Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Experiment 5 PDF

Caricato da

TatendaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Experiment 5 PDF

Caricato da

TatendaCopyright:

Formati disponibili

Hydraulics Lab (ECIV 3122)

Islamic University Gaza (IUG)

Experiment (5): Flow through small orifices

Introduction:

An Orifice is an opening in the side or base of tank or reservoir through which fluid is discharge in

the form of a jet. The discharge will depend up on the head of the fluid (H) above the level of the

orifice. The term small orifice means that the diameter of the orifice is small compared with the

head producing flow.

The analysis of the quantity of water which can be discharged through an orifice is arrived at in a

simple, straightforward manner by the application of Bernoulli's equation. However, experimental

tests typically produce a result which is only some 65% of the solution indicated by the simple

analysis. The study of water flow through an orifice is therefore a classic topic to illustrate the need

for a semi-empirical approach which is so often required in Mechanics of Fluids.

Exercise A: Flow through a small orifice

Purpose:

To investigate the discharge characteristics of circular orifices subjected to a constant head.

Apparatus:

1. Constant head inlet tank (Figure 1).

2. Circular orifices with different diameters.

3. Hydraulic bench.

Instructors : Dr. Khalil M. Alastal

Eng. Mohammed Y. Mousa

Hydraulics Lab (ECIV 3122)

Islamic University Gaza (IUG)

Figure 1: Constant head inlet tank with circular orifice

Equipment set up:

Set up the apparatus on top of the hydraulics bench with the left hand support feet of the impact of

jet apparatus located on the two left hand locating pegs of the hydraulics bench so that the

apparatus straddles the weir channel. Connect the feed tube from the hydraulics bench to the boss

on the rear of the base of the impact of jet apparatus. Fit the 5mm nozzle and the normal flat target.

1. If the hook gauge and scale are to be used to measure the trajectory of horizontal jets then place

the two positioning rails on the worktop of the hydraulics bench engaging them onto the

locating pegs. Ensure that the engraved rail is placed closest to the front of the hydraulics bench

with the engraved side uppermost.

2. Position the constant head inlet tank onto the worktop of the hydraulics bench (over the hook

gauge positioning rails, if fitted) at the left hand side engaging two of the feet of the inlet tank

onto the locating pegs. If the orifice is to be fitted into the side of the inlet tank then it should be

moved to the left so that the right hand support feet engage with the locating pegs.

3. Remove the hexagonal (37mm across flats) bush and adaptor from the side of the inlet tank. Fit

the required orifice into the screwed hole in the side and plug the unusued hole using the

blanking plug provided.

Instructors : Dr. Khalil M. Alastal

Eng. Mohammed Y. Mousa

Hydraulics Lab (ECIV 3122)

Islamic University Gaza (IUG)

4. Connect the hydraulics bench flexible delivery tube to the connection provided on the rear of

the inlet tank base. Insert the flexible overflow take off pipe, which is connected to the boss on

the front of the inlet tank, into the overflow pipe of the volumetric measuring tank.

5. Remove or refit the overflow extention tube (screwed) in the inlet head tank to obtain a

nominal head of 250mm or 500mm above the side orifice.

A. Setting the overflow: Switch on the pump and control the flow rate by either adjusting the

hydraulics bench delivery valve or by adjusting the pump speed. The flow should be adjusted

carefully to produce a small but constant overflow and then fine adjusted to give 250 or 500mm

head as required.

B. Flow measurement: The discharge from the orifice may be measured using the volumetric

measuring tank and taking the time required to collect a quantity of water. The quantity should

be chosen so that the time to collect the quantity is at least 120 seconds to obtain a sufficiently

accurate result.

C. Measurement of jet trajectory: Use the hook gauge to measure the trajectory of the jet.

D. Measurement of head: The scale attached to the side of the inlet tank has its zero level with the

centre line of the side outlet boss.

Theory:

Consider a small orifice in the side of a vessel with the head of water above the orifice kept

constant.

Figure 2: Discharge through an orifice

Applying Bernoulli's theorem between the surface of the water 1 and the orifice O yields

Instructors : Dr. Khalil M. Alastal

Eng. Mohammed Y. Mousa

Hydraulics Lab (ECIV 3122)

However

Islamic University Gaza (IUG)

= atmospheric pressure

hence substituting these into Bernoulli's equation gives

In other words, the theoretical velocity of the water passing through the orifice is given by

and hence the quantity of water being discharged through the orifice is given by

However in practice the discharge is always less than this theoretical amount due to the viscosity of

the fluid, to surface tension and due to resistance of the air. The disparity between the theoretical

discharge velocity and the actual discharge velocity is allowed for by introducing a factor

known as the coefficien of velocity so that

If the discharge from a sharp edged orifice is examined closely it will be observed that the minimum

diameter of the jet of water discharging from the orifice is smaller than the orifice diameter. The

plane at which this occurs is known as the vena contracta, which is the plane where stream lines

first become parallel. Applying the discharge equation at the vena contracta

which can be written as

Where:

or more simply as

Where:

Typical values of Cd range from 06 to 065, i.e. the actual flow through a sharp edged orifice is

approximately 60% of the theoretical value. The value of the coefficient of discharge may be

Instructors : Dr. Khalil M. Alastal

Eng. Mohammed Y. Mousa

Hydraulics Lab (ECIV 3122)

Islamic University Gaza (IUG)

determined by measuring the quantity of water discharged over a period of time whilst the head is

maintained at a constant level.

Procedures:

1.

Fit the 5mm diameter orifice into the side of the inlet head tank. Remove the overflow

extension pipe. Start the pump and set up an inlet head of 25cm. Measure the flow rate using

the volumetric measuring tank.

2.

Replace the overflow extension pipe and set up an inlet head of 50cm. Measure the flow rate.

3.

Repeat the procedure using the 8mm orifice.

Results:

1.

Record the results on a copy of the result sheet for discharge characteristics.

2.

For each result calculate the flowrate

3.

Plot a graph of square root of the head against the flow rate for each orifice diameter, the

results should lie on a straight line passing through the origin to confirm that:

Measure the slope of each graph and calculate the coefficient of discharge for each orifice from

D (mm)

H (cm)

5

50

8

25

50

25

(m)

V (L)

T (sec)

(m3/s)

Instructors : Dr. Khalil M. Alastal

Eng. Mohammed Y. Mousa

Hydraulics Lab (ECIV 3122)

Islamic University Gaza (IUG)

Exercise B: Trajectory of horizontal jet

Purpose:

To investigate the trajectory of a horizontal jet issuing from an orifice and hence determine the

coefficient of velocity for the orifice.

Apparatus:

1. Constant head inlet tank (Figure 1).

2. Circular orifices with different diameters.

3. Hook gauge and scale.

4. Hydraulic bench.

Theory:

Consider the trajectory of a jet formed by the discharge of water through an orifice mounted in the

side of a tank. The jet will be subjected to a downward acceleration of g due to gravity.

Figure 3: Trajectory of horizontal jet

Taking the origin of co-ordinates at the vena-contracta and applying the laws of motion in the

horizontal and vertical planes then ignoring any effect of air resistance on the jet.

In the horizontal direction

In the vertical direction

Solving simultaneously by eliminating t

Instructors : Dr. Khalil M. Alastal

Eng. Mohammed Y. Mousa

Hydraulics Lab (ECIV 3122)

Islamic University Gaza (IUG)

Procedures:

1.

Fit the 5mm diameter orifice into the side of the inlet head tank. Remove the overflow

extension pipe. Start the pump and set up an inlet head of 25cm.

2.

Measure the trajectory of the jet using the hook gauge. Record the horizontal and vertical

distances.

3.

Replace the overflow extension tube and establish an inlet head of 500mm. Measure the

trajectory of the jet

4.

Repeat the experiment using the 8mm diameter orifice.

Results:

1.

Draw a graph of y against x to represent the trajectory.

2.

Draw a graph of

against x and draw the best straight line through the points to represent

the results. Measure the slope of the line and hence calculate the coefficient of velocity from:

Instructors : Dr. Khalil M. Alastal

Eng. Mohammed Y. Mousa

Hydraulics Lab (ECIV 3122)

D (mm)

H (cm)

x (cm)

Islamic University Gaza (IUG)

5

25

8

50

25

50

Vertical distance below orifice center line y (cm)

0

5

10

15

20

25

30

35

40

45

50

Slope of graph

Instructors : Dr. Khalil M. Alastal

Eng. Mohammed Y. Mousa

Potrebbero piacerti anche

- Experiment 6 Hydraulics LabDocumento6 pagineExperiment 6 Hydraulics LabTinaNessuna valutazione finora

- Pipeline Design for Water EngineersDa EverandPipeline Design for Water EngineersValutazione: 5 su 5 stelle5/5 (1)

- Experiment 6 Hydraulics LabDocumento6 pagineExperiment 6 Hydraulics LabAuzaNessuna valutazione finora

- Prevention of Actuator Emissions in the Oil and Gas IndustryDa EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNessuna valutazione finora

- Flow Through An OrificeDocumento8 pagineFlow Through An OrificeKevin VillaNessuna valutazione finora

- FM Lab ManualDocumento76 pagineFM Lab ManualsidharthNessuna valutazione finora

- Southern Marine Engineering Desk Reference: Second Edition Volume IDa EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INessuna valutazione finora

- Experiment 4 Hydraulics LabDocumento10 pagineExperiment 4 Hydraulics Labحاتم الشمرانيNessuna valutazione finora

- Lab HandoutDocumento9 pagineLab HandoutlitrakhanNessuna valutazione finora

- OrificeDocumento7 pagineOrificePrasillaPrisiNessuna valutazione finora

- Ce140-0p 3x5Documento14 pagineCe140-0p 3x5naikin_10310% (1)

- Flow Through Small Orifice PDFDocumento10 pagineFlow Through Small Orifice PDFYasser AlshantiNessuna valutazione finora

- Free and Forced VortexDocumento6 pagineFree and Forced VortexSatiah WahabNessuna valutazione finora

- Flow Over WeirsDocumento13 pagineFlow Over WeirsAkmalhakim Zakaria100% (4)

- Experiment - Fre and Forced Vortex UitmDocumento22 pagineExperiment - Fre and Forced Vortex UitmAdil Rahman100% (1)

- Fluid Mechanics Lab ManualDocumento53 pagineFluid Mechanics Lab ManualprashanthreddyhNessuna valutazione finora

- 10.open ChannelDocumento23 pagine10.open ChannelNani DeramanNessuna valutazione finora

- Open Channel Flow 3711Documento3 pagineOpen Channel Flow 3711Fearless HeroNessuna valutazione finora

- Flow Through OrificesDocumento9 pagineFlow Through OrificesShida Shidot100% (1)

- Energy Losses in Bends - : Experiment No. - 09Documento7 pagineEnergy Losses in Bends - : Experiment No. - 09John Michael Menoza ZapantaNessuna valutazione finora

- Lab ReportDocumento23 pagineLab ReportAmy Farhana100% (1)

- Assignment-2: Aee244-Fluid Mechanics Aerospace Engineering DepartmentDocumento9 pagineAssignment-2: Aee244-Fluid Mechanics Aerospace Engineering DepartmentMuhammed Furkan SOYLUNessuna valutazione finora

- Faculty of Chemical EngineeringDocumento32 pagineFaculty of Chemical EngineeringArif HanafiNessuna valutazione finora

- Orifice Meter ExperimentDocumento10 pagineOrifice Meter ExperimentAmoluck BhatiaNessuna valutazione finora

- Hydraulics Experiment 7Documento9 pagineHydraulics Experiment 7Allen Jesse Alfonso AtanacioNessuna valutazione finora

- Fluid Mechanics Lab Manual - R2Documento7 pagineFluid Mechanics Lab Manual - R2Deact DiyanaNessuna valutazione finora

- Free and Forced VortexDocumento8 pagineFree and Forced Vortexsmh khanNessuna valutazione finora

- BLANKADocumento15 pagineBLANKADev jibreenNessuna valutazione finora

- Flow Over WeirsDocumento13 pagineFlow Over WeirsIwuoha Maxrofuzo ChibuezeNessuna valutazione finora

- Energy Losses in Pipes: Experiment No. - 11Documento6 pagineEnergy Losses in Pipes: Experiment No. - 11John Michael Menoza ZapantaNessuna valutazione finora

- FM CompleteDocumento19 pagineFM Completenini jasniNessuna valutazione finora

- (Chemical Engineering Laboratory 2) : Orifice Discharge Segi UniversityDocumento12 pagine(Chemical Engineering Laboratory 2) : Orifice Discharge Segi UniversitygongweejieNessuna valutazione finora

- Hydraulic Coefficients of Orifice and Bernoulli TheoremDocumento5 pagineHydraulic Coefficients of Orifice and Bernoulli TheoremerronNessuna valutazione finora

- Energy Losses in Pipes: Experiment # 4Documento4 pagineEnergy Losses in Pipes: Experiment # 4محمد جوادNessuna valutazione finora

- Hydraulics Laboratory ManualDocumento37 pagineHydraulics Laboratory ManualHarold Taylor100% (2)

- Lab ManualDocumento15 pagineLab ManualokbhaNessuna valutazione finora

- Experimental Verification of Gradually Varied Flow Profile ComputationDocumento11 pagineExperimental Verification of Gradually Varied Flow Profile ComputationLim Shwe WenNessuna valutazione finora

- MiniTilting Flume - CollectingtankDocumento11 pagineMiniTilting Flume - CollectingtankSri E.Maheswar Reddy Assistant ProfessorNessuna valutazione finora

- Laporan Praktikum Mekflud SisiDocumento9 pagineLaporan Praktikum Mekflud SisiKia FajarNessuna valutazione finora

- Experiment 3 Bernoulli's TheoremDocumento26 pagineExperiment 3 Bernoulli's TheoremSaber Minato Azrul100% (1)

- Government Polytechnic Muzaffarpur: Lab Manual of Fluid Mechanics and Machinery Lab SUBJECT CODE - 1625407Documento22 pagineGovernment Polytechnic Muzaffarpur: Lab Manual of Fluid Mechanics and Machinery Lab SUBJECT CODE - 1625407Web Tech Plus67% (3)

- Experiment Title: Study of Free and Forced VorticesDocumento9 pagineExperiment Title: Study of Free and Forced VorticesSakib RafeeNessuna valutazione finora

- CE6461 - Fluid Mechanics and Machinery Laboratory PDFDocumento65 pagineCE6461 - Fluid Mechanics and Machinery Laboratory PDFjeroldscdNessuna valutazione finora

- Experiment 2 - Flow Measurement: Page 1 of 6Documento6 pagineExperiment 2 - Flow Measurement: Page 1 of 6fadyaNessuna valutazione finora

- Orifices and WeirsDocumento46 pagineOrifices and WeirsKNARF FRANKNessuna valutazione finora

- Report 7 CE231 Real OneDocumento10 pagineReport 7 CE231 Real OneMohammed KhalidNessuna valutazione finora

- FLUID MECHANICS Lab ManualDocumento65 pagineFLUID MECHANICS Lab ManualPaulNessuna valutazione finora

- Fluid 1 LabDocumento18 pagineFluid 1 LabHassan MehrizNessuna valutazione finora

- Flow of Water by Notch and WeirsDocumento17 pagineFlow of Water by Notch and WeirsMuhammad Zulhusni Che RazaliNessuna valutazione finora

- Orifice DischargeDocumento12 pagineOrifice Dischargehammada1001100% (3)

- Performance Test of A Hydraulic Turbine Mid Term 2Documento8 paginePerformance Test of A Hydraulic Turbine Mid Term 2jethro ganeloNessuna valutazione finora

- Pipe FrictionDocumento4 paginePipe FrictionShubham ChauhanNessuna valutazione finora

- Fluid Mechanics Lab ManualDocumento25 pagineFluid Mechanics Lab Manualeklavya kumarNessuna valutazione finora

- Experiment No 1Documento14 pagineExperiment No 1man330055Nessuna valutazione finora

- Cec 107 Practical - Introduction To Fluid MechanicsDocumento28 pagineCec 107 Practical - Introduction To Fluid MechanicsVietHungCao100% (1)

- Calibration OF Volume TankDocumento16 pagineCalibration OF Volume TankMelgie Mae Matulin Dikitanan100% (1)

- Lab 4 (Thermofluids Lab)Documento32 pagineLab 4 (Thermofluids Lab)Adnan Nanda0% (1)

- Flowmeter DEMONSTRATIONDocumento20 pagineFlowmeter DEMONSTRATIONAfiq IkhwanNessuna valutazione finora

- Indigenous Chicken ProductionDocumento16 pagineIndigenous Chicken ProductionTatendaNessuna valutazione finora

- Maize Production Statistis by YearDocumento1 paginaMaize Production Statistis by YearTatendaNessuna valutazione finora

- ConsistencyDocumento8 pagineConsistencyTatendaNessuna valutazione finora

- Graph of Shear Stress Against Normal StessDocumento2 pagineGraph of Shear Stress Against Normal StessTatendaNessuna valutazione finora

- Foundation Ch.8Documento35 pagineFoundation Ch.8TatendaNessuna valutazione finora

- 304Documento8 pagine304TatendaNessuna valutazione finora

- Foundation Ch.8Documento42 pagineFoundation Ch.8Ilham HusseinNessuna valutazione finora

- The Postharvest SystemDocumento7 pagineThe Postharvest SystemTatendaNessuna valutazione finora

- The Systems ApproachDocumento20 pagineThe Systems ApproachTatendaNessuna valutazione finora

- Crop DryingDocumento42 pagineCrop DryingTatendaNessuna valutazione finora

- Crop CharacteristicsDocumento25 pagineCrop CharacteristicsTatendaNessuna valutazione finora

- Hydrology and Hydraulics - Agen 310: BSC Honours in Agricultural EngineeringDocumento5 pagineHydrology and Hydraulics - Agen 310: BSC Honours in Agricultural EngineeringTatendaNessuna valutazione finora

- Book Review: Basic and Applied Ecology 15 (2014) 720-721Documento2 pagineBook Review: Basic and Applied Ecology 15 (2014) 720-721TatendaNessuna valutazione finora

- Charging 470uf CapacitorDocumento1 paginaCharging 470uf CapacitorTatendaNessuna valutazione finora

- Fluid Mech Orifice 3Documento9 pagineFluid Mech Orifice 3TatendaNessuna valutazione finora

- 2.2 - Direct Stress Strain Ho Compound BarsDocumento33 pagine2.2 - Direct Stress Strain Ho Compound BarsTatendaNessuna valutazione finora

- Chapter 11 Beams and BendingDocumento10 pagineChapter 11 Beams and BendingTatendaNessuna valutazione finora

- Prac JetDocumento5 paginePrac JetTatendaNessuna valutazione finora

- Center of PressureDocumento7 pagineCenter of PressureHashem EL-MaRimeyNessuna valutazione finora

- Series 1 - Efflux TimeDocumento6 pagineSeries 1 - Efflux TimeLi XueNessuna valutazione finora

- Mesit Company Profile Products and ServicesDocumento26 pagineMesit Company Profile Products and ServicessahirprojectsNessuna valutazione finora

- WM1 ManualDocumento176 pagineWM1 ManualGruNessuna valutazione finora

- Tutorial 2 Corrected and Updated For Q10 PDFDocumento3 pagineTutorial 2 Corrected and Updated For Q10 PDFAnonymous 7a5KZi8MNessuna valutazione finora

- Flowing Well PerformanceDocumento57 pagineFlowing Well PerformancemkwendeNessuna valutazione finora

- EGP3-03.02 Instrumentation, Control Valve Stations and Instrument AirDocumento20 pagineEGP3-03.02 Instrumentation, Control Valve Stations and Instrument AirMathias OnosemuodeNessuna valutazione finora

- LESER High Efficiency Catalog enDocumento68 pagineLESER High Efficiency Catalog enandy131078Nessuna valutazione finora

- CE8394 Fluid Mechanics 01 - by LearnEngineering - inDocumento213 pagineCE8394 Fluid Mechanics 01 - by LearnEngineering - inpriya dharshini100% (2)

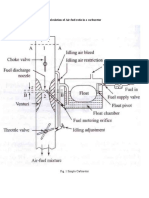

- Air-Fuel-Ratio-Calculation For CarburettorDocumento10 pagineAir-Fuel-Ratio-Calculation For Carburettorsumeetsharma27Nessuna valutazione finora

- Effects of Orifice Plate Meters Installed Backwards White PaperDocumento5 pagineEffects of Orifice Plate Meters Installed Backwards White PaperPhilip A Lawrence C.Eng. F. Inst M.C.Nessuna valutazione finora

- DR 600 CulvertsDocumento54 pagineDR 600 Culvertslinamohdzhor4815Nessuna valutazione finora

- AGA 3 Gas Flow Equation For Orifice Plates - Learning Instrumentation and Control EngineeringDocumento10 pagineAGA 3 Gas Flow Equation For Orifice Plates - Learning Instrumentation and Control EngineeringJanuar ReasNessuna valutazione finora

- Discharge CoefficientDocumento11 pagineDischarge Coefficientsisai12u2420% (2)

- LPG - Manual Gaze InerteDocumento104 pagineLPG - Manual Gaze InerteCornelNessuna valutazione finora

- Control Valve Seat Leakage ClassificationsDocumento2 pagineControl Valve Seat Leakage ClassificationsOmkar MoreNessuna valutazione finora

- Performance Testing Procedure For Centrifugal PumpsDocumento5 paginePerformance Testing Procedure For Centrifugal PumpsNitin S Jog100% (12)

- Characteristics of OrificeDocumento6 pagineCharacteristics of OrificePohSing VestNessuna valutazione finora

- Laminar and Turbulent FlowDocumento305 pagineLaminar and Turbulent Flowjochem_ligthartNessuna valutazione finora

- FM 200 Clean Agent SystemDocumento18 pagineFM 200 Clean Agent SystemMohamed AdelNessuna valutazione finora

- Me152l - Experiment 5 - AmahmudDocumento23 pagineMe152l - Experiment 5 - AmahmudAli Requiso MahmudNessuna valutazione finora

- Fluid Mechanics Sessional CE 262Documento28 pagineFluid Mechanics Sessional CE 262মোঃমেহেদী হাসান শরীফNessuna valutazione finora

- Lecture #2 (Instrumentation System Elements) v1Documento84 pagineLecture #2 (Instrumentation System Elements) v1Salina MohmadNessuna valutazione finora

- R F+460 K C+273: 14.7 Psia 101.3 KpaaDocumento47 pagineR F+460 K C+273: 14.7 Psia 101.3 KpaaYhelly27Nessuna valutazione finora

- S8 Xe-BDocumento11 pagineS8 Xe-BmnraveeNessuna valutazione finora

- C1.1 - Introduction To Instrumentation EngineeringDocumento60 pagineC1.1 - Introduction To Instrumentation EngineeringJoshua EgallaNessuna valutazione finora

- Natural Gas Measurement (Gallagher) Front Matter-FINALDocumento28 pagineNatural Gas Measurement (Gallagher) Front Matter-FINALirfanNessuna valutazione finora

- Lab 1 CE 2015Documento60 pagineLab 1 CE 2015Doaa BadarnehNessuna valutazione finora

- RM19 Hydraulics4 Part1Documento1 paginaRM19 Hydraulics4 Part1Alexander P. BelkaNessuna valutazione finora

- Up MofDocumento32 pagineUp MofKrishitva R GowdaNessuna valutazione finora

- Nuflo Orifice Flange UnionsDocumento2 pagineNuflo Orifice Flange UnionsirfanNessuna valutazione finora

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDa EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNessuna valutazione finora

- To Engineer Is Human: The Role of Failure in Successful DesignDa EverandTo Engineer Is Human: The Role of Failure in Successful DesignValutazione: 4 su 5 stelle4/5 (138)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetDa EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetValutazione: 4.5 su 5 stelle4.5/5 (10)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsDa EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNessuna valutazione finora

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesDa EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesValutazione: 5 su 5 stelle5/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDa EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tValutazione: 4.5 su 5 stelle4.5/5 (27)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialDa EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialValutazione: 3.5 su 5 stelle3.5/5 (3)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDa EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansValutazione: 4.5 su 5 stelle4.5/5 (21)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosDa EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosValutazione: 5 su 5 stelle5/5 (1)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsDa EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsValutazione: 3.5 su 5 stelle3.5/5 (2)

- Analog Design and Simulation Using OrCAD Capture and PSpiceDa EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNessuna valutazione finora

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonDa EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonValutazione: 5 su 5 stelle5/5 (2)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersDa Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersValutazione: 5 su 5 stelle5/5 (1)

- Build Your Own Electronics WorkshopDa EverandBuild Your Own Electronics WorkshopValutazione: 3.5 su 5 stelle3.5/5 (3)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeDa EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeValutazione: 4.5 su 5 stelle4.5/5 (10)

- Teach Yourself Electricity and Electronics, 6th EditionDa EverandTeach Yourself Electricity and Electronics, 6th EditionValutazione: 3.5 su 5 stelle3.5/5 (15)

- Current Interruption Transients CalculationDa EverandCurrent Interruption Transients CalculationValutazione: 4 su 5 stelle4/5 (1)