. CONCLUSION

This article gives a good solution to the small scale

industries that cannot afford a separate slotting

machine, and have in possession a drilling machine,

and may require doing certain slotting operations.

This unit eliminates the presence of slotting machine

in machine shop. The variation of the speed of

the slotting tool from that of the drill spindle makes

this product a feasible one for carrying out

machining operations on materials which require

utmost care while fabricating.

An extension of this design gives an option for

carrying out slotting operations by varying the stroke

length. This can be done by giving a lengthy slotted

hole or a series of holes in the disc of the crank shaft

instead of the hole for locking the connecting strip.

This design varies the stroke length according to the

necessity of the job, since the stroke length depends

upon the radius of the crank. The design of the

slotting attachment described in this work is simple,

portable type, low cost than the other machines

available in the market. The operating principle of

this machine is very simple, thus making this project

a successful one.

References

[1] Dr. Manfred Storr, Important facts about

spark erosion, Oelheld, innovative fluid

technology, HUTEC, 2007.

[2]

Ernest J. Allen, Drill Slotter,

Specification of Letters Patent, 1919.

[3] R.Maguteeswaran,

Fabrication of

The International

Aeronautical and

pp.

105-111, 2014.

M.Dineshkumar, et al

Multi Process Machine

Journal of Research in

Mechanical Engineering.

[4] Thomas

Schaller,

Klaus

Schubert,

Micromachining by CNC Slotting using a

Steered Tool.

[5] Thomas

Schaller,

Klaus

Schubert,

Micromachining by CNC Slotting using a

Steered Tool

[6] V B Bhandari, Design of Machine Elements,

Third Edition, 2013, pg. 730-745.

[7] Version 2 ME, IIT Kharagpur, Lesson 18:

Kinematic system and operations of drilling

machines, General Purpose Machine Tools.

[8] Version 2 ME, IIT Kharagpur, Lesson 20:

Construction,

working

principle

and

applications of shaping, planning and slotting

machines., General Purpose Machine Tools.

[9] Wen-Hsiang Hsieh and Chia-Heng Tsai, A

Study On A Novel Quick Return Mechanism,

2009.

A Brief Author Biography

P. Mayilsamy M.E., Assistant Professor,

Mechanical

Engineering

Department,

Shree

Venkateshwara Hi-Tech Engineering College, Erode.

P. Sabitha Rani ME Manufacturing Engineering,

PG Scholar at Shree Venkateshwara Hi-Tech

Engineering College, Erode.

Potrebbero piacerti anche

- NIKHIL PATEL - Application EngineerDocumento3 pagineNIKHIL PATEL - Application EngineerPatel NikhilNessuna valutazione finora

- 41Documento5 pagine41gowtham priyaNessuna valutazione finora

- Intel® System Identification UtilityDocumento2 pagineIntel® System Identification UtilityPatel NikhilNessuna valutazione finora

- Covering Letter: To, The H.R. Manager Sub: Application For The Post of Mechanical Design EngineerDocumento1 paginaCovering Letter: To, The H.R. Manager Sub: Application For The Post of Mechanical Design EngineerPatel NikhilNessuna valutazione finora

- Poly Works Beginners GuideDocumento121 paginePoly Works Beginners GuideMałgorzata Butkiewicz100% (1)

- New Text DocumentDocumento1 paginaNew Text DocumentPatel NikhilNessuna valutazione finora

- 41Documento5 pagine41gowtham priyaNessuna valutazione finora

- Sample Resignation LetterDocumento1 paginaSample Resignation LetterSivaneshen JeevakrishnanNessuna valutazione finora

- Mechanical Interview QuestionsDocumento6 pagineMechanical Interview QuestionsVerma AbhiNessuna valutazione finora

- User Guide: Default Shortcut KeysDocumento3 pagineUser Guide: Default Shortcut KeysPatel NikhilNessuna valutazione finora

- GeomagicDesignX ReleaseNotes v2016.2.0Documento12 pagineGeomagicDesignX ReleaseNotes v2016.2.0Patel NikhilNessuna valutazione finora

- Advt No 32 2016 17 SyllabusDocumento5 pagineAdvt No 32 2016 17 SyllabusAshish DabhiNessuna valutazione finora

- Cad Cam Cae: Autocad TrainingDocumento2 pagineCad Cam Cae: Autocad TrainingPatel NikhilNessuna valutazione finora

- Age Calculation CalculatorDocumento1 paginaAge Calculation CalculatorPatel NikhilNessuna valutazione finora

- Dme 1Documento2 pagineDme 1Patel NikhilNessuna valutazione finora

- Sloting MachineDocumento5 pagineSloting MachinePatel NikhilNessuna valutazione finora

- Detain ListDocumento1 paginaDetain ListPatel NikhilNessuna valutazione finora

- Bharti y Band HaranDocumento53 pagineBharti y Band HaranpankajdumadiyaNessuna valutazione finora

- Pneumatic Punching MachineDocumento26 paginePneumatic Punching MachinePatel NikhilNessuna valutazione finora

- Bharti y Band HaranDocumento53 pagineBharti y Band HaranpankajdumadiyaNessuna valutazione finora

- Press MachineDocumento34 paginePress MachinePatel Nikhil100% (1)

- Steam TurbineDocumento20 pagineSteam TurbinePatel NikhilNessuna valutazione finora

- Slot IngDocumento1 paginaSlot IngPatel NikhilNessuna valutazione finora

- Solar Energy ProjectDocumento86 pagineSolar Energy ProjectLaksh RajNessuna valutazione finora

- AbstractDocumento1 paginaAbstractPatel NikhilNessuna valutazione finora

- Pneumatic Slotting MachineDocumento4 paginePneumatic Slotting MachinePatel NikhilNessuna valutazione finora

- Design of Automatic Pneumatic Hole Punching Machine: International Research Journal of Engineering and Technology (IRJET)Documento6 pagineDesign of Automatic Pneumatic Hole Punching Machine: International Research Journal of Engineering and Technology (IRJET)Patel NikhilNessuna valutazione finora

- Mechanical Interview QuestionsDocumento6 pagineMechanical Interview QuestionsVerma AbhiNessuna valutazione finora

- Pneumatic Punching Machine DesignDocumento3 paginePneumatic Punching Machine DesignAmrinder SinghNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Experiment: Major Loss in Pipe: ObjectiveDocumento14 pagineExperiment: Major Loss in Pipe: Objectivetesfa negaNessuna valutazione finora

- Siemens SPPA P3000Documento2 pagineSiemens SPPA P3000shahin_bNessuna valutazione finora

- NUST Machine Design Lecture on Stress, Strength and UncertaintyDocumento19 pagineNUST Machine Design Lecture on Stress, Strength and UncertaintyMuhammad Zun Nooren BangashNessuna valutazione finora

- V. Jovicic and M. R. Coop1997 - Stiffness, Coarse Grained Soils, Small StrainsDocumento17 pagineV. Jovicic and M. R. Coop1997 - Stiffness, Coarse Grained Soils, Small StrainsxiangyugeotechNessuna valutazione finora

- Eclate 719520-51100 2tne68-ErDocumento10 pagineEclate 719520-51100 2tne68-ErTheo HuqueleuxNessuna valutazione finora

- Solved Problems in PsychrometryDocumento86 pagineSolved Problems in Psychrometrylakshminarayanan67% (9)

- Ball Screw SKFDocumento53 pagineBall Screw SKFRandima Gajanayaka0% (1)

- Power Systems For The 21st Century - H Gas Turbine Combined Cycles GER3935bDocumento22 paginePower Systems For The 21st Century - H Gas Turbine Combined Cycles GER3935bLTE002Nessuna valutazione finora

- ENSC-283 Assignment #8Documento5 pagineENSC-283 Assignment #8AishwaryShuklaNessuna valutazione finora

- ColumnsDocumento66 pagineColumnsArchana GSNessuna valutazione finora

- Instructions for Oil Accessory Kit InstallationDocumento7 pagineInstructions for Oil Accessory Kit InstallationOnofreNessuna valutazione finora

- Evapco Evaporative Condenser Engineering Manual 1 1 PDFDocumento32 pagineEvapco Evaporative Condenser Engineering Manual 1 1 PDFImpulsora DemaNessuna valutazione finora

- Tilt-Up Concrete Structures: (Reapproved 1997, 2003)Documento46 pagineTilt-Up Concrete Structures: (Reapproved 1997, 2003)Nazar BazaraaNessuna valutazione finora

- Tutorial 11 - MS3220 Rekayasa Termal (Mark Scheme)Documento6 pagineTutorial 11 - MS3220 Rekayasa Termal (Mark Scheme)i need documentsNessuna valutazione finora

- Grade Markings For Steel Bolts and ScrewsDocumento3 pagineGrade Markings For Steel Bolts and Screwsrexie2canos8964Nessuna valutazione finora

- NPTEL Fluid Mechanics MCQDocumento14 pagineNPTEL Fluid Mechanics MCQVijayan SnNessuna valutazione finora

- Astm Nos For PipingDocumento6 pagineAstm Nos For PipingJessica HerringNessuna valutazione finora

- Modelling and Field-Oriented Control of A Synchronous ReluctanceDocumento215 pagineModelling and Field-Oriented Control of A Synchronous ReluctanceSneha ShendgeNessuna valutazione finora

- Caja Transfer MTC - SpecDocumento2 pagineCaja Transfer MTC - SpecDanny M Hurtado TaypeNessuna valutazione finora

- Datasheet Downhole-Fluid-Sampler en ScreenDocumento8 pagineDatasheet Downhole-Fluid-Sampler en ScreenArash PourshoushtarNessuna valutazione finora

- YDG2700 / 3700E: Parts CatalogDocumento34 pagineYDG2700 / 3700E: Parts CatalogvivsencoNessuna valutazione finora

- Mesurement and Inspection SheetDocumento3 pagineMesurement and Inspection SheetSaifur RahmanNessuna valutazione finora

- Hdpe Pipe Price List 2017Documento2 pagineHdpe Pipe Price List 2017sukiraj100% (2)

- LBSC Steam CraneDocumento7 pagineLBSC Steam CraneSantiago Londoño LopezNessuna valutazione finora

- 1955 3 EngDocumento21 pagine1955 3 EngTateNessuna valutazione finora

- All in One MC 50 (2023)Documento98 pagineAll in One MC 50 (2023)YashuNessuna valutazione finora

- Catalogo Cny1000Documento1 paginaCatalogo Cny1000humbertoNessuna valutazione finora

- Calculation Salim 1Documento9 pagineCalculation Salim 1Abdullahi AwwalNessuna valutazione finora

- Tugas 07Documento6 pagineTugas 07aingNessuna valutazione finora

- Town and Contry 4.0 2008Documento4 pagineTown and Contry 4.0 2008Jessica BustillosNessuna valutazione finora