Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Effect of Different Parameters and Storage Conditions On Liquid Jaggery Without Adding Preservatives PDF

Caricato da

esatjournalsTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Effect of Different Parameters and Storage Conditions On Liquid Jaggery Without Adding Preservatives PDF

Caricato da

esatjournalsCopyright:

Formati disponibili

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

EFFECT OF DIFFERENT PARAMETERS AND STORAGE

CONDITIONS ON LIQUID JAGGERY WITHOUT ADDING

PRESERVATIVES

Supriya.D.Patil1, S.V.Anekar2

1

M.E student, Chemical Department, TKIET Warnanagar, Maharashtra, India

2

Professor, Chemical Department, TKIET Warnanagar, Maharashtra, India

Abstract

Jaggery industry is a cottage industry in India. In todays world liquid jaggery has been gaining a much importance due to its

nutritional value. Studies were conducted to investigate the parameters affecting shelf life such pH, colour, brix , moisture content

and range of temperatures on the concentration of reducing sugars. The variety Co86032 was selected to observe the effect of

storage period on quality characteristics of liquid jaggery. Samples were stored at three different conditions i.e. room

temperature(27C), refrigeration (7C) and high temperature (37C) in pre-sterilized PET bottles for 90 days .In order to

optimize the changes in properties physico-chemical tests were evaluated during storage. The pH decreased significantly,

whereas, moisture content and reducing sugar increased significantly during storage. The changes in different attributes were

significantly higher at 37C temperature as compared to room temperature and refrigeration temperature. The results revealed

that change in chemical composition was lower in case of refrigerated sample. Refrigerated sample was found more acceptable

among other two samples after storage period of three months in terms of its chemical properties.

Keywords: Liquid jaggery, without preservatives, Shelf life, Storage.

--------------------------------------------------------------------***---------------------------------------------------------------------1. INTRODUCTION

2.1 Methods of Analysis of Quality Parameters

Sugarcane belongs to the genus saccharum of the grass

family which is used as a raw material for manufacturing of

jaggery [1]. There are three types of jaggery namely solid

jaggery, liquid jaggery and granular jaggery. Out of the total

production of jaggery in India 20% jaggery is produced in

liquid and granular form and 80% is produced in solid

form[2]. Liquid jaggery is alternative source to honey.

Sugarcane crushing is the first step in liquid jaggery

manufacturing process .It is an intermediate product

collected during jaggery manufacturing

and striking

temperature of it ranges from 105C to 108C or generally it

depends upon the varieties of sugarcane used. The

composition of liquid jaggery per 100gm is: water 3035gm,invert sugar 15-25 gm, sucrose 40-60 gm, fat 0.1 gm,

protein 0.5 gm and total minerals 0.75 gm. Calorific value of

liquid jaggery is 300Kcal/100gm.[3]To increase the shelf

life of liquid jaggery preservatives like 0.1% of potassium

met bisulphate or 0.5% of benzoic acid is added. Liquid

jaggery is used as sweetening agent in daily diet in

Maharashtra, Tamilnadu, Gujrat, Andhrapradesh, Kerala.[4]

Moisture Content

2. MATERIALS AND METHODS

The variety Co86032 was selected from promising varieties

of sugarcane to study shelf life of liquid jaggery. Samples of

liquid jaggery were stored at room temperature (27C)

refrigeration (7C) and 37C temperature in pre-sterilized

PET bottles and analysed for physico-chemical properties at

every 15 days of interval for 90 days.

The moisture content of the sample was determined using

vacuum oven method.10 g of the sample was weighed and

placed into a preweighed crucible and then dried at 105C

till the dryness occurs.

Brix

A hand held refractometer with 0 to 90 brix scale was used

for brix measurement. 1-2 drops of liquid jaggery was

placed onto a prism and value of brix was recorded.

pH

pH meter was used for pH measurements. The pH meter was

calibrated using pH 7 and pH 4 standard solutions.

Reducing Sugar

The reducing sugar was determined by DNSA method,

using DNS reagent(1g of dinitrosalycilic acid; 70 ml of

NaOH at 0.5 N; 30g of Potassium Sodium tartarate tetra

hydrate)With

working

standard

1mg/ml

(50mgdextrose/50ml distilled water) and measured the

absorbance at 540nm.Standard graph was plotted as shown

in chart1.

_______________________________________________________________________________________

Volume: 03 Issue: 12 | Dec-2014, Available @ http://www.ijret.org

280

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

Chart-1: Standard graph for DNSA method

Table -1: Chemical composition of liquid jaggery

Properties

Value

Moisture content%

19

pH

4.91

Brix

71

reducing sugar %

13

Density (g/cm3)

1.34

Colour

Hunter L, a, and b colour scale was selected for all

measurements. Samples were kept on the specimen port

(95mm diameter) to cover the full exposed area of the port

to the light. All measurements were replicated thrice and the

mean readings were taken. The L, a and b values are three

dimensions of a measured colour which gives specific

colour value of the material. Colour difference (E)

indicates the degree of overall colour change of a sample in

comparison to colour values of an standard sample having

colour values of L*, a*, and b*.The colours of the samples

represents in terms of L (whiteness/darkness), a

(redness/greenness), b (yellowness/blueness). Colour

difference was calculated using equation1,

=

(1)

3. RESULTS AND DISCUSSION

3.1 Chemical Composition of Liquid Jaggery

The chemical composition of liquid jaggery (var.Co 86032)

was determined in Table 1. Fresh liquid jaggery was

analyzed for physic-chemical evaluation before storage. On

estimation, liquid jaggery was found to contain 19%

moisture content, 4.91 pH, 71 brix and 13% reducing sugar.

Maximum colour difference was observed in sample at 37C

temperature.

3.2 Effect of Parameters on Chemical Properties of

Liquid Jaggery on Storage

The data of effect of parameters on liquid jaggry during

storage on moisture content, pH, brix, reducing sugar and

colour of liquid jaggery is depicted in Table 2. The results

revealed that moisture content of liquid jaggery significantly

increased during storage period .This may be due to the high

water vapour transmission rate of PET bottles due to which

there was increase in moisture content of liquid jaggery.The

moisture content of liquid jaggery ranged from 19 to 20.9

per cent. Maximum moisture was observed at 37C

temperature stored for 90 days while minimum water

absorption after 90 days of storage was observed at

refrigeration temperature. There was no significant change

observed in brix.The content of reducing sugar increased

significantly during storage in liquid jaggery at room,

refrigeration, 37C temperature may be due to the hydrolysis

of sugars, however, the decrease was lesser at refrigeration

temperature. The pH of liquid jaggery samples decreased

significantly and it found to be reversibly related to storage

period. This decrease in pH may be due to change in

chemical properties which are affected by storage condition.

_______________________________________________________________________________________

Volume: 03 Issue: 12 | Dec-2014, Available @ http://www.ijret.org

281

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

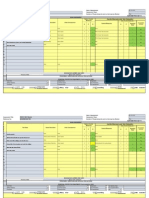

Table - 2: Effect of different parameters and storage on physic-chemical properties of liquid jaggey

Days

Sr No

Parameter

Moisture

pH

Brix

Reducing sugar

L

Colour a

b

L

Colour a

b

L

Colour a

b

Temperature

15

30

45

60

75

90

Room(27C)

Refrigeration(7C)

(37C)

Room(27C)

Refrigeration(7C)

(37C)

Room(27C)

Refrigeration(7C)

(37C)

Room(27C)

Refrigeration(7C)

(37C)

19

19

19

5.28

5.28

5.28

71

71

71

13

13

13

11.81

-1.58

0.83

11.81

-1.58

0.83

11.81

-1.58

0.83

19.2

19.1

19.5

5.27

5.23

5.22

71

71

71

13.3

12.9

13.5

5.98

-0.49

-0.79

8.68

-1.13

0.6

6.32

-0.16

-0.6

19.6

19.3

19.8

5.26

5.20

5.17

71

71

71

14.2

13.2

14.1

5.66

-1.29

0.87

4.65

-0.15

-1

7.51

-1.33

0.85

19.7

19.4

19.9

5.15

5.13

5.10

71

71

70

14.8

13.7

14.9

7.85

-1.40

0.61

6.08

-0.91

0.29

5.45

-0.05

-0.43

19.9

19.7

20.3

5.02

5.07

5.01

71

71

70

15.3

14.1

15.5

3.11

-0.55

1.38

6.33

-2.77

2.41

3.10

0.21

0.56

20.2

19.9

20.7

4.91

5.04

4.85

70

71

70

16

14.6

16.2

3.05

-1.47

1.37

5.05

-1.20

1.96

2.49

-0.45

-0.21

20.5

20.1

20.9

4.8

5

4.7

70

71

69

16.5

14.9

16.8

2.80

-0.35

0.25

3.49

-0.90

0.51

2.53

-0.85

0.67

Room(27C)

Refrigeration(7C)

(37C)

Chart-2: Colour difference of liquid jaggery during storage.

_______________________________________________________________________________________

Volume: 03 Issue: 12 | Dec-2014, Available @ http://www.ijret.org

282

IJRET: International Journal of Research in Engineering and Technology

Colour is one of the important quality factor that determines

the consumers acceptability. There was a significant effect

of storage condition and period on colour of liquid jaggery

(Chart 2). Samples stored at refrigeration had the lighter

colour; whereas at 37C was observed as darken in colour.

[8]

4. CONCLUSION

[9]

It can be concluded from the facts stated above that liquid

jaggery without adding preservatives at refrigeration found

to desirable amongst all the samples and can be stored up to

90 days without having much affect on its physico-chemical

properties. We can predict that increasing reducing sugar

and absorption of moisture set up favorable condition for

inversion. From the results of the study, refrigeration

temperature helps to extend the shelf life of liquid jaggery

without adding preservatives

[10]

[11]

[12]

ABBREVIATIONS AND NOMENCLATURE

eISSN: 2319-1163 | pISSN: 2321-7308

V. K. Jagannadha Rao, Madhusweta Das , Susanta

K. Das, Effect of moisture content on glass

transition and sticky point temperatures of

sugarcane, palmyra-palm and date-palm jaggery,

International Journal of Food Science and

Technology , 2010.

Amit Kumar Dwivedi , An Empirical Study on

Gur

(Jaggery)

Industry Indian Institute of

management 2010

O. P. Chauhan, Dheer Singh, S. M. Tyagi, and D. K.

Balyan, Studies on preservation of Sugarcane

juice , volume-5(1), 217-229, Govind Ballabh

Pant University of Agriculture and Technology,

2002

Technologies developed by Indian Institute of

sugarcane research(IISR),Lucknow.

Technologies developed by Indian Institute of

sugarcane research(IISR),Lucknow.

PET- Polyethylene terepthalate

DNSA-Dinitrosalicyclic acid

ACKNOWLEDGEMENTS

At this moment of accomplishment, I pay thanks to my

guide, Dr.S.V Anekar, Chemical Engineering Department,

Tatyasaheb Kore Institute of Engineering and Technology,

Warnanagar, Kolhapur. This work would not have been

possible without his valuable guidance, support and

encouragement. Under his guidance I successfully overcame

many difficulties and learned a lot. His energy and clear way

of thinking were the driving force for me at all stages.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

Sneh Sankhla , Anurag Chaturvedi, Aparna Kuna ,

M. Shreedhar, Studies on Effect of Packaging

Material and Irradiation on Storage Stability of

Jaggery,volume-13(3),229-235,2011

Preeti Shukla, Effect

of edible coating and

packaging on microbiological characteristics of

jaggery, volume-2(4),121-125, 2012.

PVK Jagannadha rao, Madhusweta Das, SK Das,

Jaggery-A traditional Indian sweetener, volume 6(1), 95-102, Indian Institute of Technology,

Kharagpur, 2007.

Dr.Gururaj Hunsigi, Sugarcane in agriculture and

Industry, Kama taka Institute of Applied

Agricultural Research (KIAAR),Bagalkot.

P.A Unde, P.V Adagale, Syed Imran Hashmi and

Abdul Raheem, Effect of different particle sizes of

jaggery powder on storability,volume-7(2),157160, IDOSI Publications, 2011.

Jaswant Singh, R.D. Singh, S.I Anwar, Alternative

sweeteners production from sugarcane in India :

Lump

sugar(jaggery)

volume-13(4),366-371,

Society for sugar research and promotion 2011.

J.K.Gehlawat, Monograph on jaggery and

Khandsari 78-90,78-101, Indian Institute of

technology, Kanpur, 1994

_______________________________________________________________________________________

Volume: 03 Issue: 12 | Dec-2014, Available @ http://www.ijret.org

283

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Poka Yoke BDocumento31 paginePoka Yoke BjaymuscatNessuna valutazione finora

- Financial Market and Portfolio Management Assignment 2Documento6 pagineFinancial Market and Portfolio Management Assignment 2leeroy mekiNessuna valutazione finora

- Task Based Risk Assesment FormDocumento2 pagineTask Based Risk Assesment FormKolluri SrinivasNessuna valutazione finora

- Analysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFDocumento7 pagineAnalysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFesatjournalsNessuna valutazione finora

- Employee Training and DevelopmentDocumento33 pagineEmployee Training and DevelopmentMoogii50% (2)

- Analysis of Cylindrical Shell Structure With Varying Parameters PDFDocumento6 pagineAnalysis of Cylindrical Shell Structure With Varying Parameters PDFesatjournalsNessuna valutazione finora

- PTE 3 Week Study ScheduleDocumento3 paginePTE 3 Week Study ScheduleesatjournalsNessuna valutazione finora

- An Efficient Information Retrieval Ontology System Based Indexing For Context PDFDocumento7 pagineAn Efficient Information Retrieval Ontology System Based Indexing For Context PDFesatjournalsNessuna valutazione finora

- An Improved Geo-Encryption Algorithm in Location Based Services PDFDocumento4 pagineAn Improved Geo-Encryption Algorithm in Location Based Services PDFesatjournalsNessuna valutazione finora

- Analysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFDocumento4 pagineAnalysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFesatjournalsNessuna valutazione finora

- Analysis and Characterization of Dendrite Structures From Microstructure Images of Material PDFDocumento5 pagineAnalysis and Characterization of Dendrite Structures From Microstructure Images of Material PDFesatjournalsNessuna valutazione finora

- Analytical Assessment On Progressive Collapse Potential of New Reinforced Concrete Framed Structure PDFDocumento5 pagineAnalytical Assessment On Progressive Collapse Potential of New Reinforced Concrete Framed Structure PDFesatjournalsNessuna valutazione finora

- Analysis of Outrigger System For Tall Vertical Irregularites Structures Subjected To Lateral Loads PDFDocumento5 pagineAnalysis of Outrigger System For Tall Vertical Irregularites Structures Subjected To Lateral Loads PDFesatjournalsNessuna valutazione finora

- A Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemDocumento8 pagineA Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemesatjournalsNessuna valutazione finora

- An Octa-Core Processor With Shared Memory and Message-Passing PDFDocumento10 pagineAn Octa-Core Processor With Shared Memory and Message-Passing PDFesatjournalsNessuna valutazione finora

- A Review On Fake Biometric Detection System For Various ApplicationsDocumento4 pagineA Review On Fake Biometric Detection System For Various ApplicationsesatjournalsNessuna valutazione finora

- A Review Paper On Smart Health Care System Using Internet of ThingsDocumento5 pagineA Review Paper On Smart Health Care System Using Internet of ThingsesatjournalsNessuna valutazione finora

- Analysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFDocumento6 pagineAnalysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFesatjournalsNessuna valutazione finora

- A Study and Survey On Various Progressive Duplicate Detection MechanismsDocumento3 pagineA Study and Survey On Various Progressive Duplicate Detection MechanismsesatjournalsNessuna valutazione finora

- A Critical Review On Experimental Studies of Strength and Durability Properties of Fibre Reinforced Concrete Composite PDFDocumento7 pagineA Critical Review On Experimental Studies of Strength and Durability Properties of Fibre Reinforced Concrete Composite PDFesatjournalsNessuna valutazione finora

- A New Type of Single-Mode Lma Photonic Crystal Fiber Based On Index-Matching Coupling PDFDocumento8 pagineA New Type of Single-Mode Lma Photonic Crystal Fiber Based On Index-Matching Coupling PDFesatjournalsNessuna valutazione finora

- A Servey On Wireless Mesh Networking ModuleDocumento5 pagineA Servey On Wireless Mesh Networking ModuleesatjournalsNessuna valutazione finora

- A Servey On Wireless Mesh Networking ModuleDocumento5 pagineA Servey On Wireless Mesh Networking ModuleesatjournalsNessuna valutazione finora

- I JR Et 20160503007dfceDocumento5 pagineI JR Et 20160503007dfcegtarun22guptaNessuna valutazione finora

- A Comparative Investigation On Physical and Mechanical Properties of MMC Reinforced With Waste Materials PDFDocumento7 pagineA Comparative Investigation On Physical and Mechanical Properties of MMC Reinforced With Waste Materials PDFesatjournalsNessuna valutazione finora

- Ad Hoc Based Vehcular Networking and ComputationDocumento3 pagineAd Hoc Based Vehcular Networking and ComputationesatjournalsNessuna valutazione finora

- A Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemDocumento8 pagineA Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemesatjournalsNessuna valutazione finora

- A Survey On Identification of Ranking Fraud For Mobile ApplicationsDocumento6 pagineA Survey On Identification of Ranking Fraud For Mobile ApplicationsesatjournalsNessuna valutazione finora

- I JR Et 20160503007dfceDocumento5 pagineI JR Et 20160503007dfcegtarun22guptaNessuna valutazione finora

- A Review Paper On Smart Health Care System Using Internet of ThingsDocumento5 pagineA Review Paper On Smart Health Care System Using Internet of ThingsesatjournalsNessuna valutazione finora

- A Review On Fake Biometric Detection System For Various ApplicationsDocumento4 pagineA Review On Fake Biometric Detection System For Various ApplicationsesatjournalsNessuna valutazione finora

- A Survey On Identification of Ranking Fraud For Mobile ApplicationsDocumento6 pagineA Survey On Identification of Ranking Fraud For Mobile ApplicationsesatjournalsNessuna valutazione finora

- A Women Secure Mobile App For Emergency Usage (Go Safe App)Documento3 pagineA Women Secure Mobile App For Emergency Usage (Go Safe App)esatjournalsNessuna valutazione finora

- A Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesDocumento9 pagineA Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesesatjournalsNessuna valutazione finora

- Brexit Essay - Jasraj SinghDocumento6 pagineBrexit Essay - Jasraj SinghJasraj SinghNessuna valutazione finora

- DB51 BTP 160 8PDocumento1 paginaDB51 BTP 160 8Pnagaraj.ss@quest-global.comNessuna valutazione finora

- Chapter 4-Ohm's LawDocumento12 pagineChapter 4-Ohm's LawErin LoveNessuna valutazione finora

- 2017 Advanced Computer Networks Homework 1Documento6 pagine2017 Advanced Computer Networks Homework 1Fadhli RahimNessuna valutazione finora

- Less Than a Decade to Avoid Catastrophic Climate ChangeDocumento1 paginaLess Than a Decade to Avoid Catastrophic Climate ChangeXie YuJiaNessuna valutazione finora

- Risk Assessments-These Are The Risk Assessments Which Are Applicable To Works Onsite. Risk Definition and MatrixDocumento8 pagineRisk Assessments-These Are The Risk Assessments Which Are Applicable To Works Onsite. Risk Definition and MatrixTimothy AziegbemiNessuna valutazione finora

- 2021 A Review of Image Based Pavement Crack Detection AlgorithmsDocumento7 pagine2021 A Review of Image Based Pavement Crack Detection Algorithmsgandhara11Nessuna valutazione finora

- Cs614-Mid Term Solved MCQs With References by Moaaz PDFDocumento30 pagineCs614-Mid Term Solved MCQs With References by Moaaz PDFNiazi Qureshi AhmedNessuna valutazione finora

- Akriti Shrivastava CMBA2Y3-1906Documento6 pagineAkriti Shrivastava CMBA2Y3-1906Siddharth ChoudheryNessuna valutazione finora

- Research Paper About Cebu PacificDocumento8 pagineResearch Paper About Cebu Pacificwqbdxbvkg100% (1)

- Draft SemestralWorK Aircraft2Documento7 pagineDraft SemestralWorK Aircraft2Filip SkultetyNessuna valutazione finora

- Tds Uniqflow 372s enDocumento1 paginaTds Uniqflow 372s enm daneshpourNessuna valutazione finora

- Letter Advocating For Hazard PayDocumento2 pagineLetter Advocating For Hazard PayQueens PostNessuna valutazione finora

- VVIP Circuit House achieves 5-star GRIHA ratingDocumento1 paginaVVIP Circuit House achieves 5-star GRIHA ratingmallikaNessuna valutazione finora

- Importance and Behavior of Capital Project Benefits Factors in Practice: Early EvidenceDocumento13 pagineImportance and Behavior of Capital Project Benefits Factors in Practice: Early EvidencevimalnandiNessuna valutazione finora

- G.R. No. 226140 - People Vs EspirituDocumento24 pagineG.R. No. 226140 - People Vs EspirituAlfred Robert BabasoroNessuna valutazione finora

- Marking SchemeDocumento8 pagineMarking Schememohamed sajithNessuna valutazione finora

- ReportDocumento4 pagineReportapi-463513182Nessuna valutazione finora

- The Mpeg Dash StandardDocumento6 pagineThe Mpeg Dash Standard9716755397Nessuna valutazione finora

- 19286711Documento8 pagine19286711suruth242100% (1)

- Elegant Tranquil Blue Agency by SlidesgoDocumento41 pagineElegant Tranquil Blue Agency by SlidesgoJoana TavaresNessuna valutazione finora

- Banking Software System Monitoring ToolDocumento4 pagineBanking Software System Monitoring ToolSavun D. CheamNessuna valutazione finora

- MATLAB code for Mann–Kendall test and Sen's slope estimationDocumento7 pagineMATLAB code for Mann–Kendall test and Sen's slope estimationTubaiNandiNessuna valutazione finora

- Creating A Simple PHP Forum TutorialDocumento14 pagineCreating A Simple PHP Forum TutorialLaz CaliphsNessuna valutazione finora

- Lecture 2 Leader-Centred PerspectivesDocumento24 pagineLecture 2 Leader-Centred PerspectivesLIVINGSTONE CAESARNessuna valutazione finora