Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

4t65e Epc Sol

Caricato da

alexanderCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

4t65e Epc Sol

Caricato da

alexanderCopyright:

Formati disponibili

Technical Bulletin #783A

Transmission: 4T65E

Subject: Slips, harsh upshift or garage shifts, launch shudders, flares,

erratic shifts and intermittent concerns, DTC P1811 or

P0748 Set

Application: 1999 Buick Park Avenue, V6

Issue Date: August, 2003

4T65E

Slips, Harsh Upshift or Garage Shifts, Launch Shudders, Flares, Erratic Shifts and

Intermittent Concerns, DTC P1811 or P0748 Set (Replace Pressure Control

Solenoid Valve Assembly)

Models:

1997-1999 Buick Riviera

1997-2002 Buick Park Avenue

1998-2002 Buick LeSabre

1999-2002 Buick Regal

2000-2002 Buick Century

2002 Buick Rendezvous

1997-2001 Chevrolet Lumina

1997-2002 Chevrolet Monte Carlo

1999-2002 Chevrolet Venture

2000-2002 Chevrolet Impala

1997-1999 Oldsmobile Eighty Eight

1997-2002 Oldsmobile Silhouette

1998-2002 Oldsmobile intrigue

2001-2002 Oldsmobile Aurora (3.5L)

1997-2002 Pontiac Bonneville, Grand Prix

1999-2002 Pontiac Transport/Montana

2001-2002 Pontiac Aztek with Hydra-Matic 4T65-E (RPOs MN3, MN7, M15, M76)

Some owners of the above vehicle with a 4T65-E transaxle may comment on harsh upshifts or harsh garage

shifts, soft shifts, shudders on hard acceleration, or shifts erratic. These conditions may appear intermittently or

set a DTC P1811 or P0748. During diagnosis, a low or high line pressure (actual versus desired) may be

observed.

Any of the above conditions may be intermittent, therefore, this test should be performed at least three times.

Refer to the Line Pressure Check Procedure in SI, along with the Line Pressure Specifications Table below, to

determine if actual versus desired pressures are within the values specified. The Scan Tool is only able to control

the PC solenoid valve in PARK and NEUTRAL with the vehicle stopped. This protects the clutches from

extremely high or low pressures in DRIVE or REVERSE ranges.

Copyright 2003 ATRA. All Rights Reserved.

FB! Page 1 of 3

Technical Bulletin #783A

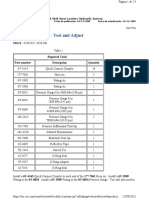

Refer to the Line Pressure Specification Table below. The pressures in the table assume a temperature of 70C.

the pressure will vary with a change in temperature.

Line Pressure Specification Table

Approximate Line Pressure*

Pressure Control Solenoid Valve Current

0 amp

0.1 amp

0.2 amp

0.3 amp

0.4 amp

0.5 amp

0.6 amp

0.7 amp

0.8 amp

0.9 amp

1 amp

1.1 amp

Metric

1675-2137 kPa

1662-2124 kPa

1613-2103 kPa

1551-2068 kPa

1448-1986 kPa

1310-1903 kPa

1172-1751 kPa

1000-1531 kPa

793-1227 kPa

565-896 kPa

469-641 kPa

448-552 kPa

English

243-310 psi

241-308 psi

234-305 psi

225-300 psi

210-288 psi

190-276 psi

170-254 psi

145-222 psi

115-178 psi

82-130 psi

68-93 psi

65-80 psi

*Approximate Line Pressure is measured at an engine speed of 1400 RPM.

If the actual versus desired pressures are not within the values specified, clean the valve body and replace the PC

solenoid valve, if necessary. Check the PC solenoid valve actual versus desired pressures to verify the new PC

solenoid valve is responding correctly.

Line Pressure Check Procedure

Important: Before performing a line pressure check, verify that the pressure control (PC) solenoid valve is

receiving the correct electrical signal from the PCM.

1. Install a Scan Tool.

CAUTION: Keep the brakes applied at all times in order to prevent unexpected vehicle motion. Personal injury

may result if the vehicle moves unexpectedly.

2.

3.

4.

5.

6.

7.

8.

9.

Start the engine and set the parking brake.

Check for a stored Diagnostic Trouble Code (DTC).

Repair the vehicle, if necessary.

Check the fluid level. Refer to the Transmission Fluid Checking Procedure.

Check the manual linkage for proper adjustment.

Turn the engine OFF. Remove the oil pressure test hole plug and install the J21867.

Put the gear selector in PARK range and set the parking brake.

Start the engine and allow the engine to warm up at idle.

Notice: Total test running time should be no longer than two minutes, or else transmission damage could occur.

10. Access the PC solenoid valve control test on the Scan Tool.

11. Increase the PC solenoid actual current from 0.0 to 1.0 amps in 0.1 amp increments. Allow the

pressure to stabilize for five seconds after each pressure change. Read the corresponding line

pressure on the J21867.

FB ! Page 2 of 3

Copyright 2003 ATRA. All Rights Reserved.

Technical Bulletin #783A

12.

13.

14.

15.

Refer to the Line Pressure specifications table. Compare the data to the table.

If pressure readings differ greatly from the table, refer to the Incorrect Line Pressure.

Remove the J21867.

Apply sealant, P/N 12345382 (in Canada, P/N 10953489), to the oil pressure test hole plug.

Notice: Refer to Fastener Notice in Cautions and Notices.

16. Install the oil pressure test hole plug.

Pressure Control Solenoid

Parts Information

Part Number

10478146

Copyright 2003 ATRA. All Rights Reserved.

Description

Pressure Control Solenoid - Valve Asm.

FB ! Page 3 of 3

Potrebbero piacerti anche

- PLD Manual MERCEDES INJECTORS FUEL SYSTEMDocumento150 paginePLD Manual MERCEDES INJECTORS FUEL SYSTEMheehawdafty95% (183)

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Da EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Nessuna valutazione finora

- Lumina 95 3.1 PDFDocumento96 pagineLumina 95 3.1 PDFLuis Alberto Gutierrez Leyva100% (2)

- John Deere Riding Mower 120 Hydrostatic Tractor ManualDocumento54 pagineJohn Deere Riding Mower 120 Hydrostatic Tractor Manualmalakas_123100% (1)

- Suzuki Grand Vitara 1999-2002 PDFDocumento3 pagineSuzuki Grand Vitara 1999-2002 PDFalexanderNessuna valutazione finora

- Suzuki Grand Vitara 1999-2002 PDFDocumento3 pagineSuzuki Grand Vitara 1999-2002 PDFalexanderNessuna valutazione finora

- Manual LPG CNG Calibration Ve1 45Documento29 pagineManual LPG CNG Calibration Ve1 45Carmen StefanNessuna valutazione finora

- (REHS0371) Installation and Initial Start Up Procedures For G3300 and G3400 EnginesDocumento16 pagine(REHS0371) Installation and Initial Start Up Procedures For G3300 and G3400 Enginesvictor.cipriani100% (1)

- Carrier Generator Diagnostic Repair Manual Aspas07-1dmDocumento144 pagineCarrier Generator Diagnostic Repair Manual Aspas07-1dmPeter Dillard100% (1)

- FFD Serive ManualDocumento23 pagineFFD Serive ManualNigel Thomas100% (1)

- Overhaul A140eDocumento84 pagineOverhaul A140eDang Tien PhucNessuna valutazione finora

- O2 Sensor Testing PDFDocumento5 pagineO2 Sensor Testing PDFford62b100% (1)

- Body Control Module V5RM2H31Documento10 pagineBody Control Module V5RM2H31Amin MombiniNessuna valutazione finora

- VolvoDocumento28 pagineVolvoJesus Vega HummerNessuna valutazione finora

- Elm327 Opel AutodijagnostikaDocumento6 pagineElm327 Opel AutodijagnostikaservisyugoNessuna valutazione finora

- 4t65e Epc Sol FallaDocumento3 pagine4t65e Epc Sol FallaTransmisiones Automáticas Chepe100% (1)

- p1811-p0748 Impala PDFDocumento5 paginep1811-p0748 Impala PDFUlloaEliasNessuna valutazione finora

- P0089 CaptivaDocumento5 pagineP0089 CaptivaHOLMAN HUMBERTO FONSECA SALAMANCANessuna valutazione finora

- Sequence Relief ValveDocumento8 pagineSequence Relief ValveSteven Y.MNessuna valutazione finora

- TVS Apache RTR 180 Service ManualDocumento25 pagineTVS Apache RTR 180 Service ManualSandino JoseNessuna valutazione finora

- Test Transmision 420E CatDocumento8 pagineTest Transmision 420E CatEdin Raul Yalle RafaelNessuna valutazione finora

- Prueba de BombaDocumento4 paginePrueba de BombaUilmerKrdenas100% (1)

- Relief Valve (Torque Converter Inlet) Pressure - Test and AdjustDocumento3 pagineRelief Valve (Torque Converter Inlet) Pressure - Test and AdjustEderMPNessuna valutazione finora

- Hyundai AT ErrorDocumento10 pagineHyundai AT ErrorPerminov SergeyNessuna valutazione finora

- BukuDocumento6 pagineBukuAsep SaefullohNessuna valutazione finora

- Hagglunds Viking MK 64 163000 Bo LN 0100Documento26 pagineHagglunds Viking MK 64 163000 Bo LN 0100thijssilderhuis100% (1)

- Sym GTS 250 (EN)Documento227 pagineSym GTS 250 (EN)manualsym100% (1)

- Gilera GP 800 I.E. (EN)Documento437 pagineGilera GP 800 I.E. (EN)ManuallesNessuna valutazione finora

- Fuel System Pressure - Test: Table 1Documento4 pagineFuel System Pressure - Test: Table 1JorgeNessuna valutazione finora

- Caterpillar 236B-246B-252B Y 262BDocumento22 pagineCaterpillar 236B-246B-252B Y 262BVictor Montesdeoca100% (1)

- Commissioning Procedure For The 797F and The 797F XQ Off-Highway Truck (0374, 1000, 7000, 7961)Documento154 pagineCommissioning Procedure For The 797F and The 797F XQ Off-Highway Truck (0374, 1000, 7000, 7961)Blenz HQNessuna valutazione finora

- User'S Manual: Digital Diesel Compression Test Kit MODEL MV5535Documento28 pagineUser'S Manual: Digital Diesel Compression Test Kit MODEL MV5535Segundo Francisco Jauregui ValenciaNessuna valutazione finora

- Actyon 201212Documento702 pagineActyon 201212Ederson BJJNessuna valutazione finora

- Correct Operation and Maintenance of TC EngineDocumento3 pagineCorrect Operation and Maintenance of TC EngineAdrian MacayaNessuna valutazione finora

- Correct Operation and Maintenance of TC Engine PDFDocumento3 pagineCorrect Operation and Maintenance of TC Engine PDFstefyharo100% (3)

- Correct Operation and Maintenance of TC Engine PDFDocumento3 pagineCorrect Operation and Maintenance of TC Engine PDFstefyharoNessuna valutazione finora

- 1989 Engine Performance On-Vehicle AdjustmentsDocumento14 pagine1989 Engine Performance On-Vehicle AdjustmentsJose PichinteNessuna valutazione finora

- Hydrostatic TestDocumento22 pagineHydrostatic TestGuido Emanuel SteinbachNessuna valutazione finora

- 789C Prueba de Calado ConvertidorDocumento5 pagine789C Prueba de Calado ConvertidorSergio Velarde Romay100% (1)

- Engine Brake Tests (Mack E-Tech™ Engine With J-Tech™ Engine Brake) Operational TestsDocumento10 pagineEngine Brake Tests (Mack E-Tech™ Engine With J-Tech™ Engine Brake) Operational TestsVictor ValenciaNessuna valutazione finora

- M.I.L. On DTC p1349 - Vvti Actuator T-Eg007-03Documento3 pagineM.I.L. On DTC p1349 - Vvti Actuator T-Eg007-03asdref100% (1)

- Ts B 0323006Documento3 pagineTs B 0323006chzhptopNessuna valutazione finora

- GMC Sierra 4800 Generator Owners Manual 11 09Documento36 pagineGMC Sierra 4800 Generator Owners Manual 11 09Shahid SiddiqueNessuna valutazione finora

- Acura TSX 2004 Manual and Power Steering, Steering Column, Gear and LinkageDocumento144 pagineAcura TSX 2004 Manual and Power Steering, Steering Column, Gear and Linkagejorge antonio guillenNessuna valutazione finora

- Priority Valve - Test and AdjustDocumento7 paginePriority Valve - Test and AdjustMARTIN GONZALEZNessuna valutazione finora

- TG 611 GovernorDocumento4 pagineTG 611 Governorveer_sNessuna valutazione finora

- Gilera Runner RST 125 - 200 (EN)Documento279 pagineGilera Runner RST 125 - 200 (EN)Manualles100% (3)

- Sp7a Sx4aDocumento69 pagineSp7a Sx4aWin CardonaNessuna valutazione finora

- Viper ManualDocumento56 pagineViper ManualDoc Holli DayNessuna valutazione finora

- Basic Testing Pajero 1991Documento12 pagineBasic Testing Pajero 1991nadaNessuna valutazione finora

- CA Motors Product DetailsDocumento25 pagineCA Motors Product DetailsP Venkata Suresh100% (2)

- Vespa S 50 4t 2v 25 KMH MY 2010 (En)Documento215 pagineVespa S 50 4t 2v 25 KMH MY 2010 (En)Manualles100% (1)

- Toyota - Paseo - Workshop Manual - 1990 - 1991Documento3.179 pagineToyota - Paseo - Workshop Manual - 1990 - 1991cginternet.ofcNessuna valutazione finora

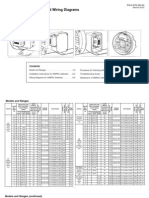

- Installation Instructions and Wiring Diagrams For All Models and RangesDocumento8 pagineInstallation Instructions and Wiring Diagrams For All Models and RangesMaria MusyNessuna valutazione finora

- Prueba de Presion de FrenoDocumento8 paginePrueba de Presion de FrenoHenry MonteagudoNessuna valutazione finora

- CatalogueDocumento55 pagineCatalogueStroia Constantin MariusNessuna valutazione finora

- Discover Dts I SRRDocumento24 pagineDiscover Dts I SRRStev Betancur90% (10)

- Off LeakDocumento26 pagineOff LeakPatriciaH20Nessuna valutazione finora

- 177-999 Rev C1Documento32 pagine177-999 Rev C1vallolet_sb5185Nessuna valutazione finora

- Ajustar Bomba Hidraulica 428EDocumento11 pagineAjustar Bomba Hidraulica 428EUilmerKrdenasNessuna valutazione finora

- Toma de Presiones #1Documento9 pagineToma de Presiones #1julianmatabajoyNessuna valutazione finora

- Hydraulic Pump - Test and Adjust: Fechar o SIS Tela AnteriorDocumento12 pagineHydraulic Pump - Test and Adjust: Fechar o SIS Tela AnteriorHelioNessuna valutazione finora

- Transmission Servicing atDocumento12 pagineTransmission Servicing atAnimemanuel MuñozNessuna valutazione finora

- Piaggio Fly150 Service Manual 150ccmDocumento239 paginePiaggio Fly150 Service Manual 150ccmgtperformasNessuna valutazione finora

- Hydrostatic System - Test and AdjustDocumento23 pagineHydrostatic System - Test and AdjustSanchez Gamarra AndyNessuna valutazione finora

- Maintenance and Tune-Up Idle Speed and Mixture AdjustmentDocumento5 pagineMaintenance and Tune-Up Idle Speed and Mixture AdjustmentFarabi ArdhiantoNessuna valutazione finora

- Motorcycle, Solo (Harley-Davidson Model WLA)Da EverandMotorcycle, Solo (Harley-Davidson Model WLA)Nessuna valutazione finora

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Da EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Valutazione: 3 su 5 stelle3/5 (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- Catalogo Conecciones. (1) OrlandoDocumento52 pagineCatalogo Conecciones. (1) OrlandoalexanderNessuna valutazione finora

- Cene JuqnjnuDocumento1 paginaCene JuqnjnualexanderNessuna valutazione finora

- 47HC00 NandDocumento17 pagine47HC00 NandWilliams Paredes CNessuna valutazione finora

- Safefast Premium: Class Ii Microbiological Safety CabinetsDocumento2 pagineSafefast Premium: Class Ii Microbiological Safety CabinetsalexanderNessuna valutazione finora

- Faster Chemfast: Laboratory Fume CupboardsDocumento8 pagineFaster Chemfast: Laboratory Fume CupboardsalexanderNessuna valutazione finora

- Multi-Purpose Electrosurgical Generator: Monitor-Set Enable RangeDocumento15 pagineMulti-Purpose Electrosurgical Generator: Monitor-Set Enable RangealexanderNessuna valutazione finora

- Smartfast and Smartfast: Vertical Laminar Airflow CabinetsDocumento6 pagineSmartfast and Smartfast: Vertical Laminar Airflow CabinetsalexanderNessuna valutazione finora

- Cytofast Elite: Cytotoxic Safety CabinetsDocumento8 pagineCytofast Elite: Cytotoxic Safety CabinetsalexanderNessuna valutazione finora

- Accessories SaleSheetDocumento2 pagineAccessories SaleSheetalexanderNessuna valutazione finora

- 47HC00 NandDocumento17 pagine47HC00 NandWilliams Paredes CNessuna valutazione finora

- Sphygmomanometer HM-HS-20A HM-HS-50C: AneroidDocumento7 pagineSphygmomanometer HM-HS-20A HM-HS-50C: AneroidalexanderNessuna valutazione finora

- Ads Ii: Anesthesia Delivery SystemDocumento2 pagineAds Ii: Anesthesia Delivery SystemalexanderNessuna valutazione finora

- Oximetro - Oxcyon IIDocumento2 pagineOximetro - Oxcyon IIalexanderNessuna valutazione finora

- Maquina de Anestesia - ADSIIDocumento2 pagineMaquina de Anestesia - ADSIIalexanderNessuna valutazione finora

- Ads Iii 2009Documento2 pagineAds Iii 2009alexanderNessuna valutazione finora

- Accessories SaleSheetDocumento2 pagineAccessories SaleSheetalexanderNessuna valutazione finora

- Oximetro Portatil - O2 SATDocumento2 pagineOximetro Portatil - O2 SATalexanderNessuna valutazione finora

- Ads Express: Portable Anesthesia MachineDocumento2 pagineAds Express: Portable Anesthesia MachinealexanderNessuna valutazione finora

- Brosur Omni ViewDocumento2 pagineBrosur Omni ViewRaimona UciNessuna valutazione finora

- Maquina de Anestesia - ADSIIDocumento2 pagineMaquina de Anestesia - ADSIIalexanderNessuna valutazione finora

- Maquina de Anestesia - ADS-IIIDocumento2 pagineMaquina de Anestesia - ADS-IIIalexanderNessuna valutazione finora

- Omni - VSDocumento2 pagineOmni - VSalexanderNessuna valutazione finora

- Omni Ii: Touch Screen Patient MonitorDocumento2 pagineOmni Ii: Touch Screen Patient MonitoralexanderNessuna valutazione finora

- Desfribilador Monitor - OMNI EMTDocumento2 pagineDesfribilador Monitor - OMNI EMTalexanderNessuna valutazione finora

- Monitor - Omni IIIDocumento2 pagineMonitor - Omni IIIalexanderNessuna valutazione finora

- Monitor - OmniDocumento2 pagineMonitor - OmnialexanderNessuna valutazione finora

- Monitor - Omni ExpressDocumento2 pagineMonitor - Omni ExpressalexanderNessuna valutazione finora

- Maquina de Anestesia - ADS-IIIDocumento2 pagineMaquina de Anestesia - ADS-IIIalexanderNessuna valutazione finora

- Catálogo Geral - Pmb7040 G Catalog WebDocumento20 pagineCatálogo Geral - Pmb7040 G Catalog Webh-97225Nessuna valutazione finora

- Bosch ECU On-Board DiagnosticsDocumento98 pagineBosch ECU On-Board DiagnosticsRafael Hubner100% (3)

- Abrites Diagnostics For VAG User Manual HTMLDocumento14 pagineAbrites Diagnostics For VAG User Manual HTMLismael pimentelNessuna valutazione finora

- 400 500 101 0 - Field Diagnostics Guide - March 2021Documento6 pagine400 500 101 0 - Field Diagnostics Guide - March 2021Zhan AinabekovNessuna valutazione finora

- P Johnstone: Jackaroo TipsDocumento5 pagineP Johnstone: Jackaroo TipsJimmy Brian KaifitiNessuna valutazione finora

- Manual de Pruebas Eficaces OSCILOSCOPIODocumento4 pagineManual de Pruebas Eficaces OSCILOSCOPIODaniel GarciaNessuna valutazione finora

- Assessment 1 Assessor Guide Questioning Written Knowledge Assessment AURETK002 V2Documento14 pagineAssessment 1 Assessor Guide Questioning Written Knowledge Assessment AURETK002 V2Tam TranNessuna valutazione finora

- Since 2002: Dedicated To Interna OnalDocumento18 pagineSince 2002: Dedicated To Interna OnalSenthil KumarNessuna valutazione finora

- TEXA Twinprobe Oscilloscope User ManualDocumento49 pagineTEXA Twinprobe Oscilloscope User Manualkallatis100% (2)

- Automotive Telematics: 1.0 Executive SummaryDocumento7 pagineAutomotive Telematics: 1.0 Executive SummaryRaghav NevatiaNessuna valutazione finora

- General Information - 07 CX7Documento40 pagineGeneral Information - 07 CX7sled novaNessuna valutazione finora

- 20.0us $ - All Data Pro Alldata 10.53 Auto Repair Software Moto Heavy Duty Vivid Workshop Full Set 1Tb HDD For Car Truck Diagnostic Tools AliexpressDocumento5 pagine20.0us $ - All Data Pro Alldata 10.53 Auto Repair Software Moto Heavy Duty Vivid Workshop Full Set 1Tb HDD For Car Truck Diagnostic Tools Aliexpressravenhotrods64Nessuna valutazione finora

- Autel MS309 - Manual - V1.01Documento27 pagineAutel MS309 - Manual - V1.01xuzebin100% (3)

- BMW Fault Codes OBDDocumento15 pagineBMW Fault Codes OBDtitibacsiNessuna valutazione finora

- IDD-213GD Technical Specification v2.0 NewDocumento3 pagineIDD-213GD Technical Specification v2.0 NewRamon AscanioNessuna valutazione finora

- Model Indentifiction For Cars TestsDocumento454 pagineModel Indentifiction For Cars TestsRichard Thodé JrNessuna valutazione finora

- Maxisys Vehicle Diagnostic Report: StatusDocumento2 pagineMaxisys Vehicle Diagnostic Report: StatusAlex SdqNessuna valutazione finora

- OBD2 Scanner ResultsDocumento3 pagineOBD2 Scanner ResultsIvan PetrovNessuna valutazione finora

- Intelligent Transportation Systems:: Real-Time Vehicle Performance Monitoring Using Wireless NetworkingDocumento19 pagineIntelligent Transportation Systems:: Real-Time Vehicle Performance Monitoring Using Wireless Networkingpervezahmad64Nessuna valutazione finora

- Calibration IDDocumento8 pagineCalibration IDYuhin WuNessuna valutazione finora

- 1kr Fe Starting Starting MotorDocumento320 pagine1kr Fe Starting Starting MotorTalleban Tal0% (1)

- Ob2 SensorDocumento25 pagineOb2 SensorNakibinge StevenNessuna valutazione finora

- Data Exchange Between TCM and CAN-Capable Control Modules, CheckingDocumento5 pagineData Exchange Between TCM and CAN-Capable Control Modules, CheckingManuel HerediaNessuna valutazione finora

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-2-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)