Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Invitation Letter PQT AEC & CWC

Caricato da

Iqbal Nurrasa BaktiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Invitation Letter PQT AEC & CWC

Caricato da

Iqbal Nurrasa BaktiCopyright:

Formati disponibili

Nomor

Subject

Attachment

To:

: 191/DIV-QA&PD/XI/2015

: Invitation Letter of PQT AEC & CWC

: 2 set Time Table of PQT for AEC & CWC

PT. COOEC INDONESIA

Menara Standard Chartered, 32nd Floor

JL. Prof. Dr. Satrio No.164, Karet Semanggi, Jakarta 12930

Tel : +62 21 2553 2525 ext.124

Fax: +62 21 2553 2181

Attn:

Mr. Zhang Project Manager

Mr. Yubin/Mr. Yap Beng Long

Dear Sir,

Herewith we invite you to witness PQT Asphalt Enamel Coating (AEC) and Concrete Weight

Coating (CWC) which will perform as follows:

ASPHALT ENAMEL COATING on Wednesday, 2 December 2015, at 10.00 AM

CONCRETE WEIGHT COATING on Thursday, 3 December 2015, at 10.00 AM

Place of PQT at PT. KHI Pipe Industries Cilegon, Banten.

Thank you for your kind attention.

Regards

Cilegon, 30 November 2015

PT. KHI Pipe Industries

Suprapto

QA Coordinator

cc:

1. BOD PT. KHI

2. Project Manager KHI

3. Project Team

4. File

1 of 1

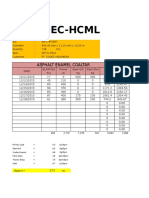

TIME TABLE OF PQT ASPHALT ENAMEL COATING

No.

1.0

Process Activity

Contract No.

: BD-PPL-C-002

Doc. No: TT-KHI-AEC-01

Customer

: PT. COOEC INDONESIA

Date: 30 November 2015

Project

: Madura BD Field Development

Description

Frequency

Pre-inspection meeting

2-Dec-15

3-Dec-15

4-Dec-15

5-Dec-15

4.1 Traceability

2.0 Incoming Rack Inspection

4.2 Surface contamination

10 Pipes

4.3 Visual Inspection

3.0 Blast Cleaning

Pipe Temperature & Humidity

1 during Blast Cleaning

6.1 Visual Blasted Surface

6.2 Blast Cleaned

4.0 Inspection After Blasting

6.3 Surface Roughness

10 pipes

6.4 Salt Contamination

6.5 Compressed Air Test

1 test

7.1 Steel Surface Temperature

7.2 Relative Humidity

5.0 Primer Application

7.3 Primer Drying

10 pipes

7.4 Visual Primer

7.5 DFT

8.1 Primed surface temperature

8.2 Relative Humidity

8.3 Temperature of Heating Kettles

6.0 Enamel Application

8.4 Visual

8.5 Application Temperature

8.6 Characteristics of Asphalt Enamel

7.0 Inner Wrap Application

8.0 Outer Wrap Application

9.0 Water Quenching

9.1 Overlap

9.2 Visual

10.1 Overlap

10.2 Width

11.1 Temperature

10 pipes

1st Heating Kettles

10 pipes

1 Test from 1st Batch and

1st Heating Kettles

10 pipes

10 pipes

Monitoring

12.1 Visual

10.0 Coating Final Inspection

12.2 Thickness

12.3 Holiday Inspection at 20 kV

10 pipes

12.4 Cut back

13.1 Continuity

11.0 Coating Testing & Adhesion Testing

13.2 Correct Placement

13.3 Thickness

10 pipes

13.4 Adhesion

12.0 Marking

Marking application

13.0 Coating Repair

Allowable repairs

14.0 Handling and Stacking

15.0 Documentation

16.0 Release

10 pipes

As required

As required

Completion of PQT

Prepared by,

6-Dec-15

1 of 1

TIME TABLE OF PQT CONCRETE WEIGHT COATING

Contract No.

Customer

Project

No.

1.0

2

3.0

4.0

5.0

5.0

6.0

7.0

8.0

location/ Production

Process

Description

Pre-inspection meeting

Receipt of Coating

Material

2.1 Cement

2.2 Aggregate

2.3 Wire Reinforcement

2.4 Water

- Check Heat Number & Pipe Number

- Check Wall Thickness

Receiving Anti-Corrosion

- Length

Coated Pipe & Incoming

- Check Quantity

Rack Inspection

- Visual Inspection

- Holiday Inspection

- Interval to appliying first and last coat

Concrete Coating

- Temperature of pipe, anti corrosion, reinforcement, or concrete

Application

- Interval for adding water to mix and final placing of concrete

5.1 Equipment

5.2 Moisture Content

Inspection and Test

5.3 Visual inspection

5.4. Dimensional Inspection

5.5. Weighing of Pipe

5.6. Compressive Strength

5.6.1 Cylindrical Molds

5.6.2 Core

Inspection and Test

5.7. Dry Density

5.8. Water Absorption

5.9. Negative Buoyancy

5.10. Reinforcement Spacing

5.11. Impact Testing

5.12. Anti Slip Test

5.13. Final Inspection

Marking

Marking application

Coating Repair

Allowable repairs

Handling and Stacking

-

9.0 Documentation

10.0 Release for shipment

: BD-PPL-C-002

: PT. COOEC INDONESIA

: Madura BD Field Development

Frequency

Doc. No: TT-KHI-CWC-01

Date: 30 November 2015

3rd

4th

5th

6th

7th

8th

Dec '2015

Jan' 16

9th 10th 11th 12th 13th 14th 15th 16th 17th 18th 19th 20th 21st 22nd 23rd 24th 25th 26th 27th 28th 29th 30th 31st

1st

1

1 Batch wich is used for PQT

1 Batch wich is used for PQT

1 Batch wich is used for PQT

1 Check

5 Pipes

5 Pipes

1

1

5 Pipes

5 Pipes

5 Pipes

5 Pipes. Each pipe 2 Sample (2 pcs for 7 days, and 2 pcs for 28 days)

5 Pipes. Each pipe 2 Sample (1 pc for 7 days, and 1 pc for 28 days)

5 Pipes

5 Pipes

5 Pipes

5 Pipes

1 Test every concrete thickness and random sampling 1 testing per

each thickness after completion of production and curing.

5 Pipes

5 Pipes

As required

5 Pipes

Completion PQT

Prepared by

Potrebbero piacerti anche

- Inspection Log Book PLMB - 040915Documento42 pagineInspection Log Book PLMB - 040915Rahmad DesmanNessuna valutazione finora

- Report PQT Elnusa PDFDocumento40 pagineReport PQT Elnusa PDFAlfian ImaduddinNessuna valutazione finora

- WIS QCWT GE 15 Rev.1 - Painting InspectionDocumento6 pagineWIS QCWT GE 15 Rev.1 - Painting Inspectionfajar aljogjaNessuna valutazione finora

- Method Statement - Non-Metallic Pipeline Instalation & Pull Through To HDDDocumento8 pagineMethod Statement - Non-Metallic Pipeline Instalation & Pull Through To HDDMuhammad IrsyadiNessuna valutazione finora

- Hydrotest - 333 AG FW 0001 - Rev03 PDFDocumento26 pagineHydrotest - 333 AG FW 0001 - Rev03 PDFIhsan IchwansyahNessuna valutazione finora

- Procedure For Handling, Storage & Transportations of Bare & Coated PipesDocumento6 pagineProcedure For Handling, Storage & Transportations of Bare & Coated Pipeskbpatel123Nessuna valutazione finora

- Heat Shrink ProcedureDocumento7 pagineHeat Shrink ProcedureBabar Manzoor GhauriNessuna valutazione finora

- SUMMARY PQT PT PERTAMINA (PERSERO) 15 February 2017Documento15 pagineSUMMARY PQT PT PERTAMINA (PERSERO) 15 February 2017YuwantoniAl100% (1)

- Test Package - NEWDocumento14 pagineTest Package - NEWDilshad AhemadNessuna valutazione finora

- Prosedur Penetran TestingDocumento11 pagineProsedur Penetran TestingIkhsan DalimuntheNessuna valutazione finora

- Palatal A408-972 (E) For PultrusionDocumento1 paginaPalatal A408-972 (E) For Pultrusionbourne029Nessuna valutazione finora

- Pttep Painitng of Offshore FacilitiesDocumento66 paginePttep Painitng of Offshore FacilitiesSufianNessuna valutazione finora

- Rapid P0030 CPP Qac PRC 0001 0024 - A CCDocumento14 pagineRapid P0030 CPP Qac PRC 0001 0024 - A CCAtuk SafizNessuna valutazione finora

- Blasting and Painting ProcedureDocumento6 pagineBlasting and Painting Procedureanon_994898767Nessuna valutazione finora

- Doc. No Revision No Revision DateDocumento6 pagineDoc. No Revision No Revision DateShyam SinghNessuna valutazione finora

- PHEWMO-OrF-Z-PRC-0033 Rev.B Prosedur Pemasangan Anchor BoltDocumento14 paginePHEWMO-OrF-Z-PRC-0033 Rev.B Prosedur Pemasangan Anchor Boltchristian210789Nessuna valutazione finora

- Donggi Senoro LNG Project: Inspection and Test Plan FOR Hot Oil Heater ErectionDocumento5 pagineDonggi Senoro LNG Project: Inspection and Test Plan FOR Hot Oil Heater ErectionAlif Rahmat FebriantoNessuna valutazione finora

- Piping Fabrication and Installation Procedure: Doc. No Rev. No DateDocumento24 paginePiping Fabrication and Installation Procedure: Doc. No Rev. No DateMechanical Static WRKNessuna valutazione finora

- QCF316 Cold Insulation Inspection Report For Vessel / MachineryDocumento1 paginaQCF316 Cold Insulation Inspection Report For Vessel / MachineryminhnnNessuna valutazione finora

- ITP Final PLPS 82336-43 - ITP 150kV KENDARI ANDOOLO SECT 1 Rev1 Baruga PDFDocumento3 pagineITP Final PLPS 82336-43 - ITP 150kV KENDARI ANDOOLO SECT 1 Rev1 Baruga PDFMuhammad YahdimanNessuna valutazione finora

- CP Painting Revised SpecsDocumento57 pagineCP Painting Revised SpecsanilnwaychalNessuna valutazione finora

- 1 VRLA BrochureDocumento6 pagine1 VRLA BrochurePT Bumi Raya PerkasaNessuna valutazione finora

- Pertamina (Persero) 080221 - Spherical Tank Terminal LPG Reff Jatim 1 - TubanDocumento1 paginaPertamina (Persero) 080221 - Spherical Tank Terminal LPG Reff Jatim 1 - TubanMochamad TaufikNessuna valutazione finora

- Data Sheet Meter Turbin G.65Documento1 paginaData Sheet Meter Turbin G.65HerruSetiawanNessuna valutazione finora

- Interseal 670HDocumento2 pagineInterseal 670Hmadmax_mfpNessuna valutazione finora

- GSB-Form-246 Dimension Inspection Report (Circum)Documento1 paginaGSB-Form-246 Dimension Inspection Report (Circum)Made GileeNessuna valutazione finora

- Lowering Pipe SafelyDocumento5 pagineLowering Pipe SafelyLarry Ubu100% (1)

- RIGZONE - CSTS Lands FEED Contract For BP's Tangguh Expansion Project in IndonesiaDocumento1 paginaRIGZONE - CSTS Lands FEED Contract For BP's Tangguh Expansion Project in IndonesiaAnonymous cekPJylABoNessuna valutazione finora

- MESC SPE 74-018 - 2010 - Nickel Alloy Pipe To Astm b167Documento7 pagineMESC SPE 74-018 - 2010 - Nickel Alloy Pipe To Astm b167sathi11189Nessuna valutazione finora

- 09 Job Procedure For Fire ProofingDocumento4 pagine09 Job Procedure For Fire ProofingAlvin Smith100% (2)

- 6 MM TCDocumento1 pagina6 MM TCpranesh kadamNessuna valutazione finora

- Steel Erection ITPDocumento26 pagineSteel Erection ITPIksan Adityo MulyoNessuna valutazione finora

- Korethan Topcoat Protects StructuresDocumento2 pagineKorethan Topcoat Protects StructuresTrịnh Minh KhoaNessuna valutazione finora

- Cb3 Ec 50 MT 001 A4 Rev.1 Mto For Civil WorkDocumento5 pagineCb3 Ec 50 MT 001 A4 Rev.1 Mto For Civil WorkRomawi StevyandiNessuna valutazione finora

- 02 - Ab-Pf1a-C000-B13-Spec-0007 - 02C2.1Documento38 pagine02 - Ab-Pf1a-C000-B13-Spec-0007 - 02C2.1Walid BdeirNessuna valutazione finora

- Work Method StatementDocumento9 pagineWork Method StatementdjvhNessuna valutazione finora

- Boq Package 4-Mep Rumus1Documento413 pagineBoq Package 4-Mep Rumus1Muhammad Iqbal ArdhiansyahNessuna valutazione finora

- As 2832.2-2003 Cathodic Protection of Metals Compact Buried StructuresDocumento9 pagineAs 2832.2-2003 Cathodic Protection of Metals Compact Buried StructuresSAI Global - APAC100% (1)

- Bulletin - PP-005 - FRP Pipe Tee-In Joint ProcedureDocumento6 pagineBulletin - PP-005 - FRP Pipe Tee-In Joint ProcedureSatria PradanaNessuna valutazione finora

- Inspection and Test Plan (ITP) (Pressure Vessel)Documento1 paginaInspection and Test Plan (ITP) (Pressure Vessel)hannanNessuna valutazione finora

- Mandolite 550 DSDocumento4 pagineMandolite 550 DSnrd9771Nessuna valutazione finora

- S0442 GPS L XXX SP 0005 - 0 - Specification For Piping Fabrication and InstallationDocumento42 pagineS0442 GPS L XXX SP 0005 - 0 - Specification For Piping Fabrication and InstallationThành TrịnhNessuna valutazione finora

- PQT Heat Treatment Tms 1Documento96 paginePQT Heat Treatment Tms 1nur wahyu dewi kusrini100% (1)

- Technical Data Sheet for Barrier 80 Zinc Epoxy PrimerDocumento5 pagineTechnical Data Sheet for Barrier 80 Zinc Epoxy PrimerBalaji GuruNessuna valutazione finora

- Standard Specification FOR Pipeline Internal CoatingDocumento2 pagineStandard Specification FOR Pipeline Internal CoatingRanjan KumarNessuna valutazione finora

- 417-DS-IMA-6144B (Junction Box Data Sheet)Documento2 pagine417-DS-IMA-6144B (Junction Box Data Sheet)mithunceaNessuna valutazione finora

- Rfi (Rfin) TQ FormDocumento4 pagineRfi (Rfin) TQ FormMatt CerosNessuna valutazione finora

- Part 4.4 - CivilDocumento334 paginePart 4.4 - Civilanjas_tsNessuna valutazione finora

- Procedure For Magnetic Particle ExaminationDocumento2 pagineProcedure For Magnetic Particle ExaminationsrinivasansmNessuna valutazione finora

- 01 SupportingDocumento1 pagina01 SupportingSaya NamaNessuna valutazione finora

- Coating Specification PAM EC 50 SP 001 1ADocumento43 pagineCoating Specification PAM EC 50 SP 001 1ADavid Ricardo Diaz0% (1)

- CC ITP Sample PDFDocumento4 pagineCC ITP Sample PDFMRezaNessuna valutazione finora

- Inspeksi Pipa BajaDocumento5 pagineInspeksi Pipa BajaBahtiar YudhistiraNessuna valutazione finora

- Bina Goodyear Berhad: Method Statement SubmittalDocumento5 pagineBina Goodyear Berhad: Method Statement SubmittalGan Chin PhangNessuna valutazione finora

- 194 Mdi-Pp STQ Viii 2022Documento3 pagine194 Mdi-Pp STQ Viii 2022Egi Nuamsyah kosasihNessuna valutazione finora

- 2632 PL DS 001 Line PipeDocumento3 pagine2632 PL DS 001 Line PipeAdvisNessuna valutazione finora

- PPR and uPVC Piping Installation Method StatementDocumento46 paginePPR and uPVC Piping Installation Method Statementjaianit8980% (5)

- Piping Engineer - Ramasamy - 14-Dec-17Documento3 paginePiping Engineer - Ramasamy - 14-Dec-17Ramasamy SivaNessuna valutazione finora

- Method Statement For Plumbing Piping Works Rev.01Documento46 pagineMethod Statement For Plumbing Piping Works Rev.01zenoses76% (37)

- Procedure Painting Mps Epoxcy - Final - PT KhiDocumento12 pagineProcedure Painting Mps Epoxcy - Final - PT KhisinambeladavidNessuna valutazione finora

- Layout Area Parkir TruckDocumento1 paginaLayout Area Parkir TruckIqbal Nurrasa BaktiNessuna valutazione finora

- Section Area Parkir TruckDocumento1 paginaSection Area Parkir TruckIqbal Nurrasa BaktiNessuna valutazione finora

- Daily Progres 22 AprilDocumento2 pagineDaily Progres 22 AprilIqbal Nurrasa Bakti100% (3)

- MADURA BD FIELD DEVELOPMENT PROJECT - HCML COORDINATION MEETING MINUTESDocumento4 pagineMADURA BD FIELD DEVELOPMENT PROJECT - HCML COORDINATION MEETING MINUTESIqbal Nurrasa BaktiNessuna valutazione finora

- Handover 3 Pcs Pipe 16 Inch THK 14.3 To SWEDocumento2 pagineHandover 3 Pcs Pipe 16 Inch THK 14.3 To SWEIqbal Nurrasa BaktiNessuna valutazione finora

- Contoh 2Documento5 pagineContoh 2Iqbal Nurrasa BaktiNessuna valutazione finora

- Summary Production of Concrete Production: No Sample Production Date Remarks Total ProdDocumento4 pagineSummary Production of Concrete Production: No Sample Production Date Remarks Total ProdIqbal Nurrasa BaktiNessuna valutazione finora

- MADURA BD FIELD DEVELOPMENT PROJECT - HCML COORDINATION MEETING MINUTESDocumento4 pagineMADURA BD FIELD DEVELOPMENT PROJECT - HCML COORDINATION MEETING MINUTESIqbal Nurrasa BaktiNessuna valutazione finora

- Inspection Report of Monolithic Isolation Joint DeliveryDocumento9 pagineInspection Report of Monolithic Isolation Joint DeliveryIqbal Nurrasa BaktiNessuna valutazione finora

- Pak Shankar Comment and Gesit Response (Review KHI)Documento1 paginaPak Shankar Comment and Gesit Response (Review KHI)Iqbal Nurrasa BaktiNessuna valutazione finora

- Inspection Report of Monolithic Isolation Joint DeliveryDocumento9 pagineInspection Report of Monolithic Isolation Joint DeliveryIqbal Nurrasa BaktiNessuna valutazione finora

- Anhidrida Asetat MsdsDocumento6 pagineAnhidrida Asetat MsdsmentaridaNessuna valutazione finora

- DAILY PROGRESS PQT and Production Asphalt Enamel CoatingDocumento1 paginaDAILY PROGRESS PQT and Production Asphalt Enamel CoatingIqbal Nurrasa BaktiNessuna valutazione finora

- Daily Progres PHE ONWJDocumento12 pagineDaily Progres PHE ONWJIqbal Nurrasa BaktiNessuna valutazione finora

- COOEC-HCML Pipe Coating Production ReportDocumento3 pagineCOOEC-HCML Pipe Coating Production ReportIqbal Nurrasa BaktiNessuna valutazione finora

- Higher Algebra - Hall & KnightDocumento593 pagineHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Receive MaterialDocumento1 paginaReceive MaterialIqbal Nurrasa BaktiNessuna valutazione finora

- Summary Production of Concrete Production: No Sample Production Date Remarks Total ProdDocumento4 pagineSummary Production of Concrete Production: No Sample Production Date Remarks Total ProdIqbal Nurrasa BaktiNessuna valutazione finora

- Higher Algebra - Hall & KnightDocumento593 pagineHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Book 1Documento15 pagineBook 1Iqbal Nurrasa BaktiNessuna valutazione finora

- Higher Algebra - Hall & KnightDocumento593 pagineHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Weather and Aviation PDFDocumento10 pagineWeather and Aviation PDFSergio GasparriNessuna valutazione finora

- EC6302 - Digital ElectronicsDocumento6 pagineEC6302 - Digital ElectronicsAdal ArasuNessuna valutazione finora

- Pages From RCJ SpecificationsDocumento1 paginaPages From RCJ Specificationsarch ragabNessuna valutazione finora

- Technical Spec & BOQ Screw ConveyorDocumento7 pagineTechnical Spec & BOQ Screw ConveyorjhsudhsdhwuNessuna valutazione finora

- 2D Vs 3D ReviewDocumento7 pagine2D Vs 3D ReviewBhasker RamagiriNessuna valutazione finora

- Siemens Technical FlyerDocumento2 pagineSiemens Technical FlyerThiagoPinheiroNessuna valutazione finora

- JR CVDocumento5 pagineJR CVMostafa MohmmedNessuna valutazione finora

- API 6D Valves Bonney Forge PDFDocumento12 pagineAPI 6D Valves Bonney Forge PDFSQUALO_122Nessuna valutazione finora

- Galvanic CorrosionDocumento35 pagineGalvanic CorrosionSyarief NahdiNessuna valutazione finora

- DE Ee1Documento4 pagineDE Ee1Jj JumawanNessuna valutazione finora

- Super PaveDocumento20 pagineSuper PaveHashem EL-MaRimeyNessuna valutazione finora

- Euro FirefighterDocumento2 pagineEuro FirefighterGustavo VydraNessuna valutazione finora

- MVC PDFDocumento197 pagineMVC PDFAnonymous PGSronUzcSNessuna valutazione finora

- THE William Francis Galvin, Secretary of The Commonwealth State Publications and RegulationsDocumento54 pagineTHE William Francis Galvin, Secretary of The Commonwealth State Publications and Regulationsbubbo07Nessuna valutazione finora

- Air SuspensionDocumento27 pagineAir SuspensionStanly JohnsonNessuna valutazione finora

- Bawana BOQDocumento28 pagineBawana BOQSasi Kiran VundamatlaNessuna valutazione finora

- Aiwa NSX-VC58Documento41 pagineAiwa NSX-VC580000AbdielNessuna valutazione finora

- Aluminium Pipe FittingsDocumento12 pagineAluminium Pipe Fittingsrahult19Nessuna valutazione finora

- 1756 Controllogix I/O ModulesDocumento7 pagine1756 Controllogix I/O ModulesminurajraNessuna valutazione finora

- If Steam Drum Under Vacuum Then What Will HappenDocumento2 pagineIf Steam Drum Under Vacuum Then What Will HappenyogacruiseNessuna valutazione finora

- Airflex C Highbay 18 DelviroDocumento3 pagineAirflex C Highbay 18 DelviroDanielNessuna valutazione finora

- MVC Project Jarvis DatabaseDocumento30 pagineMVC Project Jarvis DatabaseSravan SaiNessuna valutazione finora

- KfloppyDocumento17 pagineKfloppyBhanuNessuna valutazione finora

- Article 5 - How To Purge Husqvarna Hydrostatic TransmissionDocumento3 pagineArticle 5 - How To Purge Husqvarna Hydrostatic TransmissionSofia AlyaNessuna valutazione finora

- Mechanics of A Diesel Fuel Injection SystemDocumento8 pagineMechanics of A Diesel Fuel Injection Systemekitriandi0% (1)

- Iec 61400 Justification: E30/70 PRODocumento60 pagineIec 61400 Justification: E30/70 PROoswalfNessuna valutazione finora

- 743CBDocumento16 pagine743CBTenza Zangetsu MaetNessuna valutazione finora

- Iec61000 4 7 (Ed2.0) en - DDocumento8 pagineIec61000 4 7 (Ed2.0) en - Dtwinvbooks100% (1)

- Design & Fabrication of a Solar-Assisted Air DehumidifierDocumento17 pagineDesign & Fabrication of a Solar-Assisted Air DehumidifierSree NairNessuna valutazione finora

- User Manual Kxtda 30 600Documento252 pagineUser Manual Kxtda 30 600kabeh1Nessuna valutazione finora