Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

KTMMC 0550 Us PDF

Caricato da

ThirukkumaranBalasubramanianTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

KTMMC 0550 Us PDF

Caricato da

ThirukkumaranBalasubramanianCopyright:

Formati disponibili

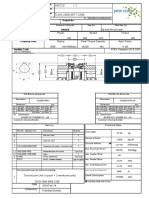

KTM Ball Valves

KTM manufactures the most complete line of quality ball valves,

and can provide the exact ball valves and actuators to meet the

most demanding application requirements.

KTM markets a complete line of ball

valves for the most demanding

application requirements of the oil and

gas, power, chemical, petrochemical

and other process industries. Types

include floating and trunnion, 3-way,

diverting and control along with premier

specialty products with unique features.

They feature several proprietary seat

designs, and offer a wide range of

performance; the E-seat, PTFE/PFE

copolymer, Gratite high temperature

seat with tight shut-off and Metaltite

metal seat.

KTM has developed a reputation for

high quality, dependable valves backed

by excellent service. Each valve is

precision manufactured from foundry

casting to final assembly.

Special options are available, including

stem extensions, body coating and

double block and bleed. Testing is also

available for chlorine service, oxygen

service, vacuum service, liquid

penetrant, magnetic particle, ultra-sonic

and x-ray.

Advantages

The most complete line of ball valves

in either a manual or an automated

mode of operation.

Standard, off-the-shelf, special and

custom-made valves.

Mill Test Reports (MTRs) available on

all valves.

Material traceability.

Continuing source guarantees.

Product warranties.

Strategically located sales, service

and distribution centers provide rapid

delivery, service and repair.

Qualified service and engineering

support.

Flow Control

Floating/Trunnion

1/2" to 30"

Size Range:

ASME Class:

150 and 2500

Temperature Rating: -328F to 932F

3-way

1/2" to 14"

Size Range:

ASME Class:

150, 300, and 600

3-way Patterns:

L, T, and Y

Temperature Rating: -20F to 932F

Single V, VS11

Size Range:

ASME Class:

Control Valve Range:

Temperature Rating:

1" to 20"

150 and 300

100:1 rangeability

-20F to 518F

Dual V

Size Range:

ASME Class:

Control Valve Range:

Temperature Rating:

1" to 8"

150 and 300

250:1

-20F to 518F

KTM is either a trademark or registered trademark of Tyco International Services AG or its affiliates in

the United States and/or other countries. All other brand names, product names, or trademarks belong

to their respective holders.

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550-US-0906

KTM Ball Valves

Contents

Product Offering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

SB11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Omni II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-23

Metal Seated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-26

Energy Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-28

3-Way . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-37

Low Temperature and

Cryogenic Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38-44

Process, Production, Floating and Trunnion Valves . . . . . . . . . . . . . . . . . . . . . 45-52

Single V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-56

VS Rotary Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57-62

Dual V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63-66

Engineering Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67-79

How to Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80-81

Standards and Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

KTM Ball Valves

Experience and Reputation

For over 60 years, we have developed a

reputation for high quality, dependable

valves and outstanding service for our

customers.

Special Options and

Testings are Available

Options

Stem extension

Body coating

Totally Integrated

Manufacturing Facility

You can count on KTM ball valves for

lasting, dependable service. Each valve

is precision manufactured from foundry

casting to final assembly. By controlling

every component of manufacturing, we

maintain total quality control.

Dependable Quality

and Performance

In addition, unique design features help

add to the life and performance of our

valves, such as an incredibly high degree

of accuracy that is machined into every

ball a sphericity of 0.0008" and a

4 RMS finish.

Double block and bleed

Tests

Chlorine service

Oxygen service

Vacuum service

Liquid penetrant

Magnetic particle

Ultra-sonic

X-ray

Process and Quality Control

(S.P.Q.C.)

KTM is committed to Statistical Process

Quality Control. Products are manufactured

utilizing S.P.Q.C. as a powerful tool for

producing quality products.

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

3

KTM Ball Valves

SB11

(Pages 9-12)

Omni II

(Pages 13-21)

Model Number

SB11

EB100/EB800/EB100-PL

Type

Bore

Pressure Class

Split Body

Floating Ball

Bi-directional

RF Flanged Ends

Full

ANSI 150 lb

Size Range

1/2"

Body Material

Carbon Steel

316 SS

Trim Options

316 SS

Split Body

Floating Ball

Bi-directional

RF Flanged Ends

Full and Reduced

ANSI 150 lb

ANSI 300 lb

1/2" to 8" (Full)

6" to 10" (Reduced)

Carbon Steel

316 SS

304 SS

Alloy 20

Monel

Special Alloys

316 SS

304 SS

Monel

Alloy 20

Hastelloy C

Special Alloys

Maximum

Working

Pressure

Temperature

Range

Seat Options

Features

to 8"

285 psi

285 psi/720 psi

-20F up to 420F

-50F up to 932F

E

Anti-static Electricity

Blow-out Proof Stem

Cavity Relief

Fire-safe

ISO Integral Mounting Flange

Locking Device

Positive Flow Stem Indicator

Positive Shut-off

NACE MR01.75

E, K, F, M, T

Anti-static Electricity

Blow-out Proof Stem

Cavity Relief

Cold-flow Resistance Seat

Fire-safe

Fugitive Emission Control Device

ISO Integral Mounting Flange

Locking Device

Positive Flow Stem Indicator

Positive Shut-off

NACE MR01.75

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

4

KTM Ball Valves

Metal Seated

(Pages 24-26)

Floating

Energy Process

(Pages 27-28)

Trunnion

Model Number EB100/EO100

Type

Split Body

Floating Ball

RF Flanged Ends

Class V Seat Leakage

Bi-directional

Bore

Full

Pressure Class ANSI 150 lb

ANSI 300 lb

ANSI 600 lb (Uni-directional)

1/2" to 8" (150/300)

Size Range

1/2" to 11/2" (600)

Body Material Carbon Steel

316 SS

Special Alloys

Trim Options

316 SS/329 SS

Monel

Hastelloy C

Special Alloys

Maximum

Working

285 psi/720 psi/1440 psi

Pressure

Temperature

-20F up to 932F

Range

Seat Options

M

Features

Anti-static Electricity

Blow-out Proof Stem

Cavity Relief

Fire-safe

Fugitive Emission Control Device

Locking Device

Positive Flow Stem Indicator

EO1200

Split Body

Trunnion

Bi-directional

RF Flanged Ends

Class 5Seat Leakage

Full

ANSI 150 lb

ANSI 300 lb

ANSI 600 lb

2" to 20" (150/300)

2" to 18" (600)

Carbon Steel

316 SS

EB100/EO100

Split Body

Floating Ball

Bi-directional

SE/SW Ends

Full

ANSI 300 lb

ANSI 600 lb (also available in Flange

End, sizes 1/2" to 4")

1/2" to 2"

316 SS/329 SS

Monel

Hastelloy C

Special Alloys

Carbon Steel

316 SS

Special Alloys

316 SS/329 SS

Monel

Hastelloy C

Special Alloys

285 psi/720 psi/1440 psi

285 psi/720 psi/1440 psi

-20F up to 932F

-50F up to 932F

M

Anti-static Electricity

Blow-out Proof Stem

Cavity Relief

Fire-safe

Fugitive Emission Control Device

Positive Flow Stem Indicator

Positive Flow Stem Indicator

F

Anti-static Electricity

Blow-out Proof Stem

Fire-safe

Fugitive Emission Control Device

Locking Device

Positive Shut-off

NACE MR01.75

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

5

KTM Ball Valves

3-Way

(Pages 29-37)

Model Number

EO3100/EO3800

E3200/E3900

EB100/EO100/EO1200

Type

3-Way, 2-Seats

Floating Ball

L Port

RF Flanged Ends

Trunnion Available

Full and Reduced

ANSI 150 lb

ANSI 300 lb

ANSI 600 lb

11/2" to 8" (Full)

6" to 10" (Reduced)

10" to 12" (Trunnion)

Carbon Steel

316 SS

Special Alloys

316 SS

Monel

Hastelloy C

Special Alloys

3-Way, 4-Seats

Floating Ball

L Port

T Port

Split Body

Floating Ball

Trunnion

Full and Reduced

ANSI 150 lb (E3900 only)

ANSI 300 lb (E3200)

ANSI 600 lb

1/2" to 8" (Full)

6" to 8" (Reduced)

Full

ANSI 150 lb

ANSI 300 lb

ANSI 600 lb

1/2 to 30

Carbon Steel

316 SS

Carbon Steel (LCC, LCB)

316 SS

316 SS

Monel

Hastelloy C

Special Alloys

304 SS

316 SS

285 psi/720 psi/1440 psi

285 psi/720 psi/1440 psi

285 psi/720 psi/1440 psi

-94F up to 550 (932F)

-20F up to 300F

-196F to -320F

E, G, K, T (F)

Anti-static Electricity

Blow-out Proof Stem

Cavity Relief

Fugitive Emission Control Device

Locking Device

Positive Flow Stem Indicator

Positive Shut-off

NACE MR01.75

T, G, E

Anti-static Electricity

Blow-out Proof Stem

Cavity Relief

Fugitive Emission Control Device

Locking Device

Positive Flow Stem Indicator

Positive Shut-off

NACE MR01.75

E, T, H

Anti-static Electricity

Block and Bleed

Blow-out Proof Stem

Cavity Relief

Fire-safe

Fugitive Emission Control Device

NACE MR01.75

Shell MESC 77/306

BS 6755, BS 6364

(valves for cryogenic service)

Bore

Pressure Class

Size Range

Body Material

Trim Options

Maximum

Working

Pressure

Temperature

Range

Seat Options

Features

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

6

KTM Ball Valves

Low Temperature and

Cryogenic Valves

(Pages 38-44)

Process, Production, Floating and

Trunnion Valves

(Pages 45-52)

EB100/EO100/EO1200

Split Body

Floating Ball

Trunnion

T Port

Full

ANSI 150 lb

ANSI 300 lb

ANSI 600 lb

Model Number EO1200/EO8200

Type

Split Body

Trunnion

Bi-directional

RF/RTJ/BW

Bore

Full and Reduced

Pressure Class ANSI 150 lb

ANSI 300 lb

ANSI 600 lb

ANSI 900 lb

ANSI 1500 lb

Size Range

1/2"

Size Range

Body Material

Carbon Steel (LCC, LCB) Body Material

316 SS

304 SS

Trim Options

316 SS

Model Number

Type

Bore

Pressure Class

Trim Options

Maximum

Working

Pressure

Temperature

Range

Seat Options

Features

to 30"

Maximum

285 psi/720 psi/1440 psi Working

Pressure

Temperature

-196F to -320F

Range

E, T, H

Seat Options

Anti-static Electricity

Features

Block and Bleed

Blow-out Proof Stem

Cavity Relief

Fire-safe

Fugitive Emission Control Device

NACE MR01.75

Shell MESC 77/306

BS 6755, BS 6364

(valves for cryogenic service)

2" to 20" (150/300)

2" to 26" (600)

11/2" to 20" (900/1500)

Carbon Steel

316 SS

316 SS

ENP

HCR

EO1100/EO8100/EO100

Split Body

Trunnion and Floating Ball

Bi-directional

RF/RTJ/BW

Full and Reduced

ANSI 150 lb

ANSI 300 lb

ANSI 600 lb

ANSI 900 lb

ANSI 1500 lb

ANSI 2500 lb

1/2" to 11/2" (600, Floating)

2" to 20" (600)

1/2" to 1" (900/1500, Floating)

11/2" to 20" (900/1500)

1/2" to 8" (2500)

2" to 30" (150/300)

Carbon Steel

316 SS

Carbon Steel

316 SS

ENP

HCR

285 psi/720 psi

1440 psi/2220 psi/3600 psi

285 psi/720 psi/1440 psi

2220 psi/3600 psi/6000 psi

-20F up to 500F

-20F up to 300F

H, K

Anti-static Electricity

Block and Bleed

Blow-out Proof Stem

Cavity Relief

Fire-safe

Fugitive Emission Control Device

Positive Flow Stem Indicator

Positive Shut-off

NACE MR01.75

H

Anti-static Electricity

Block and Bleed

Blow-out Proof Stem

Cavity Relief

Fire-safe

Fugitive Emission Control Device

Positive Flow Stem Indicator

Positive Shut-off

NACE MR01.75

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

7

KTM Ball Valves

Single V

(Pages 53-56)

Dual V

(Pages 63-66)

Model Number WO400/WO600/VS Type

WA Series

Type

One-Piece Body

Trunnion

Uni-directional

RF Flanged Ends/Wafer Ends

Class V Seat Leakage

Split Body

Trunnion

Uni-directional

RF Flanged Ends

Class II, IV Seat Leakage

VS Type - ISA S75.4

Bore

Full and Reduced

Pressure Class ANSI 150 lb

ANSI 300 lb

ANSI 600 lb

ISA

Size Range

1" to 20"

Body Material Carbon Steel

316 SS

Trim Options

316 SS/HCr

316 SS Stellited

Maximum

Working

285 psi/720 psi/1440 psi

Pressure

Temperature

-20F up to 482F

Range

Seat Options

L, S

Features

Locking Device

Positive Flow Stem Indicator

NACE MR01.75

Positive Flow Stem Indicator

NACE MR01.75

Copyright 2009 Tyco Flow Control. All rights reserved.

Reduced

ANSI 150 lb

ANSI 300 lb

1" to 8"

316 SS

316 SS/HCr

275 psi/720 psi

-20F up to 518F

M (316 SS Stellited)

Fugitive Emission Control Device

ISO Integral Mounting Flange

Locking Device

KTMMC-0550

8

KTM Ball Valves

SB11 ASME Floating Ball Valve, Cost-Effective, Two-Piece Split Body

Features

Designed and manufactured to major

international standards.

Designed for zero leakage with

standard E-seat technology.

Pure white E-seat seal helps relieve

concern over product contamination

and possible popcorning in reactive

monomer applications.

Anti-cold flow-integral seat lip

designed to eliminate seat

deformation and cold flow.

Fire-safe tested to API 607 4th Edition.

Secondary fire-safe metal-to-metal

seat is standard.

Blow-out proof stem.

Static electricity grounding device.

CE marking to PED 97/23/EC.

ISO 5211 mounting pad.

SealMaster technology on packing

area to meet most fugitive emission

requirements.

Low operating torque for ease of

operation and reduced actuator cost.

Automatic cavity pressure relief.

Special Options

Stem extensions.

Special trim configurations for

corrosive applications.

Special alloy body materials available

upon request.

General Applications

Standards

Pulp and paper

API 598

Chemical

ANSI B16.5, B16.10 and B16.34

Reactive monomers

Fire-safe approved, API 607 4th

Edition

Oil and gas productions

Fire-safe and flammables

CE marking to PED 97/23/EC

Food and beverage

Steam

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

9

KTM Ball Valves

SB11 ASME Floating Ball Valve, Cost-Effective, Two-Piece Split Body

Handle for valve size

21/2" to 8" [65 to 200 mm]

20

24

19

15

21

17

22

23

Handle for valve size

1/2" to 2" [15 to 50 mm]

15

17

14

23

13

12

11

1

7

7a

18

10

9

6

5

2

4

16

Parts and Materials

No. Part

Materials

Stainless Steel Body

WCB Body

1

2

3

4

5

61

7

7a

8

9

101

111

12

13

14

15

16

17

18

19

20

21

22

23

24

A351 Gr. CF8M

A351 Gr. CF8M

A351 Gr. CF8M

A 276 Type 316

PTFE/PFA Copolymer

PTFE

A 193 Gr. B8

A 194 Gr. 8

50% SS/ 50% PTFE

SUS 316

PTFE/ PFA Copolymer

PTFE

PEEK

SUS 304

SUS 301

SUS 304

SUS 304

SUS 304

SUS 304

SUS 304

Vinyl

SGP Zn Plating

CF8 (21/2" to 4")

SUS 304

SUS 304

Body

Cap

Ball

Stem

Seat

Body seal

Stud

Nut

Lower tost washer

Compress ring

Upper tost washer

V-ring stem packing

Tost washer

Gland

Belleville washer

Stem nut

Static ball

Lock saddle

Stop bolt

Handle (1/2" to 2")

Handle sleeve (1/2" to 2")

Handle (21/2" to 8")

Handle adapter (21/2" to 8")

Triangle stopper

Bolt (21/2" to 8")

Copyright 2009 Tyco Flow Control. All rights reserved.

Notes:Notes

Qty

A216 Gr. WCB

A216 Gr. WCB

A351 Gr. CF8M

A 276 Type 316

PTFE/PFA Copolymer

PTFE

A 193 Gr. B7

A 194 Gr. 2H

50% SS/ 50% PTFE

SUS 316

PTFE/ PFA Copolymer

PTFE

PEEK

SUS 304

SUS 301

SUS 304

SUS 304

SUS 304

SUS 304

SUS 304

Vinyl

SGP Zn Plating

A536 (6" to 8")

SUS 304

SUS 304

1

1

1

1

2

1

4 - 12

4 - 12

1

1

1

1 set

1

1

2

1-2

1

1

1

1

1

1

1

1

1

KTMMC-0550

10

1. Option For fire tested to API 607 4th Edition,

packing material will be changed to Graphite.

2. Other body materials available.

KTM Ball Valves

SB11 ASME Floating Ball Valve, Cost-Effective, Two-Piece Split Body

D:

C:

g:

f:

d:

T:

N:

m:

Flange outside diameter

Bolt pitch circle

Raised face diameter

Raised face height

Bore diameter

Flange thickness

Number of bolts

Bolt hole diameter

U

H2

H1

H3

d g C D

SW

f

N-m

1/2"

21/2" to 8" [65 - 200 mm]

to 2" [15 - 50 mm]

Flange End

Top Works

ANSI Class 150 Dimensions

Valve

Size

1/2"

3/4"

1"

11/2"

2"

21/2"

3"

4"

6"

8"

d

0.59

0.79

1.00

1.50

2.00

2.50

3.00

4.00

6.00

8.00

L

4.25

4.62

5.00

6.50

7.00

7.50

8.00

9.00

15.50

18.00

H

3.54

3.68

4.09

4.90

5.24

6.38

6.77

7.76

11.06

12.48

W

4.92

4.92

5.94

7.24

7.24

19.49

19.49

23.43

31.50

43.31

3.50

3.86

4.25

5.00

5.99

7.01

7.48

9.02

10.98

13.50

2.38

2.76

3.13

3.88

4.74

5.49

6.00

7.50

9.51

11.75

H1

H2

H3

SW

ISO

Wt.

Lbs.

1.38

1.69

2.01

2.87

3.62

4.13

5.00

6.18

8.50

10.63

0.06

0.06

0.06

0.06

0.06

0.06

0.06

0.06

0.06

0.06

0.44

0.44

0.44

0.56

0.63

0.69

0.75

0.94

1.00

1.13

4

4

4

4

4

4

4

8

8

8

0.63

0.63

0.63

0.63

0.75

0.75

0.75

0.75

0.87

0.87

0.89

0.87

0.93

1.06

1.06

1.81

1.81

2.05

2.68

2.68

0.47

0.49

0.51

0.55

0.55

0.96

0.98

1.18

1.61

1.61

0.08

0.08

0.12

0.12

0.12

0.12

0.12

0.12

0.12

0.12

0.25

0.25

0.31

0.37

0.37

0.67

0.67

0.67

0.91

0.91

1.18

1.18

1.38

2.17

2.17

2.76

2.76

2.76

3.35

3.35

F04

F04

F05

F07

F07

F10

F10

F10

F12

F12

M5

4

M5

7

M6

9

M8

15

M8

18

M10 31

M10 40

M10 60

M12 165

M12 282

35

43

51

73

92

105

127

157

216

270

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

11.2

11.2

11.2

14.3

15.9

17.5

19.1

23.9

25.4

28.6

4

4

4

4

4

4

4

8

8

8

16

16

16

16

19

19

19

19

22

22

22.5

22.0

23.5

27.0

27.0

46.0

46.0

52.0

68.0

68.0

12.0

12.5

13.0

14.0

14.0

24.5

25.0

30.0

41.0

41.0

2

2

3

3

3

3

3

3

3

3

30

30

35

55

55

70

70

70

85

85

F04

F04

F05

F07

F07

F10

F10

F10

F12

F12

M5

2

M5

3

M6

4

M8

7

M8

8

M10 14

M10 18

M10 27

M12 75

M12 128

ANSI Class 150 Dimensions [mm, kg]

15

20

25

38

50

64

76

100

150

201

108

117

127

165

178

190

203

229

394

457

90.0

93.5

104.0

124.5

133.0

162.0

172.0

197.0

280.0

315.0

125

125

151

184

184

495

495

595

800

1100

89

98

108

127

152

178

190

229

279

343

60.5

70.0

79.5

98.5

120.5

139.5

152.5

190.5

241.5

298.5

6.3

6.3

8.0

9.5

9.5

17.0

17.0

17.0

23.0

23.0

Pressure/Temperature Ratings

868

[6]

723

[5]

ANSI Class 300 Body Rating

Valve Size:

1/2"

Pressure, psi [MPa]

15

20

25

40

50

65

80

100

150

200

to 3/4" [15 to 20 mm]

579

[4]

1" to 21/2" [25 to 60 mm]

434

[3]

289

[2]

3" to 4" [80 to 100 mm]

ANSI Class 150 Body Rating

6" [150 mm]

145

[1]

8" [200 mm]

0

-20

[-29]

32

[0]

104

[40]

176

[80]

249

[120]

320

[160]

392

[200]

464

[240]

Temperature, F [C]

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

11

KTM Ball Valves

SB11 ASME Floating Ball Valve, Cost-Effective, Two-Piece Split Body

Stem Sealing

SealMaster

Our extremely high cycle stem sealing design is accomplished

by a double sealing system. The high performance of KTM

ball valves is mainly due to the unique SealMaster stem seal

arrangement, which provides primary sealing. It has been

specially designed and constructed to prevent line fluid

permeation and resultant leakage. On top of this arrangement

are multiple layers of V-ring stem packing, which act as

secondary sealing. A set of Belleville washers automatically

and constantly compresses the seals to adjust for wear,

pressure and temperature fluctuations. Every KTM ball valve

is a stalwart barrier against fugitive emissions.

V-ring

Stem Packing

Belleville

Washers

Stem Sealing Details

4

1

A

5

View 1

View 2

View 3

View 4

View 5

View 6

C

6

3

Main Features of SealMaster

Patented Stem Seal Arrangement

Multiple sealings up to 6 areas (see Views 1-6) for

pressure and high vacuum.

Encapsulated Static sealing achieved on upper

tost seal.

Constant sealing force reflects to stem (see arrows

A) and makes stem primary sealing Positive.

Excellent wear resistance on lower tost seal (50% SS

filled PTFE), 1000 times greater than that of PTFE to

prolong the compensation of Belleville washers.

Copyright 2009 Tyco Flow Control. All rights reserved.

The live-loaded SealMaster is a combination of three

components: (A) a cup and cone PFA/TFE upper tost seal;

(B) a cup and cone sintered stainless steel 316 center load ring,

and (C) a flat stainless steel/TFE lower tost seal. When tightened,

the live loaded stem pulls up, compressing the stem tost seal.

As this happens, material from upper and lower tost seal

extrudes between stem and body enclosures (see Views 1-6).

The surfaces between the bottom of the lower tost seal and top

of the stem flange are smooth and all rotation occurs between

these two surfaces, leaving the stem tost seal static to create

the best possible seal. As rotation continues, components bed in

and keep seal performance constant with usage. As operating

wear takes place, the stem tost seal can be re-tightened to

recommended torques multiple times.

KTMMC-0550

12

KTM Ball Valves

Omni II Split Body Floating Ball Valve - Full and Reduced Bore

The KTM Omni II is available in three

basic style of seats soft, hard and

metal-to-metal. Each offers a range of

performance suitable to many

applications.

Seat Temperature Range

E-seat PTFE/PFA

copolymer (standard) -148F to 500F

F-Gratite hard seat

-50F to 932F

K-PEEK

-20F to 550F

M-Metal seat

-20F to 932F

Features

Superior valve design at a competitive

price.

Fugitive emissions control for

flammable and non-flammable

applications.

Machined ISO actuator mounting pad.

Designed for zero leakage with

standard E-seat.

Pure white E-seat seal helps relieve

concern over product contamination.

Positive alignment of split body.

Fire-safe design tested to API 607

4th Edition.

Secondary fire-safe metal-to-metal

seat is standard.

Blow-out proof stem.

Static electricity grounding device.

Sphericity tolerance of the balls,

0.0008", and a 4 RMS surface

finish are unsurpassed.

Reinforced PTFE bearing and packing

rings reduce friction.

Lower operating torque for ease of

operation and reduced actuator cost.

Special Options

Special Tests

Stem extension

Liquid penetrant

Special body coatings

Magnetic-particle

Can be outfitted for cryogenic,

chlorine, oxygen and vacuum

services

Ultra-sonic

General Applications

Positive position indication.

Pulp and paper

Meets NACE MR01.75 for sulfide

cracking resistance.

Reactive monomers

Oil and gas production

Locking device capable.

Steam

Bi-directional shut-off.

Hot gases

Toxic and lethal

Fire-safe and flammables

X-ray

Technical Data

Size range: EB100 Full bore 1/2" to 8"

EB800 Reduced bore

6" to 10"

Standards: API 6D and 598

ANSI B16.5, B16.10 and

B16.34

Fire-safe approved API 607

4th Edition, EXES 3-14-1-2A

BS6755 Part 2

BS5351

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

13

KTM Ball Valves

Omni II Split Body Floating Ball Valve - Full and Reduced Bore

Features

ISO5211 Actuator Mounting

Fugitive Emissions Control

Machined automation pad allows

precise mounting of actuator; mounting

bolts independent from stem-packing

gland bolts. Exact alignment reduces

torque requirements and helps prevent

out-of-line wear.

Multiple layers of adjustable

PTFE Chevron packing rings

for non-flammable service,

and Soft Carbon braided and

die-formed for flammable service.

Live Loaded Seals

Radial Tost Bearings

Belleville washer keeps constant

force on stem-seal packing for seal

integrity and extended valve life.

Radial loading absorbed, and friction

from axial stem loading reduced.

Dual tost bearings support stem

for extended cycle life and superior

thermal characteristics.

Blowout-proof Stem and

Primary Stem Seal

Stem shoulder is an integral part

of the stem, retained internally to

help prevent stem blowout from

pressure in body cavity. Primary

stem seal prevents leakage to

atmosphere, also serves as

low-torque bearing.

Precise, Smooth Ball

Ball sphericity and surface finish

are key factors in valve life,

pressure-holding capability,

and operating torque. KTM ball

specifications are unmatched:

Sphericity : to 0.0008" and

surface finish 4 microinches RMS.

Cast Bleed-port Boss

Provisions for drain bleed port if

desired. (not shown)

Anti-static Grounding

Retained wire-ring provides positive

ground for use with volatile or

flammable liquids. (not shown)

Rigid Split Body

Designed with extra bolts to assure

positive alignment and maximum

protection against bending stresses

in the piping and forces produced by

thermal distortion; seal is fire-safe

metal-to-metal.

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

14

KTM Ball Valves

Omni II Split Body Floating Ball Valve - Full and Reduced Bore

Standard Primary Containment Seals

Fugitive Emission Control

For flammable services

For non-flammable services

Fire-safe tested per API 607 4th

Edition/EXES 3-14-1-2A. Braided Soft

Carbon for upper and lower rows,

die-formed Soft Carbon for middle seal.

Fire-safe design with multi-layered,

adjustable Chevron packing rings.

Standard bonnet

Optional Secondary Containment Seals

Fugitive Emission Control Toxic and Lethal Applications

For flammable services

For non-flammable services

Double packing gland elastomer seal

and lantern ring.

Double packing gland elastomer seal

and lantern ring.

Extended bonnet

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

15

KTM Ball Valves

Omni II Split Body Floating Ball Valve - Full and Reduced Bore

Seat Design Selection

The Omni II is available in three basic styles of seats soft, hard and metal, each

offering a range of performance suitable to many applications.

Soft Seat

Choose from three soft seat materials:

The standard E-seat PTFE/PFA

copolymer, PEEK and PTFE. Each type

of seat is retained in the same manner,

with the valve body machined with a

protective lip designed to eliminate seat

deformation and cold flow. This same

lip acts as a secondary back-up seal,

which forms a metal-to-metal contact in

the event the primary soft seal is

destroyed in a fire.

The E-seat offers process purity,

strength, integrity, low permeability

and high resiliency. It is composed of

a unique molecularly enhanced

copolymer of PTFE and PFA. It offers

a full range of properties formerly

requiring two separate materials. The

E-seat provides pressure and

temperature capabilities previously

available only with glass or carbon

fiber-reinforced PTFE. In hightemperature operations, the seat

remains white, eliminating the risk of

color contamination associated with

seats made from darker reinforced

materials. The E-seat is excellent on a

wide variety of applications but is

particularly recommended for use on

styrene and butadiene, where low

permeability is a performance factor;

and on low-pressure steam, where

flaking of virgin PTFE is a problem. It

s also recommended for use on food

and beverage, pharmaceutical and

biotech, paper, clean gas and any other

applications where product purity and

the lack of foreign fillers are critical to

success.

Burned

Seat

Seat

Body

Body

Ball

Lip

Ball

Lip

Fire-safe Seat Design

The Popcorn Factor

The photographs show a virgin PTFE

seat after attack by reactive monomers

(in this case, styrene). The materials

molecular matrix has been penetrated

by uninhibited monomers due to vapor

pressure, allowing a polymeric reaction

to take place. Commonly called

popcorn polymerization, this reaction

can totally destroy seat material.

In the second photograph, you can see

the results of a field test of the E-seat

copolymer by KTM. Using butadiene,

generally considered the worst-case

scenario due to its small molecular size,

the test ran for two years at 120 psi and

180F. The seats experienced minimum

distortion and, after the two-year period,

did not leak in service. Pressure tests

after removal, at 1.1 times design, also

showed no seat leakage. The photo

shows two of the seats tested and for

comparison, a new seat is shown in the

foreground.

Pressure/Temperature Ratings

900

800

300 lb

700

Pressure, psi

KTMs PTFE/PFA copolymer E-seat

offers the protection from color

contamination as with virgin PTFE

seats but, unlike virgin PTFE, it offers

equal or better strength, integrity,

permeability and resiliency previously

associated only with reinforced PTFE.

Rating

600

500

400

300

150 lb

200

t

ea

-S

G

at

at

se

se

EFE

PT

This graph shows pressure and

temperature ratings of the three seat

materials with a full bore of 3 and 4

inches and a reduced bore of 4 inches.

The E-seat provides characteristics

identical to the carbon-filled material,

while retaining its pure white color. The

same is true at full bores ranging from

1/2" to 8" and reduced bores of 6" to 10".

1000

Ratin

g

100

0

0

100

200

300

Temperature (F)

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

16

400

500

KTM Ball Valves

Omni II Split Body Floating Ball Valve - Full and Reduced Bore

Seat Design Selection

Metaltite Metal Seat

KTM utilizes proprietary processes with special lapping technologies, enabling us to

provide a higher quality product with a superior level of performance. Suitable for a

temperature range from -50F to 932F, the Metaltite metal seat is bi-directional and

provides a high performance solution to many difficult applications. Precision lapping

of the ball-to-seat result in superior interfacing and a tight shut-off conforming to ANSI

FCI 70-2 Class V and Class VI. Available with two different ball coatings: Hard chrome

or Nickel alloy overlay. Durable stellited stainless seats are highly corrosion and

erosion resistant. RTFE or soft carbon stem seals are available.

For complete information on Metal Seat, see page 26.

Spring

Ball

Gasket

Ball

Seat

Seat

Body

Cap

Body

Hard Gratite Seat

Cushion

Seal

Ball

Gasket

Seat

A proprietary product for high-temperature, high-pressure, flammable and corrosive

critical-process applications, the KTM Gratite seat offers superior performance and

reliability. Patented (U.S. Patent 4,269,391), it is designed to operate within a

temperature range from -50F to 932F. Gratite is a bonded composite of hard

graphite material. The cushion seal provides resiliency during thermal expansioncontraction. The result is a seat with physical properties that are far superior to

conventional ball valve seats of carbon graphite construction.

More economical than Stellite.

High resistance to thermal shock.

Body

For complete information on

Gratite seat, see page 20.

-50F to 932F

Wide Temperature Range

Pressure/Temperature Ratings (Gratite)

CF8M-316 SS

ASTM-A216 WCB - Carbon Steel

800

800

700

700

ANSI Class 300

500

400

ANSI

Class 150

300

Pressure - psi

Pressure - psi

ANSI Class 300

600

600

500

400

300

200

200

100

100

-20

100 200 300 400 500 600 700 800 900 1000

Temperature - F

Copyright 2009 Tyco Flow Control. All rights reserved.

-20

ANSI

Class 150

100 200 300 400 500 600 700 800 900 1000

Temperature - F

KTMMC-0550

17

KTM Ball Valves

Omni II Split Body Floating Ball Valve - Full and Reduced Bore

Technical Information

Gear operator

W

133/4"

41/2"

235/8"

8" to 163/16"

dG C D

N-h

Sizes 1/2" to 1"

Sizes 1/2" to 2"

Sizes 21/2" to 3"

Sizes 4" to 8"

Stem Top

8" Gear operated

Flange diameter

150 lb. Class Dimensions, Full and Reduced Bore

Valve

Size (d) Bore

1/2"

3/4"

1"

11/2"

2"

21/2"

3"

4"

6"

8"

10"

0.50

0.75

1.0

1.5

2.0

2.5

3.0

4.0

6.0

8.0

EB100 Full Bore

L

H

W

4.25

4.62

5.0

6.5

7.0

7.5

8.0

9.0

15.5

18.0

2.38

2.5

3.0

4.06

4.5

6.13

6.5

7.5

10.75

13.5

5.13

5.13

6.31

9.06

9.06

15.75

15.75

28.13

45.06

59.0

E

0.25

0.25

0.31

0.44

0.44

0.69

0.69

0.88

1.06

1.42

Weight

EB800 Reduced Bore

Lbs. (d) Bore L

H

W

5.0

6.5

10.0

17.0

23.0

42.0

51.0

74.0

151.0

238.0

Copyright 2009 Tyco Flow Control. All rights reserved.

5

6

8

10.5

11.5

13.0

10.0

10.75

15.94

28.13

45.06

59.45

Weight

Lbs.

1.06

1.25

1.42

121

182

267

KTMMC-0550

18

150 Lb. Flange

G

T

3.5

2.38 1.38

3.86 2.76 1.69

4.25 3.13 2.01

5.0

3.88 2.87

5.99 4.74 3.62

7.01 5.49 4.13

7.48 6.0

5.0

9.02 7.5

6.18

10.98 9.51 8.5

13.5 11.75 10.63

15.98 14.25 12.76

0.44

0.44

0.44

0.56

0.63

0.69

0.75

0.94

1.0

1.13

1.19

(N) - h

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(8)

(8)

(8)

(12)

5/8

5/8

5/8

5/8

3/4

3/4

3/4

3/4

7/8

7/8

KTM Ball Valves

Omni II Split Body Floating Ball Valve - Full and Reduced Bore

Technical Information

300 lb. Class Dimensions, Full Bore

Valve

EB100 Full Bore

Size (d) Bore L

H

W

1/2"

0.5

3/4"

5.5

2.25

5.13

300 Lb. Flange

C

G

0.28

3.74

2.62

1.38

Weight

(N) - h Lbs.

T

0.56

(4) 5/8

3/4

7.0

5.5

0.75

6.0

2.5

5.13

0.28

4.61

3.25

1.69

0.63

(4)

1"

1.0

6.5

3.0

6.25

0.31

4.88

3.5

2.01

0.69

(4) 3/4

11.0

11/2"

1.5

7.5

3.75

9.5

0.47

6.14

4.51

2.87

0.81

(4) 7/8

24.0

2"

2.0

8.5

4.25

9.5

0.47

6.5

5.0

3.62

0.88

(8) 3/4

33.0

7/8

52.0

79.0

21/2"

2.5

9.5

5.5

15.75

0.67

7.48

5.87

4.13

1.0

(8)

3"

3.0

11.13

6.0

15.75

0.67

8.27

6.61

5.0

1.13

(8) 7/8

4"

4.0

12.0

7.0

27.5

0.87

10.0

7.87

6.18

1.25

(8) 7/8

91.0

6"

6.0

15.88

10.75

43.25

1.06

12.52

10.63

8.5

1.44

(12) 7/8

233.0

8"

8.0

19.75

13.5

59.0

1.42

15.0

12.99

10.63

1.63

(12) 1

267.0

Weights for 6" and 8" are lever operated valves. For gear operated, add 30 lbs. for 6" and 55 lbs. for 8".

Notes:

1. Lever handle standard up to 8". Gear operators

are available. KTM furnishes a lever handle for

sizes up to 10" due to low operating torque. Gear

operators are available at users option.

2. KTM ball valves comply with one or more of the

following standard specifications as to pressure,

temperature ratings and dimensions:

ANSI B1.20.1 Pipe Threads

ANSI B16.5 Steel Pipe Flanges

ANSI B16.10 Face-to-Face Dimensions

ANSI B16.34 Valves - Flanged,

threaded and welded end

Cv Values, Full and Reduced Bore

Valve Size

1/2"

3/4"

1"

11/2"

2"

21/2"

3"

4"

6"

8"

10"

Full

Reduced

26

50

94

260

480

750

1300

2300

5400

10000

1800

2500

4500

Materials of Construction

Body:

Carbon Steel (A216, WCB)

304 SS (CF8), 316 SS (CF8M)

Ball:

304 SS (CF8), 316 SS (CF8M)

Stem:

304 SS, 316 SS

Seat:

PTFE/PFA Copolymer

Packing:

PTFE or Soft Carbon

Valve Class: 150 and 300

Test pressure per API 6D:

Shell (Hydrostatic)

Class 150 425 psig (30 kgf/cm2)

Class 300 1100 psig (77 kgf/cm2)

Seat

(Hydrostatic)

Class 150 300 psig (21 kgf/cm2)

Class 300 800 psig (56 kgf/cm2)

(Air)

Class 150 80 psig (6 kgf/cm2)

Class 300 80 psig (6 kgf/cm2)

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

19

KTM Ball Valves

Gratite Seat, Hi-Temp Ball Valves

Special Options

Extension bonnet

Special Tests

Liquid penetrant

X-ray

Standards

Design:

ASME B16.34

End connection: ASME B16.5

General Applications

Chemical plant

Oil refinery

Power plant

Pulp and paper

Steam

Dowtherm

Fused alkali

Fuel oil and gas

Technical Data

Models/Sizes:

ASME Class 150,

Full bore 1/2" to 8"

ASME Class 300,

Full bore 1/2" to 8"

ASME Class 600,

Full bore 1/2" to 4"

(Reduced bore available upon request)

KTMs Hi-Temp ball valves are designed

to operate within a temperature range

from -50F to 932F. They incorporate

valve seats of Gratite material

(a bonded composite of graphite)

formed with flexible graphite which is

used to cushion seal. The result is a

seat with physical properties that are

far superior to conventional ball valve

seats of carbon graphite construction.

Pressure rating: ASME Class 150,

300 and 600

Features

More economical than metal seat.

Temperature:

High resistance to thermal shock.

For Pressure/Temperature:

ANSI 150 and 300 refer to chart

on page 17.

High electro conductivity helps

eliminate need for grounding device.

Seats and seals are virtually

chemically inert.

Blow-out proof stem.

Two-piece body construction.

Fire-safe.

Easy actuator mounting.

Bi-directional flow.

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

20

-50F to 932F

ANSI 600 refer to chart on page 28.

KTM Ball Valves

Gratite Seat Hi-Temp Ball Valves

D:

C:

G:

T:

N:

W

W

Handle for

Valve Size 3"

H H1

Outside diameter

Bolt circle diameter

Raised face diameter

Flange thickness

Number of bolts

h: Bolt hole size

d: Bore diameter

f: Raised face height

H1

W

d

d GC D

Handle for

Valve Size 4"

L1

L1

L

L

Sizes 6" to 8"

Sizes 1/2" to 4"

N-h

Flange Ends

150 lb Class Dimensions

Valve

Size

EB100 Full Bore

L1

H

(d) Bore

1"

11/2"

2"

3"

4"

6"

0.5

0.75

1.0

1.5

2.0

3.0

4.0

6.0

4.25

4.62

5.0

6.5

7.0

8.0

9.0

15.5

1.9

2.0

2.2

2.95

3.1

3.9

4.5

7.1

8"

8.0

18.0

8.9

1/2"

3/4"

H1

Weight

Lbs.

150 lb Flange

G

T

3.2

3.3

3.9

4.9

5.3

6.9

9.4

13.0

2.6

2.8

3.2

4.3

4.7

7.9

11.2

7.9

7.9

9.4

13.8

13.8

23.6

42.0

65.0

3.5

3.86

4.25

5.0

5.99

7.48

9.02

10.98

2.38

2.76

3.13

3.88

4.74

6.0

7.5

9.51

1.38

1.69

2.01

2.87

3.62

5.00

6.18

8.50

0.44

0.44

0.44

0.56

0.63

0.75

0.94

1.00

0.6

0.6

0.6

0.6

0.6

0.6

0.6

0.6

(4)

(4)

(4)

(4)

(4)

(4)

(8)

(8)

5/8

16.0

14.4

89.0

13.5

11.75

10.63

1.13

0.6

(8)

7/8

H1

Weight

Lbs.

(N) - h

5/8

5/8

5/8

3/4

3/4

3/4

7/8

300 lb Class Dimensions

Valve

Size

EB100 Full Bore

L1

H

300 lb Flange

G

T

(d) Bore

1"

11/2"

2"

3"

4"

6"

0.5

0.75

1.0

1.5

2.0

3.0

4.0

6.0

5.5

6.0

6.5

7.5

8.5

11.13

12.0

15.88

2.4

2.8

2.9

3.1

3.5

4.7

5.7

7.5

3.2

3.3

3.9

4.9

5.3

6.9

9.4

13.0

2.6

2.8

3.2

4.3

4.7

7.9

11.2

7.9

7.9

9.4

13.8

13.8

23.6

42.0

65.0

3.74

4.61

4.88

6.14

6.5

8.27

10.0

12.52

2.62

3.25

3.50

4.51

5.0

6.61

7.87

10.63

1.38

1.69

2.01

2.87

3.62

5.00

6.18

8.50

0.56

0.63

0.69

0.81

0.88

1.13

1.25

1.44

0.6

0.6

0.6

0.6

0.6

0.6

0.6

0.6

(4)

(4)

(4)

(4)

(8)

(8)

(8)

(12)

8"

8.0

19.75

9.3

16.0

14.4

89.0

15.0

12.99

10.63

1.63

0.6

(12) 1

1/2"

3/4"

Handle for

Valve Size 2"

H1

D:

C:

G:

T:

N:

h:

d:

f:

H

W

(N) - h

5/8

3/4

3/4

7/8

3/4

7/8

7/8

7/8

Outside diameter

Bolt circle diameter

Raised face diameter

Flange thickness

Number of bolts

Bolt hole size

Bore diameter

Raised face height

H1 H

H

H1

H2

H2

H2

H1

d GC D

L1

L

L1

L1

N-h

L

L

(Uni-directional flow)

Sizes 2" to 3"

Sizes 1/2" to 11/2"

f

T

(Uni-directional flow)

Sizes 4"

Flange Ends

600 lb Class Dimensions

Valve

Size

1/2"

(d) Bore

EO100 Full Bore

L1

H

1"

11/2"

2"

3"

0.5

0.75

1.0

1.5

2.0

3.0

6.5

7.5

8.5

9.5

11.5

14.0

2.9

3.4

3.9

4.4

5.7 {5.0}

7.0

4"

4.0

17.0

8.5

3/4"

H1

3.9

4.1

4.9

5.3

7.4 {7.0}

9.6 {8.8}

13.3

3.0

3.2

4.0

4.4

7.0 {6.7}

7.9 {7.1}

11.1

Weight

Lbs.

600 lb Flange

G

T

9.4

9.4

13.8

13.8

23.6

42.0

3.7

4.6

4.9

6.1

6.5

8.3

2.6

3.2

3.5

4.5

5.0

6.6

1.37

1.7

2.0

2.9

3.6

5.0

0.56

0.63

0.69

0.88

1.00

1.25

0.25

0.25

0.25

0.25

0.25

0.25

(4)-16

(4)-19

(4)-19

(4)-22

(8)-19

(8)-22

65.0

10.7

8.5

6.2

1.50

0.25

(8)-25

N-h

{ } Dimensions for Stainless Steel Body

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

21

KTM Ball Valves

NoFill Cavity Free Valve - Full Bore, EB100 Omni II Style

This technology from KTM is superior

because:

The micro-space is designed to

severely restrict the area where

product can collect and build up

over time.

The mirror-finished interior helps

drastically reduce the potential for

bonding.

There is no excess material to flake

off with wear, helping reduce product

contamination.

Solidification of media is much more

manageable, should a severe

process change occur.

The stainless steel interior lasts much

longer, resulting in less down-time.

This, plus easy maintenance,

translates to a lower total cost of

ownership.

Applications

Styrene

Butadiene

Methylene chloride

Starches

Slurries

Food processing

Fermentation

Pharmaceuticals

Proprietary Micro-space

Design Helps Reduce

Reactive Buildup.

A frequent problem in processing

products ranging from reactive

monomers such as styrene and

butadiene to starches and slurries is

that they can, and do, build up and

polymerize or ferment within the

cavities or open spaces inside the

valves controlling the process.

A more complete solution is KTMs

NoFill valve. As its name implies, the

NoFill uses no filling material of any

kind. Instead, the cavity has been

completely eliminated except for the

micro-space required for ball movement

(shown here in red). Depending upon

the valve size, that micro-space ranges

from 0.5 to 1.0 millimeter. All wetted

surfaces are stainless steel, polished to

a mirror finish.

Until now the response to this problem

has been to fill the cavities with PFA,

FEP or another foreign material.

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

22

KTM Ball Valves

NoFill Cavity Free Valve - Full Bore, EB100 Omni II Style

More Reasons to Choose

KTMs NoFill

The KTM NoFill features a bi-directional

floating design with maximum Cv values

that provide minimal pressure drop

through the valve.

The micro-space required for

ball movement is highlighted

in red for emphasis.

The NoFills spherical-shaped seats

help ensure 360 sealing. The seat itself

is KTMs E-seat, a unique molecularlyenhanced copolymer of PTFE and PFA.

This strong, low-permeability material

provides chemical resistance to reactive

monomers. In high temperature

operations, the seat remains white,

eliminating the risk of color

contamination associated with seats

made from darker reinforced materials.

For abrasive processes, the NoFill is

also available with metal seats.

Specifications

Full Bore,

EB100 Omni II Style

A-351, Gr. CF8M

Body Material

A-351, Gr. CF8

Ball/Stem

A-276, Tp. 316 SS

Material

A-276, Tp. 304 SS

Seat Material

PTFE/PFA Copolymer

Gland Packing TFE (Standard)

Material

GRAFOIL (Optional)

150

ANSI Class

300

Mounting Pad

ISO 5211 (not shown)

L = Lever

Operator

W = Oval Handwheel

G = Gear

Special Feature NoFill Micro-space Design

Size Range

0.5" to 8.0" Full Port

Valve Model

The NoFill valve comes in two-way and

Y-pattern diverter configurations.

1. Rugged stainless steel body design.

5

2. Bi-directional floating design.

1

3. Mirror-finish stainless steel surface on

all wetted areas.

4. Strict micro-space ball clearance

tolerances:

0.5 mm for valves sized 1/2" to 2"

1.0 mm for valves sized 21/2" to 8"

5. Spherically-shaped seats ensure

positive 360 sealing.

3

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

23

KTM Ball Valves

Metaltite Metal Seated Valves - 1/2" to 20"

General Applications

Clean liquids

Dirty liquids

High viscosity

Scaling liquids

Corrosive

Erosive

Waste treatment

Sludge

Pulp stock

Saturated steam

Superheated steam

Wet slurries:

- Pellets

- Monomers

- Abrasive

- Fibers

Dry slurries:

- Powder

- Polymer fluff

- Pellets

Clean gasses

Dirty gasses

High temperature

High velocity

Features

Superior quality and dependability:

We make sure the quality is built-in,

beginning at our own foundries and

through rigorous testing each step of

our fully integrated manufacturing

process. Every KTM valve is

serialized and comes with a complete

set of mill test reports that ensures its

quality and guarantees its

performance. Very few valve

manufacturers can match this feature.

Long life: Built rugged to withstand

the toughest operating conditions,

KTM valves have a documented

history of long, uninterrupted service.

Broad product range: We offer a wide

selection of specifications that allow

you to select the right valve to meet

the requirements of your operating

process.

Availability: Historically designed as

customized products to meet specific

customer needs, our metal seated

valves today are mass produced,

which means they are available off

the shelf. No long wait for delivery.

Experience: KTM has been making

metal seated valves for more than a

quarter of a century. Our worldwide

installed base is very large.

Conformance: Precision lapping of

ball to seat and high-precision

machining result in superior ball

and seat interfacing for tight shut-off,

conforming to ANSI FCI 70-2 Class V

and Class VI.

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

24

KTM Ball Valves

Metaltite Metal Seated Valves - 1/2" to 20"

V-Port Valves for Dual Function,

On/Off or Modulating

Omni and Y-Pattern Valves for

On/Off Applications

KTMs Single V and Dual V are rugged

dual-function valves that can be used

in On/Off applications as well as

modulating applications. These valves

are designed to provide solutions to

specific operating needs.

KTMs Omni family of valves are

unmatched in general-purpose On/Off

applications. Our Y-Pattern valve adds

dependable diverter capabilities where

operations require them.

Omni II Offers:

Single V Offers:

Shearing action

Low torque

Upstream single-seat trunnion design

Non-clogging

100:1 rangeability

No body cavity

No downstream seat allows media

to flow freely and smoothly, help

prevent buildup

Fugitive emission control

Integral ISO mounting pad

Rugged split-body design

Live-loaded adjustable gland packing

Inherently fire-safe design

Anti-static grounding device

Blow-out proof stem

Radial tost bearing

Trunnion Offers:

Rugged split-body design

Double block and bleed

Adjustable gland packing

True trunnion design

Inherently fire-safe design

Rugged split-body design

Anti-static grounding device

Integral mounting pad

Blow-out proof stem

Adjustable gland packing

Dual V Offers:

Low torque

Shearing action

Inherently fire-Safe design

Low torque

Anti-static grounding device

Upstream single-seat trunnion design

Powder guard feature

Non-clogging

Blow-out proof stem

250:1 rangeability

Y-Pattern Offers:

No body cavity

Slurry diverter service

No downstream seat allows media

to flow freely and smoothly, helps

prevent buildup

Minimum body cavity

Compact unibody design

Class V shut-off

Integral ISO mounting pad

Easy installation, versatile end

connections

Polished bore

135 operation

Piggability

Top entry

Adjustable gland packing

Inherently fire-safe design

Adjustable gland packing

Anti-static grounding device

Inherently fire-safe design

Blow-out proof stem

Anti-static grounding device

No mixing of media when

changing flow

Flanged and wafer designs

Blow-out proof stem

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

25

KTM Ball Valves

Metaltite Metal Seated Valves - 1/2" to 20"

Valve Selection and Seat Designs

WonderWonder

ValveValve

(V-port)

(V-port)

Seat Design/

Seal Class:

A-2

A-1

Valve Type: Single V

Model No.: (WO 400/600)

A-1/Class IV

A-2/Class II

Characteristics:

Temp -20F to 482F, Single seat

Uni-directional Trunnion Design

ANSI 150/300, 1" to 20"

Modulating, On/Off

Class IV, Laminated seat

Class II, Thick seat

Valve Type: Dual V

Model No.: (WA Series)

Seat Design/Seal Class: B/Class V

Characteristics:

Temp -20F to 518F, Single seat

Uni-directional Trunnion Design

ANSI 150/300, 1" to 8"

Modulating, On/Off

Class V, Spring loaded stellited seat

Omni

Omni 22

C-2

C-1

Valve Type: Omni II

Model No.: (EB100)

Seat Design/Seal Class: C/Class V

Characteristics:

Temp -20F to 932F, Two seats

Bi-directional Floating Design

ANSI 150/300, 1/2" to 8"

On/Off

Bi-directional: Preferred flow is cap to body.

D-D

6" to 20"

E-E

2" to 4"

Valve Type: Trunnion

Model No.: (EO1200)

Seat Design/

Seal Class:

D/Class V

E/Class V

F/Class V

G/Class V

Scraper type with powder guard seals max. temp. 482F

G-G

F-F

6" to 20"

Characteristics:

Temp -20F to 932F, Two seats

Bi-directional or Single seat

Uni-directional Trunnion Design

ANSI 150/300, 2" to 20"

ANSI 600, 2" to 16"

On/Off

Valve Type: Y-Pattern Diverter

Model No.: (E3700)

Standard type

max. temp. 482F

Same seat applies to both sides.

Seat Design/Seal Class: H/Class V

Characteristics:

Temp -20F to 482F, Three seats

Trunnion Design

ANSI 150/300, 1" to 12"

ANSI 600, 1" to 3"

Diverting

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

26

High temperature

applications max. temp.

932F

KTM Ball Valves

Energy and Process Valve - 1/2" to 2"

Features

Patented seat design has proven

performance in both energy and

process applications.

Valve seats are Gratite (a bonded

composite of hard graphite) which

forms the seat along with soft carbon

used for the cushion seal.

The result is a seat with physical

properties that are far superior to

conventional ball valve seats of

carbon graphite construction.

Designed for zero leakage (liquid

service).

Full bore.

Full ANSI rating and suitable for

ON-OFF service up to 932F.

Reduces energy costs.

Seats and seals virtually chemically

inert.

Blow-out proof stem.

Higher CV than gate or globe valves.

Inherently fire-safe.

Designed to resist thermal and

pressure shock.

Can be welded in line without

disassembly.

Easy parts replacement.

Two-piece body.

Sphericity tolerance of the balls,

0.0008", and a 4 RMS surface

finish are unsurpassed.

General Applications

Technical Data

Process:

Vacuum service

Refinery products

Slurry service

Viscous materials

Air

Water

Energy:

Steam

Hot liquids

Hot gases

BTU conservation

Size range:

Copyright 2009 Tyco Flow Control. All rights reserved.

Full bore

1/2" to 2"

ANSI Class 300 and 600

KTMMC-0550

27

KTM Ball Valves

Energy and Process Valve - 1/2" to 2"

Detail A

Material and Model Numbers

18

6

17

20

19

W

12

15

11

7

21

16

8

16

21

5

10

See Detail A

d

2

3

4

13

14

1

No.

Part

EB162-32/39FU-30

EB132-32/39FU-30

Body

Body Cap

A216 Gr. WCB

or A105

A216 Gr. WCB

or A105

316 SS

Soft Carbon

329 SS

Carbon

Carbon Steel

Soft Carbon

304 SS

316 SS

Carbon Steel

Ductile Iron

A193 Gr. B7

A194 Gr. 2H

Steel

316 SS

304 SS

316 SS

316 SS

Soft Carbon

Soft Carbon

Gr. CF8M

or 316 SS

A351 Gr. CF8M

or 316 SS

316 SS

Soft Carbon

329 SS

Carbon

304 SS

Soft Carbon

304 SS

316 SS

304 SS

Ductile Iron

304 SS

304 SS

304 SS

316 SS

304 SS

316 SS

316 SS

Soft Carbon

Soft Carbon

3

*4

5

*6

7

*8

9

10

11

12

13

14

15

16

17

*18

19

*20

*21

Ball

Gasket

Stem

Seat

Gland Flange

Gland Packing

Live Loading Spring

Tost Bearing

Stopper

Handle

Stud

Nut

Snap Ring

Tost Washer

Gland Bolt

Seat Retainer

Inner Ring

Cushion

Stem Bearing

L1

L

Notes:

Dimensions and CV Value

1. * Denotes Spare Parts

Valve

Size

2. After Model No. add SE for Screw Ends or

SW for Socket Weld

Bore (d)

L1

CV

0.50

0.75

1.00

1.50

2.00

5.51

5.98

6.50

7.48

8.50

2.76

3.00

3.50

3.86

4.25

2.60

2.76

3.23

4.33

4.72

7.87

7.87

9.45

13.78

13.78

0.28

0.28

0.31

0.47

0.47

26

50

94

260

480

1/2"

U.S. Patent 4,269,391

3/4"

1"

11/2"

2"

Pressure/Temperature Ratings

CF8M-316 SS

ASTM A216 WCB

1600

1600

1200

1000

Class

600

800

600

ANSI C

1400

ANSI

ANSI Class 30

400

200

Pressure - psi

Pressure - psi

1400

lass 60

1200

1000

800

ANSI Class

600

300

400

200

0

-20 100 200 300 400 500 600 700 800 900 1000

-20 100 200 300 400 500 600 700 800 900 1000

Temperature - F

Temperature - F

Note: ANSI B16.34 temperature limitation is 800F on WCB material.

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

28

KTM Ball Valves

3-Way Ball Valve, 2-Seats - EO3100 Full Bore and Reduced Bore, L Port

Features

A single KTM 3-way valve replaces

several 2-way valves, saving valuable

space and simplifying piping.

Designed for zero leakage with

standard E-seat.

Pure white E-seat seal helps relieve

concern over product contamination.

Suitable for high temperature

applications when equipped with

exclusive Gratite seat.

Positive alignment of body.

Blow-out proof stem.

More than 50% of stem length is

supported by bushing and valve

body.

Packing acts as seal instead of stem

support, minimizing stem leaks.

Stainless steel static grounding

device.

Sphericity tolerance of the balls,

0.0008", and a 4 RMS surface

finish are unsurpassed.

Reinforced PTFE bearing and packing

rings help reduce friction.

Two-seat design has lower operating

torque, easing operation and

reducing actuator cost.

Automatic cavity pressure relief.

Positive position indication.

Meets NACE MR01.75 for sulfide

cracking resistance.

General Applications

Standard Materials

Dividing or mixing of liquids

Locking device capable.

Special Tests

Body: Carbon Steel (A216, WCB)

304 SS (CF8)

316 SS (CF8M)

Liquid penetrant

Ball:

Magnetic-particle

304 SS (CF8)

316 SS (CF8M)

Ultra-sonic

Stem: 304 SS, 316 SS

X-ray

Seats: Choose from five seat materials

E-seat

-94F to 400F

(PTFE/PFA copolymer)

F-Gratite hard seat -50F to 932F

G-Reinforced PTFE -94F to 400F

PEEK

-20F to 550F

T-PTFE

-94F to 400F

Technical Data

Size range: EO3100 Full bore

11/2" to 8"

EO3800 Reduced bore

6" to 10"

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

29

KTM Ball Valves

3-Way Ball Valve, 2-Seats - EO3100 Full Bore and Reduced Bore, L Port

Seat Design Selection

Port Arrangements

A proprietary product for hightemperature, high-pressure, flammable

and corrosive critical-process

applications, the KTM Gratite seat

offers superior performance and

reliability. Patented (U.S. Patent

4,269,391), it is designed to operate

within a temperature range from

-50F to 932F. Gratite is a bonded

composite of hard graphite material

sealing surface the cushion seal,

providing resiliency. The result is a

seat with physical properties that are

far superior to conventional ball valve

seats of carbon graphite construction.

The EO3100 and EO3800 are available

with soft or hard seats. Each offers a

range of performance suitable to many

applications.

The standard soft seat is our E-seat

PTFE/PFA copolymer. You may also

choose PTFE. Each is retained in the

same manner.

Also available in

Hard Gratite Seat

3-Way L Port

Form 1

Form 2

-50F to 932F

Wide Temperature Range

CV Values, Full and Reduced Bore

Valve

Size

L

L2

Full

EO3100

11/2"

2"

21/2"

3"

4"

6"

8"

L2

Reduced

EO3800

53

102

144

247

425

970

1700

670

996

150 lb. Class Dimensions

Valve

Size (d) Bore L

11/2"

1.50

8.27

2"

2.00

8.66

21/2"

2.50

9.84

3"

3.00 10.24

4"

4.00 12.99

6"

6.00 16.93

8"

8.00 21.26

EO3100

L2

H

4.13

3.81

4.34

4.25

4.94

5.63

5.13

6.00

6.50

7.00

8.47 10.75

10.63 13.50

W

9.00

9.00

15.75

15.75

27.50

43.25

59.00

Wt./Lb (d) Bore L

21

29

42

56

97

187

5.00 16.93

264

6.00 21.26

EO3800

L2

H

W

Wt./Lb

8.47 10.00 43.25

155

10.63 10.75 43.25

215

150 Lb. Flange

D

C

G

T

5.00 3.88 2.87 0.56

5.99 4.74 3.62 0.63

7.01 5.49 4.13 0.69

7.48 6.00 5.00 0.75

9.02 7.50 6.18 0.94

10.98 9.51 8.50 1.00

13.50 11.75 10.63 1.13

(N) - h

(4) 5/8

(4) 3/4

(4) 3/4

(4) 3/4

(8) 3/4

(8) 7/8

(8) 7/8

300 Lb. Flange

C

G

T

(N) - h

300 lb. Class Dimensions

Valve

Size (d) Bore

11/2"

2"

21/2"

3"

4"

6"

8"

1.50

2.00

2.50

3.00

4.00

6.00

8.00

L

8.66

9.44

10.63

11.42

13.78

18.11

22.44

EO3100

L2

H

4.31

4.72

5.31

5.72

6.91

9.06

11.25

3.81

4.25

5.63

6.00

7.00

10.75

13.50

W

9.00

9.00

15.75

15.75

27.50

43.25

59.00

Wt./Lb (d) Bore

32

37

50

79

112

224

308

Copyright 2009 Tyco Flow Control. All rights reserved.

5.00

6.00

18.11

22.44

EO3800

L2

H

9.06 10.00 43.25

11.25 10.75 43.25

KTMMC-0550

30

Wt./Lb

180

253

6.14 4.51 2.87

6.50 5.00 3.62

7.48 5.87 4.13

8.27 6.61 5.00

10.00 7.87 6.18

12.52 10.63 8.50

15.00 12.99 10.63

0.81 (4) 7/8

0.88 (8) 3/4

1.00 (8) 7/8

1.13 (8) 7/8

1.25 (8) 7/8

1.44 (12) 1

1.63 (12) 1

KTM Ball Valves

KTM 3-Way Ball Valve, 4-Seats - E3900 Full Bore, L Port and T Port

Features

Equipped with 4-seats so either

port can be used as an inlet without

leakage.

A single KTM 3-way valve replaces

several 2-way valves, saving valuable

space and simplifying piping.

Positive alignment of body.

Blow-out proof stem.

More than 50% of stem length is

supported by bushing and valve

body.

Packing acts as seal instead of stem

support, minimizing stem leaks.

Stainless steel static grounding

device.

Sphericity tolerance of the balls,

0.0008", and a 4 RMS surface finish

are unsurpassed.

Reinforced PTFE bearing and packing

rings help reduce friction.

Automatic cavity pressure relief.

Positive position indication.

Meets NACE MR01.75 for sulfide

cracking resistance.

Locking device capable.

General Applications

Standard Materials

Dividing or mixing of liquids

Special Tests

Body: Carbon Steel (A216, WCB)

304 SS (CF8)

316 SS (CF8M)

Liquid penetrant

Ball:

Magnetic-particle

304 SS (CF8)

316 SS (CF8M)

Ultra-sonic

Stem: 304 SS

316 SS

X-ray

Seats: Select from these seat materials

Technical Data

Size range:

E3900 Full bore

1/2" to 8"

G-Reinforced PTFE

-20F to 300F

E-PTFA/PFA

-20F to 300F

T-PTFE

-20F to 300F

Copyright 2009 Tyco Flow Control. All rights reserved.

KTMMC-0550

31

KTM Ball Valves

KTM 3-Way Ball Valve, 4-Seats - E3900 Full Bore, L Port and T Port

Port Arrangements

3-Way L Port

Form 1

Form 2

Form 3

Form 4

Form 1

Form 2

Form 3

Form 4

3-Way T Port

Cv Values

Size

L Port, Form 1, 2

T Port, Form 2, 3

8

14

22

57

110

160

260

446

6

13

20

50

100

150

240

400

1/2"

3/4"