Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Performance Sheet Drill Pipe: Pipe Body: Tubular Assembly

Caricato da

Garcia C L AlbertoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Performance Sheet Drill Pipe: Pipe Body: Tubular Assembly

Caricato da

Garcia C L AlbertoCopyright:

Formati disponibili

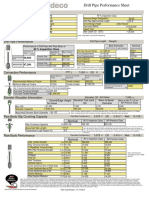

Drill Pipe Performance Sheet

Asset Number: 19206

Pipe Body:

Size and Weight: 5.000'' 19.50 ppf 0.362'' wall IEU

Grade: S-135

Range: 2

Tool Joint: 6.500'' x 3.750'' XT50

Tubular Assembly:

Nominal

100% RBW

95% RBW

Ultra Class

90% RBW

Premium

80% RBW

5.000

0.362

4.276

4.964

0.344

4.276

4.928

0.326

4.276

4.855

0.290

4.276

Tensile Strength (lbs):

Torsional Strength (ft-lbs):

712,070

74,100

673,826

70,043

635,861

66,026

560,763

58,113

Burst Capacity (psi):

Collapse Capacity (psi):

17,105

15,672

18,571

14,292

17,593

12,892

15,638

10,029

OD (in):

Wall Thickness (in):

Nominal ID (in):

Adjusted Weight (lbs/ft): 23.65

Approximate Length (ft): 32.0

Box TJ Length (in): 15

Pin TJ Length (in): 12

Upset Type: IEU

Max Upset OD (in): 5.125

Drift Size (in): 3.625

Fluid Displacement (gal/ft): 0.36

Fluid Displacement (bbls/ft): 0.0086

Fluid Capacity w/IPC (gal/ft): 0.71

Fluid Capacity w/IPC (bbls/ft): 0.0169

Fluid Capacity w/o IPC (gal/ft): 0.72

Fluid Capacity w/o IPC (bbls/ft): 0.0171

18

0

Notes: Body properties are calculated based on uniform OD and wall thickness.

Burst capacity for Nominal (100% RBW) based on 87.5% RBW per API.

Note: These are OEM values that may vary with actual values due to mill tolerances, IPC tolerances, OEM rounding, and other

factors. Pipe is purchased at a guaranteed 95% RBW. IPC is applied to a nominal thickness of 0.009''. Pipe will have an ID of

4.218'', which is smaller than pipe purchased at 87.5%.

Connection: XT50

Elevator Shoulder:

TJ OD (in): 6.500

TJ ID (in): 3.750

MYS (ksi): 120

Maximum MUT (ft-lbs):

Tension at Shoulder Separation @ Max MUT (lbs):

Tension at Connection Yield @ Max MUT (lbs):

46,100

Tensile Limited

864,400

Minimum MUT (ft-lbs):

Tension at Shoulder Separation @ Min MUT (lbs):

Tension at Connection Yield @ Min MUT (lbs):

38,500

1,077,900

1,078,000

Smooth Edge Height (in): N/A

Smooth Edge OD (in): N/A

SE Elevator Shoulder Capacity (lbs): N/A

Nominal TJ OD (in): 6.500

Nominal TJ OD Elevator Shoulder Capacity (lbs): 1,270,000

Assumed Elevator Bore (in): 5.250

N/A

N/A

Tool Joint Torsional Strength (ft-lbs): 76,900

Tool Joint Tensile Strength (lbs): 1,078,000

XT50 is a trademark of NOV Grant-Prideco.

Note: MUT values are based on a friction factor of 1.0. There is no published pressure rating for this connection.

Note: Elevator capacity based on assumed elevator bore, no wear factor, and contact stress of 110, 100 psi. An increased

elevator shoulder OD increases elevator capacity without affecting make-up torque.

The technical information containted herein, including the product performance sheet and other attached documents, has been extracted from information available from the manufacturer and is for reference only and not a recommendation. The user is fully responsible for the accuracy and suitability of use of the technical

information. Workstrings International cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various

inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable operation limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices,

and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.workstringsinternational.com

Download the Workstrings International Pipe Specification App on the App Store or Google Play

10-Dec-15

Operational Limits of Drill Pipe

Connection

Pipe Body

XT50

80 % Inspection Class

Tool Joint OD

(in)

6.500

Tool Joint ID

Pipe Body OD

(in)

Wall Thickness (in) 0.362

(in)

3.750

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

Pipe Body Grade

S-135

(ft-lbs)

(lbs)

(ft-lbs)

0

2,200

4,300

6,500

8,700

10,800

13,000

15,200

17,400

19,500

21,700

23,900

26,000

28,200

30,400

32,500

34,700

36,900

39,000

41,200

560,800

560,400

559,200

557,200

554,400

551,000

546,600

541,200

535,000

528,300

520,200

511,100

501,500

490,300

477,900

464,900

449,800

433,200

415,700

395,300

(lbs)

(ft-lbs)

(ft-lbs)

(lbs)

(lbs)

(lbs)

(lbs)

560,800

864,400

560,800

560,800

1,077,900

560,400

864,400

1,700

560,500

560,500

1,077,900

559,200

864,400

3,500

559,700

559,700

1,077,900

557,200

864,400

5,200

558,500

558,500

1,077,900

554,400

864,400

6,900

556,800

556,800

1,077,900

554,600

554,600

1,077,900

551,700

551,700

1,077,900

548,500

548,500

1,077,900

544,700

544,700

1,077,900

540,400

540,400

1,077,900

1,077,900

551,000

546,600

541,200

535,000

528,300

520,200

511,100

501,500

490,300

477,900

464,900

449,800

433,200

415,700

395,300

8,600

864,400

10,400

864,400

12,100

864,400

13,800

864,400

15,500

864,400

864,400

17,300

535,300

535,300

864,400

19,000

529,900

529,900

1,077,900

864,400

20,700

524,000

524,000

1,077,900

864,400

22,400

517,400

517,400

1,077,900

864,400

24,200

509,800

509,800

1,077,900

864,400

25,900

502,000

502,000

1,077,900

864,400

27,600

493,500

493,500

1,077,900

864,400

29,300

484,300

484,300

1,077,900

864,400

31,100

473,700

473,700

1,077,900

864,400

32,800

463,000

463,000

1,077,900

Connection

Make-up Torque Range

(ft-lbs)

38,500

39,300

40,200

41,000

41,900

42,700

43,600

44,400

45,300

46,100

(lbs)

1,077,900

1,055,600

1,030,300

1,007,800

982,500

960,000

934,700

912,200

886,900

864,400

Note: Recommended MUT should always be used when possible. If not possible, MUT should be as close to Recommended MUT as possible.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

06-17-2015

Potrebbero piacerti anche

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocumento2 paginePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNessuna valutazione finora

- 5 7/8" VM-165 R2 Pipe SpecsDocumento2 pagine5 7/8" VM-165 R2 Pipe SpecsTiffany DacinoNessuna valutazione finora

- How to prepare Welding Procedures for Oil & Gas PipelinesDa EverandHow to prepare Welding Procedures for Oil & Gas PipelinesValutazione: 5 su 5 stelle5/5 (1)

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocumento2 paginePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNessuna valutazione finora

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDa EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNessuna valutazione finora

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocumento2 paginePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNessuna valutazione finora

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocumento1 paginaPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohann ZabaletaNessuna valutazione finora

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerDa EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerValutazione: 5 su 5 stelle5/5 (1)

- 5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BDocumento3 pagine5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BJeaneth HerreraNessuna valutazione finora

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocumento1 paginaPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNessuna valutazione finora

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocumento1 paginaPerformance Sheet Drill Pipe: Pipe Body: Tubular Assemblymsm.ele2009Nessuna valutazione finora

- LandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)Documento3 pagineLandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)Garcia C L AlbertoNessuna valutazione finora

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Da EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Valutazione: 3.5 su 5 stelle3.5/5 (3)

- 4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BDocumento3 pagine4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BjohangomezruizNessuna valutazione finora

- All-in-One Manual of Industrial Piping Practice and MaintenanceDa EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceValutazione: 5 su 5 stelle5/5 (1)

- Drill Pipe Performance Sheet 5.875 XT57 G105Documento3 pagineDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoNessuna valutazione finora

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Documento3 pagineDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNessuna valutazione finora

- Semi-Active Suspension Control Design for VehiclesDa EverandSemi-Active Suspension Control Design for VehiclesValutazione: 5 su 5 stelle5/5 (1)

- Landing String 6.625 .938 v150 FH Slip Proof 95rbw PDFDocumento4 pagineLanding String 6.625 .938 v150 FH Slip Proof 95rbw PDFMarcelo VeronezNessuna valutazione finora

- Reflow Soldering: Apparatus and Heat Transfer ProcessesDa EverandReflow Soldering: Apparatus and Heat Transfer ProcessesNessuna valutazione finora

- DrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Documento3 pagineDrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Garcia C L AlbertoNessuna valutazione finora

- Xt39 Spec SheetDocumento3 pagineXt39 Spec SheetjdcomptonNessuna valutazione finora

- Trispiral XT39Documento1 paginaTrispiral XT39Cerón Niño SantiagoNessuna valutazione finora

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Documento3 pagineDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNessuna valutazione finora

- DrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.750Documento3 pagineDrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.750Инженер Луис А. ГарсиаNessuna valutazione finora

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Documento3 pagineDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaNessuna valutazione finora

- Drill Pipe Configuration: 95 % Inspection ClassDocumento3 pagineDrill Pipe Configuration: 95 % Inspection ClassSaurav SenguptaNessuna valutazione finora

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Documento3 pagineDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNessuna valutazione finora

- Drill Pipe Performance SheetDocumento3 pagineDrill Pipe Performance Sheetjinyuan74Nessuna valutazione finora

- HeavyWeight 3.5 25.58lbs NC-38Documento3 pagineHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаNessuna valutazione finora

- DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFDocumento3 pagineDrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFGarcia C L Alberto100% (1)

- Drill Pipe Performance SheetDocumento3 pagineDrill Pipe Performance SheetGarcia C L AlbertoNessuna valutazione finora

- 2.500 X 1.375 DC With MW20 SlickDocumento1 pagina2.500 X 1.375 DC With MW20 SlickHadi Bapir SlemanNessuna valutazione finora

- Tablas Tuberia XTDocumento35 pagineTablas Tuberia XTArcadio Bahena100% (1)

- Drill CollarDocumento1 paginaDrill CollarGuillermo Rangel AvalosNessuna valutazione finora

- Series 805YD Specification SheetDocumento2 pagineSeries 805YD Specification SheetFEBCONessuna valutazione finora

- WAW-600F Single Space Servo Universal Testing MachineDocumento13 pagineWAW-600F Single Space Servo Universal Testing MachineXavier Kate GalvanNessuna valutazione finora

- "Equipping The World For A Better Environment": Federal Supply ServiceDocumento4 pagine"Equipping The World For A Better Environment": Federal Supply ServiceAlberto CortezNessuna valutazione finora

- Backflow PreventersDocumento4 pagineBackflow PreventersSam WeberNessuna valutazione finora

- HUT-A Hydraulic Universal Testing Machine 2018.6.26 PDFDocumento6 pagineHUT-A Hydraulic Universal Testing Machine 2018.6.26 PDFSoup PongsakornNessuna valutazione finora

- Monolithic Isolation Fittings: The Industry's "Dual O'Ring Seal"Documento6 pagineMonolithic Isolation Fittings: The Industry's "Dual O'Ring Seal"chkzaNessuna valutazione finora

- Burst Plug Tubing Drain - Technical DatasheetDocumento8 pagineBurst Plug Tubing Drain - Technical DatasheetEvolution Oil ToolsNessuna valutazione finora

- 2.875 N80 6.51ppf EUEDocumento1 pagina2.875 N80 6.51ppf EUEANSARAKUNessuna valutazione finora

- TB 00700001 eDocumento9 pagineTB 00700001 eRicardo LopezNessuna valutazione finora

- EUROPLUS New System TYPPR EN 2005-09Documento12 pagineEUROPLUS New System TYPPR EN 2005-09Christian BenitezNessuna valutazione finora

- Series 709 Specification SheetDocumento4 pagineSeries 709 Specification SheetWattsNessuna valutazione finora

- Series 008PCQT Specification SheetDocumento2 pagineSeries 008PCQT Specification SheetWattsNessuna valutazione finora

- Static Calculation For FansDocumento4 pagineStatic Calculation For FansBadrul HishamNessuna valutazione finora

- Apartarrayo Roser PolDocumento16 pagineApartarrayo Roser PolMiguel Perez FloresNessuna valutazione finora

- AA SPEC 371001 - Conveyor Pulleys and ShaftsDocumento14 pagineAA SPEC 371001 - Conveyor Pulleys and Shaftsjonodo89Nessuna valutazione finora

- Screen Sand ControlDocumento20 pagineScreen Sand ControlsaptagunungNessuna valutazione finora

- Datasheet For MUR1620Documento6 pagineDatasheet For MUR1620WarungRobotika Milis100% (1)

- Brochure 3Documento12 pagineBrochure 3Gohilakrishnan ThiagarajanNessuna valutazione finora

- Proactive Ergonomics ChecklistDocumento5 pagineProactive Ergonomics ChecklistTiffany DacinoNessuna valutazione finora

- Plugback For Sidetrack Procedure (Proposed)Documento4 paginePlugback For Sidetrack Procedure (Proposed)Tiffany DacinoNessuna valutazione finora

- PNG 2 VssDocumento7 paginePNG 2 VssCarlos CarrilNessuna valutazione finora

- A622W User ManualDocumento54 pagineA622W User ManualTiffany DacinoNessuna valutazione finora

- 8035E Top Drive Spec SheetDocumento2 pagine8035E Top Drive Spec SheetTiffany DacinoNessuna valutazione finora

- 2010 Q3 Well Control CalendarDocumento1 pagina2010 Q3 Well Control CalendarTiffany DacinoNessuna valutazione finora

- For Reference Only: Drill Pipe Performance Characteristics ©Documento3 pagineFor Reference Only: Drill Pipe Performance Characteristics ©doploveNessuna valutazione finora

- Calcium Chloride SolutionDocumento5 pagineCalcium Chloride SolutionTiffany DacinoNessuna valutazione finora

- InvestorPresentation November2015Documento7 pagineInvestorPresentation November2015Tiffany DacinoNessuna valutazione finora

- Beautiful Night Guitar TabDocumento3 pagineBeautiful Night Guitar TabTiffany DacinoNessuna valutazione finora

- Snubbing GuidelinesDocumento1 paginaSnubbing GuidelinesTiffany DacinoNessuna valutazione finora

- A622W User ManualDocumento54 pagineA622W User ManualTiffany DacinoNessuna valutazione finora

- Goreham Shower Head Economic AnalysisDocumento1 paginaGoreham Shower Head Economic AnalysisTiffany DacinoNessuna valutazione finora

- Well Integrity / Well Plugging Guidelines (9.1 - 9.10)Documento35 pagineWell Integrity / Well Plugging Guidelines (9.1 - 9.10)Tiffany DacinoNessuna valutazione finora

- Well BarriersDocumento23 pagineWell BarriersMohamed Abd El-Moniem100% (1)

- Pipe Body Properties-CatalogueDocumento118 paginePipe Body Properties-CatalogueFredy NavasNessuna valutazione finora

- Wellhead BrochureDocumento12 pagineWellhead BrochureTiffany DacinoNessuna valutazione finora

- Cat HPBV 01 14Documento8 pagineCat HPBV 01 14Renzo Conde MontenegroNessuna valutazione finora

- Drill MecDocumento12 pagineDrill MecKhaled AmmarNessuna valutazione finora

- Improved Development of BOP Systems in Offshore Drilling (Shallow Gas Hazard)Documento36 pagineImproved Development of BOP Systems in Offshore Drilling (Shallow Gas Hazard)Tiffany DacinoNessuna valutazione finora

- PC 1555 Installation ManualDocumento52 paginePC 1555 Installation ManualTiffany DacinoNessuna valutazione finora

- Cat HPBV 01 14Documento8 pagineCat HPBV 01 14Renzo Conde MontenegroNessuna valutazione finora

- Series 7 User ManualDocumento81 pagineSeries 7 User ManualTiffany DacinoNessuna valutazione finora

- 225 BBL Mud System Drawing Ground PlanDocumento1 pagina225 BBL Mud System Drawing Ground PlanTiffany DacinoNessuna valutazione finora

- Magnum ManualDocumento2 pagineMagnum ManualTiffany DacinoNessuna valutazione finora

- JAN15 MEXmapDocumento1 paginaJAN15 MEXmapGuillermo Lira GuzmánNessuna valutazione finora

- Free Body Diagram (FBD)Documento1 paginaFree Body Diagram (FBD)Tiffany DacinoNessuna valutazione finora

- 0513hep Ultra FMCDocumento2 pagine0513hep Ultra FMCPaulo RobertoNessuna valutazione finora