Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Studying The Behaviour of Lap Splices in RCC BEAMS 09 July

Caricato da

GJESRTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Studying The Behaviour of Lap Splices in RCC BEAMS 09 July

Caricato da

GJESRCopyright:

Formati disponibili

IJBSTR RESEARCH PAPER VOL 1 [ISSUE 7] JULY 2013

ISSN 2320 6020

Studying the Behaviour of Lap Splices in RCC BEAMS

Ashish Singh

ABSTRACT: This paper presents results of an experiment of an experiment investigation of actual performance of the reinforced

concrete beam with varying lap splices length. The major variables studied include lap length that five different lap length. It is

observed that as the lap length taken as the calculated development length so four type of lap length observed of length LD/2 , LD,1.5

LD, 2 LD. The value of development length obtained using ACI 318:1999 , BS 8110:1985 and IS 456:200 is compared it is observed

that the value of development length obtained in tension using is code is 8% more as compared to BS code and 11% more as

compared to ACI code .

KEYWORDS: DC motor, Fuzzy logic controller, Fuzzy logic.

INTRODUCTION

EXPERIMENTAL PROGRAM

When reinforcement is spliced together within a concrete

beam, it is necessary to overlap the bars long enough for

tensile stresses in one bar to be fully transferred to other bars

without inducing a pullout failure in the concrete. Most design

codes allow the use of bars with lap splice and Reinforcement

is needed to be joined to make it longer by overlapping

sufficient length or by welding to develop its full design bond

stress. They should be away from the sections of maximum

stress and be staggered. IS 456 (cl. 26.2.5) recommends that

splices in flexural members should not be at sections where

the bending moment is more than 50 per cent of the moment

of resistance and not more than half the bars shall be spliced at

a section specify minimum length of the lap as well as the

required transverse reinforcement.

Fifteen simply supported reinforced concrete beams of

dimension 150mm x 250mm x 2500mm were tested in

Structural Engineering Lab, Madan Mohan Malaviya

Engineering College. All specimens had the same concrete

strength and the same longitudinal reinforcement. 2, 10 mmdiameter 500 high strength steel were used in tension

reinforcement. Stirrups of 6mm-diameter of 420 grade were

used. The rest set up of the studied beam is shown in figure 1.

Figure 2 shows reinforcement details of some of the test

beams.

Since beam of 2.5 m is being used in the experiment. The lap

length has been kept at 300 mm, 600 mm, 900 mm and 1200

mm for steel bar of 12 mm diameter.

They should be used for bar diameters up to 36 mm. They

should be considered as staggered if the centre to centre

distance of the splices is at least 1.3 times the lap length

calculated as mentioned below. The lap length including

anchorage value of hooks for bars in flexural tension shall be

L or 30, whichever is greater. The same for direct tension

d

shall be 2L or 30, whichever is greater. The lap length in

d

compression shall be equal to L in compression not less than

d

24. The lap length shall be calculated on the basis of

diameter of the smaller bar when bars of two different

diameters are to be spliced. Lap splices of bundled bars shall

be made by splicing one bar at a time and all such individual

splices within a bundle shall be staggered.

Fig 1: Testing frame

RESULT AND DISCUSSION

LOAD AND DEFLECTION ANALYSIS

Ashish Singh

Research Scholar

Department of Civil Engineering

M.M.M. Engineering College Gorakhpur

273010 (UP) India

Here the deflection of each beam is analyzed.

Deflection of each beam is compared with the deflection of

control beam. Since the loading arrangement is same for all

beams so the crack pattern deflection behaviour and failure

analysis is done by comparing the group beams of B-2 , B-3

,B-4 ,B-5 with B-1.

ijbstr.org

44

IJBSTR RESEARCH PAPER VOL 1 [ISSUE 7] JULY 2013

Since the lap lengths are taken with the relation of

development lent length as ld/2 , ld , 3ld/2 , 2ld. For control

beam the ld is calculated as 600 mm so the lap length are 300

mm, 600 mm , 900 mm and 1200mm. We have observe that

the beam with the lap length less then ld means the with 300

mm, fails more rapidly due to flexure cracks.. Cracks

developed at much low than designed value and fails just

above the designed value of 44 kn. By taking the factor of

safety the beam should bear almost up to 65 kn before any

type of sudden failure.

ISSN 2320 6020

In group two B-2 as the load is being applied the first hair line

crack is observed at 26KN. The cracks are being especially

between the constant bending zones and are at 300-400. The

cracks propagates and after going up some distance then

further divided into other cracks. More of the cracks are

between L/3 and 2L/3.

As the load and deflection curve is being curved out of

first group beam .All the dial gauges reading is being marked

out in this curve. Load is being applied on control beam the

first hair line crack is being observed at the load of 48 KN.

The cracks are observed at the flexure region in middle as well

as around L/6 distance. The cracks which are being observed

in the middle are like at 800 - 900 and the one which are at L/6

and 5L/6 are at 400-500.

Graph 2: Load Deflection Curve of the Group B-2

In group three B-3 as the load is being applied the first hair

line crack is observed at 32KN. The cracks are being seen and

are at 700-800. The cracks propagates in a zig-zag manner and

seen all over the flexure area between L/6 and 5L/6. The

cracks are single and propagated from bottom to compression

region.

Table 1:

Details of Tested Beam Specimens

Graph 3: Load Deflection Curve of the Group B-4

Graph 1: Load Deflection Curve of B-1

In group four B-4 as the load is applied the first hair line crack

is observed at the load of 37 KN. The cracks are being seen

mostly around L/6 and 5L/6 and around centre line elsewhere

nothing much. This shows cracks basically observed in middle

due to flexure and around the steel bars where the lapped

portion of steel bars ends. In this beam crack are observed of

very zig-zag manner and are at 400 700 variation.

ijbstr.org

45

IJBSTR RESEARCH PAPER VOL 1 [ISSUE 7] JULY 2013

ISSN 2320 6020

As seen below load and deflection curve between group B-1

and B-3. In this curve we observe that till 40kn the deflection

almost have constant difference but soon after 40 KN

deflections start increasing its ultimate strength reach only till

60 KN. So this group beam did not bear load up to the 65 KN

desired load after factor of safety.

Graph 4: Load Deflection Curve of Group 4

In group five B-5 as the load is being applied the first hair line

crack is observed at 41kn. The most of the cracks are being

seen between L/6 and L/3 and same on other side to the of

beam centre and are at 300-400. The crack generates from

bottom and then propagates towards the compression zone

where point load is being applied and cracks are less in the

middle of beam. The cracks are propagated from bottom and

joined around compression region.

Graph7: Load Deflection Curve between Group B-1 and

B-3

As seen below in load deflection curve between group B-1 and

B-4. In this curve it is observe that its deflection is better than

previous group beam and it also reached required ultimate

load. So this beam has desired strength as group b-1 but its

deflection is more. Means 1.5 ld is can be used as desired lap

length to get nearly same behaviour as no lap beam.

Graph 5: Load Deflection Curve of the Group B-5.

COMPARISON WITH CONTROL BEAM

As seen below the load deflection curve shows the

curve between the control beam B-1 and group B-2 beams

shows that the deflection in group is to high as compared to

group B-1. This shows the beam which have lap length less

than the Ld dont have desired strength as required so the lap

length less than ld should not be done.

Graph 8: Load Deflection Curve between Group B-1 and

B-4

Graph 6: Load Deflection Curve between Group B-1 and

B-2.

As this the last group b-5 which is being compared with b-1

according to load deflection curve it is observed that

previous group b-4 show greater deflection than b-5 its have 2

Ld lap length . There is not much difference between previous

group4 beams and this group5 so by taking economical

condition group 4 is better.

ijbstr.org

46

IJBSTR RESEARCH PAPER VOL 1 [ISSUE 7] JULY 2013

ISSN 2320 6020

5.

Ld play more important role in deciding the lap length

since its give the bond strength between the steel bar

as well as the concrete. That is why the lap length

less than development length fail soon before desired

load and the steel bars which have value large or

equal show good result.

6.

This also shows that after some lap length larger than

development shows constant behavior so its very

useful to use right value of lap length. According to

this experiment 1.5 Ld is right value.

7.

The value of development length obtained in tension

using IS code is 8 percent more as compared to BS

code and 11 percent as compared to ACI code

Graph 9: Load Deflection Curve between Group B-1 and

B-5

REFERENCES

1.

2.

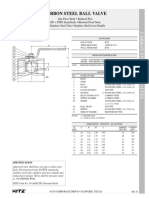

Table 2: Development Length

The development length for 8mm ,10mm,12mm bar diameters

is being tabulated in above table for ACI 318:1999 , IS

456:200 and BS 8110:2000 and are being compared , it is

observed that the value of development length obtained in

tension using IS code is 8 percent more as compared to BS

code and 11 percent as compared to ACI code

SUMMARY AND CONCLUSION

3.

4.

5.

Orangun, C.O., and Breen, J. E., Strength of

anchored bars: A re-evaluation of test data on

development length and splices, Research Report No.

154-3F, Center for Highway Research, University of

texas at Austin, Austin, Tex., (1975)78.

Orangun, C. O., and Breen, J. E., Reevaluation of test

data on development length and splices, ACI Journal,

Proceedings, No. 3, 74(1977) 114-122.

Zuo, J., and Darwin, D., Splice strength of

conventional and high relative rib area bars and high

strength concrete, ACI Structural Journal, No. 4,

97(2000) 630-641.

Jain, A.K., Reinforced Concrete Limit State Design,

Nem Chand and Bros. Roorkee, 2000.

Macginley T.J. and Choo B.S., Reinforced Concrete

Design Theory and Examples, E. & F.N. Spon,

London, 1990.

Fifteen concrete beams were tested to study the effect of lap

splice of tension reinforcement with different splice lengths.

From the results of the studied beams, the following

conclusion were obtained

1.

The beam with Lap length of 300 mm resulted in

much earlier failure then required.

2.

As the beam have same transverse reinforcement but

if the transverse reinforcement is not there in spliced

zone then there will be more severe failure like brittle

bond failure can be occurred.

3.

All the beams with spliced bars shows large

deflection with respect to the no lap beam.

4.

The behavior of a beam without any spliced beam

can be achieved in a spliced beam of lap length 2L d

and for the economical and nearly achieving the same

strength as control beam the value 1.5 Ld can as

spliced length.

ijbstr.org

47

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Review On Polymer Nanocomposites by Using Various Resins and Nanoclays and Their Applications 06 JuneDocumento8 pagineReview On Polymer Nanocomposites by Using Various Resins and Nanoclays and Their Applications 06 JuneGJESRNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Sewage Smells Like A Power Source For Developing 03 MayDocumento2 pagineSewage Smells Like A Power Source For Developing 03 MayGJESRNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- StabilizationSolidification and Micro-Structural Analysis of Pond Ash Using Lime 05Documento4 pagineStabilizationSolidification and Micro-Structural Analysis of Pond Ash Using Lime 05GJESR0% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- 02 July 2013Documento4 pagine02 July 2013IJBSTRNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Second Generation Feedstock Biodiesel From Jatropha 01 MayDocumento5 pagineSecond Generation Feedstock Biodiesel From Jatropha 01 MayGJESRNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Speed Control of Doubly-Fed Induction Generator Using PI-Controller 06 AugDocumento5 pagineSpeed Control of Doubly-Fed Induction Generator Using PI-Controller 06 AugGJESRNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Soil Modification Using Shredded Scrap TiresDocumento4 pagineSoil Modification Using Shredded Scrap TiresIJBSTRNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Utilization of Sugarcane Bagasse Ash (SCBA) As Pozzolanic Material in Concrete A Review 09 AugDocumento3 pagineUtilization of Sugarcane Bagasse Ash (SCBA) As Pozzolanic Material in Concrete A Review 09 AugGJESRNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- 07 July 2013Documento5 pagine07 July 2013IJBSTRNessuna valutazione finora

- Stabilization of Incinerated Hospital Waste Using Different Type of Binders A Review 03 AugDocumento4 pagineStabilization of Incinerated Hospital Waste Using Different Type of Binders A Review 03 AugGJESRNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Performance Estimate of Gateway Discovery Techniques in MANET Internet Connectivity 03 JulyDocumento4 paginePerformance Estimate of Gateway Discovery Techniques in MANET Internet Connectivity 03 JulyGJESRNessuna valutazione finora

- Experimental Modeling of Shear Behavior of Reinforced Concrete Pile Caps 01 AugDocumento9 pagineExperimental Modeling of Shear Behavior of Reinforced Concrete Pile Caps 01 AugfannypramisNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Single Phase Supply Fed Three Phase Induction Motor Using SVPWM Inverter 04 JuneDocumento4 pagineSingle Phase Supply Fed Three Phase Induction Motor Using SVPWM Inverter 04 JuneGJESRNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- 04 July 2013Documento7 pagine04 July 2013IJBSTRNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- A Comprehensive Analysis of Space Vector Pulse Width Modulation For 3-Phase Voltage Source Inverter (VSI) 01 JuneDocumento7 pagineA Comprehensive Analysis of Space Vector Pulse Width Modulation For 3-Phase Voltage Source Inverter (VSI) 01 JuneGJESR100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Improving The Behavior of Reinforced Concrete Beam With Varying Lap Splices Length 04 AugDocumento4 pagineImproving The Behavior of Reinforced Concrete Beam With Varying Lap Splices Length 04 AugGJESRNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Parametric Optimization of Wire EDM by Using Fuzzy Logic 08 AugDocumento5 pagineParametric Optimization of Wire EDM by Using Fuzzy Logic 08 AugGJESRNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- Noise Pollution An Overview 13 AugDocumento4 pagineNoise Pollution An Overview 13 AugGJESRNessuna valutazione finora

- Rabies Vaccine Production From Different Viral Infected Cell Line and Vaccine Production 04 FebDocumento6 pagineRabies Vaccine Production From Different Viral Infected Cell Line and Vaccine Production 04 FebGJESRNessuna valutazione finora

- Paper Mill Sludge Utilization in Ground Improvement 15 AugDocumento4 paginePaper Mill Sludge Utilization in Ground Improvement 15 AugGJESRNessuna valutazione finora

- Environmental Impact of Paper Industry 05 JuneDocumento5 pagineEnvironmental Impact of Paper Industry 05 JuneGJESRNessuna valutazione finora

- Control Strategies For Water Level Control of Two Tank System 11 AugDocumento7 pagineControl Strategies For Water Level Control of Two Tank System 11 AugGJESRNessuna valutazione finora

- Induce Pluripotent Stem Cell Methods, Development and Advancesn 02 FebDocumento11 pagineInduce Pluripotent Stem Cell Methods, Development and Advancesn 02 FebGJESRNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Design Optimization of The Formation of Boss or Ridge and Passivation of Electrolyte Flow in ECM Process Using CFD Simulation 05 JulyDocumento8 pagineDesign Optimization of The Formation of Boss or Ridge and Passivation of Electrolyte Flow in ECM Process Using CFD Simulation 05 JulyGJESRNessuna valutazione finora

- Comparison of Traffic Noise Prediction Using FHWA and ERTC Models in Gorakhpur City 16 AugDocumento7 pagineComparison of Traffic Noise Prediction Using FHWA and ERTC Models in Gorakhpur City 16 AugGJESRNessuna valutazione finora

- Comparison of Core and Cube Compressive Strength of Hardened Concrete 02 JuneDocumento6 pagineComparison of Core and Cube Compressive Strength of Hardened Concrete 02 JuneGJESRNessuna valutazione finora

- 10 Aug 2013Documento9 pagine10 Aug 2013IJBSTRNessuna valutazione finora

- Carbon Steel Ball Valve: Code # 50 (Aksctk)Documento1 paginaCarbon Steel Ball Valve: Code # 50 (Aksctk)thilina lakhithaNessuna valutazione finora

- Wide-Lite Spectra VI Commercial Indoor Bulletin 1989Documento4 pagineWide-Lite Spectra VI Commercial Indoor Bulletin 1989Alan MastersNessuna valutazione finora

- The Essential Ingredients in A PVC Formulation AreDocumento7 pagineThe Essential Ingredients in A PVC Formulation AreRicky DavisNessuna valutazione finora

- Vlsidesign MCQDocumento18 pagineVlsidesign MCQAkanksha DixitNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- A Detailed Lesson Plan in ScienceDocumento4 pagineA Detailed Lesson Plan in SciencemarigoldNessuna valutazione finora

- Astm A184 - A184m-01 STD Specs For Welded Deformed Steel BarDocumento4 pagineAstm A184 - A184m-01 STD Specs For Welded Deformed Steel BarCharwin PicaoNessuna valutazione finora

- Handling of MaterialsDocumento34 pagineHandling of MaterialsJerome GarganeraNessuna valutazione finora

- Cement and Steel Rates For The Month of August 2013Documento1 paginaCement and Steel Rates For The Month of August 2013Guru PrasadNessuna valutazione finora

- Customer Price List: Certified Code Compliant Steel Stud Manufacturer Manufacturer of Supreme Framing SystemsDocumento5 pagineCustomer Price List: Certified Code Compliant Steel Stud Manufacturer Manufacturer of Supreme Framing SystemsRamonNessuna valutazione finora

- Stability Analysis of Geocell Reinforced Slopes by Considering Bending EffectDocumento13 pagineStability Analysis of Geocell Reinforced Slopes by Considering Bending EffectRakesh KapoorNessuna valutazione finora

- Biobased Materials For Paper Coating: Charles P. Klass Klass Associates Inc. Redington Beach, FLDocumento32 pagineBiobased Materials For Paper Coating: Charles P. Klass Klass Associates Inc. Redington Beach, FLlucy.hughesNessuna valutazione finora

- Tribological Analysis of Thin Films by Pin-On-Disc Evaluation of Friction PDFDocumento10 pagineTribological Analysis of Thin Films by Pin-On-Disc Evaluation of Friction PDFDavid Rafael RamírezNessuna valutazione finora

- Fsci Assignment ADocumento29 pagineFsci Assignment ARaj PrateekNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Cutting Machines in Apparel IndustryDocumento11 pagineCutting Machines in Apparel IndustryProtim Saikia85% (13)

- Everything You Need to Know About Thermoplastic PolyethyleneDocumento3 pagineEverything You Need to Know About Thermoplastic PolyethyleneJoan M. EspelimbergoNessuna valutazione finora

- PDQXDO GH LDYDYDMLOODV LQVWUXFFLRQHVDocumento34 paginePDQXDO GH LDYDYDMLOODV LQVWUXFFLRQHVjarroyojNessuna valutazione finora

- Advancesin Bricksand Blocksfor Building ConstructionDocumento14 pagineAdvancesin Bricksand Blocksfor Building ConstructionBharath GowdaNessuna valutazione finora

- LypholizationDocumento19 pagineLypholizationNaeem Khan MalizaiNessuna valutazione finora

- Eng Chem Lecture NotesDocumento2 pagineEng Chem Lecture NotesJunell TadinaNessuna valutazione finora

- Dayu 12Documento3 pagineDayu 12Wayan SukerayasaNessuna valutazione finora

- PREFORMULATION STUDIEsDocumento8 paginePREFORMULATION STUDIEsTanishaNessuna valutazione finora

- Petron Plustm Formula 7 Diesel Engine ConditionerDocumento2 paginePetron Plustm Formula 7 Diesel Engine ConditionerwellblablablaNessuna valutazione finora

- Solid and Liquid Silicone Rubber Product Selection GuideDocumento16 pagineSolid and Liquid Silicone Rubber Product Selection GuideD.I. Pablo BoverioNessuna valutazione finora

- 750-302 Models D, DL and DLDDocumento31 pagine750-302 Models D, DL and DLDrickNessuna valutazione finora

- JEE Main 2019 Chemistry April Attempt Shift - 1 (08th April, 2019)Documento16 pagineJEE Main 2019 Chemistry April Attempt Shift - 1 (08th April, 2019)Resonance Eduventures83% (24)

- Important MCQ on VLSI Design Logic Gates and CMOS TechnologyDocumento4 pagineImportant MCQ on VLSI Design Logic Gates and CMOS TechnologyAkanksha DixitNessuna valutazione finora

- Eq Tip No. Short Column Effect: Prepared by ContactDocumento24 pagineEq Tip No. Short Column Effect: Prepared by ContactNasshikin RamliNessuna valutazione finora

- NC-559-ASM Rev 0510Documento2 pagineNC-559-ASM Rev 0510electrosysro8560Nessuna valutazione finora

- FEA Tutorials NL4Documento29 pagineFEA Tutorials NL4Tran Tien Dung100% (1)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetDa EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetValutazione: 4.5 su 5 stelle4.5/5 (10)

- Dark Aeon: Transhumanism and the War Against HumanityDa EverandDark Aeon: Transhumanism and the War Against HumanityValutazione: 5 su 5 stelle5/5 (1)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDa EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNessuna valutazione finora

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDa EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNessuna valutazione finora

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessDa EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNessuna valutazione finora

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeDa EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeValutazione: 4.5 su 5 stelle4.5/5 (59)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceDa EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceValutazione: 5 su 5 stelle5/5 (9)