Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Combined Economic Emission Dispatch With New Price Penalty Factors

Caricato da

Zellagui EnergyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Combined Economic Emission Dispatch With New Price Penalty Factors

Caricato da

Zellagui EnergyCopyright:

Formati disponibili

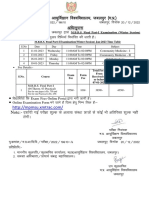

4th International Conference on Electrical Engineering (ICEE 2015)

IGEE, Boumerdes, December 13th-15th 2015

Combined Economic Emission Dispatch With New

Price Penalty Factors

Ismail Ziane(1), Farid Benhamida, Amel Graa

Yacine Salhi

Irecom laboratory, dept. of electrotechnics

UDL university of Sidi Bel Abbes

Sidi Bel Abbes, Algeria

(1)

ziane_ismail2005@yahoo.fr

Apelec laboratory, dept. of electrotechnics

UDL university of Sidi Bel Abbes

Sidi Bel Abbes, Algeria

(2)

salhiyacine13@yahoo.fr

Abstract This paper presents combined of economic and

emission load dispatch (CEED). The price penalty factor is

considered in the multi-objective function of (CEED). In this

paper, we use various price penalty factors (Max/Max, Min/Max

and average). Simulated annealing method is our method to find

the optimal solution. The SA algorithm is used to minimize the

fuel cost and the gas emissions as SO2 and NOx in the power

systems. In this study, in order to evaluate the performance of

the SA algorithm, it is tested on 3-unit system with fuel cost and

emission functions. The results obtained from SA method are

compared with other method in literatures. The results show

that the SA algorithm is better than the others at solving such a

problem.

Keywordscombined economic and emission dispatch, price

penalty factor, simulated annealing.

I.

INTRODUCTION

Economic dispatch (ED) problem is one important task in

power system. The main objective of the ED problem can be

defined as meeting the power demand by operating power

generation units with the minimum cost while satisfying the

equality and inequality constraints of the system. [1]. The

cost of electrical production is described with three main

sources: facility construction, ownership cost, and operating

costs. The operating cost is the most significant of these

three, and so the focus will be on the economics of the

operation [2].

The fuel cost function optimizes the total cost of active

power generation, assuming that every generator has a

convex cost curve related to its own active power, every

generator has upper and lower active power generating limits

and it is also assumed that the sum of all active powers of

generator must be equal to a given total system load plus total

system losses [3].

On the other hand, the amendments of the world law of

1990 (clean Air Act Amendments) forced the producers of

energy and the engineers in charge of the electrical energy

management to modify their algorithms of standard

optimization by taking in consideration the pollution (to

reduce the emissions to the atmosphere of greenhouse gas by

the thermal power plants which are toxic gases (NOx, SO2, and

CO2) [4, 5].

A major challenge for all power utilities is to satisfy the

consumer demand for power at minimal cost and minimal gas

emission.

To solve the economic load dispatch problems,

researchers may use algorithms [6] that terminate in a finite

number of steps, Iterative methods [7] that converge to a

solution (on some specified class of problems), and heuristics

[8] that may provide approximate solutions (A good

feasible solution) to some problems.

SA is an effective method to find global minima for

optimization problem having cubic objective function with

linear constraints. In this paper the effectiveness of the

proposed algorithm is demonstrated using 6-unit test system.

II. MATHEMATICAL MODEL OF CEED

Generator cost curves are usually not smooth. However

the curves can usually be adequately approximated using

piece-wise smooth, functions. So that, the fuel cost curve can

be presented as a smooth function. The smooth fuel cost

function is defined by quadratic function:

FCi (Pi ) ai Pi 2 bi Pi c i

(1)

The criterion for minimization of the SO2 emission is

formulated as

E SO 2 i ( Pi ) aSO 2i Pi 3 bSO 2i Pi 2 c SO 2i

(2)

where aSO2i , bSO2i and cSO2i are the SO2 emission co-efficient

of unit i.

2015 IEEE

The criterion for minimization of the NOx emission is

formulated as

E NOxi ( Pi ) aNOxi Pi 3 b NOxi Pi 2 c NOxi

The criterion for minimization of the SO2 emission is

formulated as

where aCO2i , b CO2i, and c

efficient of unit i.

CO2i

(4)

hAvgSO 2i

hAvgNOxi

FTSO 2 i ( Pi )

FCi (Pi ) hSO 2i E SO 2i ( Pi )

(5)

FTNOxi ( Pi )

FCi (Pi ) hNOxi E NOxi ( Pi )

(6)

FTCO 2i (Pi )

FCi ( Pi ) hCO 2i E CO 2i ( Pi )

(7)

where hSO2, hNOx and hCO2 are price penalty factors for SO2,

NOx, and CO2, respectively, blending the emission costs

with the normal fuel costs.

The above mentioned multi- objective optimization

problem can be converted to a single objective optimization

problem by introducing price penalty factors as follows:

FCi ( Pi ) hSO 2i E SO 2i (Pi ) ..

...hNOxi E NOxi ( Pi ) hCO 2i E CO 2i ( Pi )

(13)

hCO 2 i

FCi ( PMini )

E CO 2 i ( PM axi )

(14)

Another price is used which can be calculated by the

average of price Max/Max and Min/Max penalty factors

as proposed in [ ] to solve the multi-objective economic

emission dispatch problem as follows:

are the CO2 emission co-

A multi-objective optimization is converted into a single

objective optimization problem by introducing price penalty

factor hi to the various pollutants. Three problems are

formulated for every pollutant separately as follows

FTi ( Pi )

FCi ( PMini )

E NOxi ( PMaxi )

(3)

where aNOxi , bNOxi and cNOxi are the NOx emission co-efficient

of unit i.

E CO 2 i ( Pi ) aCO 2i Pi 3 bCO 2i Pi 2 cCO 2i

hNOxi

(8)

hAvgCO 2i

FCi (PMaxi ) / ESO 2i (PMaxi )

2

FCi (PMaxi ) / E NOxi (PMaxi ) FCi (PMini ) / ENOxi (PMaxi )

2

FCi (PMaxi ) / ECO 2i (PMaxi ) FCi (PMini ) / ECO 2i (PMaxi )

2

FCi ( PMaxi )

E SO 2i ( PMaxi )

(9)

hNOxi

FCi ( PMaxi )

E NOxi ( PMaxi )

(10)

hCO 2 i

FCi ( PMaxi )

E CO 2 i ( PM axi )

(11)

hSO 2 i

FCi ( PMini )

E SO 2i ( PMaxi )

(16)

(17)

Pi

PD

PL

(18)

where PD is the load demand and PL is the total transmission

network losses.

Generator limit Constraints

Generators have limits on the minimum and maximum

amount of power they can produce. Often times the minimum

limit is not zero. This represents a limit on the generators

operation with the desired fuel type because of varying

system economics usually many generators in a system are

operated at their maximum MW limits.

Pi

Pi max

(19)

where Pi min is the minimum generation limit of unit i and Pi max

is the maximum generation limit of unit i.

Power balance constraints

This paper suggests a deferent price penalty factor

Min/Max considering the multi-objective dispatch

problem. It is formulated as follows:

hSO 2 i

(15)

Power balance constraints

Pi min

Commonly used form for the price penalty factor hi is the

ratio between maximum fuel cost and maximum emission of

corresponding generator

FCi (PMini ) / ESO 2i (PMaxi )

(12)

Pi

PD

PL

(20)

where PD is the load demand and PL is the total transmission

network losses.

The simplest form of loss equation is Georges formula,

which is given by:

n

PL

B ij Pi Pj

i 1 j 1

Bij is called the loss coefficient

(21)

Generator limit Constraints

The power generation of unit i should be between its

minimum and maximum limits.

Pi min

Pi

Pi max

(22)

where Pi min is the minimum generation limit of unit i and Pi max

is the maximum generation limit of unit i.

III. A SIMULATED ANNEALING ALGORITHM FOR

ECONOMIC DISPATCH PROBLEM

The simulated annealing method [9] is a heuristic

optimization technique and it has the ability to find

global or near global optimum solutions for large

combinatorial optimization problems. This method is similar

to the local search technique in optimization, which can only

guarantee a local optimum solution. Simulated annealing is

proposed in Kirkpatrick, Gelett and Vecchi in 1983 and

Cerny [10] in 1985 for finding the global minimum of a cost

function that may presses several local minima [11].

The name simulated annealing comes from an analogy

between combinatorial optimization and the physical process

of annealing. In physical annealing a solid is cooled very

slowly, starting from a high temperature, in order to achieve a

state of minimum internal energy. It is cooled slowly so that

thermal equilibrium is achieved at each temperature. Thermal

equilibrium can be characterized by the Boltzmann

distribution.

C 0; (Global iteration count)

T

T0; (T0 Initial system temperature)

Iterative Processes

Nbiter

0;

While (Nbiter < nb_iter)

C C+1; Nbiter

Nbiter+1;

Generate randomly a solution S ' N S ;

F F(S)-F(S);

if F <0) then

S S;

Otherwise

Prob ( F, T) exp (- F/T);

Generate q uniformly in the interval: [0,1];

If (q< prob ( F, T)) then

S S;

If F(S) < F(S*) then

S* S;

T= T ; (0 < <1 cooling coefficient).

IV. RESULTS AND DISCUSSION

The proposed optimization algorithm is applied on 2

systems, a 3 unit and 6 unit systems to verify its effectiveness.

For conducting the test, the initial temperature is fixed at 10

C, alpha is fixed at 0.99 and max tries is 10000. The final

temperature is 1e-10 C.

In this paper, we consider three types of price penalty factor

Max/Max price penalty factor.

Min/Max price penalty factor.

Average price penalty factor.

(23)

The fuel cost coefficients,

SO2, and NOx emission

coefficients, and the real power limits of the generators are

taken from [13] with 1800 MW of load demand.

The SA algorithm for dispatch problem is stepped as follows

[12]:

Table I presents a comparison between our proposed

methods and other methods such as NSGA, OBBO, BBO, and

BB_BC for combined economic and emission load dispatch

with Max/Max price penalty factor. It can be seen that SA

gives the best solution (25035.1214 $).

Paccept x , y

1,

e

( E x E y )/ k BT

if E X

EY

if E X

EY

A. Simulated Annealing algorithm

Initialisation

Choose an initial solution S

S* S;

TABLE I.

X;

COMPARAISON OF CEED-SO2 -NOX EMISSION D ISPATCH (MAX/MAX PENALTY PRICE FACTOR)

P1

P2

P3

Losses(MW)

Fuel cost ($/h)

SO2 Emission (ton/h)

NOX Emission (ton/h)

Total cost ($/h)

NSGA-II[13]

496.328

260.426

108.144

14.898

8358.896

8.97870

0.09599

31234.99029

OBBO[14]

507.11971

251.64200

106.00030

14.76251

8364.30627

8.974195

0.0959248

31226.40958

BBO[14]

507.11954

251.64262

106.00042

14.76258

8364.31126

8.974201

0.0959248

31226.41898

BB_BC[15]

442.893

305.503

117.546

15.94

8345.813

9.01602

0.09776

25035.140

SA

442.1752

305.8545

117.9238

15.9535

8345.7469

9.0166

0.0978

25035.1214

Tables II, III and IV present the combined of economic and

emission load dispatch of SO2, NOx for Max/Max,

Min/Max, and Average price penalty factors respectively

with load variation.

TABLE II.

DYNAMIC CEED-SO2 -NOX EMISSION D ISPATCH OF 3 UNIT SYSTEM (MAX/MAX PENALTY PRICE FACTOR )

Load

P1

P2

P3

Losses(MW)

Fuel cost ($/h)

SO2 Emission (ton/h)

NOx Emission (ton/h)

Total cost ($/h)

TABLE III.

550

307.1316

160.3256

88.6287

6.0859

5581.4797

6.0071

0.0880

18760.5958

600

329.3203

184.6109

93.4374

7.3685

6028.7083

6.4941

0.0882

19660.5278

700

374.0706

233.1530

103.1433

10.3669

6939.2481

7.4855

0.0902

21633.8869

800

419.3435

281.6375

112.9646

13.9456

7871.4467

8.5004

0.0947

23841.8787

850

442.1716

305.8557

117.9262

15.9536

8345.7465

9.0166

0.0978

25035.1214

DYNAMIC CEED-SO2 -NOX EMISSION D ISPATCH OF 3 UNIT SYSTEM (MIN/MAX PENALTY PRICE FACTOR )

Load

P1

P2

P3

Losses(MW)

Fuel cost ($/h)

SO2 Emission (ton/h)

NOx Emission (ton/h)

Total cost ($/h)

TABLE IV.

550

297.8166

166.9111

91.4438

6.1716

5579.6607

6.0136

0.0881

9489.5798

600

320.3985

189.8446

97.2144

7.4574

6027.4533

6.5010

0.0883

10070.9167

700

365.9145

235.6758

108.8471

10.4374

6938.6103

7.4925

0.0906

11295.9982

800

411.9024

281.4606

120.6021

13.9651

7870.7391

8.5066

0.0952

12605.4117

850

435.0792

304.3310

126.5251

15.9354

8344.7479

9.0223

0.0985

13292.1702

DYNAMIC CEED-SO2 -NOX EMISSION D ISPATCH OF 3 UNIT SYSTEM (AVERAGE PENALTY PRICE FACTOR)

Load

P1

P2

P3

Losses(MW)

Fuel cost ($/h)

SO2 Emission (ton/h)

NOx Emission (ton/h)

Total cost ($/h)

550

304.6979

162.1333

89.2763

6.1075

5580.9171

6.0087

0.0881

14125.6180

600

327.0093

186.0701

94.3120

7.3914

6028.3028

6.4958

0.0882

14866.2649

700

371.9969

233.9175

104.4714

10.3857

6939.0150

7.4872

0.0903

16465.6246

800

417.5038

281.6956

114.7518

13.9512

7871.1966

8.5018

0.0948

18224.6205

850

440.4460

305.5663

119.9370

15.9493

8345.4170

9.0179

0.0979

19164.8259

P1

P2

P3

Losses

500

400

Power output (MW)

In figure 1, it can be seen the CEED-SO2-NOx for various

price penalty factors with load variation obtained by our

proposed. The dynamic of the power output for the three

units is presented in figure 2. The NOx emission output for

Max/Max, Min/Max, and Average price penalty factors

is shown in figure 3. We can see that the minimum total cost

is given by Min/Max factor price penalty and the minimum

of NOx emission is give by Min/Max factor price penalty.

300

200

100

Max/Max

Min/Max

Average

26000

24000

0

1

FT of CEED-SO2-NOx ($/h)

22000

Time interval (h)

20000

18000

Figure 2. Power output for each generator for the 5 load demands

(Max/Max).

16000

14000

12000

10000

8000

6000

4000

2000

0

550

600

650

700

750

800

850

Load variation (MW)

Figure 1. CEED-SO2-NO x solution for various price penalty factors.

[3]

Max/Max

Min/Max

Average

0,098

NOx Emission (Ton/h)

0,096

[4]

0,094

0,092

[5]

0,090

0,088

550

600

650

700

750

800

850

[6]

Load variation (MW)

[7]

Figure 3. NOxEmission output of CEED-SO2 -NOx

penalty factors.

for various price

[8]

V. CONCLUSION

In this paper, the combined of economic and emission

load dispatch problem of both fuel cost and emission

functions are formulated with fuel cost and emissions

functions. Simulated annealing algorithm is developed for the

solution of the dispatch problem. The 3 unit system multiobjective dispatch problem is solved separately for various

price penalty factors such as Max/Max, Min/Max, and

Average. The conclusion obtained is that the Min/Max

price penalty factor is good to yield the best total cost of

CEED SO2NOx- CO2. The Max/Max price penalty factor

can give the minimum emissions of NOx and SO2.

[9]

[10]

[11]

[12]

[13]

VI. REFERENCES

[1]

[2]

D. Aydin , S. zyn, C. Yasar , T. Liao, Arti cial bee colony algorithm

with dynamic population size to combined economic and emission

dispatch problem, Electrical Power and Energy Systems, 54, 144153,

2014.

C. Mittal, Fuel cost function estimation for economic load dispatch

using evolutionary programming, Master thesis, electrical and

[14]

[15]

instrumentation engineering departement, Thapar university, Patalia,

2011.

F. Benhamida, I. Ziane, A. Graa S. Souag, Y. Salhi, An effective

GAMS optimization for dynamic economic load dispatch with ramp

rate limit, AMO - Advanced Modeling and Optimization, Vol. 15,

Number 2, pp. 477-485, 2013.

B. Mahdad, K. Srairi, B. Tarek, and A. Bensalem, Dispatching

Economique du Rseau Electrique Algrien en Prsence des dispositifs

Shunt FACTS avec Considration de la Pollution, confrence

internationale sur les rseaux lectriques ICEN10, Sidi bel-abbes,

Algeria, (2010).

U. Gven., Combined Economic and Emission Dispatch solution

using Genetic Algorithm based on similarity crossover, Scientific

Research and Essays, vol.5, no. 17, pp. 24512456, (2010).

Jean Cea, Optimization Theory and Algorithms, Lectures, Tata

Institute of Fundamental Research, Bombay, 1978.

C.T. Kelley, Iterative Methods for Optimization, Society for Industrial

and Applied Mathematics Philadelphia North Carolina State University

Raleigh, North Carolina.

M. Gilli, An Introduction to Optimization Heuristics, Seminar

University of Cyprus Department of Public and Business

Administration, 2004.

F. Kolahan, and M. Abachizadeh, Optimizing Turning Parameters for

Cylindrical Parts Using Simulated Annealing Method, World Academy

of Science Engineering and Technology, Vol.22, pp.436-439, 2008.

N. Metropolis, A. Rosenbluth, M. Rosenbluth, A. Teller, and E. Teller.,

Equation of State Calculations by Fast Computing Machines, Journal of

Chemical Physics, Vol. 21, pp. 1087-1092, 1953.

M. S. Kaurav, H. M. Dubey, M. Pandit and B. K. Panigrahi, imulated

Annealing Algorithm for Combined Economic and Emission Dispatch,

International Conference, ICACCN, pp. 631-636, 2011.

L. Abdou, O. Taibaoui, A. Moumen and A. Taleb Ahmed, Threshold

Optimization in Distributed OS-CFAR System by using Simulated

Annealing Technique, Proceedings of the 4th International Conference

on Systems and Control, Sousse, Tunisia,pp.295-301, 2015.

R. T. F. Ah King , H. C. S. Rughooputh, Elitist Multiobjective

Evolutionary Algorithm for Environmental/Economic Dispatch,

Congress on Evolutionary computation, vol. 2, pp: 1108-14, 2003.

A. B. Pranab, K.Chattopadhyay, Oppositional Biogeography-Based

Optimization for Multi-objective Economic Emission Load Dispatch,

Annual IEEE India Conference (INDICON),2010.

Y. Labbi, D. Ben Attous, Combined Economic and Emission Dispatch

Using Big BangBig Crunch Optimization Algorithm, ICEN2010

International Conference on Electrical Networks,2010.

Potrebbero piacerti anche

- Test Bank Contemporary Behavior Therapy - Michael-Spiegler - 6th EditionDocumento12 pagineTest Bank Contemporary Behavior Therapy - Michael-Spiegler - 6th Editionlewisbacha0% (1)

- Gastronomia 10 Competition GuideDocumento21 pagineGastronomia 10 Competition Guidefpvillanueva100% (1)

- FAT Form Winch UnitDocumento7 pagineFAT Form Winch UnitYadi KusmayadiNessuna valutazione finora

- Pile Foundation As Per IRC 112Documento59 paginePile Foundation As Per IRC 112ARVIND SINGH RAWAT0% (1)

- JAFZA Construction Regulation - Third Edition 2003Documento73 pagineJAFZA Construction Regulation - Third Edition 2003Abdul JabbarNessuna valutazione finora

- CFD Report For BasementDocumento31 pagineCFD Report For Basementrajarathnam.k100% (1)

- Time-Current Coordination ExampleDocumento6 pagineTime-Current Coordination ExamplekishansaiNessuna valutazione finora

- ASTM D1123 Contenido Agua en Glicol PDFDocumento5 pagineASTM D1123 Contenido Agua en Glicol PDFdianacalixtogNessuna valutazione finora

- 517 141Documento11 pagine517 141sorincarmen88Nessuna valutazione finora

- General Indications: AnticoagulantsDocumento15 pagineGeneral Indications: AnticoagulantswahidNessuna valutazione finora

- EVA and MVADocumento19 pagineEVA and MVATanveer Ahmad100% (1)

- Carbon Capture Technologies for Gas-Turbine-Based Power PlantsDa EverandCarbon Capture Technologies for Gas-Turbine-Based Power PlantsNessuna valutazione finora

- Predicting the Price of Carbon Supplement 1: Hinkley Point C Nuclear Power Station Enhanced Carbon Audit LCA Case StudyDa EverandPredicting the Price of Carbon Supplement 1: Hinkley Point C Nuclear Power Station Enhanced Carbon Audit LCA Case StudyNessuna valutazione finora

- CO2 Removal in Power PlantsDocumento27 pagineCO2 Removal in Power Plantslagr2000Nessuna valutazione finora

- Anatomy of Lone Wolf Terrorism Special EDocumento30 pagineAnatomy of Lone Wolf Terrorism Special EMika RainmanNessuna valutazione finora

- Optimization of Combined Economic and Emission Dispatch Problem A Comparative Study-10702808Documento15 pagineOptimization of Combined Economic and Emission Dispatch Problem A Comparative Study-10702808kanuvietNessuna valutazione finora

- Modified Biogeography Based Optimization Algorithm For Power Dispatch Using Max/Max Price Penalty FactorDocumento6 pagineModified Biogeography Based Optimization Algorithm For Power Dispatch Using Max/Max Price Penalty FactorKS SanNessuna valutazione finora

- Ijest NG Vol.1 No.1 pp.272 282Documento11 pagineIjest NG Vol.1 No.1 pp.272 282prabhjot singh1Nessuna valutazione finora

- Multiobjective Particle Swarm Optimization For Environmental/Economic Power Dispatch ProblemDocumento6 pagineMultiobjective Particle Swarm Optimization For Environmental/Economic Power Dispatch ProblemGRD JournalsNessuna valutazione finora

- Modified Particle Swarm Optimization For Economic-Emission Load Dispatch of Power System OperationDocumento15 pagineModified Particle Swarm Optimization For Economic-Emission Load Dispatch of Power System OperationArifAmzarNessuna valutazione finora

- Comprehensive Learning Particle Swarm Optimization (CLPSO) For Multi-Objective Optimal Power FlowDocumento9 pagineComprehensive Learning Particle Swarm Optimization (CLPSO) For Multi-Objective Optimal Power FlowabhywaNessuna valutazione finora

- Multi-Objective Ant Lion Optimizer For Solving Environmental/Economic DispatchDocumento6 pagineMulti-Objective Ant Lion Optimizer For Solving Environmental/Economic DispatchsabhanNessuna valutazione finora

- Ijiset V5 I11 07Documento6 pagineIjiset V5 I11 07Norman Al SyahnaNessuna valutazione finora

- Fuzzified Multiobjective Pso For Ceed With Voltage Stability ConstraintDocumento61 pagineFuzzified Multiobjective Pso For Ceed With Voltage Stability ConstraintPraveen Nayak BhukyaNessuna valutazione finora

- Optimum Power Dispatch Problems: An Overview: F. R. Pazheri, N. H. Malik, M. F. Othman and M. BabarDocumento6 pagineOptimum Power Dispatch Problems: An Overview: F. R. Pazheri, N. H. Malik, M. F. Othman and M. BabarInternational Journal of Engineering Inventions (IJEI)Nessuna valutazione finora

- Rapid Thermodynamic Simulation Model of An Internal Combustion EngineDocumento6 pagineRapid Thermodynamic Simulation Model of An Internal Combustion Enginefogler833Nessuna valutazione finora

- 6unit - Optimization Algorithm For Combined Economic and Emission Dispatch With Security ConstraintsDocumento4 pagine6unit - Optimization Algorithm For Combined Economic and Emission Dispatch With Security ConstraintsDr. B. Srinivasa Rao Professor, EEE DepartmentNessuna valutazione finora

- Full494 510806Documento13 pagineFull494 510806raj 2007Nessuna valutazione finora

- Single Cylinder Four Stroke Spark Ignition Engine - Thermodynamic Simulation ModelDocumento11 pagineSingle Cylinder Four Stroke Spark Ignition Engine - Thermodynamic Simulation Modelmishranamit2211Nessuna valutazione finora

- Economic and Emission Load Dispatch Using Cuckoo Search AlgorithmDocumento7 pagineEconomic and Emission Load Dispatch Using Cuckoo Search AlgorithmkkNessuna valutazione finora

- I Nternational Journal of Computational Engineering Research (Ijceronline - Com) Vol. 2 Issue. 7Documento6 pagineI Nternational Journal of Computational Engineering Research (Ijceronline - Com) Vol. 2 Issue. 7International Journal of computational Engineering research (IJCER)Nessuna valutazione finora

- Multi-Objective, Short-Term Hydro Thermal Scheduling Based On Two Novel Search TechniquesDocumento14 pagineMulti-Objective, Short-Term Hydro Thermal Scheduling Based On Two Novel Search TechniquesEngr Muhammad Mansoor AshrafNessuna valutazione finora

- Economic Load Dispatch Problem With Ant Lion Optimization Using Practical Constraints (#421816) - 725471Documento19 pagineEconomic Load Dispatch Problem With Ant Lion Optimization Using Practical Constraints (#421816) - 725471Mehmet YILMAZNessuna valutazione finora

- Unit Commitment and Economic Load Dispatch OptimizationDocumento42 pagineUnit Commitment and Economic Load Dispatch OptimizationSantosh ThapaNessuna valutazione finora

- Lecture 1 - Intro To Math OptimisationDocumento8 pagineLecture 1 - Intro To Math OptimisationKuknesvary PuniamurthyNessuna valutazione finora

- Multiple Objective Particle Swarm Optimization Technique For Economic Load DispatchDocumento8 pagineMultiple Objective Particle Swarm Optimization Technique For Economic Load DispatchbaalaajeeNessuna valutazione finora

- Improved Particle Swarm Optimisation For Multi-Objective Optimal Power Flow Considering The Cost, Loss, Emission and Voltage Stability IndexDocumento13 pagineImproved Particle Swarm Optimisation For Multi-Objective Optimal Power Flow Considering The Cost, Loss, Emission and Voltage Stability IndexAhmed WestministerNessuna valutazione finora

- Carbon Footprint Assessment of Low-Rank Coal-Based Acetylene SystemDocumento6 pagineCarbon Footprint Assessment of Low-Rank Coal-Based Acetylene SystemS.P.Nessuna valutazione finora

- A Direct Method For Combined Economic & Emission Dispatch (CEED)Documento4 pagineA Direct Method For Combined Economic & Emission Dispatch (CEED)erpublicationNessuna valutazione finora

- A Tank-To-wheel Analysis Tool For Energy and Emissions Studies in Road VehiclesDocumento7 pagineA Tank-To-wheel Analysis Tool For Energy and Emissions Studies in Road VehiclesMuhammad Imran KhanNessuna valutazione finora

- 56621 Điều văn bản 161021 2 10 20210514Documento11 pagine56621 Điều văn bản 161021 2 10 20210514Tường DuyNessuna valutazione finora

- Solution of Non-Convex Economic Load Dispatch Problem With Valve Point Loading Effects Using PSODocumento9 pagineSolution of Non-Convex Economic Load Dispatch Problem With Valve Point Loading Effects Using PSOTaimur KhanNessuna valutazione finora

- A Multi-Objective Optimal Power Flow Using Particle Swarm OptimizationDocumento18 pagineA Multi-Objective Optimal Power Flow Using Particle Swarm OptimizationSurya Ch VenkataNessuna valutazione finora

- Cost Co2 CaptureDocumento6 pagineCost Co2 CaptureMostafa BazriNessuna valutazione finora

- Eld26 PDFDocumento6 pagineEld26 PDFanjit mahatoNessuna valutazione finora

- A Modified Pso Based Solution Approach For Economic Load Dispatch Problem in Power SystemDocumento63 pagineA Modified Pso Based Solution Approach For Economic Load Dispatch Problem in Power SystemRaj Mike100% (1)

- Final1 Ecoquest Finalreport PDFDocumento58 pagineFinal1 Ecoquest Finalreport PDFAdlin RajNessuna valutazione finora

- Multi Objective Economic Load Dispatch Using Hybrid Fuzzy, BacterialDocumento10 pagineMulti Objective Economic Load Dispatch Using Hybrid Fuzzy, BacterialIAEME PublicationNessuna valutazione finora

- Solving Multiobjective Unit Commitment Problem To Minimize Operation Cost and Emissions Using HBMO AlgorithmDocumento6 pagineSolving Multiobjective Unit Commitment Problem To Minimize Operation Cost and Emissions Using HBMO Algorithmkanda71Nessuna valutazione finora

- E3sconf Icbt2018 01009Documento10 pagineE3sconf Icbt2018 01009Belay AyalewNessuna valutazione finora

- Fuzzified Multiobjective PSO For Optimising The Cost, Emission, Losses With Voltage Stability ConstraintsDocumento14 pagineFuzzified Multiobjective PSO For Optimising The Cost, Emission, Losses With Voltage Stability ConstraintsInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Acetone 3Documento5 pagineAcetone 3Juan Medina CollanaNessuna valutazione finora

- JJMIE-116-09 - Modified Exergoeconomic Analysis For Unit Gt14 of South Tripoli Gas Turbine Power PlantDocumento10 pagineJJMIE-116-09 - Modified Exergoeconomic Analysis For Unit Gt14 of South Tripoli Gas Turbine Power PlantElzimar FreitasNessuna valutazione finora

- Dynamic Economic Dispatch Using MPC AlgorithmDocumento7 pagineDynamic Economic Dispatch Using MPC Algorithmselaroth168Nessuna valutazione finora

- Energies 05 00355Documento16 pagineEnergies 05 00355notat80726Nessuna valutazione finora

- Lecture 7 PDFDocumento24 pagineLecture 7 PDFSubrat BarsainyaNessuna valutazione finora

- Combustion of Industrial Gas in Porous Media Burner: Hui Liu, Wenzhong Chen Benwen LiDocumento4 pagineCombustion of Industrial Gas in Porous Media Burner: Hui Liu, Wenzhong Chen Benwen LiMuhammad AwaisNessuna valutazione finora

- CFD REPORT FOR BASEMENT B2 L&T Prolofic-B-1 PDFDocumento31 pagineCFD REPORT FOR BASEMENT B2 L&T Prolofic-B-1 PDFrajarathnam.k100% (1)

- HTFF 123Documento10 pagineHTFF 123Masoud ZakeriNessuna valutazione finora

- Leonardo SPEADocumento17 pagineLeonardo SPEAMikael Mitch LanzoniNessuna valutazione finora

- Measuring Toxic Gases Using Low-Cost Electrochemical SensorsDocumento6 pagineMeasuring Toxic Gases Using Low-Cost Electrochemical SensorsIvan KraljNessuna valutazione finora

- A Multi-Objective OptimizationDocumento3 pagineA Multi-Objective OptimizationDrSakthivelNessuna valutazione finora

- Social Cost-Benefit Analysis of CC Mitigation Options in EUDocumento90 pagineSocial Cost-Benefit Analysis of CC Mitigation Options in EUHBSIE7Nessuna valutazione finora

- Assgmnt Thermal MEC551Documento9 pagineAssgmnt Thermal MEC551khazwanNessuna valutazione finora

- Journal of Power Sources: Sepehr Sanaye, Arash KatebiDocumento13 pagineJournal of Power Sources: Sepehr Sanaye, Arash KatebiVenkateswarlu VelisalaNessuna valutazione finora

- Performance and Emission Characteristics of Green Diesel Blends Containing Diethyl-Succinate and 1-OctanolDocumento6 paginePerformance and Emission Characteristics of Green Diesel Blends Containing Diethyl-Succinate and 1-OctanolIkbaalNessuna valutazione finora

- Thermo-hydrodynamic Lubrication in Hydrodynamic BearingsDa EverandThermo-hydrodynamic Lubrication in Hydrodynamic BearingsNessuna valutazione finora

- Finite Physical Dimensions Optimal Thermodynamics 1: FundamentalsDa EverandFinite Physical Dimensions Optimal Thermodynamics 1: FundamentalsNessuna valutazione finora

- Energy and Thermal Management, Air-Conditioning, and Waste Heat Utilization: 2nd ETA Conference, November 22-23, 2018, Berlin, GermanyDa EverandEnergy and Thermal Management, Air-Conditioning, and Waste Heat Utilization: 2nd ETA Conference, November 22-23, 2018, Berlin, GermanyChristine JuniorNessuna valutazione finora

- A Carrier-Based PWM Techniques Applied To A Three-Level Four-Leg Inverter For Use As A Shunt Active Power FilterDocumento6 pagineA Carrier-Based PWM Techniques Applied To A Three-Level Four-Leg Inverter For Use As A Shunt Active Power FilterZellagui EnergyNessuna valutazione finora

- 87 053 - Pages 6Documento5 pagine87 053 - Pages 6Zellagui EnergyNessuna valutazione finora

- Characteristics of The Non-Sinusoidal Coefficient of The Voltage at Node Containing A Thyristor Compensator in Presence of HarmonicsDocumento4 pagineCharacteristics of The Non-Sinusoidal Coefficient of The Voltage at Node Containing A Thyristor Compensator in Presence of HarmonicsZellagui EnergyNessuna valutazione finora

- 86 199 - Pages 5Documento5 pagine86 199 - Pages 5Zellagui EnergyNessuna valutazione finora

- Observer-Based Adaptive Fuzzy Control For SISO Nonlinear Systems Via BacksteppingDocumento5 pagineObserver-Based Adaptive Fuzzy Control For SISO Nonlinear Systems Via BacksteppingZellagui EnergyNessuna valutazione finora

- A Hybrid Optimization Algorithm (IA-PSO) For Optimal Coordination of Directional Overcurrent Relays in Meshed Power SystemsDocumento11 pagineA Hybrid Optimization Algorithm (IA-PSO) For Optimal Coordination of Directional Overcurrent Relays in Meshed Power SystemsZellagui EnergyNessuna valutazione finora

- AC Insulation Technology JJicable11 - 0030 - Final INFLUENCE OF ADDITIVES ON THE WATER TREEING IN XLPE INSULATED CABLES PDFDocumento5 pagineAC Insulation Technology JJicable11 - 0030 - Final INFLUENCE OF ADDITIVES ON THE WATER TREEING IN XLPE INSULATED CABLES PDFZellagui EnergyNessuna valutazione finora

- Condition Assesment 2015 D10 2 LIFE CYCLE ASSESSMENT MEDIUM VOLTAGE FOR FRENCH MARKET PDFDocumento5 pagineCondition Assesment 2015 D10 2 LIFE CYCLE ASSESSMENT MEDIUM VOLTAGE FOR FRENCH MARKET PDFZellagui EnergyNessuna valutazione finora

- Optimum Coordination of Directional Overcurrent Relays Using The Hybrid GA-NLP ApproachDocumento11 pagineOptimum Coordination of Directional Overcurrent Relays Using The Hybrid GA-NLP ApproachZellagui EnergyNessuna valutazione finora

- Observer-Based Adaptive Fuzzy Control For SISO Nonlinear Systems Via BacksteppingDocumento5 pagineObserver-Based Adaptive Fuzzy Control For SISO Nonlinear Systems Via BacksteppingZellagui EnergyNessuna valutazione finora

- Optimal Overcurrent Relay Coordination Using Artificial Bees Colony AlgorithmDocumento4 pagineOptimal Overcurrent Relay Coordination Using Artificial Bees Colony AlgorithmZellagui EnergyNessuna valutazione finora

- Release NotesDocumento2 pagineRelease NoteswilmanzitoNessuna valutazione finora

- Cara Tatahan Perlindungan OC Dan EFR Papan Suis Utama PDFDocumento15 pagineCara Tatahan Perlindungan OC Dan EFR Papan Suis Utama PDFMuhrif MaharoffNessuna valutazione finora

- Paper Id276Documento8 paginePaper Id276Zellagui EnergyNessuna valutazione finora

- Lecture - Distribution Protection Overview (P. 1)Documento60 pagineLecture - Distribution Protection Overview (P. 1)Zellagui EnergyNessuna valutazione finora

- ABB DA Section 8.2Documento28 pagineABB DA Section 8.2ronald_chan_2Nessuna valutazione finora

- Icee2015 Paper Id240Documento5 pagineIcee2015 Paper Id240Zellagui EnergyNessuna valutazione finora

- Paper Id276Documento8 paginePaper Id276Zellagui EnergyNessuna valutazione finora

- Paper ID198 PDFDocumento6 paginePaper ID198 PDFZellagui EnergyNessuna valutazione finora

- Id 271 PDFDocumento4 pagineId 271 PDFZellagui EnergyNessuna valutazione finora

- Id 285Documento4 pagineId 285Zellagui EnergyNessuna valutazione finora

- ICEE2015 Paper ID292 PDFDocumento5 pagineICEE2015 Paper ID292 PDFZellagui EnergyNessuna valutazione finora

- Id 86Documento5 pagineId 86Zellagui EnergyNessuna valutazione finora

- Icee2015 Paper Id346Documento6 pagineIcee2015 Paper Id346Zellagui EnergyNessuna valutazione finora

- Id 167Documento5 pagineId 167Zellagui EnergyNessuna valutazione finora

- Id 311Documento4 pagineId 311Zellagui EnergyNessuna valutazione finora

- GSR (ROAD) 2015Documento74 pagineGSR (ROAD) 2015Gautam RaiNessuna valutazione finora

- PunchesDocumento25 paginePunchesJhoanne NagutomNessuna valutazione finora

- Heat Affected Zone: Page 1 of 5Documento5 pagineHeat Affected Zone: Page 1 of 5sujkubvsNessuna valutazione finora

- Dasar Genetik GandumDocumento282 pagineDasar Genetik GandumAlekkyNessuna valutazione finora

- URINALYSISDocumento6 pagineURINALYSISmaeNessuna valutazione finora

- Week 2 National Income-2Documento41 pagineWeek 2 National Income-2elijah thonNessuna valutazione finora

- Confined Space Planning ChecklistDocumento3 pagineConfined Space Planning ChecklistKB100% (1)

- Top Sellers Fall Protection Catalogue 2020 ENDocumento44 pagineTop Sellers Fall Protection Catalogue 2020 ENtcNessuna valutazione finora

- Properties of X-Rays and Gamma RaysDocumento13 pagineProperties of X-Rays and Gamma RaysjishnusajiNessuna valutazione finora

- Veterinary Medicines ReportDocumento28 pagineVeterinary Medicines Reportvikram chhabraNessuna valutazione finora

- Forensic Science Project Group B5518Documento5 pagineForensic Science Project Group B5518Anchit JassalNessuna valutazione finora

- Navi Cure prospectus summaryDocumento50 pagineNavi Cure prospectus summaryGaurav SrivastavaNessuna valutazione finora

- MBBS Final Part-I (Winter Session) Time Table (Jan 2023)Documento1 paginaMBBS Final Part-I (Winter Session) Time Table (Jan 2023)crystal mindNessuna valutazione finora

- UntitledDocumento77 pagineUntitledVedranL84Nessuna valutazione finora

- Developmental Psychology - Socioemotional Development in Middle & Late ChildhoodDocumento56 pagineDevelopmental Psychology - Socioemotional Development in Middle & Late ChildhoodAlyNessuna valutazione finora

- Proforma For Iphs Facility Survey of SCDocumento6 pagineProforma For Iphs Facility Survey of SCSandip PatilNessuna valutazione finora

- Lembar Latihan - P1 - PD MitraDocumento123 pagineLembar Latihan - P1 - PD MitratiengcityNessuna valutazione finora

- Report Information From Proquest: February 24 2014 06:18Documento19 pagineReport Information From Proquest: February 24 2014 06:18Emma Elena StroeNessuna valutazione finora

- Cognitive Development of Infants and ToddlersDocumento1 paginaCognitive Development of Infants and ToddlersCyrell Rondina100% (2)

- Humiseal Thinner 73 MSDSDocumento3 pagineHumiseal Thinner 73 MSDSibnu Groho Herry sampurnoNessuna valutazione finora

- AHG-003 Guideline On GHG Accounting and Reporting 1junDocumento16 pagineAHG-003 Guideline On GHG Accounting and Reporting 1junbagjabuktiNessuna valutazione finora