Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

(SEBD9391) Sealing and Installing The Flywheel Housing

Caricato da

victor.cipriani0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

11 visualizzazioni2 pagineFlywheel

Titolo originale

(SEBD9391) Sealing and Installing the Flywheel Housing

Copyright

© © All Rights Reserved

Formati disponibili

PDF o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoFlywheel

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

11 visualizzazioni2 pagine(SEBD9391) Sealing and Installing The Flywheel Housing

Caricato da

victor.ciprianiFlywheel

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

Sei sulla pagina 1di 2

CATERPILLAR’ Service Information System

Pantalla anterior

Bienvenido: 1180exma

4 Producto: NO SE HA ESCOSIDO NINGUN EQUIPO

Modelo: NO SCH ESCOSIDO NINGUN EQUIPO.

Configuracién: NO S= HA ESCOCIDO NINGUN &QUIPO

Crénica de Motores

2006/03/27

‘Nimero de medio -SEBD9391-00 Facha de publicacién -27/03/2006 Fecha de actualizacién -27/03/2006

102512617

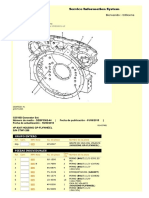

Sealing and Installing the Flywheel Housing {1157, 7555}

SMCS - 1157; 7555

Caterpillar Products:

+ 3500 Family Generator Sets and Power Modules

+ 3500 Family Pumpers

+ G3500 Family Generator Sets and Power Modules

Engine: Commercial

+ 3500 and 3S00B Family All

+ 63800 Family All

ReferenceFor more information, refer to Engine News, SEBD9326, 01 October 2003, "The Cylinder Block Has

Changed”

Description of Change: Anaerobic sealants replace the existing gasket for the flywheel housing to the block joint

on 3500 Diesel Engines and 3500 Gas Engines. Hard washers have been added to the bolts.

Adaptable To: The sealants are adaptable to the flywheel housing to the block joint on all 3500 Diesel Engines

and all 3500 Gas Engines,

The following part numbers replace the former gasket:

+ 185-3984 Gasket Sealant

* 4

300 Gasket Sealant

Apply the Sealant

Use the applicable Disassembly and Assembly manual for the tools and for the procedure in order to remove the

flywheel housing.

|. After removing the flywheel housing, clean the mating surface of the cylinder block and the mating surface

of the flywheel housing. If necessary, use a gasket scraper and a solvent in order to remove any residual

gasket material. Both mating surfaces must be clean, dry, and free of any oil before the anaerobic sealant is

applied.

201256259,

Mustration 1

Location forthe sealant

2. Apply a 6 mm (0.250 inch) of 4C-5300 Gasket Sealant or 185-3984 Gasket Scalant to the mating surface of

the flywheel housing, Refer to Illustration 1

ind for the procedure in order to install the

le 1. Refer to the Specifications

Use the applicable Disassembly and Assembly manual for the tool:

flywheel housing. During assembly, use the hard washers that are listed in T

manual for the torque values.

Table 1

Diameter of the Bolts | 1.54 Washer

inch

V2 5P-8245

5/8 SP-8247

Potrebbero piacerti anche

- 1.29. 7w-3724 Housing Gp-Front - Accessory DriveDocumento2 pagine1.29. 7w-3724 Housing Gp-Front - Accessory Drivevictor.ciprianiNessuna valutazione finora

- 1.19. 8N-7182 Damper GPDocumento2 pagine1.19. 8N-7182 Damper GPvictor.ciprianiNessuna valutazione finora

- Entire Group: 7E-6767 Lines Gp-Water - Turbocharger ExhaustDocumento3 pagineEntire Group: 7E-6767 Lines Gp-Water - Turbocharger Exhaustvictor.ciprianiNessuna valutazione finora

- 200-6504 Heater Gp-Jacket Water PDFDocumento1 pagina200-6504 Heater Gp-Jacket Water PDFvictor.ciprianiNessuna valutazione finora

- 14.3. 158-6181 Relay GPDocumento1 pagina14.3. 158-6181 Relay GPHugo CiprianiNessuna valutazione finora

- 1.21. 7n-4871 Drive Gp-Accessory - Upper, RHDocumento3 pagine1.21. 7n-4871 Drive Gp-Accessory - Upper, RHHugo CiprianiNessuna valutazione finora

- 1.18. 206-1558 Cylinder Head GPDocumento2 pagine1.18. 206-1558 Cylinder Head GPvictor.ciprianiNessuna valutazione finora

- 8n-9639 Guard Gp-DamperDocumento2 pagine8n-9639 Guard Gp-Dampervictor.ciprianiNessuna valutazione finora

- (c10282441) Update On Na EmissionsDocumento5 pagine(c10282441) Update On Na Emissionsvictor.ciprianiNessuna valutazione finora

- 1.45. 133-9376 Piston & Rod GPDocumento2 pagine1.45. 133-9376 Piston & Rod GPHugo CiprianiNessuna valutazione finora

- 24.1. 200-6504 Heater Gp-Jacket WaterDocumento2 pagine24.1. 200-6504 Heater Gp-Jacket WaterHugo CiprianiNessuna valutazione finora

- (Lexe0599-01) Uptime Tier III and IV Data CenterDocumento1 pagina(Lexe0599-01) Uptime Tier III and IV Data Centervictor.ciprianiNessuna valutazione finora

- 1.42. 4p-8354 Lines Gp-Water - UpperDocumento3 pagine1.42. 4p-8354 Lines Gp-Water - UpperHugo CiprianiNessuna valutazione finora

- 4P-9597 Indicator Gp-Air Filter ChangeDocumento2 pagine4P-9597 Indicator Gp-Air Filter Changevictor.ciprianiNessuna valutazione finora

- 1.44. 7C-4711 Pan Gp-OilDocumento2 pagine1.44. 7C-4711 Pan Gp-OilHugo CiprianiNessuna valutazione finora

- Installation Tips For Reducing Gas Generator Set Maintenance CostsDocumento5 pagineInstallation Tips For Reducing Gas Generator Set Maintenance Costsvictor.ciprianiNessuna valutazione finora

- (Lexe0625-01) Operation of Flywheel UpsDocumento6 pagine(Lexe0625-01) Operation of Flywheel Upsvictor.ciprianiNessuna valutazione finora

- White Paper - Generator Selection Harsh Environment - Lexe0011-01 CatDocumento3 pagineWhite Paper - Generator Selection Harsh Environment - Lexe0011-01 CatDaniel Andres Delgado CabreraNessuna valutazione finora

- (SEBD9326) The Cylinder Block Has ChangedDocumento8 pagine(SEBD9326) The Cylinder Block Has Changedvictor.ciprianiNessuna valutazione finora

- (Lexe0046!01!1) SustainabilityDocumento9 pagine(Lexe0046!01!1) Sustainabilityvictor.ciprianiNessuna valutazione finora

- Good Spark Plug Maintenance - Better Engine PerformanceDocumento4 pagineGood Spark Plug Maintenance - Better Engine Performancevictor.ciprianiNessuna valutazione finora

- Installation Tips For Reducing Gas Generator Set Maintenance CostsDocumento5 pagineInstallation Tips For Reducing Gas Generator Set Maintenance Costsvictor.ciprianiNessuna valutazione finora

- 190-4872 Housing Gp-Flywheel (GZP)Documento2 pagine190-4872 Housing Gp-Flywheel (GZP)victor.ciprianiNessuna valutazione finora

- Caterpillar - The Impact of Generator Set Underloading - Online CommunityDocumento4 pagineCaterpillar - The Impact of Generator Set Underloading - Online Communityvictor.ciprianiNessuna valutazione finora

- What Has The Biggest Impact On Gas Gen Set Operating CostsDocumento6 pagineWhat Has The Biggest Impact On Gas Gen Set Operating Costsvictor.ciprianiNessuna valutazione finora

- Loctite - CAT Cross ReferenceDocumento12 pagineLoctite - CAT Cross Referencevictor.cipriani100% (3)

- 4p 8307 Housing GP FlywheelDocumento2 pagine4p 8307 Housing GP Flywheelvictor.ciprianiNessuna valutazione finora

- Bulletin 509 - Impact of Misfire On AFR Control Performance PDFDocumento2 pagineBulletin 509 - Impact of Misfire On AFR Control Performance PDFvictor.ciprianiNessuna valutazione finora

- Good Spark Plug Maintenance - Better Engine PerformanceDocumento4 pagineGood Spark Plug Maintenance - Better Engine Performancevictor.ciprianiNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)