Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

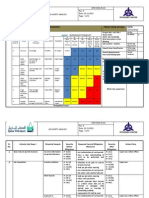

0102 Powder Coating Work Area

Caricato da

ernestoemCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

0102 Powder Coating Work Area

Caricato da

ernestoemCopyright:

Formati disponibili

NOMBRE DEL DOCUMENTO

POWDER COATING WORK

AREA

IDENTIFICACION DEL DOCUMENTO

NL-PED-10-0102

REV. 0

PAGINA 1 DE 4

1.0 PURPOSE

1.1 Provide instructions on the operation of the powder coating system.

2.0 SCOPE

2.1 Applies to all components powder coated in house.

3.0 RELATED DOCUMENTS

3.1 Please refer the specification APP-MY51-Z0-001. APP-G1-MX-001 and

APP-G1-SX-001. And the coating must meet the requirements in the

reference documents.

4.0 RESPONSIBILITIES

4.1 It is the responsibility of the powder coating operators to follow all

Chromalox safety policies and procedures. Proper safety equipment must

be worn at all times while operating the powder coating station.

4.2 It is the responsibility of all operators to read and understand the RPO,

drawing, and all other paper work that comes with the order. If at any time,

the paper work is incomplete or cannot be understood, stop and contact

your lead or quality.

4.3 It is the responsibility of all operators to maintain and clean and safe work

area. Remove any out of place material to prevent any tripping hazards.

5.0 PROCEDURE

5.1 Every Monday before beginning any powder coating, clean the spray

platform and filters per standard shop practice. Every three months or at the

beginning of each quarter, clean out the washer unit this includes cleaning

the spray nozzles.

FECHA DE EMISION: 06/23/2014

PREPARADO POR: MARCO MORALES

UNCONTROLLED COPY

NOMBRE DEL DOCUMENTO

POWDER COATING WORK

AREA

IDENTIFICACION DEL DOCUMENTO

NL-PED-10-0102

REV. 0

PAGINA 2 DE 4

5.2 Verify that the temperature of both ovens is 375 degrees.

5.3 Visually inspect parts to be painted for obvious damage when hanging the

parts on the paint line.

FECHA DE EMISION: 06/23/2014

PREPARADO POR: MARCO MORALES

UNCONTROLLED COPY

NOMBRE DEL DOCUMENTO

POWDER COATING WORK

AREA

IDENTIFICACION DEL DOCUMENTO

NL-PED-10-0102

REV. 0

PAGINA 3 DE 4

5.4 Verify paint color per the RPO before hanging parts. Obtain the proper

color from the paint storage area and prepare for painting per standard shop

practice.

5.5 Paint the parts per the RPO and standard shop practice.

5.6 When removing the parts from the paint line visually inspect parts for

complete coverage and acceptance.

5.7 Package, bag, tag painted parts as required to maintain traceability.

5.8 Do not forward any part to the next work center or shipping that does not

meet engineering requirements and requirements in the RPO. If any part

FECHA DE EMISION: 06/23/2014

PREPARADO POR: MARCO MORALES

UNCONTROLLED COPY

NOMBRE DEL DOCUMENTO

POWDER COATING WORK

AREA

IDENTIFICACION DEL DOCUMENTO

NL-PED-10-0102

REV. 0

PAGINA 4 DE 4

does not meet the requirements at this level initiate an NCM tag and place

the components in the NCM cart along with the NCM tag.

6.0 APPROVAL

DEPARTMENT:

APPROVER:

SIGNATURES:

DATE:

Production

Manufacturing

Quality Assurance

ISO Coordinator

Aurelio Mendoza

Dante Gonzalez

Marcela Eng.

Patricia Arenas

Aurelio Mendoza

Dante Gonzalez

Marcela Eng.

Patricia Arenas

06/24/14

06/24/14

07/03/14

06/23/14

7.0 REVISION NOTES

Fecha

Nivel de

revisin

Comentarios

Firma

06/23/2014

New Document

Marco Morales

FECHA DE EMISION: 06/23/2014

PREPARADO POR: MARCO MORALES

UNCONTROLLED COPY

Potrebbero piacerti anche

- Abrasive Blasting HSE Icp003v1 PDFDocumento66 pagineAbrasive Blasting HSE Icp003v1 PDFdrbeyerNessuna valutazione finora

- Powder Coating GuideDocumento35 paginePowder Coating Guidegcldesign100% (1)

- Spray Painting and Powder Coating NDocumento38 pagineSpray Painting and Powder Coating NAbdulSamad100% (1)

- Powder Coating PDFDocumento56 paginePowder Coating PDFMalathi ISO100% (1)

- Painting Procedure For Field Erected Tank FINAL (13850)Documento22 paginePainting Procedure For Field Erected Tank FINAL (13850)Parthiban NCNessuna valutazione finora

- Abrasive Blasting and Spray Painting SafetyDocumento10 pagineAbrasive Blasting and Spray Painting SafetyOgala OscarNessuna valutazione finora

- Assembly Transmission Volvo A40GDocumento52 pagineAssembly Transmission Volvo A40GNanang SetiawanNessuna valutazione finora

- The Powder Coaters ManualDocumento209 pagineThe Powder Coaters ManualOvation Audio Labs100% (4)

- Paint & CoatingDocumento43 paginePaint & CoatingKelly Bates80% (5)

- COATING PROCEDURES AT A GLANCEDocumento10 pagineCOATING PROCEDURES AT A GLANCENanang Cesc Utta100% (1)

- Marginal Field Development Concepts (Compatibility Mode)Documento17 pagineMarginal Field Development Concepts (Compatibility Mode)nallay1705100% (1)

- Product Details CD Programs: Basic Injection Molding Machine OperationsDocumento25 pagineProduct Details CD Programs: Basic Injection Molding Machine OperationsOmar A. Hernandez100% (1)

- SSPC Trainthepainter WebinarDocumento64 pagineSSPC Trainthepainter WebinarFreddy Carl Fredricksen100% (2)

- Industrial Solutions Powder Applications: Market-leading manufacturer WAGNERDocumento280 pagineIndustrial Solutions Powder Applications: Market-leading manufacturer WAGNERoarionIIINessuna valutazione finora

- Lead Funnels On Funnel Swipe File - TrelloDocumento5 pagineLead Funnels On Funnel Swipe File - TrelloKatherie BriersNessuna valutazione finora

- Metal Factory Powder Coating ProcessDocumento2 pagineMetal Factory Powder Coating Processshrikanth5singh100% (2)

- QP Blasting JSADocumento6 pagineQP Blasting JSAMohammed Mujahid100% (1)

- Protective Coatings Technician Certification SchemeDocumento4 pagineProtective Coatings Technician Certification Schemezeidisuck100% (1)

- Coating Application ProcedureDocumento15 pagineCoating Application ProcedureThinh NguyenNessuna valutazione finora

- 1.1 Thermodynamics 1Documento28 pagine1.1 Thermodynamics 1Lyan SantosNessuna valutazione finora

- Corrosion ProtectionDocumento95 pagineCorrosion ProtectionNestor Mijares100% (1)

- Painting ProcedureDocumento17 paginePainting Procedurestdshop75% (4)

- Shot Blasting Painting PRDocumento41 pagineShot Blasting Painting PRjoseph100% (3)

- Corrosion Protection MeasuresDocumento17 pagineCorrosion Protection MeasuresIliyanPetrov100% (1)

- Triocon Powder Coating - ProcedureDocumento15 pagineTriocon Powder Coating - ProceduresindalisindiNessuna valutazione finora

- Hemispherical Head Design ToolDocumento1 paginaHemispherical Head Design Toolnaveen_86Nessuna valutazione finora

- NORSOK Coating System No. 1 Carbon Steel 120CDocumento5 pagineNORSOK Coating System No. 1 Carbon Steel 120CSam Jose100% (1)

- Process Document: Health Safety & Environment Management (Version 1.0)Documento8 pagineProcess Document: Health Safety & Environment Management (Version 1.0)Tonmay MajumderNessuna valutazione finora

- Painting Specification for Aegean Refinery ProjectDocumento18 paginePainting Specification for Aegean Refinery Projectraluca_19735597Nessuna valutazione finora

- b25d b30d Mkiii HydraulicsDocumento28 pagineb25d b30d Mkiii HydraulicsErmias100% (3)

- Abrasive Blasting Safe Work PDFDocumento2 pagineAbrasive Blasting Safe Work PDFamirthraj74100% (1)

- Coating Procedure - General Rev.03Documento35 pagineCoating Procedure - General Rev.03moytabura96100% (2)

- Con-011 Instruction For Painting Work Rev.0Documento11 pagineCon-011 Instruction For Painting Work Rev.0monchai_626Nessuna valutazione finora

- 1method Statement For Passivation and PicklingDocumento6 pagine1method Statement For Passivation and PicklinggatoNessuna valutazione finora

- Blasting & Painting Ops ProcedureDocumento12 pagineBlasting & Painting Ops ProcedurekolaaruNessuna valutazione finora

- Blasting & Painting EquipmentDocumento15 pagineBlasting & Painting EquipmentDihya Khalifa Al-qalbiNessuna valutazione finora

- E & C Stycast 2651-40 PDFDocumento3 pagineE & C Stycast 2651-40 PDFernestoemNessuna valutazione finora

- E & C Stycast 2651-40 PDFDocumento3 pagineE & C Stycast 2651-40 PDFernestoemNessuna valutazione finora

- Ebook Powder CoatingDocumento27 pagineEbook Powder Coatinggcldesign100% (1)

- Wi (2) Powder CoatingDocumento9 pagineWi (2) Powder CoatingMalathi ISONessuna valutazione finora

- Contractor IOT Infrastructure & Energy Services LTDDocumento38 pagineContractor IOT Infrastructure & Energy Services LTDNaveen KurupNessuna valutazione finora

- Blasting Painting ProcedureDocumento4 pagineBlasting Painting ProcedureRyanNessuna valutazione finora

- Statistics Interview QuestionsDocumento5 pagineStatistics Interview QuestionsARCHANA R100% (1)

- ICorr CED CT02 CoatingSurfacePreparationMethods Issue1 PDFDocumento13 pagineICorr CED CT02 CoatingSurfacePreparationMethods Issue1 PDFOsama Elhadad100% (1)

- Jotun Powder CoatingDocumento12 pagineJotun Powder Coatingzahee007100% (1)

- JSA Tank Coating WorkDocumento7 pagineJSA Tank Coating WorkPerwez21Nessuna valutazione finora

- Painting Over Hot Dip Galvanized SteelDocumento6 paginePainting Over Hot Dip Galvanized SteelRico Tong100% (1)

- Painting Procedure NG SystemsDocumento6 paginePainting Procedure NG SystemsTanveer Rajput EngrNessuna valutazione finora

- Corporate Safety & Environmental Inspection ReportDocumento5 pagineCorporate Safety & Environmental Inspection ReportPang Lee ChingNessuna valutazione finora

- AI Hempel's Galvosil 15700 EnglishDocumento7 pagineAI Hempel's Galvosil 15700 EnglishvitharvanNessuna valutazione finora

- Application Guide Penguard MidcoatDocumento6 pagineApplication Guide Penguard Midcoatadeoye_okunoyeNessuna valutazione finora

- Working Procedure For Coating Repair C4Documento7 pagineWorking Procedure For Coating Repair C4tuyen nguyenNessuna valutazione finora

- Painting Procedure For CondenceDocumento26 paginePainting Procedure For CondenceNamta GeorgeNessuna valutazione finora

- Ves 5140 R13Documento23 pagineVes 5140 R13Dwiadi CahyabudiNessuna valutazione finora

- FBE Testleri - DeFelskoDocumento54 pagineFBE Testleri - DeFelskoÖzgür TuştaşNessuna valutazione finora

- Surfacepreparation StandardDocumento11 pagineSurfacepreparation StandardAri SupramonoNessuna valutazione finora

- Academic Transition To Senior High SchoolDocumento30 pagineAcademic Transition To Senior High SchoolGabriel ExalaNessuna valutazione finora

- MN00119 Unicom LT User ManualDocumento45 pagineMN00119 Unicom LT User ManualPhilipp A IslaNessuna valutazione finora

- Powder Coating ProcessDocumento4 paginePowder Coating ProcessDeep Narayan JaiswalNessuna valutazione finora

- Monthly Inspection Report For Cranes and HoistsDocumento2 pagineMonthly Inspection Report For Cranes and HoistsGrace PassiniNessuna valutazione finora

- Bright Blue Chromate Coating for Zinc ProtectionDocumento3 pagineBright Blue Chromate Coating for Zinc ProtectionLuuThiThuyDuongNessuna valutazione finora

- Job Safety Analysis (Jsa)Documento9 pagineJob Safety Analysis (Jsa)MohdHuzairiRusliNessuna valutazione finora

- Unitech Metro - SAFE WORK METHOD STATEMENT - PAINTINGDocumento4 pagineUnitech Metro - SAFE WORK METHOD STATEMENT - PAINTING'David TeeNessuna valutazione finora

- 01fitting in FabricationDocumento11 pagine01fitting in Fabricationv.bhamidi100% (1)

- Carboguard 703 GFDocumento2 pagineCarboguard 703 GFlhanx2100% (2)

- GAMESA Handbook Hempel 024 en Rev5 June2016Documento47 pagineGAMESA Handbook Hempel 024 en Rev5 June2016asim alok swain100% (2)

- JD Manager-Machine ShopDocumento2 pagineJD Manager-Machine ShopParveen (Atam Valves)Nessuna valutazione finora

- BGAS-CSWIP Site Coatings Inspector TrainingDocumento3 pagineBGAS-CSWIP Site Coatings Inspector Trainingdang21720140% (2)

- GS-09 (Painting) PDFDocumento22 pagineGS-09 (Painting) PDFSarbendu PaulNessuna valutazione finora

- SKMBT 22315021610591Documento5 pagineSKMBT 22315021610591clintonNessuna valutazione finora

- RoadDocumento1 paginaRoadernestoemNessuna valutazione finora

- LagoDocumento1 paginaLagoernestoemNessuna valutazione finora

- FRESASDocumento1 paginaFRESASernestoemNessuna valutazione finora

- MU8063 KitchenCabMadeSimpleDocumento4 pagineMU8063 KitchenCabMadeSimpleernestoemNessuna valutazione finora

- Sport CarDocumento1 paginaSport CarernestoemNessuna valutazione finora

- Tuffaloy SpotcoDocumento54 pagineTuffaloy SpotcoernestoemNessuna valutazione finora

- George JonesDocumento1 paginaGeorge JonesernestoemNessuna valutazione finora

- MontanaDocumento1 paginaMontanaernestoemNessuna valutazione finora

- Rot in SolitudeDocumento1 paginaRot in SolitudeernestoemNessuna valutazione finora

- Petro LeoDocumento2 paginePetro LeoernestoemNessuna valutazione finora

- Inv 214041 From Hill Tool LLC 15176 PDFDocumento1 paginaInv 214041 From Hill Tool LLC 15176 PDFernestoemNessuna valutazione finora

- Tool Holder RackDocumento1 paginaTool Holder RackernestoemNessuna valutazione finora

- Constitucion Politica Del Estado de TamaulipasDocumento1 paginaConstitucion Politica Del Estado de TamaulipasernestoemNessuna valutazione finora

- Inv 214041 From Hill Tool LLC 15176 PDFDocumento1 paginaInv 214041 From Hill Tool LLC 15176 PDFernestoemNessuna valutazione finora

- EZ Industrial Enclosure Booth Drawing PDFDocumento1 paginaEZ Industrial Enclosure Booth Drawing PDFernestoemNessuna valutazione finora

- M-Series II Flame SafeguardDocumento2 pagineM-Series II Flame SafeguardernestoemNessuna valutazione finora

- Modc Pepi PDFDocumento1 paginaModc Pepi PDFernestoemNessuna valutazione finora

- C 466160-2 JDocumento1 paginaC 466160-2 JernestoemNessuna valutazione finora

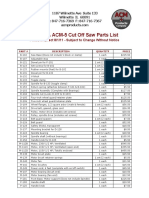

- ACM Parts Pricing 2011Documento1 paginaACM Parts Pricing 2011ernestoemNessuna valutazione finora

- ATEXDocumento2 pagineATEXernestoemNessuna valutazione finora

- 013 - FlashdanceDocumento11 pagine013 - FlashdanceernestoemNessuna valutazione finora

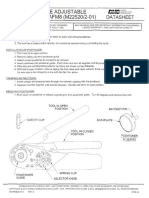

- AFM8 DsDocumento2 pagineAFM8 DsernestoemNessuna valutazione finora

- Disney - SomedayDocumento1 paginaDisney - SomedayernestoemNessuna valutazione finora

- Plyometric Training Programs For Young Soccer Players: A Systematic ReviewDocumento7 paginePlyometric Training Programs For Young Soccer Players: A Systematic ReviewsteNessuna valutazione finora

- Ajp Microproject ReportDocumento9 pagineAjp Microproject ReportRushikesh KanseNessuna valutazione finora

- Computers and Operations Research: Yulin Sun, Simon Cong Guo, Xueping LiDocumento12 pagineComputers and Operations Research: Yulin Sun, Simon Cong Guo, Xueping LiQuỳnh NguyễnNessuna valutazione finora

- 5e Lesson Plan s16 - MagnetsDocumento6 pagine5e Lesson Plan s16 - Magnetsapi-317126609Nessuna valutazione finora

- BOQ Sample of Electrical DesignDocumento2 pagineBOQ Sample of Electrical DesignAshik Rahman RifatNessuna valutazione finora

- Ayurveda Signs of LifeDocumento15 pagineAyurveda Signs of LifeSanjeethNessuna valutazione finora

- Food Conformity BA 550-13Documento9 pagineFood Conformity BA 550-13puipuiesperaNessuna valutazione finora

- Soft Computing Techniques Assignment1 PDFDocumento14 pagineSoft Computing Techniques Assignment1 PDFshadan alamNessuna valutazione finora

- The Chair As Health Hazard Part II J of PDFDocumento11 pagineThe Chair As Health Hazard Part II J of PDFPablo BuniakNessuna valutazione finora

- Application-Form MRP-INFORMCC 2021 VFFDocumento5 pagineApplication-Form MRP-INFORMCC 2021 VFFBouramaNessuna valutazione finora

- BS (English) Dept of English University of SargodhaDocumento36 pagineBS (English) Dept of English University of SargodhaFEROZ KHANNessuna valutazione finora

- Formulating and Solving LPs Using Excel SolverDocumento8 pagineFormulating and Solving LPs Using Excel SolverAaron MartinNessuna valutazione finora

- 10 ExtSpringsDocumento27 pagine10 ExtSpringsresh27Nessuna valutazione finora

- Global Financial Reporting Convergence: A Study of The Adoption of International Financial Reporting Standards by The Swedish Accountancy ProfessionDocumento21 pagineGlobal Financial Reporting Convergence: A Study of The Adoption of International Financial Reporting Standards by The Swedish Accountancy Professionihda0farhatun0nisakNessuna valutazione finora

- ABS Approved Foundries May 12 2014Documento64 pagineABS Approved Foundries May 12 2014Joe ClarkeNessuna valutazione finora

- ME1001, ME1004, ME1005 - Basic Mech+Graphics+Workshop Pract.Documento6 pagineME1001, ME1004, ME1005 - Basic Mech+Graphics+Workshop Pract.Mayank AgarwalNessuna valutazione finora

- Part A - Exercises: © Festo Didactic GMBH & Co. KG - 541091Documento128 paginePart A - Exercises: © Festo Didactic GMBH & Co. KG - 541091Franklin BosiNessuna valutazione finora

- Bashir Ahmad NewDocumento3 pagineBashir Ahmad NewBashir AhmadNessuna valutazione finora

- PC 5400 PC 5500Documento53 paginePC 5400 PC 5500ArturHeiseNessuna valutazione finora

- Chem 361 Separation Methods IntroDocumento8 pagineChem 361 Separation Methods IntroTwum SomoahNessuna valutazione finora

- Influence of Social Studies Education On Ethnic and Religious Tolerance Among National Certificate of Education Students in Kaduna State.Documento104 pagineInfluence of Social Studies Education On Ethnic and Religious Tolerance Among National Certificate of Education Students in Kaduna State.Tsauri Sule SalehNessuna valutazione finora