Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ESCL-SOP-018, Inspection and Test Procedure For Egba Split-Clamps

Caricato da

adiqualityconsultTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ESCL-SOP-018, Inspection and Test Procedure For Egba Split-Clamps

Caricato da

adiqualityconsultCopyright:

Formati disponibili

EGBA SPLIT-CLAMPS LIMITED

Inspection and Test Procedure for

Egba Split-Clamps

Ref. No: ESCL-SOP-018

Rev. No: 00

Issue Date:12th Nov, 2012

Page 1 of 6

Inspection and Test Procedure for

Egba Split-Clamps

APPROVAL AND REVISION STATUS

Rev. No.

00

Issue Date

Revision

12/11/2012

Identification

First Issue

Prepared by

Reviewed

Approved by

QHSE

Manager

by

Production

Manager

Managing

Director

EGBA SPLIT-CLAMPS LIMITED

Ref. No: ESCL-SOP-018

Inspection and Test Procedure

for Egba Split-Clamps

Rev. No: 00

Issue Date:12th Nov, 2012

Page 2 of 6

CHANGE (S)/AMENDMENT (S)

The change(s)/amendment(s) noted below have been made and approved by the

Managing Director for issue.

Change/Amendment No.

Date

Page

Description of Change/Amendment

EGBA SPLIT-CLAMPS LIMITED

Inspection and Test Procedure

for Egba Split-Clamps

1.0

Ref. No: ESCL-SOP-018

Rev. No: 00

Issue Date:12th Nov, 2012

Page 3 of 6

PURPOSE

The purpose of this procedure is to define the monitoring and measurement activities

in the production of Egba Split-Clamps.

2.0

SCOPE

This procedure is applicable to in-coming materials, in-process and finished product.

3.0

REFERENCES

NIS ISO 9001:2008, Quality Management Systems-Requirements

NIS ISO 9000:2005, Quality Management Systems-Fundamentals and Vocabulary

ESCL Quality Manual (ESCL-QM-001)

ESCL-QSP-004, Control of Nonconforming Product

ESCL-SOP-012, Procurement Control Procedure

ESCL-SOP-014, Materials/Store Control Procedure

ESCL-SOP-016, Work Instruction for Workshop Operators

Form 125, Job Card

Form 126, Certificate of Conformance

Form 127, Client Feedback

4.0

TERMS AND DEFINITIONS

The following terms and definitions and the ones given in ESCL Quality Manual and

NIS ISO 9000: 2005 apply:

4.1

ESCL: Egba Split-Clamps Limited.

4.2

ISO: International Organization for standardization.

4.3

NIS: Nigerian Industrial Standard.

4.4

Inspection: Conformity evaluation by observation and judgement accompanied as

appropriate by measurement, testing or gauging.

4.5

Quality Control (QC): Part of quality management focused in fulfilling quality

requirements

5.0

RESPONSIBILITIES AND AUTHORITY

5.1

Production Manager, QHSE Manager: Overall responsibility for quality

control activities in the workshop.

EGBA SPLIT-CLAMPS LIMITED

Inspection and Test Procedure

for Egba Split-Clamps

5.2

Ref. No: ESCL-SOP-018

Rev. No: 00

Issue Date:12th Nov, 2012

Page 4 of 6

QHSE Manager, QC Inspector: Responsible for material receiving inspection, inprocess inspection, final product inspection/test.

6.0

PROCEDURE

6.1

Incoming Materials Inspection

6.1.1 Incoming materials and equipment are subjected to receiving inspection to verify

conformance to purchase requirements (see document Ref. No. ESCL-SOP-012).

6.1.2 No product is received into stock without such inspection.

6.2

In-process inspection

6.2.1 General in-process inspection during the production of Egba Split-Sleeve Clamps

provide assurance that the required quality is being obtained in accordance with the

requirements. It also ensures that deficient items or processes are found and

corrected before further processing.

6.2.2 Cutting Operation

In-process inspections during the cutting operation include but are not limited to the

following:

Dimensional measurement of materials being cut;

Visual inspection of the materials.

6.2.3 Machining Operation

In-process inspections during the machining operation include but are not limited to

the following:

Machine set-up (by Operator) for fit for use;

Check for concentricity;

Dimensional accuracy;

Check for alignment.

6.2.4 Milling Operation

In process inspection during the milling operation include but are not limited to the

following:

Dimensional checks;

Check for alignment(Geometry of the Machine).

EGBA SPLIT-CLAMPS LIMITED

Inspection and Test Procedure

for Egba Split-Clamps

Ref. No: ESCL-SOP-018

Rev. No: 00

Issue Date:12th Nov, 2012

Page 5 of 6

6.2.5 Cutting of Girder Rings and Side Strips

In process inspections during the cutting of girder rings and side strips include but are

not limited to the following:

Dimensional measurement of materials being cut(thickness);

Visual inspection of the materials.

6.2.6 Arms Production

In process inspections during the production of the arms include but are not limited to

the following:

Dimensional checks;

Check for alignment.

6.2.7 Assembly Stage

In process inspections during the assembly stage include but are not limited to the

following:

Check for alignment;

Dimensional accuracy;

Check on the assembled (tac-welded) product to ensure conformity before

welding;

Visual check on the welded product.

6.3

Final Product Inspection/test

General final inspection/test of completed Egba Split-Sleeve Clamps is carried out to

verify that the completed product is in conformance with specified requirements.

These include but are not limited to the following:

Visual inspection of the product;

Welding inspection;

Pressure Testing;

Paint thickness measurement.

EGBA SPLIT-CLAMPS LIMITED

Inspection and Test Procedure

for Egba Split-Clamps

6.4

Ref. No: ESCL-SOP-018

Rev. No: 00

Issue Date:12th Nov, 2012

Page 6 of 6

Product Certification and Release

Upon the satisfactory completion of final product inspection, the product is signed off

for release to the customer or storage. A completed Certificate of Conformance (COC)

is among the delivery documentation..

7.0

RECORDS

7.1

Incoming materials inspection/test record

7.2

In-process inspection records

7.3

Final inspection/test record

7.4

Certificate of Conformance(Form 126).

Potrebbero piacerti anche

- Escl Iso Quality Manual Rev. 0Documento54 pagineEscl Iso Quality Manual Rev. 0adiqualityconsultNessuna valutazione finora

- ESCL-SOP-019, Procedure For Control of Inspection, Measurement and Test EquipmentDocumento5 pagineESCL-SOP-019, Procedure For Control of Inspection, Measurement and Test EquipmentadiqualityconsultNessuna valutazione finora

- Escl Iso Quality Manual Rev. 01Documento52 pagineEscl Iso Quality Manual Rev. 01adiqualityconsultNessuna valutazione finora

- ESCL-QSP-005, Corrective Action ProcedureDocumento6 pagineESCL-QSP-005, Corrective Action Procedureadiqualityconsult100% (1)

- ESCL-SOP-017, Procedure For Control of Workshop-Project OperationsDocumento8 pagineESCL-SOP-017, Procedure For Control of Workshop-Project Operationsadiqualityconsult100% (1)

- ESCL-QSP-006, Preventive Action ProcedureDocumento5 pagineESCL-QSP-006, Preventive Action ProcedureadiqualityconsultNessuna valutazione finora

- QSP 02 - Record Control ProcedureDocumento5 pagineQSP 02 - Record Control ProcedureVivek V100% (1)

- Quality Record Procedure Rev-JDocumento4 pagineQuality Record Procedure Rev-JherminNessuna valutazione finora

- SOP02-Control of Quality RecordsDocumento6 pagineSOP02-Control of Quality RecordsAna Hidayah SyuhadaNessuna valutazione finora

- QSP 05 - Corrective ActionDocumento4 pagineQSP 05 - Corrective ActionVivek V100% (2)

- HR-2-001, Issue 01, Procedure For Training & DevelopmentDocumento2 pagineHR-2-001, Issue 01, Procedure For Training & Developmentsajid waqasNessuna valutazione finora

- 5.7 - Non-Conforming Material & Product Control Procedure.Documento1 pagina5.7 - Non-Conforming Material & Product Control Procedure.Md.Akidul Islam AkidNessuna valutazione finora

- IAC Corrective Action ReportDocumento2 pagineIAC Corrective Action Reportsvanand500Nessuna valutazione finora

- Control of Monitoring & Measuring DevicesDocumento10 pagineControl of Monitoring & Measuring DevicesRamesh mudunuriNessuna valutazione finora

- COMP-OPP-02 Procedure For Control and Validation of Service ProvisionDocumento6 pagineCOMP-OPP-02 Procedure For Control and Validation of Service ProvisionISODCC DSPINessuna valutazione finora

- Steel Konnect (India) Pvt. Ltd. Procedure Manual: Procedure For Internal Quality AuditDocumento2 pagineSteel Konnect (India) Pvt. Ltd. Procedure Manual: Procedure For Internal Quality AuditmahendraNessuna valutazione finora

- QP-72-03 Customer CommunicationDocumento3 pagineQP-72-03 Customer CommunicationSamsudin AhmadNessuna valutazione finora

- MP12 Monitoring, Measurment and ImprovementDocumento6 pagineMP12 Monitoring, Measurment and ImprovementSuchhanda SarkarNessuna valutazione finora

- Inspection Procedure MaterialDocumento1 paginaInspection Procedure MaterialZharel AhmadNessuna valutazione finora

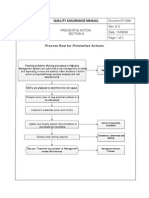

- Quality Assurance Manual: Preventive Action Section 8 Rev: E 0 Date: 15/08/09 Page 1 of 2Documento2 pagineQuality Assurance Manual: Preventive Action Section 8 Rev: E 0 Date: 15/08/09 Page 1 of 2Ngonidzashe ZvarevasheNessuna valutazione finora

- Maruti Fabricators: Page 1 of 3 Midc Hingna Nagpur Management Review MeetingDocumento3 pagineMaruti Fabricators: Page 1 of 3 Midc Hingna Nagpur Management Review MeetingAnkush Chourasia100% (1)

- 1635 - 03 Control of Non Conforming Products Rev. 01Documento5 pagine1635 - 03 Control of Non Conforming Products Rev. 01Senthilkumar NarayananNessuna valutazione finora

- N Quality Management System Planning Section 14Documento3 pagineN Quality Management System Planning Section 14Ngonidzashe ZvarevasheNessuna valutazione finora

- QP Nonconforming Product Sample 2014Documento2 pagineQP Nonconforming Product Sample 2014Anna Maree100% (1)

- CSL P5-007229 AuditReportDocumento5 pagineCSL P5-007229 AuditReportIdrus IsmailNessuna valutazione finora

- Employee Training RecordDocumento19 pagineEmployee Training Recordklinik utama Bali Puri MedikaNessuna valutazione finora

- Employee Training LogDocumento6 pagineEmployee Training LogRoosy RoosyNessuna valutazione finora

- Incoming Inspection-Qmp-Qc-01Documento2 pagineIncoming Inspection-Qmp-Qc-01Rohit VishwakarmaNessuna valutazione finora

- IMS APEX Manual Final LOCODocumento64 pagineIMS APEX Manual Final LOCOMarjorie Dulay Dumol100% (1)

- F-05 Corrective Action FormDocumento1 paginaF-05 Corrective Action Formsuhara hussainNessuna valutazione finora

- Form 102, Documents Distribution RecordDocumento2 pagineForm 102, Documents Distribution RecordadiqualityconsultNessuna valutazione finora

- Quality Record Control ProcedureDocumento6 pagineQuality Record Control ProcedurePrime CapNessuna valutazione finora

- 4-04-1 Contract ReviewDocumento4 pagine4-04-1 Contract Reviewjeric bañaderaNessuna valutazione finora

- Quality ControlDocumento51 pagineQuality ControlOprisor CostinNessuna valutazione finora

- Internal Audit Observation ReportDocumento2 pagineInternal Audit Observation Reportsenk197100% (1)

- 05.0review of RequirementsDocumento5 pagine05.0review of RequirementsrodwellbNessuna valutazione finora

- Control of Monitoring and Measuring EquipmentDocumento3 pagineControl of Monitoring and Measuring EquipmentLinda Setya WatiNessuna valutazione finora

- PRO-CAL-01 Measuring Equipment Calibration ProgramDocumento2 paginePRO-CAL-01 Measuring Equipment Calibration ProgramChiekoi PasaoaNessuna valutazione finora

- Temecula Quality Plating AS9100 REV C MANUALDocumento13 pagineTemecula Quality Plating AS9100 REV C MANUALHoang TanNessuna valutazione finora

- RC 2022 Summary CAFDDocumento4 pagineRC 2022 Summary CAFDEjazNessuna valutazione finora

- HIRA 038 Cleaning of Cranes .Documento4 pagineHIRA 038 Cleaning of Cranes .srinibas mohapatraNessuna valutazione finora

- ASMI-OSHMS-PR-14 - Control of Documents and Record Retention ProcedureDocumento10 pagineASMI-OSHMS-PR-14 - Control of Documents and Record Retention ProcedureJHUPEL ABARIALNessuna valutazione finora

- Non Conformity ReportDocumento1 paginaNon Conformity ReportaikqualityNessuna valutazione finora

- Internal Audit NC ReportDocumento1 paginaInternal Audit NC Reportmorshed_mahamud7055Nessuna valutazione finora

- QSV 2 Product Release Procedure EN 01Documento6 pagineQSV 2 Product Release Procedure EN 01prashanthNessuna valutazione finora

- Master List of Forms FormatsDocumento1 paginaMaster List of Forms Formatschahi100% (1)

- NCR Procedure Rev. 0Documento8 pagineNCR Procedure Rev. 0Ganjar Dreadlocks NugrahaNessuna valutazione finora

- Non Conformity ReportDocumento1 paginaNon Conformity ReportBasker Balu0% (1)

- ISO-Control of Non Conforming ProductsDocumento3 pagineISO-Control of Non Conforming Productsnoufal27100% (2)

- Document Change RequestDocumento1 paginaDocument Change RequestvyerramallaNessuna valutazione finora

- Audit Report Template 13Documento5 pagineAudit Report Template 13Ahmed HosneyNessuna valutazione finora

- ESCL-QSP-002, Records Control ProcedureDocumento6 pagineESCL-QSP-002, Records Control Procedureadiqualityconsult100% (1)

- QP-001 Control of DocumentsDocumento4 pagineQP-001 Control of DocumentsMartinNessuna valutazione finora

- A6. Control of Nonconforming ProductDocumento6 pagineA6. Control of Nonconforming ProductStanley MtamboNessuna valutazione finora

- Performance EvaluationDocumento3 paginePerformance Evaluationmool raj100% (1)

- E9. Non-Conformity Report NCRDocumento2 pagineE9. Non-Conformity Report NCRPeter IyereNessuna valutazione finora

- Request For Inspection:: EmployerDocumento2 pagineRequest For Inspection:: Employerhovael laboratoryNessuna valutazione finora

- Sop-01 - Pur R-1Documento6 pagineSop-01 - Pur R-1Shakti ShuklaNessuna valutazione finora

- Customer Related ProcessesDocumento3 pagineCustomer Related ProcessesatiquegeeNessuna valutazione finora

- ESCL-SOP-016, Work Instruction For WorkShop OperatorsDocumento5 pagineESCL-SOP-016, Work Instruction For WorkShop OperatorsadiqualityconsultNessuna valutazione finora

- ESCL-SOP-013, Outsourcing Procedure - Doc Rev 01Documento6 pagineESCL-SOP-013, Outsourcing Procedure - Doc Rev 01adiqualityconsult0% (2)

- ESCL-SOP-015, Procedure For Production of Egba Split-Sleeve ClampsDocumento12 pagineESCL-SOP-015, Procedure For Production of Egba Split-Sleeve Clampsadiqualityconsult100% (1)

- ESCL-SOP-020, Technical Specification For Egba Split-Sleeve ClampsDocumento8 pagineESCL-SOP-020, Technical Specification For Egba Split-Sleeve ClampsadiqualityconsultNessuna valutazione finora

- ESCL SOP 014, Materials Store Control ProcedureDocumento5 pagineESCL SOP 014, Materials Store Control ProcedureadiqualityconsultNessuna valutazione finora

- ESCL SOP 013, Outsourcing ProcedureDocumento7 pagineESCL SOP 013, Outsourcing ProcedureadiqualityconsultNessuna valutazione finora

- ESCL-SOP-011, Design and Development ProcedureDocumento8 pagineESCL-SOP-011, Design and Development Procedureadiqualityconsult100% (1)

- ESCL SOP 009, Maintenance ProcedureDocumento6 pagineESCL SOP 009, Maintenance Procedureadiqualityconsult100% (1)

- ESCL-SOP-012, Procurement Control ProcedureDocumento7 pagineESCL-SOP-012, Procurement Control ProcedureadiqualityconsultNessuna valutazione finora

- ESCL SOP 010, Sales Marketing ProcedueDocumento5 pagineESCL SOP 010, Sales Marketing Procedueadiqualityconsult0% (1)

- ESCL-SOP-011, Design and Development Procedure - Doc Rev 01Documento6 pagineESCL-SOP-011, Design and Development Procedure - Doc Rev 01adiqualityconsultNessuna valutazione finora

- ESCL SOP 007, Accounts ProcedureDocumento5 pagineESCL SOP 007, Accounts ProcedureadiqualityconsultNessuna valutazione finora

- ESCL-QSO-001, Documents Control ProcedureDocumento7 pagineESCL-QSO-001, Documents Control ProcedureadiqualityconsultNessuna valutazione finora

- ESCL SOP 008, Admin Human Resources ProcedureDocumento8 pagineESCL SOP 008, Admin Human Resources ProcedureadiqualityconsultNessuna valutazione finora

- ESCL-QSP-004, Procedrue For Control of Nonconforming ProductDocumento6 pagineESCL-QSP-004, Procedrue For Control of Nonconforming Productadiqualityconsult100% (1)

- Form 132, Contract Review RecordDocumento2 pagineForm 132, Contract Review RecordadiqualityconsultNessuna valutazione finora

- ESCL-QSP-006, Preventive Action ProcedureDocumento5 pagineESCL-QSP-006, Preventive Action ProcedureadiqualityconsultNessuna valutazione finora

- ESCL-QSP-003, Internal Quality Audit ProcedureDocumento7 pagineESCL-QSP-003, Internal Quality Audit ProcedureadiqualityconsultNessuna valutazione finora

- Contract Review Record AmendmentDocumento1 paginaContract Review Record AmendmentadiqualityconsultNessuna valutazione finora

- ESCL-QSP-002, Records Control ProcedureDocumento6 pagineESCL-QSP-002, Records Control Procedureadiqualityconsult100% (1)

- List of Escl FormsDocumento2 pagineList of Escl FormsadiqualityconsultNessuna valutazione finora

- Form 128, Calibration Status LogDocumento1 paginaForm 128, Calibration Status LogadiqualityconsultNessuna valutazione finora

- Form 127, Client FeedbackDocumento2 pagineForm 127, Client FeedbackadiqualityconsultNessuna valutazione finora

- Form 130, Design Review-VerificationDocumento3 pagineForm 130, Design Review-VerificationadiqualityconsultNessuna valutazione finora

- Form 131, Supplier Site Audit Checkklist-RecordDocumento3 pagineForm 131, Supplier Site Audit Checkklist-RecordadiqualityconsultNessuna valutazione finora

- Form 125, Workshop Job CardDocumento1 paginaForm 125, Workshop Job CardadiqualityconsultNessuna valutazione finora

- Chiba International, IncDocumento15 pagineChiba International, IncMiklós SzerdahelyiNessuna valutazione finora

- OD - SAP Connector UtilityDocumento22 pagineOD - SAP Connector UtilityShivani SharmaNessuna valutazione finora

- Pinto pm5 Tif 02Documento24 paginePinto pm5 Tif 02Salem BawazirNessuna valutazione finora

- Val Ed SyllabusDocumento25 pagineVal Ed Syllabusroy piamonteNessuna valutazione finora

- Control Flow, Arrays - DocDocumento34 pagineControl Flow, Arrays - DocHARIBABU N SEC 2020Nessuna valutazione finora

- 05271/MFP YPR SPL Sleeper Class (SL)Documento2 pagine05271/MFP YPR SPL Sleeper Class (SL)Rdx BoeNessuna valutazione finora

- International Beach Soccer Cup Bali 2023 October 4-7 - Ver 15-3-2023 - Sponsor UPDATED PDFDocumento23 pagineInternational Beach Soccer Cup Bali 2023 October 4-7 - Ver 15-3-2023 - Sponsor UPDATED PDFPrincess Jasmine100% (1)

- Ojt HRMDocumento7 pagineOjt HRMArlyn Joy NacinoNessuna valutazione finora

- SAP IAG Admin GuideDocumento182 pagineSAP IAG Admin GuidegadesigerNessuna valutazione finora

- BMW Engine Wiring 2 OxDocumento4 pagineBMW Engine Wiring 2 OxTomáš TdcNessuna valutazione finora

- Dhulikhel RBB PDFDocumento45 pagineDhulikhel RBB PDFnepalayasahitya0% (1)

- Flyweis Services Pvt. LTDDocumento11 pagineFlyweis Services Pvt. LTDFlyweis TechnologyNessuna valutazione finora

- Merchant Accounts Are Bank Accounts That Allow Your Business To Accept Card Payments From CustomersDocumento43 pagineMerchant Accounts Are Bank Accounts That Allow Your Business To Accept Card Payments From CustomersRohit Kumar Baghel100% (1)

- What Is A Timer?Documento12 pagineWhat Is A Timer?Hemraj Singh Rautela100% (1)

- Cavitation in Francis PDFDocumento373 pagineCavitation in Francis PDFAlberto AliagaNessuna valutazione finora

- Digital Economy 1Documento11 pagineDigital Economy 1Khizer SikanderNessuna valutazione finora

- Authenticating Digital EvidenceDocumento36 pagineAuthenticating Digital Evidenceatty_gie3743Nessuna valutazione finora

- Sip TrunkDocumento288 pagineSip TrunkSayaOtanashiNessuna valutazione finora

- Reflection Frog 1Documento3 pagineReflection Frog 1mariamNessuna valutazione finora

- Homework 1 Tarea 1Documento11 pagineHomework 1 Tarea 1Anette Wendy Quipo Kancha100% (1)

- Ramrajya 2025Documento39 pagineRamrajya 2025maxabs121Nessuna valutazione finora

- Finite Element Method For Eigenvalue Problems in ElectromagneticsDocumento38 pagineFinite Element Method For Eigenvalue Problems in ElectromagneticsBhargav BikkaniNessuna valutazione finora

- General LPG Installation Guide PDFDocumento60 pagineGeneral LPG Installation Guide PDFgheorghe garduNessuna valutazione finora

- SITXWHS001 - Participate in Safe Work Practices Student GuideDocumento42 pagineSITXWHS001 - Participate in Safe Work Practices Student GuideMarianne FernandoNessuna valutazione finora

- MY-SDK-10000-EE-005 - Method Statement For Concrete Pole Installation - GVB Rev1Documento7 pagineMY-SDK-10000-EE-005 - Method Statement For Concrete Pole Installation - GVB Rev1Seeths NairNessuna valutazione finora

- CP AssignmentDocumento5 pagineCP AssignmentMSSM EngineeringNessuna valutazione finora

- Topic 3 - Analyzing The Marketing EnvironmentDocumento28 pagineTopic 3 - Analyzing The Marketing Environmentmelissa chlNessuna valutazione finora

- Topics For AssignmentDocumento2 pagineTopics For AssignmentniharaNessuna valutazione finora

- Topics For Oral PresentationDocumento6 pagineTopics For Oral PresentationMohd HyqalNessuna valutazione finora

- Lite Indicator Admin ManualDocumento16 pagineLite Indicator Admin Manualprabakar070Nessuna valutazione finora