Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Swing Check

Caricato da

Suresh RamanujaluCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Swing Check

Caricato da

Suresh RamanujaluCopyright:

Formati disponibili

Technical Feedback

Page 1 of 3

FEEDBACK NO. 19

SWING CHECK

General Description

The swing check is the measurement of radial throw at the free end of the coupled rotor caused

due to non parallelity of the coupling faces and / or their out of square ness wrt rotor axis etc.

The high swing check value may cause high shaft vibration, high bearing shell temperature etc. The

value of swing check depends on axial run out of coupling faces, the diameter of the coupling and

the length of the rotor. During the machining of rotors in the works some tolerances are permitted

by designers on the coupling faces of the rotor resulting to some radial throw at the free end. The

maximum permissible swing values caused due to the above tolerance for different diameter and

length of the rotor can be worked out from the enclosed graph. However it is recommended to

keep the swing values to minimum for better results during operation of the machine. In a multi

rotor turbine generator system it is essential to measure the swing value in both extreme end

where the weight of the rotors are light. For example 200/210 MW machine with Russian Generator

and static excitation system the swing check values are measured on HP rotor front end only. In

500 MW machine the swing values measured in HP front and on exciter rear end.

It is advisable to measure value on IP rotor front end also for better results during operation of the

units. This can be done initially during erection with temporary coupling bolts on LP-IP coupling

before reaming / honing of coupling.

Any variation in swing values may be corrected during erection of machine. Any compromise at

erection stage may cause serious problem during operation of the unit and any correction becomes

much more tedious at a later stage. The correction may be carried out either by interchanging the

coupling position or by correcting the coupling faces by scraping / cutting in consultation of

designers.

Procedure

1)

Before placement of Module / Rotor in position the coupling faces of all the rotors are to

be checked for concavity / convexity of their coupling faces. This can be checked with the

help of a thin rectangular lightweight straight edge. No concavity of about 0.02 / 0.03 mm

is permitted to manufacturing units.

2)

After placement of individual Module / Rotor the coupling faces are to be checked /

measured for axial run out before taking up alignment of various rotors. The HP rotor rear

coupling face can be measured after placing it on both of its bearing. The IP rotor faces are

to be measured after placing IP rear end on bearing and front end on lifting tackle. Similarly

LP rotor may be placed on bearing on its rear end and front end supported on lifting tackle.

Axial run out on coupling faces more than 0.02 mm. may be referred to designers before

http://www.bhelpswr.co.in/Technical/MAIN%20TURBINES%20FEEDBACKS/mai...

9/12/2014

Technical Feedback

Page 2 of 3

taking up further works.

3)

After completing final alignment of various rotors they are to be coupled with temporary

bolts, taking into account the axial run out of the coupling faces. During coupling with

temporary bolts the highest point of one of the rotor face is to be coupled with lowest point

of coupling face of the adjoining rotor.

4)

During coupling on temporary bolts the equal tightening on all the four temporary bolts is

to be ensured otherwise it can disturb the swing value of the rotor.

5)

First IP-LP coupling is to be made with temporary bolts and swing in IP rotor front end is

recorded. After this only HP-IP rotor is to be coupled with temporary bolts and the swing

value on HP front rotor is recorded.

6)

During swing check of IP rotor its front end is to be supported on auxiliary bearings and

suspended by a sling of 24 mm diameter with a distance of 3.0 to 3.5 meter from crane

hook, without making any connection between HP-IP rotor.

7)

While recording swing check of HP rotor the front end of the rotor is to be supported on

auxiliary bearings and suspended by a sling of 18 mm diameter with a distance of 3.0 to 3.5

meter from crane hook.

8)

During checking of swing measure radial movement of rotor on parting plane and rotate

the rotor in normal direction of rotation either on jacking oil with hand barring or with the

help of E.O.T. crane with thick oil on bearings. Avoid jerk during rotation of rotor while

recording the swing check values. If jacking oil system is used during rotation of the rotor

while recording swing check values, the readings are to be taken stopping the JOP.

9)

After ensuring the swing check values as per the graph with temporary coupling bolts,

the HP-IP coupling may be cleared for reaming / honing of the coupling holes. Any variation

need correction of the coupling before reaming / honing of the holes.

10) The final swing check value of HP front rotor is to be recorded after fitting / elongation of

all the coupling bolts of HP-IP & LP-IP rotors. For improvement of the swing values, the

uneven and non-sequential tightening of the coupling bolts may be avoided.

11) During checking of swing readings, 8-10 initial rotations are to be given and then only the

readings are to be recorded.

12) Similar method is to be adopted while measuring the swing check value of the exciter and

t he rotor is to be hanged on the suitable size of sling.

13) While recording the swing initially with temporary bolts for HP & IP rotor, the fitting of

eight number temporary bolts are preferred in place of four bolts on the coupling.

http://www.bhelpswr.co.in/Technical/MAIN%20TURBINES%20FEEDBACKS/mai...

9/12/2014

Technical Feedback

Page 3 of 3

Back to Technical Services

http://www.bhelpswr.co.in/Technical/MAIN%20TURBINES%20FEEDBACKS/mai...

9/12/2014

Potrebbero piacerti anche

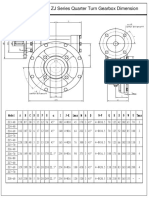

- Greatork-ZJ Series Gearbox DimensionDocumento3 pagineGreatork-ZJ Series Gearbox DimensionCan PoonsawatNessuna valutazione finora

- Vacuum Breaker ValveDocumento2 pagineVacuum Breaker ValveRaghunath YeturiNessuna valutazione finora

- KCDocumento3 pagineKCSandheepKumarNessuna valutazione finora

- Project Report (Design of Slurry Pump For Siliminate Extraction)Documento10 pagineProject Report (Design of Slurry Pump For Siliminate Extraction)Sreekuttan NairNessuna valutazione finora

- Conbextra GP2 PDFDocumento4 pagineConbextra GP2 PDFRaja SundaramNessuna valutazione finora

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineDa EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineValutazione: 5 su 5 stelle5/5 (1)

- Pages From API Standard 610 Centrifugal PumpsDocumento1 paginaPages From API Standard 610 Centrifugal PumpsAgustin A.100% (1)

- Standard For Hydraulic Turbine and Generator Shaft Couplings and Shaft Runout TolerancesDocumento22 pagineStandard For Hydraulic Turbine and Generator Shaft Couplings and Shaft Runout Toleranceschecho_mdz100% (1)

- Manual: STD: Is-5120: Series: VCPDocumento21 pagineManual: STD: Is-5120: Series: VCPKaushik ChakrabortyNessuna valutazione finora

- Continuous Thread Stud Double End Stud ADocumento11 pagineContinuous Thread Stud Double End Stud AMarius Mihai Buzduga0% (1)

- Type SCR 25W Sizes 18 To 52 - EngDocumento2 pagineType SCR 25W Sizes 18 To 52 - EngKUNALJAY100% (1)

- Oil Whirl and WhipDocumento8 pagineOil Whirl and WhipAsim GillaniNessuna valutazione finora

- 002-Steam Turbines Basics For BeginnersDocumento10 pagine002-Steam Turbines Basics For BeginnersGeorge J AlukkalNessuna valutazione finora

- Fan Calculation MooreDocumento8 pagineFan Calculation MooreArjun GirishNessuna valutazione finora

- IIT-Intake and Exhaust Manifold DesignDocumento28 pagineIIT-Intake and Exhaust Manifold DesignVasudev GuptaNessuna valutazione finora

- Noreva Valve Cat - 2018 Online Download PDFDocumento46 pagineNoreva Valve Cat - 2018 Online Download PDFSirvan HomaNessuna valutazione finora

- Thyristor Control Heater Panel GuideDocumento63 pagineThyristor Control Heater Panel Guidevaithy1990Nessuna valutazione finora

- Pelton Turbine Erection ProcedureDocumento91 paginePelton Turbine Erection Procedurebhanu prasad100% (1)

- GBT 8564 2003 Specification For Installation of Hydraulic Turbine Generator UnitsDocumento104 pagineGBT 8564 2003 Specification For Installation of Hydraulic Turbine Generator UnitsvietnhuNessuna valutazione finora

- A New Method For Calculating The Busemann Head Coefficients For Radial ImpellersDocumento7 pagineA New Method For Calculating The Busemann Head Coefficients For Radial ImpellersIvan RaulNessuna valutazione finora

- Jeida Farm Supply Corporation Catalog 2014Documento10 pagineJeida Farm Supply Corporation Catalog 2014Taj Deluria100% (3)

- Horizontal MultiStage Pump Data SheetDocumento6 pagineHorizontal MultiStage Pump Data Sheetسمير البسيونىNessuna valutazione finora

- BPCL Training ReportDocumento34 pagineBPCL Training ReportVishalVaishNessuna valutazione finora

- Is 4721Documento7 pagineIs 4721dak2anshulNessuna valutazione finora

- Pressure Safety Relief Valves Pressure Safety Relief Valves: Technical Bulletin 3 Technical Bulletin 3-IDocumento16 paginePressure Safety Relief Valves Pressure Safety Relief Valves: Technical Bulletin 3 Technical Bulletin 3-Isabi_shiNessuna valutazione finora

- Iec60045-1 (Ed1 0) B Img PDFDocumento11 pagineIec60045-1 (Ed1 0) B Img PDFshaanNessuna valutazione finora

- Hydraulicturbines DrtinaDocumento19 pagineHydraulicturbines DrtinanazarasimNessuna valutazione finora

- Air-Operated Valve Maintenance Guide PDFDocumento301 pagineAir-Operated Valve Maintenance Guide PDFSuprapto Desmosedici100% (1)

- Effect of Viscosity On PumpsDocumento4 pagineEffect of Viscosity On PumpsChemkhiNessuna valutazione finora

- Run Away SpeedDocumento15 pagineRun Away SpeedSouravSawNessuna valutazione finora

- 23 09 13.33 - Control ValvesDocumento25 pagine23 09 13.33 - Control Valvesforevertay2000Nessuna valutazione finora

- Is Iec 41 1991Documento214 pagineIs Iec 41 1991OmerfAta100% (1)

- Comet Diaphragm Pump Instruction ManualDocumento7 pagineComet Diaphragm Pump Instruction ManualAnonymous FnTx4lxZNiNessuna valutazione finora

- ID Khargone ProtoDocumento17 pagineID Khargone ProtojeetendraNessuna valutazione finora

- Vertical Solid Shaft (VSS), High Thrust, TEFCDocumento9 pagineVertical Solid Shaft (VSS), High Thrust, TEFCeliahudNessuna valutazione finora

- Hda Operational ManualDocumento48 pagineHda Operational ManualDouglas DuarteNessuna valutazione finora

- TurbinesDocumento34 pagineTurbinesSharath ChandraNessuna valutazione finora

- Ludeca Vertical Turbine Bearing AlignmentDocumento6 pagineLudeca Vertical Turbine Bearing AlignmentSivananthaa MurtheeNessuna valutazione finora

- Improved Analysis of External Loads On Flanged JointsDocumento1 paginaImproved Analysis of External Loads On Flanged JointsTiHoRNessuna valutazione finora

- 07MnMoVR Steel chn786s1 - T PDFDocumento11 pagine07MnMoVR Steel chn786s1 - T PDFAnonymous AkzeMHNTUyNessuna valutazione finora

- Vorecon Applications PDFDocumento46 pagineVorecon Applications PDFlancasaNessuna valutazione finora

- Hyundai: Vertical Mixed / Axial FlowDocumento12 pagineHyundai: Vertical Mixed / Axial FlowdkspplNessuna valutazione finora

- 541 - E5 PADocumento3 pagine541 - E5 PARamesh Yadla0% (1)

- Bettis CBA 725Documento16 pagineBettis CBA 725kutts76100% (1)

- Benefits of HI 14-6 FINAL FULL VERSION PDFDocumento8 pagineBenefits of HI 14-6 FINAL FULL VERSION PDF1sympatyagaNessuna valutazione finora

- Butterfly ValveDocumento8 pagineButterfly ValvebrunoNessuna valutazione finora

- COUPLINGDocumento11 pagineCOUPLINGabduallah rabahNessuna valutazione finora

- Bombas Sumergibles KSBDocumento92 pagineBombas Sumergibles KSBArturPNessuna valutazione finora

- Basic Valve & SizingDocumento8 pagineBasic Valve & SizingRio Ananda PutraNessuna valutazione finora

- Unit 4steamturbine 160705174835Documento48 pagineUnit 4steamturbine 160705174835Ruby ShajiNessuna valutazione finora

- Virtual Model Test For A Francis Turbine: Home Search Collections Journals About Contact Us My IopscienceDocumento11 pagineVirtual Model Test For A Francis Turbine: Home Search Collections Journals About Contact Us My Iopsciencecojo_drNessuna valutazione finora

- Modern Design For Variable Speed Motor-GeneratorsDocumento18 pagineModern Design For Variable Speed Motor-Generatorsmunagala balasubramanyamNessuna valutazione finora

- Is Rod Drop Measurement Right For My CompressorDocumento4 pagineIs Rod Drop Measurement Right For My CompressorMadhana GopalNessuna valutazione finora

- Elliott Brush Ring Seals: Installation KitDocumento2 pagineElliott Brush Ring Seals: Installation Kitfouzi gher100% (1)

- Catalogo de Bombas de Caudal VariableDocumento29 pagineCatalogo de Bombas de Caudal VariableRaul Rivera100% (1)

- Petrosadid - Centrifugal (API 617)Documento16 paginePetrosadid - Centrifugal (API 617)lafsifatNessuna valutazione finora

- Control Valve Technical Specification For Severe Service - CCIDocumento5 pagineControl Valve Technical Specification For Severe Service - CCIVikas SinghNessuna valutazione finora

- Profile of the International Pump Industry: Market Prospects to 2010Da EverandProfile of the International Pump Industry: Market Prospects to 2010Valutazione: 1 su 5 stelle1/5 (1)

- Vertical Axis Hydrokinetic Turbines: Numerical and Experimental Analyses: Volume 5Da EverandVertical Axis Hydrokinetic Turbines: Numerical and Experimental Analyses: Volume 5Nessuna valutazione finora

- Modern Developments in the Mechanics of ContinuaDa EverandModern Developments in the Mechanics of ContinuaSalamon EskinaziNessuna valutazione finora

- Structural Health MonitoringDa EverandStructural Health MonitoringDaniel BalageasNessuna valutazione finora

- PS-2.0109 - Pole Balance and ImpedanceDocumento8 paginePS-2.0109 - Pole Balance and ImpedanceSuresh RamanujaluNessuna valutazione finora

- HVPSI Standard DC-DC ConvertersDocumento1 paginaHVPSI Standard DC-DC ConvertersSuresh RamanujaluNessuna valutazione finora

- Generator Field Winding Shorted Turns: Observed Conditions and CausesDocumento11 pagineGenerator Field Winding Shorted Turns: Observed Conditions and CausesFritz HasugianNessuna valutazione finora

- Genadvisor Shaft Volt Current Mon PSPG b10244 00 7600 en LR Fina PDFDocumento2 pagineGenadvisor Shaft Volt Current Mon PSPG b10244 00 7600 en LR Fina PDFSourav RanaNessuna valutazione finora

- The Effects of High Vibration On The Steam Turbo-Generator MachinesDocumento55 pagineThe Effects of High Vibration On The Steam Turbo-Generator MachinesFarhad YahyaieNessuna valutazione finora

- Insulation AnalyzerDocumento2 pagineInsulation AnalyzerSuresh RamanujaluNessuna valutazione finora

- Industrial: Test and Instruments CatalogDocumento16 pagineIndustrial: Test and Instruments CatalogSuresh RamanujaluNessuna valutazione finora

- Rotor Earth Fault ProtectionDocumento8 pagineRotor Earth Fault ProtectionSuresh RamanujaluNessuna valutazione finora

- Catelogue Mtekprof 1Documento12 pagineCatelogue Mtekprof 1Suresh RamanujaluNessuna valutazione finora

- The Complete Line of Products (May 2008)Documento2 pagineThe Complete Line of Products (May 2008)Suresh RamanujaluNessuna valutazione finora

- DD and IRC TestDocumento7 pagineDD and IRC Testamrit403Nessuna valutazione finora

- Generator Hydrogen Cooling SystemDocumento2 pagineGenerator Hydrogen Cooling Systemraja020Nessuna valutazione finora

- LL PSKDocumento19 pagineLL PSKSuresh RamanujaluNessuna valutazione finora

- Gen. Seal Oil System Emergency DPR Valve Not Operating-May09Documento4 pagineGen. Seal Oil System Emergency DPR Valve Not Operating-May09Adnan Habib Khan100% (2)

- Generator Hydrogen Cooling SystemDocumento2 pagineGenerator Hydrogen Cooling Systemraja020Nessuna valutazione finora

- RX Marine International: Electrosol PlusDocumento1 paginaRX Marine International: Electrosol PlusSuresh RamanujaluNessuna valutazione finora

- Manaiyadi EnglishDocumento7 pagineManaiyadi EnglishSuresh RamanujaluNessuna valutazione finora

- Swing CheckDocumento3 pagineSwing CheckSuresh RamanujaluNessuna valutazione finora

- CKYC Individual.1Documento4 pagineCKYC Individual.1Suresh RamanujaluNessuna valutazione finora

- Vastu ShastraDocumento32 pagineVastu ShastraHarsha ShivannaNessuna valutazione finora

- RX Marine International: Electrosol PlusDocumento1 paginaRX Marine International: Electrosol PlusSuresh RamanujaluNessuna valutazione finora

- CRD-100X2 Datasheet PDFDocumento2 pagineCRD-100X2 Datasheet PDFSuresh RamanujaluNessuna valutazione finora

- RX Marine International: Electrosol PlusDocumento1 paginaRX Marine International: Electrosol PlusSuresh RamanujaluNessuna valutazione finora

- Major ActivitiesDocumento5 pagineMajor ActivitiesSuresh RamanujaluNessuna valutazione finora

- 2.7-3502-0001 Insulation Resistance Test Slip RingDocumento1 pagina2.7-3502-0001 Insulation Resistance Test Slip RingSuresh RamanujaluNessuna valutazione finora

- Dew Point TemperatureDocumento1 paginaDew Point TemperatureSuresh RamanujaluNessuna valutazione finora

- Rotor Assembly ProcedureDocumento66 pagineRotor Assembly ProcedureSuresh RamanujaluNessuna valutazione finora

- Pages From (Demagnetisation of Gen Rotor) PDFDocumento1 paginaPages From (Demagnetisation of Gen Rotor) PDFSuresh RamanujaluNessuna valutazione finora

- Apollo15 Colossus3 CMC Data CardsDocumento18 pagineApollo15 Colossus3 CMC Data CardsPablo De LeonNessuna valutazione finora

- Vale International Pellet Plant PDFDocumento2 pagineVale International Pellet Plant PDFSrinivasanNessuna valutazione finora

- FDP ECE BrochureDocumento3 pagineFDP ECE BrochureBalasanthosh SountharajanNessuna valutazione finora

- Zipf's Law and Heaps LawDocumento10 pagineZipf's Law and Heaps Lawadvita sharmaNessuna valutazione finora

- Bakker Et Al 2016 GroundwaterDocumento7 pagineBakker Et Al 2016 GroundwaterkmcoulibNessuna valutazione finora

- Antonio Stradivari, Cello, Cremona, 1726, The 'Comte de Saveuse' - TarisioDocumento1 paginaAntonio Stradivari, Cello, Cremona, 1726, The 'Comte de Saveuse' - TarisioUrko LarrañagaNessuna valutazione finora

- Operating Manual: Wheel Loader L538 - 432 From 13100Documento284 pagineOperating Manual: Wheel Loader L538 - 432 From 13100Jacques Van Niekerk80% (5)

- 2 BoilersDocumento83 pagine2 BoilersSurasan ThepsiriNessuna valutazione finora

- Adxrs610 Yaw Rate GyroDocumento12 pagineAdxrs610 Yaw Rate GyroTarek Car MillaNessuna valutazione finora

- AT&T Syntax MMXDocumento17 pagineAT&T Syntax MMXakirank1Nessuna valutazione finora

- Title Proposal Form For StudentsDocumento3 pagineTitle Proposal Form For StudentsHelen AlalagNessuna valutazione finora

- Summer Training ReportDocumento133 pagineSummer Training ReportRitesh Meena100% (3)

- CIV211 - Module1Documento49 pagineCIV211 - Module1Dayalan JayarajNessuna valutazione finora

- Brakel Eura Excellent: Highly Insulated Louvred VentilatorDocumento4 pagineBrakel Eura Excellent: Highly Insulated Louvred VentilatorhjduarteNessuna valutazione finora

- CO2 System ManualDocumento11 pagineCO2 System Manualthugsdei100% (1)

- Chemical EarthingDocumento18 pagineChemical EarthingDivay ChadhaNessuna valutazione finora

- LTE KPI StatisticsDocumento11 pagineLTE KPI Statisticskhurramrno100% (1)

- Ip Nat Guide CiscoDocumento418 pagineIp Nat Guide CiscoAnirudhaNessuna valutazione finora

- Skills, Techniques and Production in Contemporary Art HANDOUT PDFDocumento4 pagineSkills, Techniques and Production in Contemporary Art HANDOUT PDFKeyy TaezaNessuna valutazione finora

- Participatory EvaluationDocumento4 pagineParticipatory EvaluationEvaluación Participativa100% (1)

- The Diffusion of Innovation and Adopter CategoriesDocumento3 pagineThe Diffusion of Innovation and Adopter CategoriesMark Angelo TitcoNessuna valutazione finora

- Coding CarnivalDocumento12 pagineCoding CarnivalSuchitra WathiNessuna valutazione finora

- Id Based Multicast Secret-Key Management Scheme (SKMS) in ManetsDocumento10 pagineId Based Multicast Secret-Key Management Scheme (SKMS) in ManetsSandhya RaniNessuna valutazione finora

- Lesson Plan MathsDocumento3 pagineLesson Plan MathsRuthira Nair AB KrishenanNessuna valutazione finora

- Brevity CodeDocumento18 pagineBrevity CodeArash AziziNessuna valutazione finora

- M180: Data Structure and Algorithms in Java Arab Open UniversityDocumento18 pagineM180: Data Structure and Algorithms in Java Arab Open Universityamr201020Nessuna valutazione finora

- Hyb 96 MhuaDocumento13 pagineHyb 96 Mhuaأبو زينب المهندسNessuna valutazione finora

- A 2G Rfid Based e Health Care SystemDocumento1 paginaA 2G Rfid Based e Health Care SystemrthilipNessuna valutazione finora

- Move All Database Objects From One Tablespace To AnotherDocumento2 pagineMove All Database Objects From One Tablespace To AnotherJabras GuppiesNessuna valutazione finora

- Full Circle Magazine Issue 19Documento34 pagineFull Circle Magazine Issue 19vwvr9Nessuna valutazione finora