Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Crankshaft

Caricato da

matjaz555Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Crankshaft

Caricato da

matjaz555Copyright:

Formati disponibili

International Journal of Scientific & Engineering Research Volume 2, Issue 8, August-2011

ISSN 2229-5518

Computer Aided Modeling and Optimization

of Crankshaft

C.M.Balamurugan, R.Krishnaraj, Dr.M.Sakthivel, K.Kanthavel, Deepan Marudachalam M.G, R.Palani

Abstract The Computer aided modeling and optimization analysis of crankshaft is to study was to evaluate and compare the fatigue

performance of two competing manufacturing technologies for automotive crankshafts, namely forged steel and ductile cast iron. In this

study a dynamic simulation was conducted on two crankshafts, cast iron and forged steel, from similar single cylinder four stroke engines.Finite element analyses was performed to obtain the variation of stress magnitude at critical locations. The dynamic analysis was

done analytically and was verified by simulations in ANSYS.Results achived from aforementioned analysis were used in optimization of the

forged steel crankshaft.Geometry,material and manufacturing processes were optimized considering different constraints,manufacturing

feasibility and cost.The optimization process included geometry changes compatible with the current engine,fillet rolling and result in increased fatigue strength and reduced cost of the crankshaft, without changing connecting rod and engine block.

Index Terms Crankshaft, Forged steel, Cast iron

1 INTRODUCTION

he objective of this study was to compare the durability of crankshafts from two competing manufacturing processes, as well as to perform dynamic load

and stress analysis, and optimization. The crankshafts

used in the study were forged steel and ductile cast iron

from a one-cylinder gasoline engine. Strain-controlled

monotonic and fatigue tests as well as impact tests were

performed on specimens machined from the crankshafts.

Load-controlled component bending fatigue tests were

also carried out on the crankshafts. Material tests showed

that the forged steel had 26% higher tensile strength and

37% higher fatigue strength than the ductile cast iron,

while component tests showed that the forged steel

crankshaft had 32% higher fatigue strength resulting in a

factor of six

longer fatigue life. The S-N approach used to predict the

fatigue lives of both crankshafts showed reasonable correlation to the experimental data from the Component

tests. Dynamic load analysis was performed to determine the in service loading of the crankshafts and FEA

was conducted to find stresses at critical locations. Finally, the geometry, material, and manufacturing processes

were optimized for the forged steel crankshaft (1) The

optimization process included geometry changes compatible with the current engine, fillet rolling, and the use

of MA steel, resulting in18% weight reduction, increased

fatigue strength and reduced cost of the crankshaft.

`The load distribution along all 6 cylinders of fillet has been investigated (2)Previously crankshaft has

maximum stress level near 45 through the pin fillet radius the crankshaft which has larger pin journal, produces a greater overlap between the main and pin journals.

The stresses are now nearly equal in both the main and

pin.

The exact pattern of residual stresses will depend on the heat treatment temperatures employed, the

depth of hardening and the type of quenchant. Process

conditions that give rise to compressive residual stresses

on the surface of heat treated components are favorable.

This type of residual stress delays the initiation of fatigue

cracking in service, which typically occurs on the surface

of the part under the action of cyclic tensile stresses. The

last phase in the manufacturing of crank shafts is finish

grinding in order to achieve the desirable condition of

the surface and the subsurface layer,i.e. suitable dimensions, suitable surface roughness and the corresponding

distribution of relative grinding residual stress in the

subsurface have to be ensured (3) By correct selection of

the grinding wheel and grinding conditions, taking into

account the physical and mechanical properties of the

work piece material, the very favorable compressive residual stresses in the hardened surface layer.

Nearside this dissertation describes the stress

distribution of the upper crankshaft for six stroke engine

by using finite element analysis. The finite element analysis is performed by using computer aided engineering

(CAE) software. The main objectives of this project are to

investigate and analyze the stress distribution of upper

piston at the real engine condition during combustion

process. The dissertation describes the mesh optimization with using finite element analysis technique to predict the higher stress and Critical region on the component (4) The upper crankshaft is implemented in the six

stroke engine of 110 cc Modems motorcycle. Aluminum

356-T7 is selected as an upper crankshaft material. Despite all the stresses experience by the upper crankshaft

does not damage the upper crankshaft due to high tensile strength but the upper crankshaft may fail under

fatigue loading.

The engine crankshaft of a vehicle suddenly

fractured, as the vehicle was running normally on a

highway. The engine crankshaft was made from ductile

cast iron. The failure cause was analyzed by chemical

and metallographic examination, evaluation of mechanical properties, determination of depth of the quenched

layer, measurement of distance between the quenched

layer and the web, observation on the fracture surface as

well as value determination of the fillet radius. The results showed that the failure mechanism of the crankshaft was fatigue fracture resulting from co-effect of

bending and twisting, and the crack originated from the

subsurface shrinkage in the unquenched layer of the

crankshaft journal (5) Several aspects of the crankshaft

were not up to the technical standards, such as distance

IJSER 2011

http://www.ijser.org

International Journal of Scientific & Engineering Research Volume 2, Issue 8, August-2011

ISSN 2229-5518

between the quenched layer and the web, chemical composition, hardness and microstructure of the quenched

layer, yield strength, and impact toughness.

The increasing levels of power being made

available in automotive engines are bringing with it a

new constraint, the levels of crankshaft and block stiffness. The stiffness as a function of design is often compromised by the needs to save weight, controlling manufacturing costs and the complexity of the supporting

software models used to predict end results. Crankshafts

have to cope with high process loads. Reducing internal

bending forces produced from dynamic unbalance along

their length can mean the difference between acceptable

or unacceptable performance and reliability inhibited by

crankshaft stiffness. Crankshafts have traditionally been

treated as rigid rotors and balanced as such, getting traditional methods and practice changed takes some

doing. The use of empirical tests to support or challenge

the modeling software has to be made available to improve end results and save on time and budgets (6)One

such method is to use a specially adapted balancing machine to balance check complete engine assemblies driven at low speeds, another is to use a multi-channel vibration instrument to monitor crank case deflections on a

powered engine.

This paper presents the result of a literature

survey focused on fatigue performance evaluation and

comparisons of forged steel and cast iron crankshafts.

Crankshaft specifications, operating conditions, and various failure sources are first reviewed. Then design aspects and manufacturing procedures for crankshafts are

discussed. This includes a review of the effects of influential parameters such as residual stresses on fatigue

behavior and methods of their production in crankshafts.

The common crankshaft material and manufacturing

process technologies currently in use are then compared

with regards to their durability performance. This is followed by a discussion of durability assessment procedures used for crankshafts, as well as bench testing and

experimental techniques(7)Geometric optimization of

crankshafts is also briefly discussed and cost analysis

and potential cost saving potentials from several studies

in the literature are present.

A crankshaft for vessel engine is one of the most

vital parts for ships. Crankshafts are roughly classified

into two categories; built-up type crankshafts for 2-cycle

diesel engines and solid type crankshafts for 4-cycle diesel engines.

Built-up type crankshafts are made by shrink fitting journals to crank throws for the numbers of cylinders and are widely used for marine diesel engines with

cylinder bore-diameters larger than approx. 400 mm. The

two oil shocks forced low speed, two cycle, engine manufacturers to pursue lower energy consumptions and

lower fuel costs. As a result, the engine strokes have become longer and the cylinder pressures have become

higher. Also, the recent increasing size of ships has resulted in a requirement for higher powers and, at the

same time, the needs to reserve maximum cargo space

require downsizing of engines (8)The technical trend in

the low-speed engine requires the built-up type crankshafts to have high.

Stress

Analysis and Optimization of Crank

shafts Subject to Dynamic Loading. The main objective of

this study was to investigate weight and cost reduction

opportunities for a forged steel crankshaft. The need of

load history in the FEM analysis necessitates performing

a detailed dynamic load analysis. Therefore, this study

consists of three major sections: dynamic load analysis,

FEM and stress analysis, optimization for weight and

cost reduction. In this study a dynamic simulation was

conducted on two crankshafts, cast iron and forged steel,

from similar single cylinder four stroke engines. Finite

element analysis was performed to obtain the variation

of stress magnitude at critical locations. The pressurevolume diagram was used to calculate the load boundary condition in dynamic simulation model, and other

simulation inputs were taken from the engine specification chart. The dynamic analysis was done analytically

and was verified by simulations in ADAMS which resulted in the load spectrum applied to crankpin bearing.

This load was then applied to the FE model in ABAQUS,

and boundary conditions were applied according to the

engine mounting conditions (9) The analysis was done

for different engine speeds and as a result, critical engine

speed and critical region on the crankshafts were obtained.

2. PROBLEM DEFINITION

1.

Crankshafts are typically manufactured by casting and forging processes.

2.

Manufacturing by forging has the advantage of

obtaining a homogeneous part that exhibits less

number of micro structural voids and defects

compared to casting.

3.

In addition, directional properties resulting from

the forging process help the part acquire higher

toughness and strength in the grain-flow direction.

4.

While designing the forging process for crankshaft, the grain-flow direction can be aligned

with the direction of maximum stress that is applied to the component.

5.

We are going to design two types of crankshafts,one with cast iron and other with forged

steel

6.

We are doing finite element analysis for finding

out the optimized product in crankshaft.

3. FINITE ELEMENT METHOD

The finite element method is numerical analysis

technique for obtaining approximate solutions to a wide

variety of engineering problems. Because of its diversity

and flexibility as an analysis tool, it is receiving much

attention in engineering schools and industries. In more

and more engineering situations today, we find that it is

necessary to obtain approximate solutions to problems

rather than exact closed form solution.

IJSER 2011

http://www.ijser.org

International Journal of Scientific & Engineering Research Volume 2, Issue 8, August-2011

ISSN 2229-5518

It is not possible to obtain analytical mathematical solutions for many engineering problems. An analytical solutions is a mathematical expression that gives the

values of the desired unknown quantity at any location

in the body, as consequence it is valid for infinite number

of location in the body. For problems involving complex

material properties and boundary conditions, the engineer resorts to numerical methods that provide approximate, but acceptable solutions.

The finite element method has become a powerful tool for the numerical solutions of a wide range of

engineering problems. It has developed simultaneously

with the increasing use of the high-speed electronic digital computers and with the growing emphasis on numerical methods for engineering analysis. This method

started as a generalization of the structural idea to some

problems of elastic continuum problem, started in terms

of different equations or as an extrinum probl.

The fundamental areas that have to be learned for working capability of finite element method include:

Matrix algebra.

Solid mechanics.

Variation methods.

Computer skills.

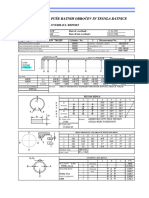

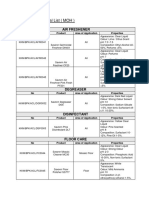

Fig 1.Crank Shaft (Cast Iron)

Matrix techniques are definitely most efficient

and systematic way to handle algebra of finite element

method. Basically matrix algebra provides a scheme by

which a large numStructural

ber of equations can

be stored and maniYoung's Modulus 1.78e+005 M Pa

pulated. Since vast

Poisson's Ratio

0.3

Density 7.197e-006 kg/mm majority of literature

on the finite element

method treats problems in structural and continuum

mechanics, including soil and rock mechanics, the knowledge of these fields became necessary. It is useful to consider the finite element procedure basically as a Variation

approach. This conception has contributed significantly

to the convenience of formulating the method and to its

generality.

The term finite element distinguishes the

technique from the use of infinitesimal differential elements used in calculus, differential equations. The method is also distinguished from finite difference equations, for which although the steps in to which space is

divided into finite elements are finite in size; there is a

little freedom in the shapes that the discrete steps can

take. F.E.A is a way to deal with structures that are more

complex than dealt with analytically using the partial

differential equations. F.E.A deals with complex boundaries better than finite difference equations and gives answers to the real world structural problems.

TABLE 1

CAST IRON PROPERTIES

4. RESULT AND DISCUSSION

4.1. ANALYSIS OF

IRON

CRANKSHAFT - CAST

Fig. 2 Crank Shaft (cast iron)meshed

IJSER 2011

http://www.ijser.org

International Journal of Scientific & Engineering Research Volume 2, Issue 8, August-2011

ISSN 2229-5518

Fig. 6 Crank Shaft (cast iron) Elastic stress

Fig. 3 Crank Shaft (cast iron)loading

Fig. 4 Crank Shaft (cast iron)Total Deformation

Fig. 7 Crank Shaft (cast iron) Elastic strain

4.2. ANALYSIS OF CRANKSHAFT- FORGED

STEEL

Fig. 5 Crank Shaft (cast iron) Elastic strain

IJSER 2011

http://www.ijser.org

International Journal of Scientific & Engineering Research Volume 2, Issue 8, August-2011

ISSN 2229-5518

Fig. 10 Crank shaft (Forged steel) Total deformation

Fig. 8 Crank shaft (Forged steel)

TABLE 2

FORGED STEEL PROPERTIES

Structural

Young's Modulus

Poisson's Ratio

2.21e+005 M Pa

0.3

Density 7.833e-006 kg/mm

Fig. 11 Crank shaft (Forged steel) Elastic strain

Fig. 9 Crank shaft (Forged steel) (meshed)

Fig. 12 Crank shaft (Forged steel) Elastic stress

IJSER 2011

http://www.ijser.org

International Journal of Scientific & Engineering Research Volume 2, Issue 8, August-2011

ISSN 2229-5518

Fig. 13 Crank shaft (Forged steel) Shear stress

TABLE 3

2)

Muhammed Nasiruddin Bin Anidin Finite element

analysis of upper crank shaft six stroke engine using CAE

Software University Malaysia Pahang.

3)

Steve Smith Utilizing crankcase deflection analysis to

improve crankshaft design and engine performance

Oxford, U.K

4)

Jonathan Williams, Farzin Montazersadgh and Ali Fatemi

Fatigue performance comparison and life prediction of

forged steel and ductile cast-iron crankshafts

University of Toledo, Ohio.

5)

M.Zorouf and A.Fatemi- The durability evaluation of

crankshafts including comparisons of competing manufacturing processes and cost analysis.

6)

Zissions P.Mourelatos A crank shaft system model for

structural dynamic analysis of internal combustion engines.

7)

J.Grum Analysis of residual stresses in main crank shaft

bearings after induction surface hardening and finish

grinding University of Ljublijana, Slovenia.

8)

Xue-Qin Hou, Ying Li,Tao Jiang- Fracture failure analysis of ductile cast iron crankshaft in a vehicle engine Beijing Institute of Aeronautical Materials ,China.

9)

Tian Guanglai,Wei Hanbing,-Analysis

of Stresses in

Forged steel Crankshaft of internal combustion engines

COMPARISON OF PROPERTIES OF FORGED STEEL AND

CAST IRON

PROPERTIES

TOTAL

(mm)

DEFORMATION

VON MISES STRESS (MPa)

VON

MISES

STRAIN

ELASTIC

SHEAR STRESS(MPa)

FORGED

STEEL

3.95E-02

1141.5

5.17E-03

299.27

CAST IRON

2.40E-03

15.251

8.57E-05

3.7276

5.CONCLUSION

Analysis results from testing the crank shaft under static load containing the stresses and deflection are

listed in the Table. Since the forged iron crankshaft is

able to withstand the static load, it is concluded that

there is no objection from strength point of view also, in

the process of replacing the cast iron crankshaft by

forged crankshaft. We also reduce forged crankshaft the

cost by the mass production. The project carried out by

us will make an impressing mark in the field of automobile industries. This project we are study about the leaf

spring in the automobile vehicles. Doing this project we

are study about the 3Dmodelling software (SOLID

EDGE) and the Analyzing software (ANSYS) to develop

our basic knowledge to know about the industrial design

REFERENCES

1)

Farzin H. Montazersadgh and Ali Fatemi Stress Analysis and Optimization of Crankshafts Subject to Dynamic Loading - FIERF, AISI

IJSER 2011

http://www.ijser.org

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Valter Brani Sarajevo Klavir PDFDocumento2 pagineValter Brani Sarajevo Klavir PDFmatjaz555Nessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- A Swinkling Christmas - Trumpet 3Documento2 pagineA Swinkling Christmas - Trumpet 3matjaz555Nessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Valter Brani Sarajevo Pozavna 1 PDFDocumento3 pagineValter Brani Sarajevo Pozavna 1 PDFmatjaz555Nessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- SteelDocumento6 pagineSteelmatjaz555Nessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Valter Brani SarajevoDocumento3 pagineValter Brani Sarajevomatjaz555Nessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- A Swinkling Christmas - Trombone 1Documento2 pagineA Swinkling Christmas - Trombone 1matjaz555Nessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- A Swinkling Christmas - Trumpet 1Documento2 pagineA Swinkling Christmas - Trumpet 1matjaz555Nessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Michael Jackson Tribute Horn 1FDocumento4 pagineMichael Jackson Tribute Horn 1Fmatjaz555Nessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- A Swinkling Christmas - Trumpet 2Documento2 pagineA Swinkling Christmas - Trumpet 2matjaz555Nessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- A Swinkling Christmas - TimpaniDocumento2 pagineA Swinkling Christmas - Timpanimatjaz555Nessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Swinkling Christmas - Tenor SaxDocumento2 pagineA Swinkling Christmas - Tenor Saxmatjaz555Nessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- A Swinkling Christmas - Sax 1Documento2 pagineA Swinkling Christmas - Sax 1matjaz555Nessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- A Swinkling Christmas - FluteDocumento2 pagineA Swinkling Christmas - Flutematjaz555Nessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Swinkling Christmas - Bariton ViolinDocumento2 pagineA Swinkling Christmas - Bariton Violinmatjaz555Nessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On The Sunny Side of The Street Sax TenorDocumento1 paginaOn The Sunny Side of The Street Sax Tenormatjaz555Nessuna valutazione finora

- Gremo V Kino Krilnica 2Documento2 pagineGremo V Kino Krilnica 2matjaz555Nessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- On The Sunny Side of The Street Bar CDocumento1 paginaOn The Sunny Side of The Street Bar Cmatjaz555Nessuna valutazione finora

- Meritve Ojnice in Krizne GlaveDocumento1 paginaMeritve Ojnice in Krizne Glavematjaz555Nessuna valutazione finora

- Pressure Measurement and CalibrationDocumento6 paginePressure Measurement and Calibrationmatjaz555Nessuna valutazione finora

- Telwin PDFDocumento24 pagineTelwin PDFmatjaz555Nessuna valutazione finora

- Pressure Measurement and CalibrationDocumento6 paginePressure Measurement and Calibrationmatjaz555Nessuna valutazione finora

- Shaft Line Alignment AnalysisDocumento23 pagineShaft Line Alignment Analysismatjaz555Nessuna valutazione finora

- Kyma Diesel AnalyzerDocumento4 pagineKyma Diesel Analyzermatjaz5550% (1)

- Meritve Valjeve Puše Batnih Obročev in Tesnla Batnice: M/E Cylinder Liner - Overhaul ReportDocumento1 paginaMeritve Valjeve Puše Batnih Obročev in Tesnla Batnice: M/E Cylinder Liner - Overhaul Reportmatjaz555Nessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- 28Documento12 pagine28physicsdocsNessuna valutazione finora

- MasterMind 1 Unit 5 Extra LifeSkills Lesson 2Documento2 pagineMasterMind 1 Unit 5 Extra LifeSkills Lesson 2Hugo A FENessuna valutazione finora

- Nastran 2012 Superelements UgDocumento974 pagineNastran 2012 Superelements Ugds_srinivasNessuna valutazione finora

- Applied Nutrition: Nutritional Consideration in The Prevention and Management of Renal Disease - VIIDocumento28 pagineApplied Nutrition: Nutritional Consideration in The Prevention and Management of Renal Disease - VIIHira KhanNessuna valutazione finora

- Calendar of Cases (May 3, 2018)Documento4 pagineCalendar of Cases (May 3, 2018)Roy BacaniNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Hedonic Calculus Essay - Year 9 EthicsDocumento3 pagineHedonic Calculus Essay - Year 9 EthicsEllie CarterNessuna valutazione finora

- Hce ReviewerDocumento270 pagineHce ReviewerRaquel MonsalveNessuna valutazione finora

- Romanian Oil IndustryDocumento7 pagineRomanian Oil IndustryEnot SoulaviereNessuna valutazione finora

- Springfield College Lesson Plan Template PHED 237: The Learning and Performance of Physical ActivitiesDocumento5 pagineSpringfield College Lesson Plan Template PHED 237: The Learning and Performance of Physical Activitiesapi-285421100Nessuna valutazione finora

- Counselling and PsychotherapyDocumento12 pagineCounselling and PsychotherapyD.Sreenivasa ReddyNessuna valutazione finora

- Business Finance and The SMEsDocumento6 pagineBusiness Finance and The SMEstcandelarioNessuna valutazione finora

- Uptime Elements Passport: GineerDocumento148 pagineUptime Elements Passport: GineerBrian Careel94% (16)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Case AnalysisDocumento25 pagineCase AnalysisGerly LagutingNessuna valutazione finora

- Finding The NTH Term of An Arithmetic SequenceDocumento3 pagineFinding The NTH Term of An Arithmetic SequenceArdy PatawaranNessuna valutazione finora

- Catastrophe Claims Guide 2007Documento163 pagineCatastrophe Claims Guide 2007cottchen6605100% (1)

- Lesson Plan Pumpkin Moon SandDocumento3 pagineLesson Plan Pumpkin Moon Sandapi-273177086Nessuna valutazione finora

- Approved Chemical ListDocumento2 pagineApproved Chemical ListSyed Mansur Alyahya100% (1)

- Poet Forugh Farrokhzad in World Poetry PDocumento3 paginePoet Forugh Farrokhzad in World Poetry Pkarla telloNessuna valutazione finora

- Atul Bisht Research Project ReportDocumento71 pagineAtul Bisht Research Project ReportAtul BishtNessuna valutazione finora

- Proper AdjectivesDocumento3 pagineProper AdjectivesRania Mohammed0% (2)

- A Guide To Relativity BooksDocumento17 pagineA Guide To Relativity Bookscharles luisNessuna valutazione finora

- Feline Neonatal IsoerythrolysisDocumento18 pagineFeline Neonatal IsoerythrolysisPaunas JoshiNessuna valutazione finora

- The 5 RS:: A New Teaching Approach To Encourage Slowmations (Student-Generated Animations) of Science ConceptsDocumento7 pagineThe 5 RS:: A New Teaching Approach To Encourage Slowmations (Student-Generated Animations) of Science Conceptsnmsharif66Nessuna valutazione finora

- Quarter: FIRST Week: 2: Ballecer ST., Central Signal, Taguig CityDocumento2 pagineQuarter: FIRST Week: 2: Ballecer ST., Central Signal, Taguig CityIRIS JEAN BRIAGASNessuna valutazione finora

- Clearing Negative SpiritsDocumento6 pagineClearing Negative SpiritsmehorseblessedNessuna valutazione finora

- 19 Amazing Benefits of Fennel Seeds For SkinDocumento9 pagine19 Amazing Benefits of Fennel Seeds For SkinnasimNessuna valutazione finora

- Affirmative (Afirmativa) Long Form Short Form PortuguêsDocumento3 pagineAffirmative (Afirmativa) Long Form Short Form PortuguêsAnitaYangNessuna valutazione finora

- Kurukku PadaiDocumento4 pagineKurukku PadaisimranNessuna valutazione finora

- United States Court of Appeals, Third CircuitDocumento1 paginaUnited States Court of Appeals, Third CircuitScribd Government DocsNessuna valutazione finora

- Digital TransmissionDIGITAL TRANSMISSIONDocumento2 pagineDigital TransmissionDIGITAL TRANSMISSIONEla DerarajNessuna valutazione finora