Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chm145L Experiment 3

Caricato da

Froileth PulidoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Chm145L Experiment 3

Caricato da

Froileth PulidoCopyright:

Formati disponibili

CHM145L Organic Chemistry 1 Laboratory

1st Quarter, S.Y. 2015-2016

Simple and Steam Distillation

Castro, Ethan Zachary G., Pasia, Abraham Paul L., Pulido, Froileth S.1

1

Professor Oliver Villaflores, School of Chemical Engineering, Chemistry, Biological Engineering and Materials

Science Engineering, Mapa Institute of Technology; 2Castro, Ethan Zachary G., Pasia, Abraham Paul L., Pulido,

Froileth S., CHM145L-C11, School of Chemical Engineering, Chemistry, Biological Engineering and Materials

Science Engineering, Mapa Institute of Technology

ABSTRACT

One unique physical property that may distinguish the identities of substances, most especially

liquids, is their boiling point, or the temperature where the vapor pressure they exert equals the pressure of

the surroundings or the atmosphere. This characteristic of liquids also dictates another property called

volatility, which is defined as the tendency of a liquid to evaporate quickly. Due to the vast combinations of

intermolecular forces present in different liquid substances, and other factors as well, almost every substance

has its own distinct boiling point, different from another, although there are theoretical situations where boiling

points of various substances are equal (such as in vacuum, where there is no pressure). However, in real

life, most liquids have their own boiling points: thus, they have varying volatilities as well. The difference in

volatility of substances is what makes the process of separation and purification, called distillation, possible.

In the first part of the experiment, simple distillation of impure toluene was demonstrated, by taking advantage

of the difference in volatility of toluene and the impurity present. Toluene, which is more volatile, is converted

to vapor as heat is provided to the distillation system via a hot plate. As the vapor form of toluene passes

through the condenser, the difference in temperature between the vapor and the fresh water that is constantly

flowing in that part of the set-up allows the toluene to condense back to its liquid form, thereby separating it

from the impurity. The pure toluene was then collected in a graduated cylinder to measure the amount of

toluene being distilled in a certain level of temperature. The toluene, as observed, began to boil at around

38C and began condensing when the temperature was approximately 101C. Of 15 milliliters of the impure

sample, 12.5 milliliters of toluene were recovered. Moreover, the second part of the experiment dealt with

steam distillation, which is utilized when the substance to be distilled is not exerting enough vapor pressure

at high temperatures, such as para-dichlorobenzene, the substance analyzed in the experiment. Additional

vapor pressure is added by the steam to the distillation system via steam generator, allowing the pdichlorobenzene to boil even without reaching its boiling point yet. The distillate were collected in a flask and

then cooled in a cold-water bath. After cooling, the mixture was filtered, immediately dried and weighed.

Keywords: boiling point, volatility, distillation

INTRODUCTION

Volatility can be defined as the tendency

of a compound to vaporize. In a specific

temperature, a compound that has a higher

vapor pressure will vaporize more readily than a

substance with a lower vapor pressure. To put it

in other words, at a certain temperature, the

more volatile the compound is, the higher will be

Experiment 2 | Group 4 | October 15, 2015

the pressure of the vapor in dynamic equilibrium

with its vaporizing substance.

Vapor pressure can be described as the

pressure at which the gaseous phase is in

equilibrium with its liquid or solid phase. It can be

a measure of the tendency of molecules and

atoms to escape from a liquid or solid. In

atmospheric pressures, an instance when the

1 of 7

CHM145L Organic Chemistry 1 Laboratory

1st Quarter, S.Y. 2015-2016

vapor pressure of a liquid increases with the

temperature increases to the point at which it

equals the atmospheric pressure, the liquid has

attained the temperature at which the liquid

changes its state from a liquid to a gas

throughout its bulk, this can be referred as boiling

point. It is commonly called as the liquids normal

boiling point.

The normal boiling point of a liquid will be

at a lower temperature the greater is the

susceptibility of its molecules to escape from the

liquid, specifically, the higher the vapor pressure.

In other words, the higher the vapor pressure of a

liquid, the higher is the volatility and the lower is

the normal boiling point of the liquid, therefore, a

direct relationship can be deduced between the

vapor pressure and the volatility.

Figure 1. A common vapor pressure chart for several

liquids

Experiment 2 | Group 4 | October 15, 2015

Different compounds will exert different

vapor pressures at a given temperature because

of variations in the intermolecular forces of

attraction working in these different compounds.

In terms of intermolecular forces, the boiling point

acts as the temperature at which the liquid

molecules hold enough kinetic energy to

surmount the several intermolecular attractions

binding molecules to each other within the liquid.

Hence, the boiling point is also an indicator of the

strength of those intermolecular attractive forces.

The stronger the intermolecular attractive forces

are, the more difficult it is for molecules to

escape from the liquid and therefore, a lower

vapor pressure of the liquid. Through this, an

indirect relationship can be established, for

instance, the lower the liquids vapor pressure,

the higher the temperature must be to initiate

boiling and then, resulting to a direct relationship

between intermolecular attractive forces and the

normal boiling point.

Through the aforementioned discussed

concepts, it is therefore possible to separate

compounds from each other in a mixture based

on volatility differences. More volatile compounds

have higher possibility to be converted into vapor

earlier than with low volatilities, this process is

known as distillation. Distillation is a widely used

method for separating mixtures based on the

differences in the conditions (boiling point,

volatility, etc.) required to change the phase of

the components of the solution. To perform this

process, the liquid must be heated to transform

the components into vapor (Again, this process is

feasible since compounds with higher volatilities

vaporize earlier.) then, the vapor will be

condensed back into liquid form and collected in

a receiving container. Usually, distillation can

help the researchers to determine the boiling

point and to purify compounds (repeating the

describe process can make the compound

purer).

2 of 7

CHM145L Organic Chemistry 1 Laboratory

1st Quarter, S.Y. 2015-2016

In this experiment, two types of

distillation were performed, simple and steam

distillation.

Simple distillation is a procedure in which

a volatile compound is separated to a nonvolatile

compound or separating compounds with

different boiling points through application of

heat. This can be used to virtually separate

liquids that have at least fifty degrees difference

in their boiling point, or to separate highly volatile

compound from a lowly volatile compound. As

the liquid being distilled is heated, the vapors that

form are the richest in the component that boils

at the lower temperature and highly volatile. As

the process progresses, the vapors of the volatile

compound goes to the distilling flask through a

sidearm and then reaches the condenser, which

should be surrounded by fresh water at all times.

The difference between the temperature of the

fresh water and the vapor in the condenser

forces the vapor to change back into liquid form

which is then collected in another flask. It is also

important to take note of the following in order for

simple distillation to be successful:

1. The substances to be separated must

have a large volatility difference. Often,

this translates to a boiling point

difference of around 80C to 100C.

Otherwise, both compounds may be

distilled off and will not be separated

from each other.

2. Gently supply the heat to the distilling

flask.

3. The thermometer bulb used to measure

the boiling of the distilling liquid must be

at the level of the sidearm.

4. The distilling flask must be in an upright

position at all times.

5. Glass beads or ceramic material must

always be present inside the distilling

flask prior to heating of the mixture.

Experiment 2 | Group 4 | October 15, 2015

6. Fresh cooled water must always fill the

condenser, therefore, running water

should be applied to the condenser.

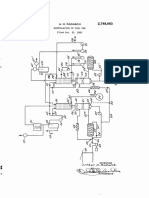

Figure 2. A typical simple distillation set-up

When a solution or mixture of two nearly

immiscible liquids is heated while being

discomposed to display the surface of one liquid

to the vapor phase, each of the component

independently wields its own vapor pressure as a

function of temperature as if the other component

were not present. Resulting to the increase of the

vapor pressure of the whole system. Take note

that boiling starts when the sum of the vapor

pressures of the two immiscible liquids just

predominates the atmospheric pressure. In such

way, several organic compounds insoluble in

water may be purified at a specific temperature

well below the point at which decomposition

occurs. Typically, water is introduced into the

distillation apparatus to provide additional vapor

pressure to help a nonvolatile organic compound

to boil off and be distilled at a temperature much

lower than its normal boiling point. The water

vapor bears the small amounts of the vaporized

compound to the condensation flask, where the

3 of 7

CHM145L Organic Chemistry 1 Laboratory

1st Quarter, S.Y. 2015-2016

separation of the condensed liquids phase

happens, allowing then for easy collection. This

concept effectively allows for distillation at lower

temperatures, reducing the decomposition or

deterioration of the desired products. After

distillation, the vapors, again, are condensed

suitably. Usually, the immediate product is a twophase system of water and the organic distillated,

this can be separated by decantation, partitioning

or other appropriate methods. In this experiment,

the water in the distillate is separated through a

separatory funnel.

Figure 3. A typical steam distillation set-up

The steam distillation apparatus are

constituted of three main parts:

Steam Generator

Sample Flask

Collecting Flask

This part supplies

sufficient steam to

add to the vapor

pressure of the

organic compound.

This flask contains

the compound to be

distilled with water,

and heat sources for

both the steam

generator and the

sample flask.

Guides the collection

of distillate.

It is also important to take not of the

following to successfully perform steam

distillation:

1. Boiling chips must be present both in the

steam generator and the sample flask before

heating is started.

2. Gently apply heat to the steam generator

and the sample flask.

3. The condenser must always be filled with

fresh water during the entire process.

4. No reactions should happen between the

compound being steam distilled and with

water.

Experiment 2 | Group 4 | October 15, 2015

METHODOLOGY

The experiment are divided into two

parts, the first part is the simple distillation and

the second part is the steam distillation.

In the first part of the experiment, the

researchers must assemble the set-up shown in

the figure in their laboratory manual (Figure 3.1,

page 19). Transfer 15 milliliters of impure carbon

tetrachloride into the pear-shaped flask using a

pipette (the flask should contain only 1/3 of its

total volume). Then, turn on the hot plate and

switch on the heat regulator to number 6. As it

progresses, collect the distillate at different

temperatures at the rate of 1 drop per second.

Measure, then, the volume of the distillate

obtained at different temperatures. Continue the

distillation until about 1 to 2 milliliters of distillate

is left in the flask. After this, plot the temperature

against the volume of distillate collected. Also,

record the temperature at which most of the

liquid distills as the boiling point.

Obtain a 2 grams-sample of impure pdichlorobenzene from the instructor and

determine the melting point range of the mixture.

Assemble the set-up like in Figure 3.2, page 19

of the laboratory manual, the researchers should

make sure that there is no leak in the set-up.

4 of 7

CHM145L Organic Chemistry 1 Laboratory

1st Quarter, S.Y. 2015-2016

RESULTS AND DISCUSSION

For the first part of the experiment in

which simple distillation was used, the impure

toluene was purified. After boiling the substance

in the distilland for about 10-15 minutes, the first

drop was collected at the temperature of 102C

and the distillation stopped at the temperature of

123C. The boiling point range of toluene was

therefore concluded to be 102-123 C. The graph

below illustrates the temperature plotted against

the volume of the distillate. At the end, 83.33

percent of the 15 milliliters of toluene was

recovered. Also, the recovered substance is

clear. Theoretically, simple distillation, is only

successful when the difference between the

boiling points of the components of the mixture is

very large but compared to other types of

distillation, it has a simpler set up and it

consumes less energy. In simple distillation, the

more volatile component of the mixture, which is

toluene, is being removed by turning it to vapors

Experiment 2 | Group 4 | October 15, 2015

and condensing it into another flask. It was

observed that as the temperature rises the

volume of the liquid in the receiving flask is also

increasing. On the other hand, the less volatile

component of the mixture is left in the distilland.

Through slow distillation via controlled heating,

both the components can be separated by

changing the receiving flask. This explains the

significance of the addition of glass beads. The

borosilicate glass beads provide surface area for

the condensation-evaporation process, this

prevents bumping or the rapid boiling which

could ruin the setup. Heating rate is also

controlled to prevent superheating which also

results into bumping.

Temperature,C

Boil slightly a hundred milliliters of water

in the Erlenmeyer flask before connecting it to

the set-up, this will serve as the steam generator.

As the researchers heat the water, put the

sample inside the pear-shaped with arm flask

and partly dissolve it in 5 milliliters of water by

gently applying heat in the mixture. After which,

connect all the apparatus and heat the steam

generator before proceeding with the distillation.

Continue the process until all the pdichlorobenzene has distilled, this should take

about 10 to 15 minutes. Before disconnecting the

apparatus, cool the mixture in the receiving tube.

Then, filter the p-dichlorobenzene with suction

and air dry the compound, the researchers

should not allow it to stand in the open for a

longer period since it will evaporate. Weigh the

dried material, obtain its melting point and

compute the percentage recovery.

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

104

103

102

0.75 1.75 2.75 3.75 4.75 5.75 6.75 7.75 8.75 9.75 10.75 11.75 12.75

Volume of the Distilate, mL

Figure 4. Plot of temperature against the volume of the

distillate

In the second part of the experiment,

para-dichlorobenzene was purified using steam

distillation. Simple distillation is not applied in

purifying this compound because boiling it will

only cause the compound to decompose so,

steam distillation is executed instead. Steam

distillation is used in purifying temperaturesensitive material such as para-dichlorobenzene

5 of 7

CHM145L Organic Chemistry 1 Laboratory

1st Quarter, S.Y. 2015-2016

which is a hydrocarbon aromatic compound.

Steam is added to the distillation apparatus to

lower the boiling point of para-dichlorobenzene

and prevents its decomposition. A hundred

milliliter water was boiled which will act as a

steam generator while heating the slightly

dissolved test compound. Cloudiness was

observed as the test compound was transferred

to the pear-shaped flask. Before the distillation

started, a safety tube was connected to the cork

of the steam generator to allow the water to

escape when the pressure is too high. The

distillation lasted until all the p-dichlorobenzene

has been distilled. The liquid in the receiving

flask was cooled, filtered and air dried. At the

end, 95.2 percent of the 2.00 grams of paradichlorobenzene was extracted.

CONCLUSION AND RECOMMENDATIONS

The researchers were able to apply the

technique of distillation in both simple and steam

distillation. In the former, it is known that in order

to be able to accomplish a successful

experiment, the substances in question must

have large differences in volatility. Without this in

consideration, both constituents may be distilled

off together and result in an unsuccessful

experiment. In the latter, steam distillation is

often used when the vapor pressure of a

dissolved organic compound still remains low

even at high temperature levels. Steam

distillation is effective due to its means of addition

of vapor pressure through a steam generator.

This addition of vapor pressure results in the

mixture attaining atmospheric pressure at lower

temperatures. This is significantly important

because, sometimes, organic compounds will

decompose faster than it will take for it to boil. A

decomposition of the desired product will result in

a very fruitless distillation experiment.

Experiment 2 | Group 4 | October 15, 2015

Simple distillation is effective in terms of

its setup and the time it takes to distill a liquid.

Compared to the steam distillation, simple

distillation required less apparatus to be used

and required less time to finish its distillation

process. Simple distillation however, is limited to

mixtures that have large differences in boiling

points. If simple distillation is done on a mixture

that had fairly close (<80C) boiling points, this

would not be a very effective means of

separation of constituents.

Steam distillation is most useful in trying

to avoid decomposition of organic compounds.

By providing additional vapor pressure, the

researchers lowered the required heat needed to

boil the liquid. This prevented the organic

material from decomposing before being distilled

off and separated from the original mixture.

Steam distillation however, requires more

equipment in comparison to simple distillation.

It is recommended for researchers to

absolutely make sure that your setup is properly

assembled and has no leaks where steam or gas

might escape. This is crucial for distillation relies

heavily on the gas evolved from the heated

mixture that is then cooled to be turned into a

liquid. It is also recommended that researchers

try different organic compounds to thoroughly

see the effects of volatilities in distillation setups.

References

Baluyut, J. G., & De Castro, K. A. (2001). Organic

Chemistry Laboratory Manual for Chemistry

Students Part 1. Intramuros, Manila: Mapua

Institute of Technology.

Beychok, M. (2012, January 1). Volatility (chemistry).

Retrieved from The Encyclopedia of Earth:

http://www.eoearth.org/view/article/172247/

6 of 7

CHM145L Organic Chemistry 1 Laboratory

1st Quarter, S.Y. 2015-2016

Klein, D. (2012). Organic Chemistry. In D. Klein,

Organic Chemistry (p. 41). New Jersey: John

Wiley and Sons, Inc.

Samal. (2015). Department of Chemistry. Retrieved

from Univeristy of Massachusetts:

http://www.chem.umass.edu/~samal/269/cry

st1.pdf

Experiment 2 | Group 4 | October 15, 2015

7 of 7

Potrebbero piacerti anche

- Problem Set Mock Exam CHEDocumento11 pagineProblem Set Mock Exam CHEFroileth PulidoNessuna valutazione finora

- Physical ChemistryDocumento8 paginePhysical ChemistryFroileth PulidoNessuna valutazione finora

- Practice Test 4 CHM 112Documento16 paginePractice Test 4 CHM 112Froileth PulidoNessuna valutazione finora

- Physical ChemistryDocumento8 paginePhysical ChemistryFroileth PulidoNessuna valutazione finora

- 10 CHM 5710 Vibrational SpectrosDocumento47 pagine10 CHM 5710 Vibrational SpectrosFroileth PulidoNessuna valutazione finora

- Experiment 1Documento9 pagineExperiment 1Froileth PulidoNessuna valutazione finora

- Group 17: HalogensDocumento56 pagineGroup 17: HalogensFroileth PulidoNessuna valutazione finora

- Experiment 6 FinalDocumento13 pagineExperiment 6 FinalFroileth Pulido100% (1)

- Hum 17 - Notes (Co3)Documento5 pagineHum 17 - Notes (Co3)Froileth PulidoNessuna valutazione finora

- Chm145L Experiment 1 PDFDocumento9 pagineChm145L Experiment 1 PDFFroileth PulidoNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- A Guide To Kjeldahl Nitrogen Determination Methods and ApparatusDocumento13 pagineA Guide To Kjeldahl Nitrogen Determination Methods and ApparatusNoranisza MahmudNessuna valutazione finora

- Aci 221R-96Documento3 pagineAci 221R-96farhadamNessuna valutazione finora

- D322-97 (2012) Standard Test Method For GasolineDocumento4 pagineD322-97 (2012) Standard Test Method For GasolinelukmanNessuna valutazione finora

- Acn Laboratory ApparatusDocumento40 pagineAcn Laboratory ApparatusAlma Cecilia QuiaoNessuna valutazione finora

- SPC F1 IS Unit 2 Water - TeacherEdDocumento29 pagineSPC F1 IS Unit 2 Water - TeacherEdFor BackupNessuna valutazione finora

- Optimization and Dynamics of Distillation Column Using Aspen PlusDocumento7 pagineOptimization and Dynamics of Distillation Column Using Aspen PlusResmi SureshNessuna valutazione finora

- Fistreem CycloneDocumento44 pagineFistreem CyclonedavidadyNessuna valutazione finora

- UniEquip Unicryo Cold Trap MC 2LDocumento6 pagineUniEquip Unicryo Cold Trap MC 2Lhb04155Nessuna valutazione finora

- Simple Distillation: Raoult's LawDocumento2 pagineSimple Distillation: Raoult's LawGarcia RaphNessuna valutazione finora

- Hawassa University Institute of Technology Chemical Engineering Department Research Methods and Project Proposal Research TitleDocumento19 pagineHawassa University Institute of Technology Chemical Engineering Department Research Methods and Project Proposal Research TitleAbdulkudus AbdulshukurNessuna valutazione finora

- Edibon Refrigeration Cycle ManualDocumento66 pagineEdibon Refrigeration Cycle Manualleo besaNessuna valutazione finora

- Effect of Partical Size On The Manufactacturing of Oil and Essential Oil From Lemon GrassDocumento19 pagineEffect of Partical Size On The Manufactacturing of Oil and Essential Oil From Lemon GrassAniket GiriNessuna valutazione finora

- Characterization Studies Waste Plastic Oil and Its BlendsDocumento12 pagineCharacterization Studies Waste Plastic Oil and Its BlendsPieyah ChomelNessuna valutazione finora

- Condensers: J. M. McnaughtDocumento6 pagineCondensers: J. M. McnaughtLTE002Nessuna valutazione finora

- Synthesis of Phenyl-2-PropanoneDocumento14 pagineSynthesis of Phenyl-2-Propanonescrewyoureg89% (18)

- Distillation Model Rev1Documento9 pagineDistillation Model Rev1mehul1094167% (3)

- NF Monographs - Maltodextrin PDFDocumento4 pagineNF Monographs - Maltodextrin PDFNadia FahmiNessuna valutazione finora

- Bioreactors DesignDocumento33 pagineBioreactors DesignTamer Abd Elrasoul100% (1)

- Patent US2748063Documento6 paginePatent US2748063Gökhan Kürşat demirNessuna valutazione finora

- Chapter 4. Problem SM.4 - Toluene/Ethylbenzene Column BackgroundDocumento11 pagineChapter 4. Problem SM.4 - Toluene/Ethylbenzene Column BackgroundBashar JawadNessuna valutazione finora

- Pharmaceutics 1 (Chapter 7 To 11) BOOKDocumento58 paginePharmaceutics 1 (Chapter 7 To 11) BOOKshahida hassanNessuna valutazione finora

- ASTM D4442-07 - Direct Moisture Content Measurement of WoodDocumento6 pagineASTM D4442-07 - Direct Moisture Content Measurement of Woodpoliveirauct100% (2)

- Iso 5565 2 1999Documento9 pagineIso 5565 2 1999luz andrea ximenezNessuna valutazione finora

- Complete Proximate Analysis For Animal Feed PDFDocumento14 pagineComplete Proximate Analysis For Animal Feed PDFtestNessuna valutazione finora

- Organic Chemistry 1909Documento372 pagineOrganic Chemistry 1909Luma SbtNessuna valutazione finora

- Separation TechniquesDocumento14 pagineSeparation TechniquesNathaniel WhyteNessuna valutazione finora

- Tecator Digestion Datasheet - GBDocumento8 pagineTecator Digestion Datasheet - GBNestor PosadaNessuna valutazione finora

- Brosur No. 6Documento51 pagineBrosur No. 6Gunarso KurniawanNessuna valutazione finora

- Full Chemistry ProjectDocumento21 pagineFull Chemistry Projectshreyansh sinha67% (3)

- Group A5 - EXP 5 Batch Packed DistillationDocumento35 pagineGroup A5 - EXP 5 Batch Packed DistillationKabilashini Mana Mohan100% (3)