Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

United States Patent (191: Lietard Et A1. (45) Jan. 3, 1978

Caricato da

syafiq izzuddin bin sapriDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

United States Patent (191: Lietard Et A1. (45) Jan. 3, 1978

Caricato da

syafiq izzuddin bin sapriCopyright:

Formati disponibili

United States Patent [191

[11]

4,066,748

Lietard et a1.

[45]

Jan. 3, 1978

[54] CONTINUOUS PROCESS FOR PRODUCING

AN AQUEOUS SOLUTION OF FERRIC

CHLORIDE

[75] Inventors: Jean-Marie Lietard, Gent; Guido

Matthijs, Mariakerke, both of

Belgium

[73] Assignee: U C B, Soeiete Anonyme, Brussels,

Belgium

Primary Examiner0. R. Vertiz

Assistant Examiner-Brian E. Hearn

Attorney, Agent, or Firm-Wenderoth, Lind & Ponack

[57]

ABSTRACT

An aqueous solution of ferric chloride directly usable

for purifying water is produced from a pickling liquor

containing ferrous chloride by a process comprising the

steps of

1. continuously concentrating the pickling liquor by

[21] Appl. No.: 714,323

[22] Filed:

Aug. 13, 1976

[30]

Foreign Application Priority Data

evaporation to at least about 34.25% by weight fer

rous chloride concentration;

2. continuously neutralizing the resulting concentrated

liquor, which still contains free hydrochloric acid, by

United Kingdom ............. .. 33701/75

means of a ?uidized bed of iron oxide particles (e.g.

[51]

Int. 01.2 ............................................ .. C01G 49/10

[52]

us. 01. .................................. .. 424/147; 423/150;

3. continuously countercurrently chlorinating the re

sulting neutralized concentrated liquor in two succes

[58]

Field of Search ................... .. 423/150, 493, 658.5,

[56]

423/659 F, DIG. 1, DIG. 16, 659; 75/101 R;

424/147; 252/175

References Cited

Aug. 13, 1975

423/DIG. 16; 423/493

U.S. PATENT DOCUMENTS

2,096,855

10/1937

3,682,592

8/1972

Ladd .................................. .. 423/493

Kovacs

3,873,678

3/1975

McCormick et a1.

3,928,551

3,929,963

12/1975

12/ 1975

. 423/DIG. 1

423/493

Booth ..................... ..

423/659

Kurata ............................. .. 75/101 R

mill scales); and

sive reaction zones, to the extent of from 73 to 86% at

a temperature of from 35 to 75 C in the ?rst reaction

zone and the balance at a temperature of from 40 to

100 C in the second reaction zone.

The product of said process is an aqueous solution con

taining per liter at least 40% by weight of ferric chlor

ide, less than 0.1% by weight of ferrous chloride and

less than 0.1% by weight of ferrous chloride. Chlorina

tion yield is practically quantitative.

5 Claims, 1 Drawing Figure

U.S. Patent

Jan. 3, 1978

4,066,748

/4

13

+1

~

\\\\\\\\\\

'in

4,066,748

CONTINUOUS PROCESS FOR PRODUCINGAN

AQUEOUS SOLUTION OF FERRIC CHLORIDE

entent of from 73 to 86% at a temperature of from 35 to

75 C in the ?rst reaction zone and the balance at a

temperature of 40 to 100 C in the second reaction zone,

whereby an aqueous solution containing per liter at least

The present invention relates to a new process for the 5 40% by weight of ferric chloride, less than 0.1% by

production of an aqueous solution of ferric chloride of

great purity from residual pickling liquors'containing

ferrous chloride.

Ferric chloride is a product used in large quantities,

particularly for the puri?cation of drinking, industrial,

and waste water; for this kind of application it is neces

sary for the ferric chloride to be of great purity, failing

which it will in turn become a contamination agent for

water.

It is known to produce anhydrous ferric chloride by

the action of gaseous chlorine on granulated iron at

bright red heat, or on iron oxide and iron phosphate at

a temperature of about 1000 C, or else from iron oxides

weight of ferrous chloride, and less than 0.1% by

weight of free hydrochloric acid, is obtained, said solu

tion being directly usable for purifying water.

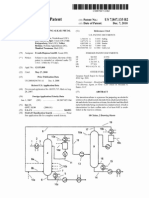

BRIEF DESCRIPTION OF THE DRAWING

The drawing schematically illustrates the process of

the instant invention.

The pickling liquor used as raw material in the pro

cess according to the invention generally contains from

10 to 11% of Fe2+ which corresponds to from 22.7 to

25% of ferrous chloride. In addition, the liquor contains

variable amounts of free hydrochloride acid, which

may amount to 1% by weight or more, together with

and hydrochloric acid (Ullmanns Encyklopaedie der

organic impurities. However, the contents of these sub

technischen Chemie, third edition, vol. 6,l955,p.4l5 et 20 stances are not critical for use in the process of the

seq.).

invention and they may vary between lower values and

higher values than those mentioned above by way of

by dissolving granulated iron in hydrochloric acid and

illustration.

oxidizing the resulting ferrous chloride with gaseous

As it is proposed to prepare a ferric chloride solution

chlorine or nitric acid in the presence of hydrochloric 25 which is directly usable for purifying water, and since a

solution of this kind must contain at least about 40% by

acid (Ullmanns, loc.cit., page 417).

Similarly, it is known to operate in aqueous solution

Processes also exist in which the raw material used is

ferrous chloride, which is oxidized with gaseous chlo

rine, either at high temperature or in aqueous solution

(see for example British Pat. No. 547,005).

'

In industry large amounts of aqueous hydrochloric

acid baths are used to eliminate the ?lms or incrusta

tions of iron oxides which are formed on the surface of

weight of ferric chloride, the crude pickling liquor must

consequently be concentrated by evaporation in a ?rst

stage. By way of example without limitation, it being

known that the molecular weights of the materials con

cerned are as follows:

FeClz: 126.75

C12 2

workpieces during their metallurgical treatment. These

FeCl3: 162.2,

baths, generally called pickling liquors, contain large 35 it is calculated that in order to obtain 40 g of FeCl; it is

amounts of ferrous chloride, generally between about

20 and 25% by weight, when they are exhausted. These

pickling liquors are therefore an abundant and inexpen

sive source of ferrous chloride, which can be utilized

particularly for the purpose of producing an aqueous 40

solution of ferric chloride. However, one disadvantage

of this raw material is that it is heavily contaminated,

particularly by free hydrochloric acid and by the auxil

iary substances used in processing iron, particularly

necessary to start with:

1261652 2 4 = 31.26 g of Feel, and with

70.9 5 40

1622 X 2 = 8.74 g of C12.

In order to obtain 100 g of solution containing 40 g of

FeCl;, it is necessary to start from 100 8.74 = 91.26

passivating agents, lubricating oils or greases, tars, etc. 45 g of solution containing 31.26 g of FeCl;, that is to say

Consequently, a ?rst condition is the development of a

process making it possible to obtain ferric chloride free

from these contaminants, so that the resulting aqueous

solution of ferric chloride can be used direct for the

purpose of purifying water. Furthermore, if the process 50

is to be economically viable it is also important to be

from a solution containing

311:1 261) = 34.25% of FcCIZ.

If the pickling liquor serving as raw material contains

for example from 22.7 to 25% of FeCl;, it is therefore

necessary to concentrate it by evaporation so that it

as to obtain an aqueous solution of ferric chloride of

contains at least 34.25% by weight of FeCl;. It is obvi

constant quality. It is to this problem that the process of

55 ously possible to concentrate the ferrous chloride solu

the invention provides a solution.

tion still further, optionally effecting subsequent dilu

Thus according to the invention, there is provided a

tion to bring the FeCl; content in the ?nal solution to

process for producing an aqueous solution of ferric

about 40% by weight. The ?rst stage of the process

chloride from a pickling liquor containing ferrous

according to the invention can be carried out in any

chloride comprising the steps of

continuous evaporation apparatus, such as for example

1. continuously concentrating the picking liquor by

a thermosiphon evaporator, a thin layer evaporator, etc.

evaporation to at least about 34.25% by weight of fer

The concentrated liquor thus obtained passes out of the

rous chloride concentration;

?rst stage at a temperature of about 70 to 100 C.

2. continuously neutralizing the resulting concen

In the second stage of the process of the invention the

trated liquor, which still contains free hydrochloric

acid, by means of a ?uidized bed of iron oxide particles; 65 pickling liquor which has just been concentrated in the

?rst stage is neutralized. The neutralization temperature

and

is between 30 and 100 C, preferably between 60 and

3. continuously countercurrently chlorinating the

90 C. In order to neutralize the free hydrochloric acid,

resulting liquor in two successive reaction zones, to the

able to carry out this process in a continuous manner so

4,066,748

according to the invention use is made of a dynamic

outlet pipe for the neutralized concentrated picking

neutralization technique in which the concentrated

pickling liquor is brought into contact with a ?uidized

suspension of iron oxide particles. It would also be pos

liquor. It is advantageous to widen the diameter of the

column in its upper portion in order to reduce the linear

speed of circulation of the liquor and thus to reduce

sible to consider using particules of metallic iron (and

considerably the entrainment of ?nes. Foreign elements

(iron oxide ?nes, oils, tars, and other organic substances

originating from the starting liquor and from the scales)

not of iron oxides) in order to neutralize the concen

trated pickling liquor. However, this procedure is not

advisable because the hydrogen formed might consti

which collect on the surface of the liquid are removed

tute an explosion risk. It is for that reason that iron oxide

periodically or continously from the process by skim

particles are preferred, such as for example rolling mill

scales, purple ore (that is to say the residue of the roast

10

ming. The liquor concentrated, neutralized, and freed of

oxide should be as reactive as possible. In this connec

organic contaminants in this manner is passed on to the

third stage of the process.

It would obviously be possible to conceive the rever

sal of the ?rst two stages of the process, that is to say

?rst to neutralize the pickling liquor and then to con

centrate it. However, this method would have the dis

advantage that in the course of the concentration of the

tion mill scales give particularly good satisfaction and

neutralized liquor there would be partial hydrolysis of

ing of pyrites), iron ores, such as hematite, magnetite,

etc. In theory, neutralization may be effected with any

iron oxide; however, when it is required to neutralize

the free acid within a period of time compatible with the

pro?tability of the process, it is important that this iron

are advantageously used in the process of the invention.

the ferrous chloride with the reappearance of hydro

The mill scales should have a particle size of form 0.1 to 20 chloric acid in the top distillation products and in the

10 mm, preferably from 0.25 to 5 mm.

concentrate, which would make it necessary for the

As indicated above, the neutralization by iron oxides

liquor to be passed a second time through a bed of iron

of the free hydrochloric acid contained in the concen

oxides. Furthermore, the quantities of liquor to be neu

trated pickling liquor is carried out under dynamic con

tralized would be greater. It is for this reason that ac

ditions in order to accelerate considerably the speed of 25 cording to the invention it is preferred to concentrate

neutralization as compared with static conditions (see

the pickling liquor ?rst and then to neutralize it (see

examples). According to the invention, the liquor is

Example 2).

circulated countercurrent to the bed of iron oxide parti

In the third stage of the process of the invention, the

cles. The concentrated pickling liquor is introduced

ferrous chloride is converted into ferric chloride liquor

from the bottom into a vessel (for example a column) 30 according to the equation:

and the iron oxide particles are added at the top, contin

uously or batchwise, the speed of circulation of the

liquor being so adjusted that the iron oxide particles are

maintained at least partly in the form of a ?uidized bed.

FeClz + i 012 -> Feel,

In order to ensure the complete chlorination of

This speed of circulation of the liquor is dependent on 35 FeCl; to FeCl3, this operation is carried out continu

various parameters, such as the volume of the vessel, its

geometrical shape, the height of the ?uidized bed, the

dimensions and reactivity of the iron oxide particles, the

temperature of the liquor, and so on; it is important to

ously in two consecutive stages. For this purpose, the

operation is carried out in two separate reaction zones,

namely ?rstly in a circuit comprising an absorption .

tower, and then in a reactor-?nisher. The reactants are

select these parameters so as to ensure the completest 40 circulated in countercurrent, the gaseous chlorine being

admitted at the bottom of the reactor-?nisher in a very

possible neutralization of the free hydrochloric acid

contained in the liquor. It will also be noted that in the

course of time the dimensions of the iron oxide particles

will be progressively reduced, as the result of attack by

the hydrochloric acid. Consequently, it is dif?cult to

give precise information regarding the parameters to be

?nely divided state, and the excess chlorine passing out

at the top of the reactor-?nisher is passed on to the

absorption tower, while the neutralized concentrated

liquor coming from the second stage of the process is

?rst passed through the absorption tower, where it

encounters the excess gaseous chlorine coming from the

reactor-fmisher, and ?nally passes out in the form of

fmished product at the bottom part of the reactor-?n

is neutralized in the second stage of the process with a 50 isher. This counter-current circulation of the liquor and

gaseous chlorine ensures practically complete conver

?uidized bed of mill scales at a temperature of 80 C for

sion of ferrous chloride into ferric chloride (for example

6 minutes, the hydrochloric acid content of the liquor is

less than 0.033% by weight of Fe2+ in the ?nal solution

reduced to 0.05% by weight. Generally speaking, the

of FeCl;), the chlorination being effected to the extent

minimum speed of circulation of the liquor is that start

ing from which the particles commence to form a ?uid 55 of about 73-86% in the circuit comprising the absorp

tion tower and of about 27l4% (the balance) in the

ized bed, while the maximum speed of circulation

reactor-?nisher. The chlorination of ferrous chloride to

which must not be exceeded is that starting from which

ferric chloride according to the invention is preferably

iron oxide particles are entrained and at which so high

effected at a temperature higher than normal, in view of

a hydrochloric acid content remains in the liquor (more

the fact that the rate of chlorination increases with

than 0.1% by weight of HCl) that the ferric chloride

rising temperature; in the absorption column the tem

solution obtained at the end of the process of the inven

perature may vary between 35 and 75 C and in the

tion cannot be used as such for purifying water.

reactor-?nisher between 40 and 100 C. It is advanta

The continuous apparatus for carrying out the second

geous for the apparatus to be thermally insulated in

stage of the process of the invention may, as an example

without limitation, consist of a thermally insulated col 65 order to reduce losses of heat to a minimum. Further

respected. As a concrete example, when the concen

trated pickling liquor coming from the ?rst stage con

tains 0.56% by weight of free hydrochloric acid and it

umn provided at the bottom with an inlet for the con

centrated pickling liquor, at the top with an inlet for the

iron oxides, and provided in its upper'portion with an

more, in order to increase as far as possible the contact

between the gaseous chlorine and the liquor, it is advan

tageous to supply the chlorine in very ?nely divided

4,066,748

form (for example through a fritted plate) and to pro

vide ?lling elements (Raschig rings, etc.) in the absorp

tion tower and also in the reactor-?nisher. The resi

dence time of the liquor in the third stage of the process

is about 0.5 to 3 hours, preferably from 1 to 2 hours.

The ?nal product recovered at the base of the reac

tor-fmisher is an aqueous solution containing about 40%

V out the operation ever having to be interrupted because

of clogging.

EXAMPLE 2

This example shows the advantage of concentrating

the pickling solution before it is neutralized.

The apparatus used is a glass boiler with forced circu

by weight of ferric chloride, which is preferably suit

lation, which has useful capacity of 800 ml and is pro

able for the puri?cation of water.

The following Examples are given for the purpose of

denser. Feeding is carried out directly in the boiler with

illustrating the invention.

'

Example 1

Neutralization; comparison of a ?xed bed with a

?uidized bed

The reactor used in both cases is a jacketed glass tube

(inside diameter 39 mm, length 1000 mm, capacity

1194.5 ml), provided at the top with a widened portion

with a diameter of 150 mm and a height of 200 mm.

The pickling solution to be neutralized has a density

of 1.34 g/cm3 at 20 C and contains 29.06% of FeCl;,

1.23% of FeCl;, and 0.81% of HCl.

The reactor contains a bed of mill scales (of a particle

vided with a dephlegmator and a water-cooled con

the aid of a peristaltic pump; the condensed water is

withdrawn from the top and the concentrated solution

from the bottom.

In a ?rst test, not according to the invention, a pick

ling solution, previously neutralized by passing over a

bed of mill scales, was concentrated. 960 ml (1200 g) of

this solution containing 26.4% of FeCl; + FeCl; and

containing no HCl is introduced per hour. 424 ml of

water containing 0.1% of HCl (0.424 g) are condensed

per hour at the top. 545 ml (774 g) of solution containing

40.4% of FeCl; + FeCl; and containing 0.013% of HCl

(0.1 g) are withdrawn per hour at the bottom of the

boiler. 0.524 g of HCl has therefore been formed per

size of from 1 to 6 mm in diameter) of a height of about

40 cm. The mill scales have a purity of 92.79% and

contain 59.47% of FeO and 33.32% of Fe2O3.

hour by hydrolysis of iron chloride.

column every hour. The ?ow of 2500 ml per hour is

place. 1

In a second test, which is according to the invention,

960 ml (1196 g) per hour of an unneutralized pickling

The reactor is maintained at a constant temperature

solution, containing 25.5% of FeCl; + FeCl; and 0.64%

of 80 C by circulating hot water in the jacket. The

of HCl (7.774 g) is concentrated, and 418 ml of water

solution to be neutralized, which is likewise heated to

containing

0.34% of HCl (1.421 g) are condensed per

30

80 C, is fed at a ?ow of 2500 ml per hour.

hour. 552 ml (775 g) of solution containing 39.3% of

In a ?rst test, which is not according to the invention,

FeCl; + FeCl; and 0.82% of HCl (6.355 g) are with

the pickling solution is fed at the top of the column and,

drawn per hour from the bottom of the apparatus. 7.776

after passing through the bed of mill scales, the neutral

g of HCl per hour are therefore found in the condensate

ized solution is withdrawn from the bottom. A make-up

and concentrate. Consequently, no hydrolysis has taken

of 30 g of fresh mill scales is added at the top of the 35

easily maintained in the beginning, but at the end of 12

hours the ?ow has already fallen to about 1000 ml per

hour. The experiment is stopped at the end of 60 hours,

EXAMPLE 3

This example shows the necessity of chlorination in

when the ?ow has fallen to 100 ml per hour. Mean 40 two stages. In a ?rst test, which is not according to the

invention, chlorination is effected in one co-current

residence time = 38 minutes. During this period, 45,000

'm1 of pickling liquor have thus been neutralized.

stage.

Both the ferrous chloride solution and the gaseous

In a second test, which is in accordance with the

chlorine are fed at the bottom of an absorption "column.

invention, the pickling solution is fed at the bottom of

The chlorination solution and the excess of chlorine

the column, likewise with a flow of 2500 ml per hour. 45

pass out at the top of the column.

With this ?ow at least the particles of small diameters

are ?uidized; the widening of the top of the column

prevents their entrainment with the neutralized solution

passing out through a side branch below the top. A

make-up of 30 g of fresh mill scales is likewise added at

the top of the column every hour. After 60 hours opera

tion the ?ow was still 2500 ml per hour. During this

period, 150,000 ml of pickling liquor were thus neutral

For an hourly ?ow of 1500 ml (2053 g) of a solution

containing 35.0% of FeCl;, 201 g per hour of chlorine

are required to convert all the FeClz into FeCl3.

Using this ?ow of chlorine at a temperature of 70-C,

2214 g of a solution containing 33.30% of FeCl; and

6.44% of FeCl; (HClznil) are obtained per hour after

normal operating conditions have been achieved in the

column. The chlorination yield is 80.1%.

"ized. Mean residence time = 11.5 minutes.

It was subsequently attempted to achieve complete

In a third test according to the invention, the same 55

chlorination, likewise at 70 C, by progressively in

operating conditions are maintained as in the second

test, except that the ?ow of the pickling solution and

also the amount of mill scales added are progressively

increased. It is thus found possible to neutralize 5000 ml

per hour of pickling solution by adding 60 g of mill

scales per hour, while obtaining a neutralized liquor

which contains less than 0.1% by weight of free HCl.

The mean residence time is then 6 minutes. If the ?ow

creasing the ?ow of chlorine to 287 g per hour.

2253 g of a solution containing 40.72% of FeCl;,

0.09% of FeCl;. and 0.04% of HCl are now obtained

per hour, but the yield based on the chlorine fed is only

69.05%.

In a second test, likewise not according to the inven

tion, chlorination is effected in one countercurrent

stage; chlorine is introduced at the bottom, FeClz at the

of 5000 ml per hour is exceeded, an increase of free acid

65 top, and the chlorinated solution is withdrawn at the

is found (more than 0.1% by weight of free HCl).

The ?uidized bed system according to the invention

is therefore considerably more effective than the ?xed

bed system, and it can be carried out inde?nitely, with

bottom.

Starting with the same ?ow of the same ferrous chlor

ide solution as in the ?rst test, 2222 g per hour of a

4,066,748

FeCl; (HClznil) are obtained at 70 C and with a flow of

chlorine of 201 g per hour. The chlorination yield is

84.1%.

Subsequently, by increasing the ?ow of chlorine to

269 g per hour, 2253 g of solution containing 40.74% of

A make up of 2.7.5 g-of mill scales coming from the

reservoir 11 is added per hour. Grease and part of the

foreign bodies accumulate on the surface of the liquid,

solution containing 34.80% of FeCl; and 5.14% of

FeCl;, 0.05% of FeCl;, and 0.07% of HCl are obtained

per hour, but the yield based on the chlorine fed is only

74.7%.

In a third chlorination test according to the invention,

the operation is carried out in two stages as described

below. The operating temperature is here again 70 C.

The 35.0% solution of ferrous chloride circulates con

tinuously with a ?ow of 36 liters per hour through an

from which they are skimmed from time to time. The

neutralized solution still contains very ?ne solid parti

cles, which are eliminated by two glass wool ?lters 12

used alternately; it is then passed to the thermally in

sulatd storage reservoir 13. The temperature is about

60 C.

>

Mean analysis gives:

FeClz: 35.25%

FeCl3: 0.47%

HCl: zero

The yield of the neutralization is 87.5% based on the

weight

of the mill scales, and 94.3% based on their iron

absorption tower ?lled with Raschig rings. The solution

oxide content. The remainder of the iron, which is

absorbs the gaseous chlorine coming from a second

found in the skimmed material and on the ?lters, is not

absorption tower, which will here be called the reactor

re-usable.

?nisher. Through the top of this ?nisher 1560 ml of

From the reservoir 13 the neutralized ferrous chlor

FeCl; solution, already partially chlorinated and taken

from the circulation circuit of the absorption tower, is 20 ide solution is passed at a ?ow of 100 liters per hour by

means of the circulation pump 14 through the pipe 15 to

continuously introduced. This solution is distributed

an

absorption tower 16 Filed with Rascig rings, and

over the ?lling elements of the reactor-?nisher and it is

returns

to the storage reservoir 13 through the pipe 17.

chlorinated in countercurrent by the gaseous chlorine

From this circuit 2675 ml of FeCl2/FeC13 solution are

introduced in excess (63 l per hour = 201 g per hour) at

25 taken per hour by means of a metering pump 18 and

the bottom of the ?nisher.

delivered to the top of the reactor-?nisher l9 ?lled with

The excess chlorine (42 ml per hour

134 g per

Raschig rings, in which it is chlorinated in countercur

hour) passing out at the top of the ?nisher is introduced

rent.

at the bottom of the absorption tower, in which it is

The gaseous chlorine coming from the cylinder 20

absorbed. 1500 ml per hour of fresh 34.25% ferrous

through the pipe 21 is injected at the base of the reactor

chloride solution are introduced per hour into the ab

?nisher. The excess of chlorine leaves the reactor-?n

sorption tower circuit. 1585 ml (2250 g) containing

isher 19 through the pipe 22, and passes to the bottom of

40.75% of FeCl;, 0.04% of FeCl;, and 0.05% of HCl are

the absorption tower 16, in which it is completely ab

withdrawn per hour at the bottom of the reactor-fm

sorbed.

isher. The yield based on the chlorine fed is quantita 35

0n starting up the installation, no FeCl2/FeCl3-solu

tive.

tion is fed to the reactor-?nisher and all the chlorine is

supplied to the absorption tower circuit. As soon as

EXAMPLE 4

50% of the FeClz has been converted into FeCl3, the

Process and apparatus according to the invention.

feeding of the reactor-fmisher is started. The flow of

For the description of this test, reference will be

chlorine is adjusted so as to obtain a conversion of

made to the accompanying drawing.

FeCl; to FeCl; of about 75-80% in the absorption tower

From a storage reservoir 1 holding a pickling solution

circuit. When stationary operating conditions are

containing 24.2% of FeCl; and 0.60% of HCl, 4000 ml

reached, the ?ow of chlorine is 107 liters per hour

(= 4960 g) of solution are fed per hour into an evapora

(342.5 g), and that of the FeClz-FeCl3 mixture to the

tor 3 by means of a metering pump 2. 1504 g of water 45 ?nisher amounts to 2675 ml per hour (3746 g).

and 4.5 g of HCl are evaporated per hour. The vapors

The chlorinated solution leaving at the bottom of the

evolving at the top of the evaporator are condensed in

?nisher 19 (3814.5 g or 2680 ml/h) is passed to the stor

a washer 4 by a current of cold water. The water then

enters a mixer 5, in which it is neutralized by a 30%

age vessel 24 through the pipe 23.

Mean analysis:

NaOH solution coming from the reservoir 6; it then 50 FeCl3: 41.45%

passes out by over?owing and is discharged to the

FeClz: 0.02%

drain.

At the bottom of the evaporator 3 there are obtained

per hour 2550 ml (3450 g) of a solution containing

HCl : 0.05%

C12: nil

The chlorination yield is practically quantitative.;'lhe

assembly comprising the absorption tower circuit and

34.75% of FeCl; and 0.74% of HCl; this solution is 55

passed through a thermally insulated pipe 7 to a ther

reactor-?nisher and also all the pipes are thermally

mally insulated tank 8. The still hot solution (80 C) is

insulated in order to maintain the solution at a fairly

delivered by the pump 9 into the thermally insulated

high temperature and to obtain a good speed of chlori

neutralization reactor 10, in which it passes from bot

nation (50 to 70 C).

tom to top through a bed of iron oxide mill scales 60

We claim:

(height 40 cm 640 g of mill scales) at a space velocity

1. A process for producing an aqueous solution of

of about 42.5 cm3 per minute, so that at least part of the

mill scales is ?uidized. The mill scales have the same

ferric chloride from a pickling liquor containing ferrous

chloride comprising the steps of

composition as in Example 1. The widened top portion

of the reactor reduces the ascending speed by the factor 65

15, thus substantially reducing the entrainment of small

l. continuously concentrating the pickling liquor by

particles by the neutralized solution passing out through

2. continously neutralizing the resulting concentrated

liquor, which still contains free hydrochloric acid,

a side branch situated below the level'of the liquid.

evaporation to at least about 34.25% by weight

ferrous chloride concentration;

4,066,748

10

tained, said solution being directly usable for puri

by means of a ?uidized bed of iron oxide particles;

fying water.

and

. continuously countercurrently chlorinating the

2. A process according to claim 1, wherein the con

centrated liquor at the end of step (1) is at a temperature

of about 70 to 100 C.

resulting neutralized concentrated liquor in two

3. A process according to claim 1,

tralization in step (2) is carried out

86% at a temperature of from 35 to 75 C in the

between 30 and 100 C.

?rst reaction zone and the balance at a temperature

4. A process according to claim 1,

of from 40 to 100 C in the second reaction zonez I0 tralization in step (2) is carried out

between 60 and 90 C.

whereby an aqueous solution containing per liter at

succesive reaction zones, to the extent of from 73 to

wherein the neu

at a temperature

wherein the neu

at a temperature

5. A process according to claim 1, wherein in step (2)

least 40% by weight of ferric chloride, less than

mill scales having a particle size of from 0.1 to 10 mm

0.1% by weight of ferrous chloride and less than

are used as iron oxide particles.

*

I

8

i

i

0.1% by weight of free hydrochloric acid, is ob 15

20

25

30

35

45

50

55

65

Potrebbero piacerti anche

- AlkylationDocumento9 pagineAlkylationabhishek sharma100% (1)

- Sodium Hydroxide Production With A Calcium CarbonaDocumento7 pagineSodium Hydroxide Production With A Calcium CarbonaFebri SandiNessuna valutazione finora

- A751 11Documento6 pagineA751 11Evandro Luis Gomes100% (2)

- The Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresDa EverandThe Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresValutazione: 5 su 5 stelle5/5 (1)

- MetoxidoDocumento8 pagineMetoxidocessavelinoNessuna valutazione finora

- Acetaldehyde Methods 2520of 2520 ProductionDocumento6 pagineAcetaldehyde Methods 2520of 2520 Productionapi-3714811100% (3)

- Organic and Inorganic MineralsDocumento6 pagineOrganic and Inorganic Mineralsartisanicview100% (1)

- Sulfuric Acid Dew Point Corrosion in Waste Heat Boiler Tube For Coppe PDFDocumento8 pagineSulfuric Acid Dew Point Corrosion in Waste Heat Boiler Tube For Coppe PDFFaiz AgungNessuna valutazione finora

- DRI A Hot Briquetted Iron HBI at Terminals Guide For Transporting and HandlingDocumento50 pagineDRI A Hot Briquetted Iron HBI at Terminals Guide For Transporting and Handlingفردوس سليمان100% (2)

- Preparation of Sheet Steel For Porcelain EnamelingDocumento9 paginePreparation of Sheet Steel For Porcelain EnamelingMohammad YoussefiNessuna valutazione finora

- Clay Brick ManufactureDocumento4 pagineClay Brick ManufactureDaniel Reynolds100% (1)

- US4780303 PatensDocumento5 pagineUS4780303 PatensEby OkvaleyNessuna valutazione finora

- United States Patent (191: Yamamoto, Shibukawa SyukiDocumento6 pagineUnited States Patent (191: Yamamoto, Shibukawa SyukiUntung SetiawanNessuna valutazione finora

- Translate Paten US5976485Documento24 pagineTranslate Paten US5976485Lenywulandari AyundaNessuna valutazione finora

- US4780224Documento4 pagineUS4780224Mohamad Reza JahanbakhshNessuna valutazione finora

- Cacl2 Concntrating - 1 PDFDocumento2 pagineCacl2 Concntrating - 1 PDFvahidNessuna valutazione finora

- Us 4899000Documento5 pagineUs 4899000Karen Vanessa GonzalezNessuna valutazione finora

- United States Patent 0 ": Patented Dec. 15, 1959Documento2 pagineUnited States Patent 0 ": Patented Dec. 15, 1959Aaron CurrieNessuna valutazione finora

- United States: Patent OfficeDocumento2 pagineUnited States: Patent OfficeShandy ArmandoNessuna valutazione finora

- United States Patent Office: Patented Jan. 23, 1973Documento2 pagineUnited States Patent Office: Patented Jan. 23, 1973Ahmad DawamNessuna valutazione finora

- Hydrogenation Raney Nickel PatentDocumento3 pagineHydrogenation Raney Nickel PatentIlham FajriNessuna valutazione finora

- United States Patent 0: '3, l50, l74 ICCDocumento2 pagineUnited States Patent 0: '3, l50, l74 ICCMuhammadAmdadulHoqueNessuna valutazione finora

- Us 1045139Documento1 paginaUs 1045139mahmoud IbrahimNessuna valutazione finora

- Sulfuric Acid TreatmentDocumento9 pagineSulfuric Acid TreatmentShankar AcharNessuna valutazione finora

- This Invention Relates To A Process For Making A Stable CopperDocumento3 pagineThis Invention Relates To A Process For Making A Stable CopperAngel BuenoNessuna valutazione finora

- Us2901407 PDFDocumento4 pagineUs2901407 PDFMufita RamadhinaNessuna valutazione finora

- F. J. Klem 3,218,128 : Filed Sept. l0, 1962Documento10 pagineF. J. Klem 3,218,128 : Filed Sept. l0, 1962Yourdan WijayaNessuna valutazione finora

- United States: Patent OfficeDocumento3 pagineUnited States: Patent OfficeIRIENE DELFITA TKIMNessuna valutazione finora

- Method For Preparing Anhydrous Iron ChloridesDocumento4 pagineMethod For Preparing Anhydrous Iron ChloridesVioleta GrigorasNessuna valutazione finora

- US4094913Documento4 pagineUS4094913Ranjana MadabushiNessuna valutazione finora

- European Patent Specification: For The Production of Acetic AcidDocumento9 pagineEuropean Patent Specification: For The Production of Acetic AcidWisnu Rochman HidayatullahNessuna valutazione finora

- A Convenient Preparation of Volatile Acid ChloridesDocumento4 pagineA Convenient Preparation of Volatile Acid ChloridesScott SwartzNessuna valutazione finora

- United States Patent Office: Patented Sept. 5, 1950Documento2 pagineUnited States Patent Office: Patented Sept. 5, 1950ari factoryNessuna valutazione finora

- ANEXO 1 EP 2617678 A1 Método y Sistema para La Preparación de Cloruro de Hidrógeno de Alta PurezaDocumento12 pagineANEXO 1 EP 2617678 A1 Método y Sistema para La Preparación de Cloruro de Hidrógeno de Alta PurezaCésarSánchezRosasNessuna valutazione finora

- Production of Sodium DithioniteDocumento10 pagineProduction of Sodium DithioniteDhaval PadaliaNessuna valutazione finora

- United States Patent: Patented Feb. 2, 1960Documento2 pagineUnited States Patent: Patented Feb. 2, 1960amitNessuna valutazione finora

- Us 4222819Documento10 pagineUs 4222819Omar NinoNessuna valutazione finora

- Ford f150 2019 Electrical Wiring DiagramDocumento22 pagineFord f150 2019 Electrical Wiring Diagramsamuelwilliams190691rmw99% (98)

- Product Description (KNO3)Documento2 pagineProduct Description (KNO3)Vanjared OcampoNessuna valutazione finora

- Indigo Prodn. From Phenyl-Glycine Carboxylic Acid Salt - by Fusion in Mixed Potassium Hydroxide and Sodium Hydroxide Melt, Then OxidnDocumento4 pagineIndigo Prodn. From Phenyl-Glycine Carboxylic Acid Salt - by Fusion in Mixed Potassium Hydroxide and Sodium Hydroxide Melt, Then OxidnCillian CreedonNessuna valutazione finora

- EP2540692A2Documento10 pagineEP2540692A2Aide SyafiqNessuna valutazione finora

- Process For Manufacturing Methyl Chloride Patten 2001Documento6 pagineProcess For Manufacturing Methyl Chloride Patten 2001Mufita RamadhinaNessuna valutazione finora

- TCCA - US3898222 - P - Process For Preparing Trichloroisocyanuric AcidDocumento3 pagineTCCA - US3898222 - P - Process For Preparing Trichloroisocyanuric AcidListya Eka AnggrainiNessuna valutazione finora

- Patent Benzil KloridaDocumento3 paginePatent Benzil KloridaShochib Al FatihNessuna valutazione finora

- Ip ApplicationDocumento29 pagineIp Applicationjarbas juniorNessuna valutazione finora

- Patent 01Documento3 paginePatent 01fatemeh afariNessuna valutazione finora

- Patent EsDocumento8 paginePatent EsWalter RaulNessuna valutazione finora

- Method 410.3: Chemical Oxygen Demand (Titrimetric, High Level For Saline Waters) by TitrationDocumento4 pagineMethod 410.3: Chemical Oxygen Demand (Titrimetric, High Level For Saline Waters) by TitrationMulti Idola TriciaNessuna valutazione finora

- Aiiii: July 7, 1942. E. Mazabraud 2,289,286Documento3 pagineAiiii: July 7, 1942. E. Mazabraud 2,289,286Özlem YılmazNessuna valutazione finora

- Sodium BisulphateDocumento14 pagineSodium BisulphatemelvinkuriNessuna valutazione finora

- TEPZZ 9 9995A - T: European Patent ApplicationDocumento10 pagineTEPZZ 9 9995A - T: European Patent ApplicationAyub riyanNessuna valutazione finora

- United States Patent O?ice: 15H: LLQ?ZDocumento3 pagineUnited States Patent O?ice: 15H: LLQ?ZadamNessuna valutazione finora

- US3093691Documento2 pagineUS3093691Ayu GirlsNessuna valutazione finora

- United States PatentDocumento4 pagineUnited States Patentwiam wiamNessuna valutazione finora

- HCLDocumento13 pagineHCLHussein AlkafajiNessuna valutazione finora

- BleachingDocumento11 pagineBleachingPRATEEKMAHAJAN02Nessuna valutazione finora

- Arease: Nov. 8, 1966 W. Wogt Et Al 3,284,495 Process For The Continuous Manufacture, Purification andDocumento3 pagineArease: Nov. 8, 1966 W. Wogt Et Al 3,284,495 Process For The Continuous Manufacture, Purification andRachmad HermawanNessuna valutazione finora

- US3218127Documento6 pagineUS3218127PABLO URIZ CEREZONessuna valutazione finora

- Materi Sesi 3 - 27 - Hugot - CarbonatationDocumento12 pagineMateri Sesi 3 - 27 - Hugot - CarbonatationAngella LalaNessuna valutazione finora

- US3689216Documento5 pagineUS3689216PABLO URIZ CEREZONessuna valutazione finora

- Unied States W 0: Patented Nov. 11, 1969Documento2 pagineUnied States W 0: Patented Nov. 11, 1969Yeisson MoraNessuna valutazione finora

- United States Patent (191: Inoue Et A) - (11) Patent Number: (45) Date of PatentDocumento4 pagineUnited States Patent (191: Inoue Et A) - (11) Patent Number: (45) Date of PatentShrutiNessuna valutazione finora

- A Further Investigation of the Symmetrical Chloride of Paranitroorthosulphobenzoic AcidDa EverandA Further Investigation of the Symmetrical Chloride of Paranitroorthosulphobenzoic AcidNessuna valutazione finora

- Legal Chemistry: A Guide to the Detection of Poisons, Examination of Tea, Stains, Etc., as Applied to Chemical JurisprudenceDa EverandLegal Chemistry: A Guide to the Detection of Poisons, Examination of Tea, Stains, Etc., as Applied to Chemical JurisprudenceNessuna valutazione finora

- Recent Advances in the Science and Technology of Zeolites and Related Materials: Proceedings of the 14th International Zeolite Conference, Cape Town, South Africa, 25-30th April 2004Da EverandRecent Advances in the Science and Technology of Zeolites and Related Materials: Proceedings of the 14th International Zeolite Conference, Cape Town, South Africa, 25-30th April 2004Nessuna valutazione finora

- State Point Analysis SPA Updated 13jan21Documento19 pagineState Point Analysis SPA Updated 13jan21syafiq izzuddin bin sapriNessuna valutazione finora

- Temperature Control ApplicationDocumento22 pagineTemperature Control Applicationsyafiq izzuddin bin sapriNessuna valutazione finora

- TAPLOT June 2021 SetupsDocumento14 pagineTAPLOT June 2021 Setupssyafiq izzuddin bin sapriNessuna valutazione finora

- 09 RenewablesDocumento33 pagine09 Renewablessyafiq izzuddin bin sapriNessuna valutazione finora

- 1899 - BKAWAN - AnnualReport - 2018-09-30 - BKB 2018 Annual Report (Bursa) - 1747549728 PDFDocumento178 pagine1899 - BKAWAN - AnnualReport - 2018-09-30 - BKB 2018 Annual Report (Bursa) - 1747549728 PDFsyafiq izzuddin bin sapriNessuna valutazione finora

- Stream Table Production of Ferric Chloride SolutionDocumento2 pagineStream Table Production of Ferric Chloride Solutionsyafiq izzuddin bin sapriNessuna valutazione finora

- SRK (Soave Redlich Kwong) Property PackageDocumento5 pagineSRK (Soave Redlich Kwong) Property Packagesyafiq izzuddin bin sapriNessuna valutazione finora

- Globalization and Cultural Hybridization (Print This)Documento19 pagineGlobalization and Cultural Hybridization (Print This)syafiq izzuddin bin sapriNessuna valutazione finora

- Tutorial 4 DateDocumento1 paginaTutorial 4 Datesyafiq izzuddin bin sapriNessuna valutazione finora

- Bugle Hex Drive Roofix Type 17 Wood Tec (Class 2, 3 & 4) : Part NumberDocumento18 pagineBugle Hex Drive Roofix Type 17 Wood Tec (Class 2, 3 & 4) : Part NumbersdewssNessuna valutazione finora

- ENDocumento1 paginaENreacharunkNessuna valutazione finora

- Slide 1Documento44 pagineSlide 1imtinanNessuna valutazione finora

- MDS Report Substances of Assemblies and Materials: 1. Company and Product NameDocumento13 pagineMDS Report Substances of Assemblies and Materials: 1. Company and Product Namejavier ortizNessuna valutazione finora

- fourtyYearsOfcgiInChina PDFDocumento7 paginefourtyYearsOfcgiInChina PDFfdcarazoNessuna valutazione finora

- North-European Trading Centres and The Early Medieval Craftsman Craftsmen at Åhus, North-Eastern Scania, Sweden Ca. AD 750-850+Documento33 pagineNorth-European Trading Centres and The Early Medieval Craftsman Craftsmen at Åhus, North-Eastern Scania, Sweden Ca. AD 750-850+oldenglishblogNessuna valutazione finora

- Iron Carbon Phase DiagramDocumento4 pagineIron Carbon Phase DiagramMizanur RahmanNessuna valutazione finora

- Visa Steel LimitedDocumento7 pagineVisa Steel LimitedDurgadatta RayNessuna valutazione finora

- Kendriya Vidyalaya Sangathan: Chennai RegionDocumento281 pagineKendriya Vidyalaya Sangathan: Chennai RegionAshray EapurNessuna valutazione finora

- Anemia in Pregnancy With Risk FactorsDocumento40 pagineAnemia in Pregnancy With Risk FactorsMohammad Shafiq100% (2)

- Pyrometallurgical Refining of Copper in An Anode Furnace: January 2005Documento13 paginePyrometallurgical Refining of Copper in An Anode Furnace: January 2005maxi roaNessuna valutazione finora

- (@bohring - Bot) 25 - 12 - 2023 - SR - IIT - STAR - CO - S (@HeyitsyashXD)Documento22 pagine(@bohring - Bot) 25 - 12 - 2023 - SR - IIT - STAR - CO - S (@HeyitsyashXD)Idhant SinghNessuna valutazione finora

- Taler Chemical Reactios. General Chemistry Teacher: William Alejandro Andrade BarreiroDocumento8 pagineTaler Chemical Reactios. General Chemistry Teacher: William Alejandro Andrade BarreiroENITH HERRERA MONTALVONessuna valutazione finora

- Color AffectsDocumento4 pagineColor Affectshyde2520015754Nessuna valutazione finora

- Otc 17355https://www - Scribd.com/upload-Document?archive - Doc 235698286&escape False&metadata ("Context":"archive","page":"read","action":"toolbar - Download","logged - In":false,"platform":"web") #Documento10 pagineOtc 17355https://www - Scribd.com/upload-Document?archive - Doc 235698286&escape False&metadata ("Context":"archive","page":"read","action":"toolbar - Download","logged - In":false,"platform":"web") #GNessuna valutazione finora

- Hubungan Konsumsi Suplemen Tablet Fe Dengan Kebugaran Jasmani (Studi Pada Siswi Di SMA Negeri 15 Semarang)Documento7 pagineHubungan Konsumsi Suplemen Tablet Fe Dengan Kebugaran Jasmani (Studi Pada Siswi Di SMA Negeri 15 Semarang)Sri SuryaniNessuna valutazione finora

- Oil Filter Final RPTDocumento69 pagineOil Filter Final RPTNazeeh Abdulrhman AlbokaryNessuna valutazione finora

- HyMelt Gasification Process Development ProjectDocumento50 pagineHyMelt Gasification Process Development ProjectBá Văn TôNessuna valutazione finora

- Ground Water Quality Assessment of Rajshahi City Bangladesh A Case Study PDFDocumento6 pagineGround Water Quality Assessment of Rajshahi City Bangladesh A Case Study PDFArif HasnatNessuna valutazione finora

- Jsunil Tutorial, Samastipur: Vi Science Chapter - Fun With Magnets I. Fill in The BlanksDocumento1 paginaJsunil Tutorial, Samastipur: Vi Science Chapter - Fun With Magnets I. Fill in The BlankspreethaNessuna valutazione finora

- Martensitic Transformation in AISI 440C Stainless SteelDocumento5 pagineMartensitic Transformation in AISI 440C Stainless SteelSergio Fernando Resendiz PerezNessuna valutazione finora

- VSA Type QuestionsDocumento7 pagineVSA Type QuestionsTapas BanerjeeNessuna valutazione finora

- Engineering Materials For Electrical Engineers: INGE 3045Documento43 pagineEngineering Materials For Electrical Engineers: INGE 3045Seema SharmaNessuna valutazione finora

- Physical and Chemical Changes Class 7 ScienceDocumento17 paginePhysical and Chemical Changes Class 7 Sciencesanyam nayakNessuna valutazione finora