Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

User'S Manual: Cleaning and Disinfection

Caricato da

PabloBaquedanoSilvaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

User'S Manual: Cleaning and Disinfection

Caricato da

PabloBaquedanoSilvaCopyright:

Formati disponibili

USERS MANUAL

Cleaning and disinfection

Document number:

20018_00_00_ENG

Marel Townsend Further Processing B.V.

Handelstraat 3

P.O. Box 233

5830 AE Boxmeer

The Netherlands

T: +31 (0)485 586122

F: +31 (0)485 586655

I: www.marel.com

20018_00_00_ENG / 10-12-2002

TABLE OF CONTENTS

Townsend Further Processing

TABLE OF CONTENTS

1

PREFACE ............................................................................................................................................................. 3

1.1 Reading indicator ......................................................................................................................................... 3

SAFETY ................................................................................................................................................................ 4

2.1 Safety at work .............................................................................................................................................. 4

2.2 Pictographs .................................................................................................................................................. 4

2.3 Noise pollution ............................................................................................................................................. 4

2.4 Hygiene and environment ............................................................................................................................ 4

IN GENERAL ........................................................................................................................................................ 6

DETERGENTS...................................................................................................................................................... 7

4.1 Acidic detergents ......................................................................................................................................... 7

4.2 Neutral detergents ....................................................................................................................................... 7

4.3 Alkaline detergents ...................................................................................................................................... 7

CLEANING ........................................................................................................................................................... 8

5.1 Removing coarse dirt ................................................................................................................................... 8

5.2 Applying detergent ....................................................................................................................................... 8

5.3 Soaking ........................................................................................................................................................ 9

5.4 Rinsing ......................................................................................................................................................... 9

DISINFECTION................................................................................................................................................... 11

6.1 Rinsing ....................................................................................................................................................... 11

This users manual is a translation of the original users manual.

Copyright Marel Townsend Further Processing B.V.

All rights reserved.

All technical and technological information contained in this Users Manual as well as any drawings and technical specifications made

available by us shall remain our property and shall not be utilised (other than for the operation of the equipment), reproduced, transmitted, or

disseminated to any unauthorised person, in any form or by any means, without our prior written permission.

2 / 11

20018_00_00_ENG / 10-12-2002

Townsend Further Processing

PREFACE

1

PREFACE

1.1

Reading indicator

The User's Manual uses the term "machine". By

"machine" is meant: the specific module, installation,

unit or system with the corresponding equipment.

This User's Manual contains several boxes. They draw

your attention to dangerous situations for the user,

machine and/or product and give you tips. They are

subdivided and displayed as follows:

DANGER OF LIFE

The users life is instantly threatened.

WARNING

The user can be (seriously) injured or

seriously damage the machine.

The pictograph in this box depends on the

risk-bearing action that is discussed.

CAREFUL

The user can damage the machine or

products when the instructions are not

carried out with care.

NOTE

Observation containing additional

information for the user.

TIP

Provides suggestions and advice to the

user to carry out certain instructions more

skilfully and easier.

Page and document numbers

Each page has a unique identification and consists of:

the page number with the total number of pages.

Example:

4 / 24

the document number and the date of issue.

Example:

20738_00_01_NLD / 17-08-2002

Position numbers and letters in text

Position numbers and letters in bold in the text refer to

the specific section in the figure.

Example:

Guides 40 and 41 stop the product when....

20018_00_00_ENG / 10-12-2002

11

3 / 11

SAFETY

Townsend Further Processing

danger of personal injury caused

by sharp objects

danger of personal injury caused

by rotating parts

danger of personal injury caused

by seizure

danger of personal injury caused

by electrical power

SAFETY

2.1

Safety at work

Townsend Further Processing has made every possible

effort to provide you with comprehensive, accurate

information as regards any hazards relating to the

operation of the machine. The purchaser shall be

responsible for the implementation and proper

observance of these rules of conduct.

Observe the current state of labour, safety and

environmental regulations when carrying out any

operations.

2.2

Pictographs

The pictographs on this page alert the user to possible

dangers. You will find them on the machine and in the

text of this User's Manual.

2.3

Noise pollution

danger of personal injury caused

by high temperatures

Townsend Further Processing designs and constructs

machines where noise pollution has been reasonably

reduced to a minimum.

danger of hearing impairments

through noise pollution

However it is possible that users, due to local

circumstances, will be exposed to noise pollution which

may cause hearing impairment.

approaching danger zone

danger of personal injury caused

by inhaling dangerous gases

WARNING

To prevent hearing impairment due to

noise pollution, you should always

observe the legal standards and

regulations relating to noise pollution

and take proper measures if required.

The noise pollution of the machine is mentioned in the

Technical Data.

We draw your attention to the fact that wrong settings

and overdue maintenance can cause an increase in

noise pollution.

2.4

Hygiene and environment

Uphold the rules of hygiene and environment during

(maintenance) operations on the machine.

Make sure that the production process does not take in

any negative influences from outside, such as

detergents and maintenance agents.

Chemical waste

4 / 11

20018_00_00_ENG / 10-12-2002

Townsend Further Processing

SAFETY

Materials that come under the category of chemical

waste must be discharged separately. In this context you

should consider batteries, oil filters, oils and greases.

Waste discharge

Only offer waste to recognized waste-processing

companies that meet local laws, standards and

regulations.

20018_00_00_ENG / 10-12-2002

11

5 / 11

IN GENERAL

Townsend Further Processing

3

IN GENERAL

Clean and disinfect your convenience food machine

thoroughly at regular intervals. This will guarantee

optimal hygiene of the convenience food products.

Some components of the convenience food machines

are made of high-quality materials. These materials can

be affected by certain detergents and disinfectants.

This can have an adverse effect on the operation and

the economic life of the machine. Therefore when

selecting detergents and disinfectants consider all

possible adverse effects they may have on the machine.

Negative side effects can also be limited by cleaning

and disinfecting the machine regularly according to a

fixed schedule.

NOTE

Also consult the chapter Cleaning in the

User's Manual for the machine to be

cleaned.

MORTAL DANGER

Activities described in this chapter must

only be carried out by competent,

professional and trained personnel.

Should you have any questions, do not hesitate to

contact the service department of Townsend Further

Processing.

6 / 11

20018_00_00_ENG / 10-12-2002

Townsend Further Processing

DETERGENTS

4

acidic

neutral

alkaline

9 10 11 12 13 14

Detergents can be classified as follows on the basis of

their pH-value:

Acidic detergents

Neutral detergents

Alkaline detergents

See fig. 1.

4.1

fig. 1

pH-scale

DETERGENTS

Acidic detergents

CAREFUL

Detergents with a pH-value below 4 have a

damaging effect on the machines.

Detergents with a pH-value below 4 affect most

synthetic materials and are therefore unsuitable for daily

cleaning.

At times the use of acidic detergents will be required due

to scale. However do not use any acidic detergents

when the machine will stand still for a prolonged period

of time after cleaning. The remaining acidic liquids can

affect the machine.

The use of acidic detergents should be restricted to a

minimum; once every 4 weeks at most.

4.2

Neutral detergents

Preferably use neutral detergents.

4.3

Alkaline detergents

CAREFUL

Detergents with a pH-value exceeding 12

are damaging to the machines.

Alkaline detergents with a pH-value between 7 and 12

are generally suitable for daily cleaning.

When particular inhibitors (= chemical substances which

have the effect of reducing material corrosion) are

added to highly alkaline detergents (pH-value exceeding

12) these highly alkaline detergents are also suitable for

use.

20018_00_00_ENG / 10-12-2002

11

7 / 11

CLEANING

Townsend Further Processing

5

CLEANING

The cleaning process can be divided into the following

stages:

Removing coarse dirt.

Applying detergent.

Soaking.

Rinsing.

60C

fig. 2

Maximum cleaning temperature

5.1

DANGER OF LIFE

Take the necessary measures and use

the personal protection prescribed by

the supplier of the detergent.

NOTE

Consult the User's Manual of the supplier of

the detergent for the correct application,

soaking time, concentration and

temperature of the detergent.Check the pHvalue of the detergent applied.

DANGER OF LIFE

Maximum temperature of the detergent

at discharge of the spray gun is 60C.

Higher temperatures can constitute

danger or cause damage.

Removing coarse dirt

Effective detergent use first requires the removal of

loose coarse dirt. This also prevents the loose particles

from being sprayed about.

5.2

Applying detergent

Bring the detergent into contact with the contaminated

surfaces as much as possible. Detergents can be

applied as follows:

Manually, for instance with brushes.

By atomizing.

8 / 11

NOTE

When spreading the detergent by atomizing

it is hard to distinguish between the treated

and untreated surfaces.

WARNING

During atomizing certain detergents cause

irritation of the skin and bronchial tubes.

20018_00_00_ENG / 10-12-2002

Townsend Further Processing

CLEANING

-

Through injection into a high-pressure system.

NOTE

The use of a high-pressure system uses up

a lot of water and detergent making it hard

to distinguish between treated and

untreated surfaces.

WARNING

When using a high-pressure system certain

detergents cause irritation of the skin and

bronchial tubes.

By foaming.

5.3

NOTE

Foam soaks into the contaminations

properly, treated surfaces are clearly visible

and there is no vaporization, causing less

irritation of the skin and bronchial tubes.

Soaking

Temperature, soaking time and concentration of the

detergent are crucial for an optimal effect of the

detergent on the contamination.

Soaking time and concentration depend on:

the materials to be cleaned.

the nature and level of contamination.

the detergent used.

the cleaning method.

the hardness of the water.

5.4

Rinsing

The dirt which has been soaked loose and chemically

converted must be rinsed off with clean water. Also rinse

off all traces of detergent from the machine to avoid a

negative effect of the disinfection process.

CAREFUL

Remaining traces of detergent can cause

material corrosion.

High-pressure spraying is highly effective. The dirt is

quickly loosened and rinsed off. Places which are hard

to reach can be cleaned more easily with high-pressure

spraying.

20018_00_00_ENG / 10-12-2002

11

9 / 11

CLEANING

Townsend Further Processing

-

Rinse at a 45 angle for effective cleaning.

CAREFUL

Carefully clean motors, bearings, bearing

sealings, pneumatic and electric

components and synthetic parts. These

parts can suffer damage when subjected to

high-pressure water spraying.

If high-pressure spraying cannot be

avoided, use flat jet sprayers whenever

possible at an angle of 15 to 25.

In case high-pressure cannot be applied, rinsing will

have to suffice.

10 / 11

20018_00_00_ENG / 10-12-2002

Townsend Further Processing

DISINFECTION

6

DISINFECTION

For a sound level of hygiene regular disinfection of the

machines is required.

With highly contaminated machines cleaning and

disinfection are to be carried out as two separate

operations: first cleaning and then disinfection.

Contamination makes disinfectants less effective.

Remaining contamination can be a source of microorganisms, so that disinfection becomes useless.

For disinfection on a daily basis it is preferable to use

disinfectants containing quaternary ammonium

compounds.

NOTE

It is crucial that you stick to the

recommended solutions and soaking times

of the disinfectant to prevent resistance. It

may be necessary to change your

disinfectant from time to time.

Disinfectants based on chlorine must be applied very

sparingly.

CAREFUL

Disinfectants based on chlorine have a

negative effect on the machines.

Consult the instructions and User's Manual of the

supplier of the disinfectants for the correct application,

soaking time, concentration and temperature of the

disinfectant.

6.1

Rinsing

The prescribed soaking time of the disinfectant must be

followed by thoroughly rinsing the machine with cold

water.

20018_00_00_ENG / 10-12-2002

11

11 / 11

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Research Proposal: Kosha Devendra VasavadaDocumento4 pagineResearch Proposal: Kosha Devendra VasavadaSatya Mehta100% (3)

- HazmatDocumento7 pagineHazmatSuresh KumarNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Environmental Management Plan For Hotel BuildingDocumento8 pagineEnvironmental Management Plan For Hotel BuildingGt Madan100% (1)

- Rain Water HarvestingDocumento24 pagineRain Water Harvestinganon_100565624100% (1)

- Full BSRIA ICE GuideDocumento136 pagineFull BSRIA ICE GuideShweta MahajanNessuna valutazione finora

- PB Waste Management FormDocumento3 paginePB Waste Management Formslamet4riadiNessuna valutazione finora

- School Solid Waste Management Program Sy2019-20Documento5 pagineSchool Solid Waste Management Program Sy2019-20JONATHAN SABALO100% (3)

- Carbon Capture and Sequestration Projects Benefit From Enhanced Oil RecoveryDocumento3 pagineCarbon Capture and Sequestration Projects Benefit From Enhanced Oil RecoveryGabriel DiazNessuna valutazione finora

- Individual Performance Commitment and Review (Ipcr) : Reviewed: Date Approved byDocumento28 pagineIndividual Performance Commitment and Review (Ipcr) : Reviewed: Date Approved byLorna U. Fernandez-EspinozaNessuna valutazione finora

- Pulp and Paper Mill WasteDocumento15 paginePulp and Paper Mill WasteManu Jain100% (1)

- Minutes of Baler's Regular Session on Ecological Solid WasteDocumento19 pagineMinutes of Baler's Regular Session on Ecological Solid Wastehoswakihoti100% (1)

- Minghu Wetland ParkDocumento12 pagineMinghu Wetland ParkKuhu DhingraNessuna valutazione finora

- Razing of RomaniaDocumento201 pagineRazing of RomaniaIngrid Tony100% (1)

- Thesis Presentation - Building Ratings & Carbon TradingDocumento31 pagineThesis Presentation - Building Ratings & Carbon TradingshravaniguptaNessuna valutazione finora

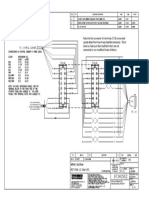

- D Ra W in G Is R e Le A Se D (2 3 0) D A Te S Ta Tu SC H A N G e 2 5 .0 6 .2 0 1 3Documento1 paginaD Ra W in G Is R e Le A Se D (2 3 0) D A Te S Ta Tu SC H A N G e 2 5 .0 6 .2 0 1 3PabloBaquedanoSilvaNessuna valutazione finora

- 8FGU25 - Section E Chapter 6Documento11 pagine8FGU25 - Section E Chapter 6PabloBaquedanoSilvaNessuna valutazione finora

- Vol. 2 CU053 Parts CatalogDocumento2 pagineVol. 2 CU053 Parts CatalogPabloBaquedanoSilvaNessuna valutazione finora

- CU053 CoverDocumento2 pagineCU053 CoverPabloBaquedanoSilvaNessuna valutazione finora

- APES Chapter 11 PowerpointDocumento49 pagineAPES Chapter 11 PowerpointAnonymous tbJUb0BNessuna valutazione finora

- Water Quality Assessment of Adyar River Using GIS (2018) (Lib)Documento76 pagineWater Quality Assessment of Adyar River Using GIS (2018) (Lib)Yogesh RkoNessuna valutazione finora

- Air Pollution Co Benefits From Strengthening Electric Transmission - 2023 - EnerDocumento11 pagineAir Pollution Co Benefits From Strengthening Electric Transmission - 2023 - EnerChester Kazakh ManNessuna valutazione finora

- Emission Control Strategies and Technologies for Meeting Stringent Emission StandardsDocumento1 paginaEmission Control Strategies and Technologies for Meeting Stringent Emission StandardsSmitha MohanNessuna valutazione finora

- Comma Splices & Run-Ons Exercise 1 - Answer KeyDocumento3 pagineComma Splices & Run-Ons Exercise 1 - Answer KeyGael KasongaNessuna valutazione finora

- Prime Cut MsdsDocumento2 paginePrime Cut MsdsMarvin BarahonaNessuna valutazione finora

- Pimentel Speech On Organic FarmingDocumento19 paginePimentel Speech On Organic FarmingThe Outer MarkerNessuna valutazione finora

- Sewage Treatment ProcessDocumento8 pagineSewage Treatment ProcessSanshlesh VermaNessuna valutazione finora

- Long An Net Power StationDocumento4 pagineLong An Net Power Stationdjc49Nessuna valutazione finora

- Netherlands Flood Prevention MethodsDocumento2 pagineNetherlands Flood Prevention MethodsNazhim Muhammad100% (2)

- High-Performance Membrane Element CPA5 MAXDocumento1 paginaHigh-Performance Membrane Element CPA5 MAXlordsethdarknessNessuna valutazione finora

- Concrete Compost Bin GuideDocumento6 pagineConcrete Compost Bin GuideAmos Mccray-GoldsmithNessuna valutazione finora

- Carpet Green Label InfoDocumento2 pagineCarpet Green Label InfoTariq KhurshaidiNessuna valutazione finora

- Gas or Grouse NotesDocumento11 pagineGas or Grouse NotesAngelicaNessuna valutazione finora

- Asif Uz Zaman (Lecturer) Civil Engineering Department Faculty of Engineering Rabigh King Abdulaziz UniversityDocumento17 pagineAsif Uz Zaman (Lecturer) Civil Engineering Department Faculty of Engineering Rabigh King Abdulaziz Universityالجارح الجارحNessuna valutazione finora

- EVS Global Warming, Ozone DepletionDocumento35 pagineEVS Global Warming, Ozone DepletionYashKhanijoNessuna valutazione finora